Method for manufacturing pressure-resistant plate

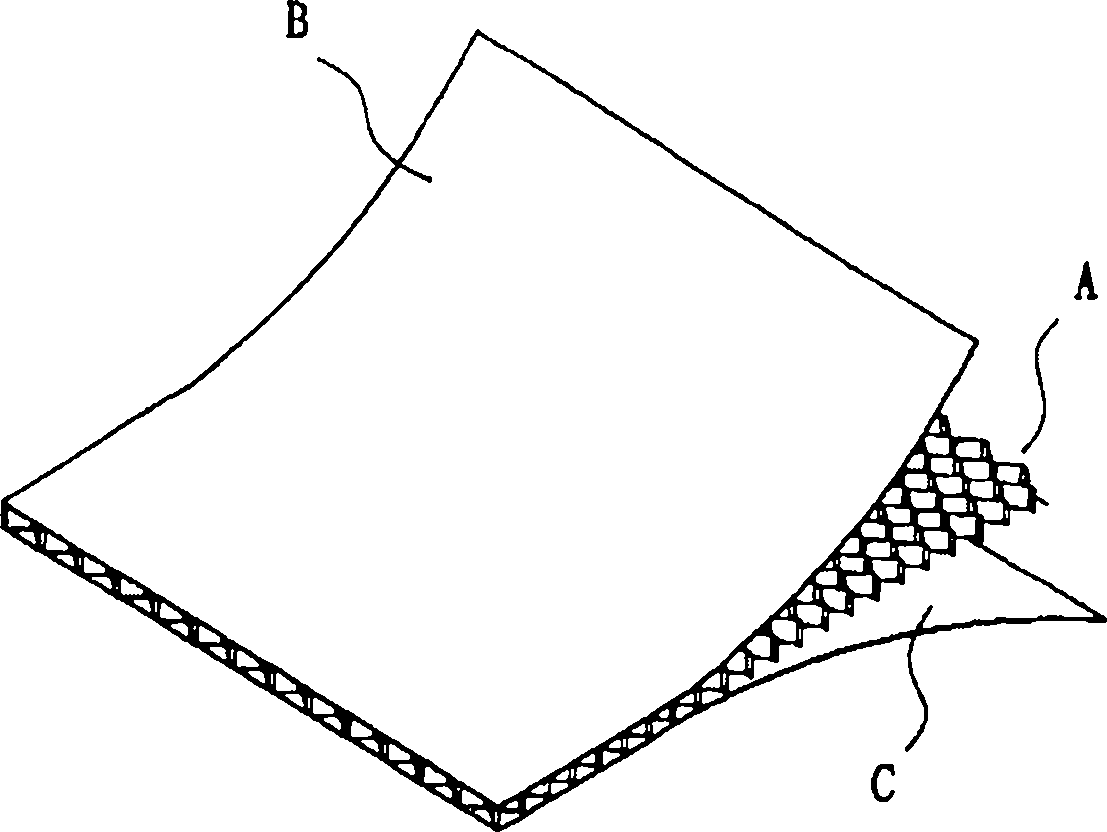

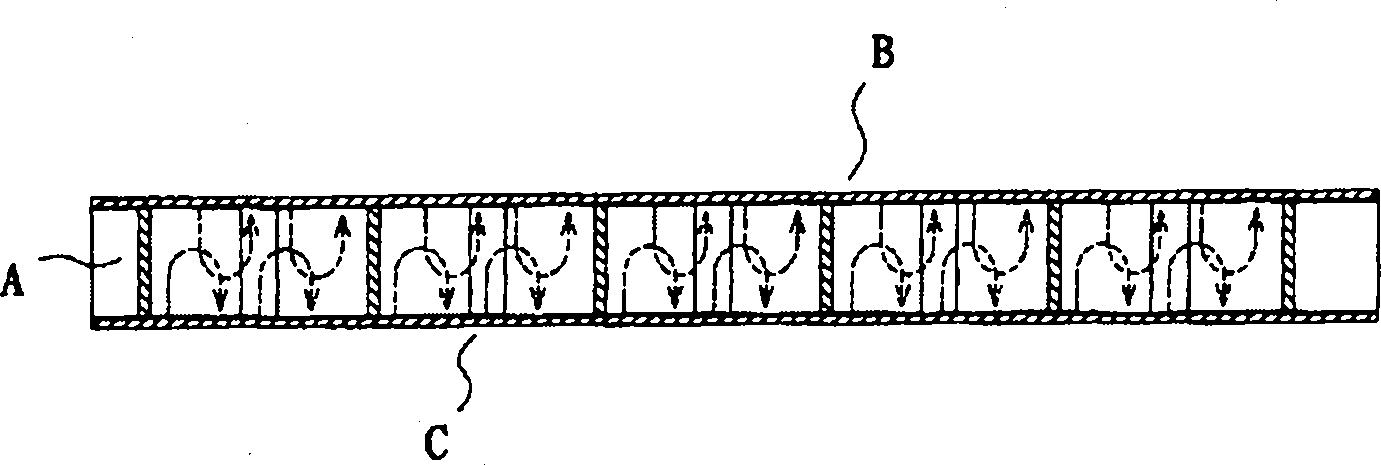

A manufacturing method and technology of pressure-resistant boards, applied in chemical instruments and methods, lamination, sheets/boards, etc., can solve problems such as low production efficiency, pressure-resistant body A is not hard enough and cannot be discharged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

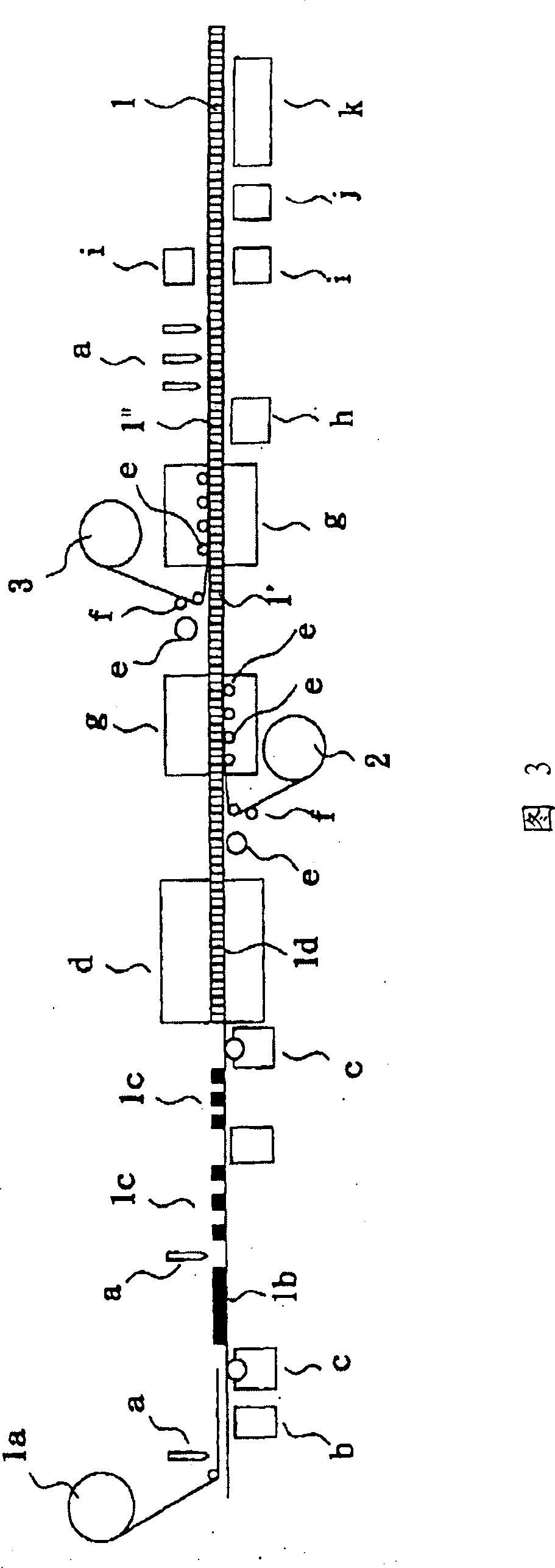

[0021] see image 3 , according to an embodiment of the present invention, the steps are as follows, specifically:

[0022] Substrate cutting

[0023] A roll of recycled paper substrate 1a is sequentially cut into a predetermined number of small-area substrates 1b of appropriate specifications by paper cutter a as required, and then each cut small-area substrate 1b is cut by a paper feeder b. Substrates 1b are sent to the pasting machine c one by one for gluing operation. After gluing, the front and rear sheets are laminated and bonded to each other sequentially. When gluing, the small-area substrates 1b of the odd number and the even number of sheets The parts to be pasted are completely different, that is, after the pasting operation of the small-area substrate 1b, different pasting parts will appear if the arrangement sequence is odd number sheets and even number sheets.

[0024] Small unit withstand voltage single formation

[0025] According to the design height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com