Pipe clamp structure

A technology of pipe clamps and pipes, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problem of high cost of solid pipe clamps, achieve uniform fatigue distribution, strong bearing capacity, and enhanced bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

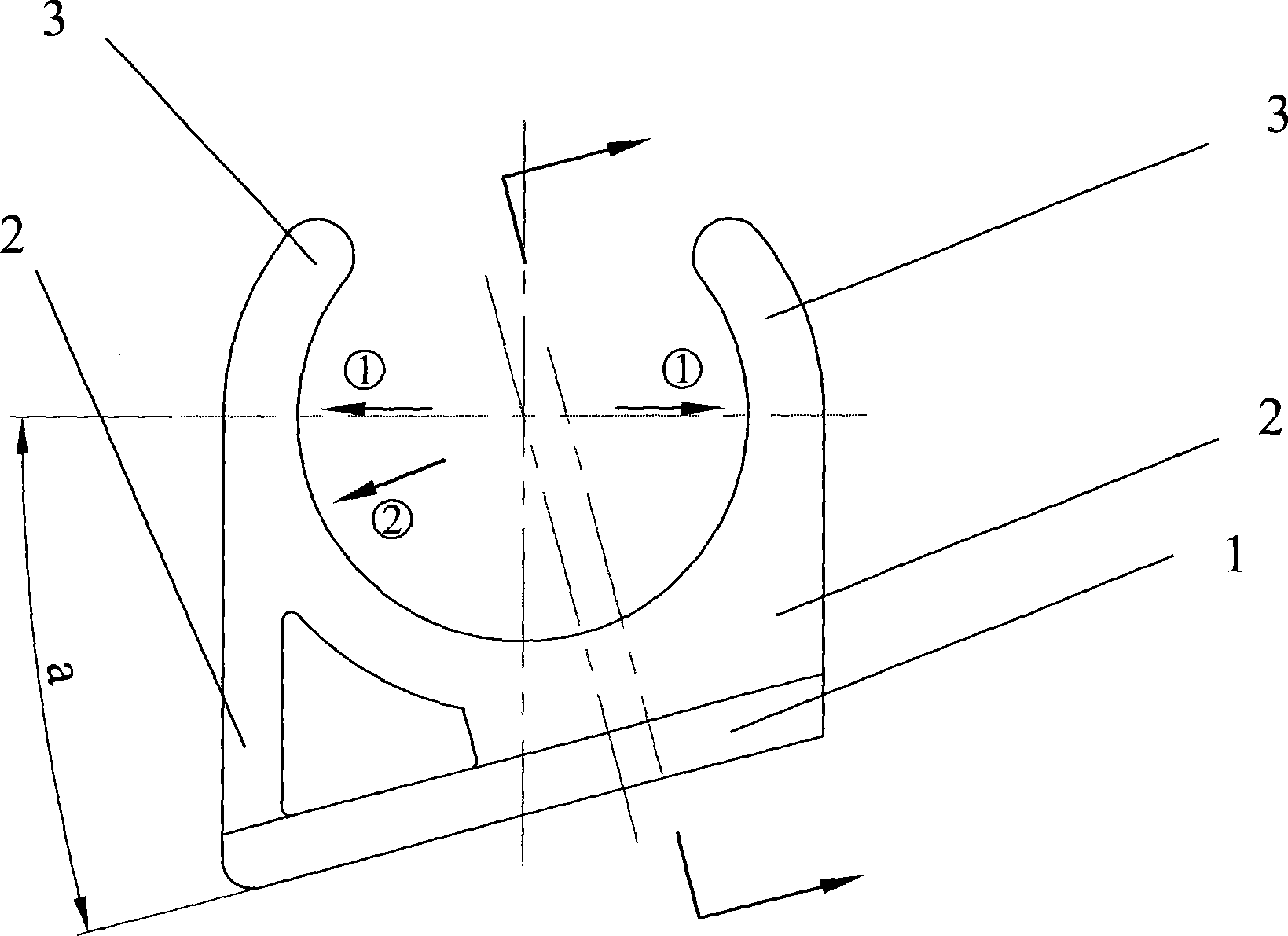

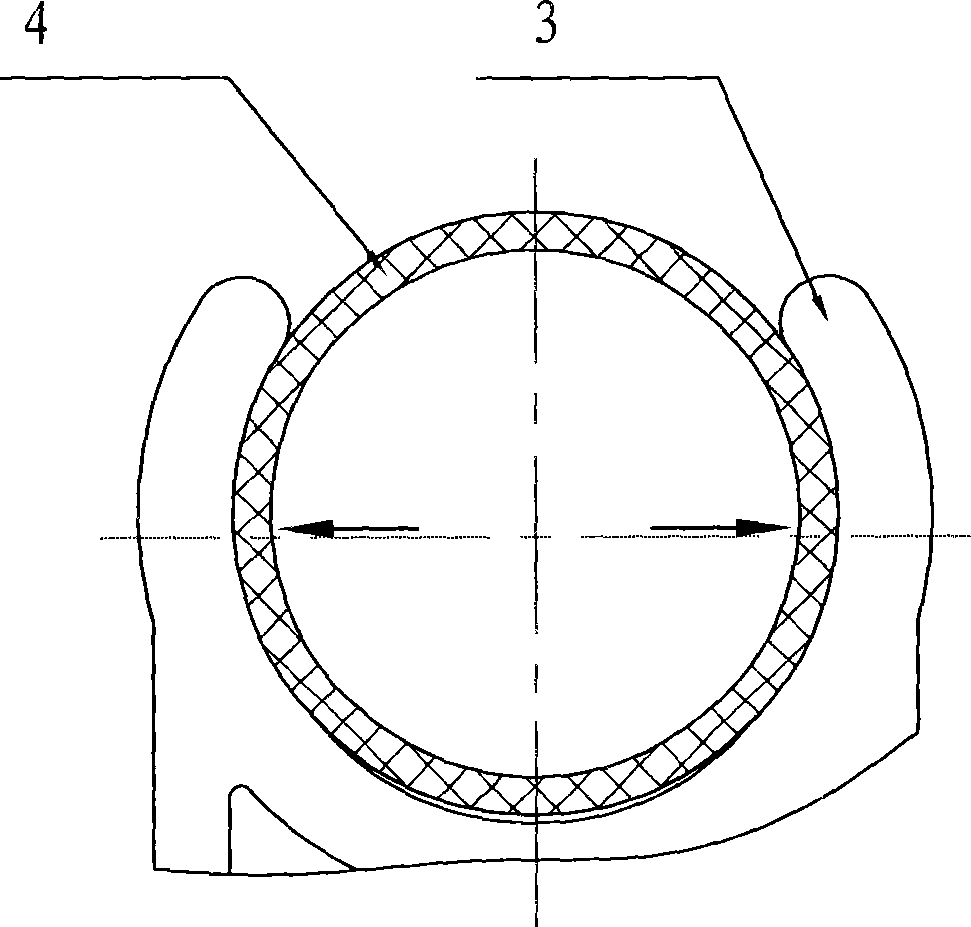

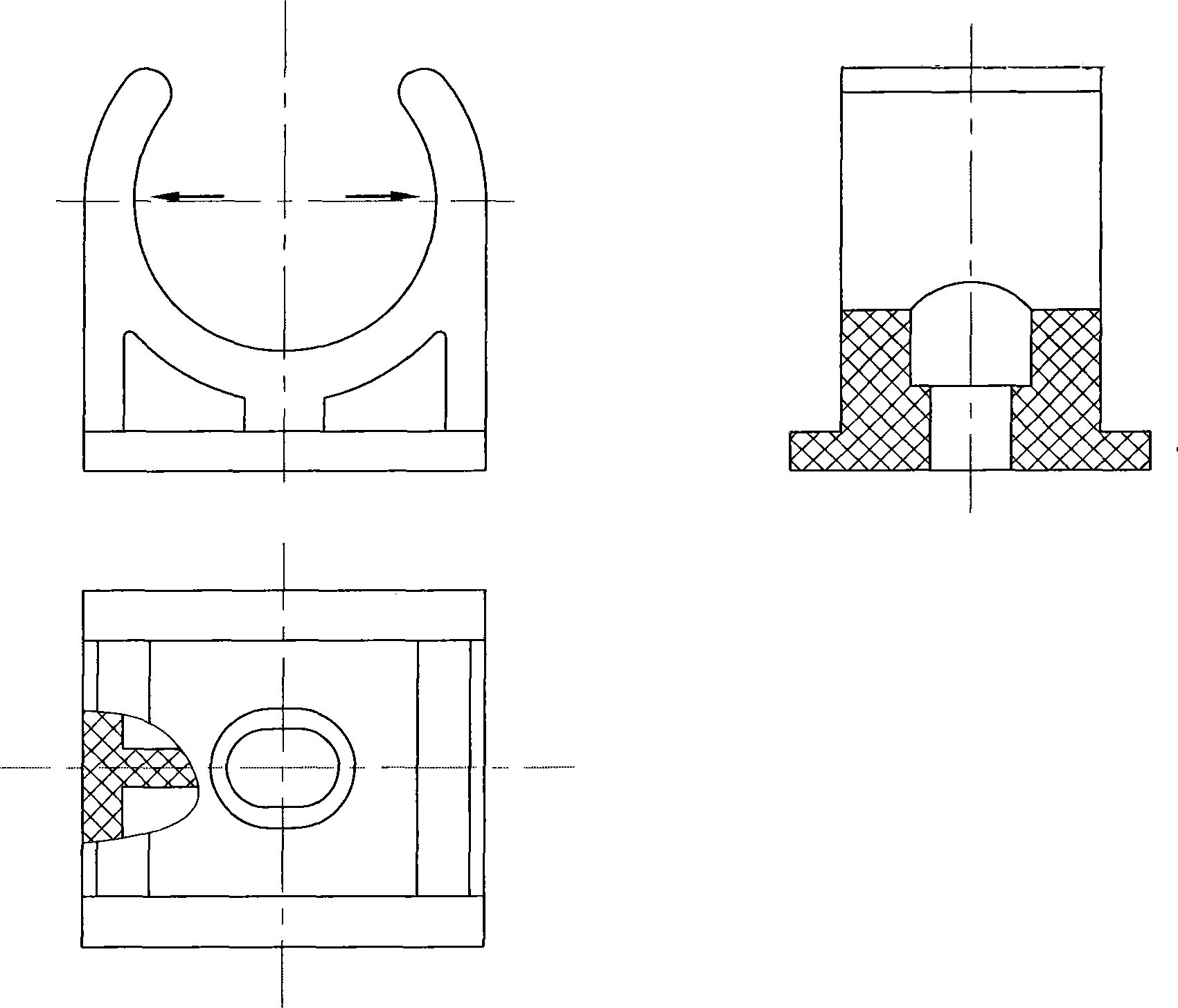

[0024] Structural schematic diagram of the present invention is attached figure 1 As shown, it includes a connection base 1, a support part 2 and a pipe clamp ring 3. One side of the connection base 1 is flush and close to the wall when installed. The other side of the connection base 1 is provided with a support part 2, and the pipe clamp ring 3 is arranged on the support part 2, and the geometric center symmetry line of the pipe clamp ring 3 forms an acute angle with the flush side of the connection base 1.

[0025] The structural feature of the present invention is that it has an acute inclined angle a, and its main direction of installation deformation force is reasonably staggered from the main direction of external force in the application after installation, such as figure 1 As shown, the arrow ① is the main deformation force, and the arrow ② is the main exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com