Method for preparing modified supported liquid membrane

A technology for supporting liquid membranes and supporting membranes, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve problems such as the stability of supporting liquid membranes, obstacles, etc., to improve anti-pollution ability, increase selectivity, enhance the effect of the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a kind of preparation method of modified support liquid membrane, concrete steps comprise:

[0023] Step 1, activate the support membrane: place the polyvinylidene fluoride membrane in 3mol / L sulfuric acid for surface soaking treatment, then wash it with deionized water, and dry it for later use.

[0024] Step 2, (1) Synthesis of ionic liquid: Mix n-butane bromide and N-methylimidazole at a ratio of 1.2:1 at room temperature, and reflux the mixture at 70° C. for 24 h. After the reaction, the reaction solution was cooled to room temperature, washed with ethyl acetate, and then placed in a constant temperature electric drying oven to dry to constant weight to obtain brominated 1-butyl-3-methylimidazole. Weigh 16.3gNH 4 PF 6 Dissolve in 100 mL of deionized water, add an equimolar amount of 1-butyl-3-methylimidazole bromide, and stir in a water bath at 30°C for 6 h. After the reaction is over, let it stand for stratification, wash the lower layer with deion...

Embodiment 2

[0027] Embodiment 2, a kind of preparation method of modified support liquid membrane, concrete steps comprise:

[0028] Step 1: Place the polyvinylidene fluoride membrane in 3mol / L sulfuric acid for surface immersion treatment, then wash it with deionized water, dry it, and set it aside.

[0029] Step 2, (1) Synthesis of ionic liquid: Mix n-butane bromide and N-methylimidazole at a ratio of 1.2:1 at room temperature, and reflux the mixture at 70° C. for 24 h. After the reaction, the reaction solution was cooled to room temperature, washed with ethyl acetate, and then placed in a constant temperature electric drying oven to dry to constant weight to obtain brominated 1-butyl-3-methylimidazole. Weigh 16.3gNH 4 PF 6 Dissolve in 100mL deionized water, add an equimolar amount of 1-butyl-3-methylimidazole bromide, and stir in a water bath at 20-40°C for 4-7h. After the reaction is over, let it stand for stratification, wash the lower layer with deionized water, and 1-butyl-3-met...

Embodiment 3-5

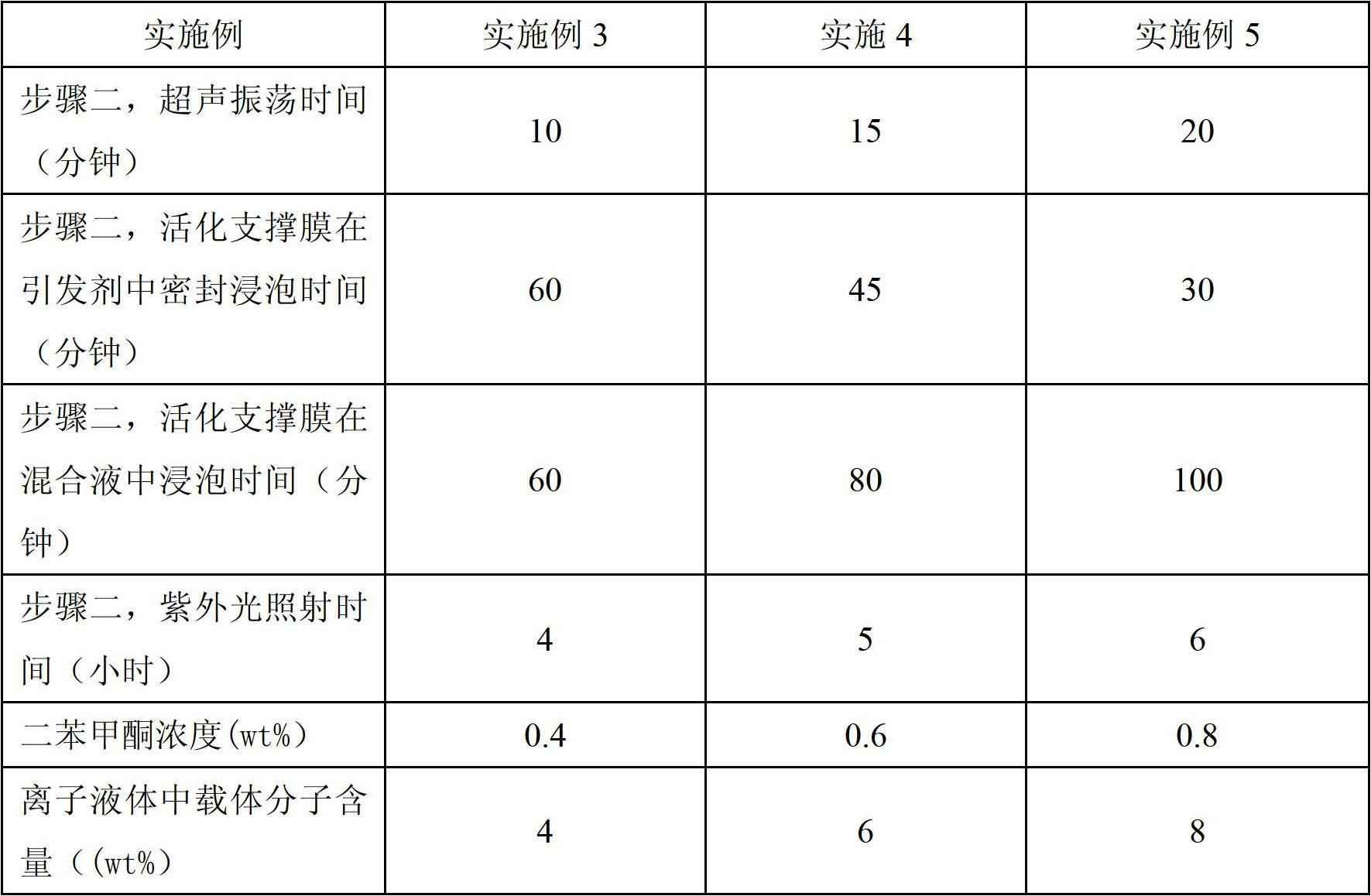

[0032] Example 3-5, a method for preparing a modified support liquid membrane, see Example 1 for specific steps, and see Table 1 for relevant data and process conditions.

[0033] Relevant data and processing conditions of table 1 embodiment 3-5

[0034]

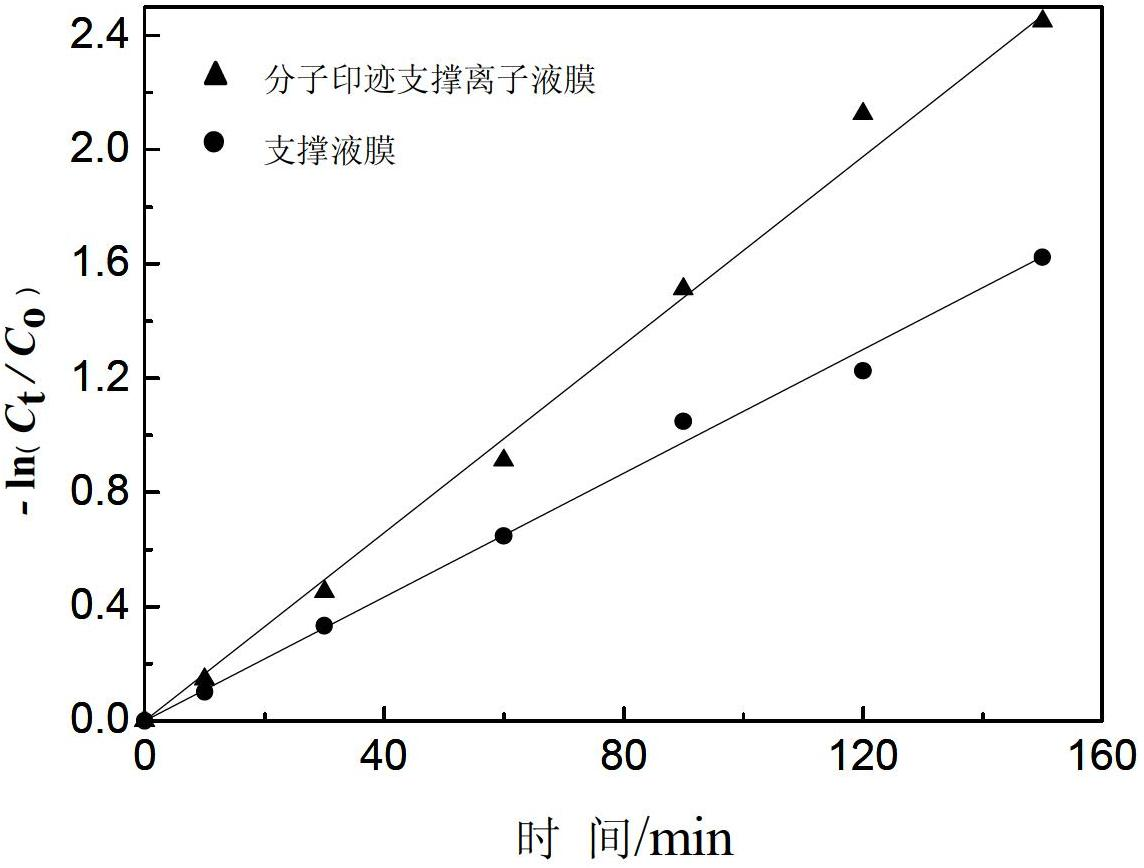

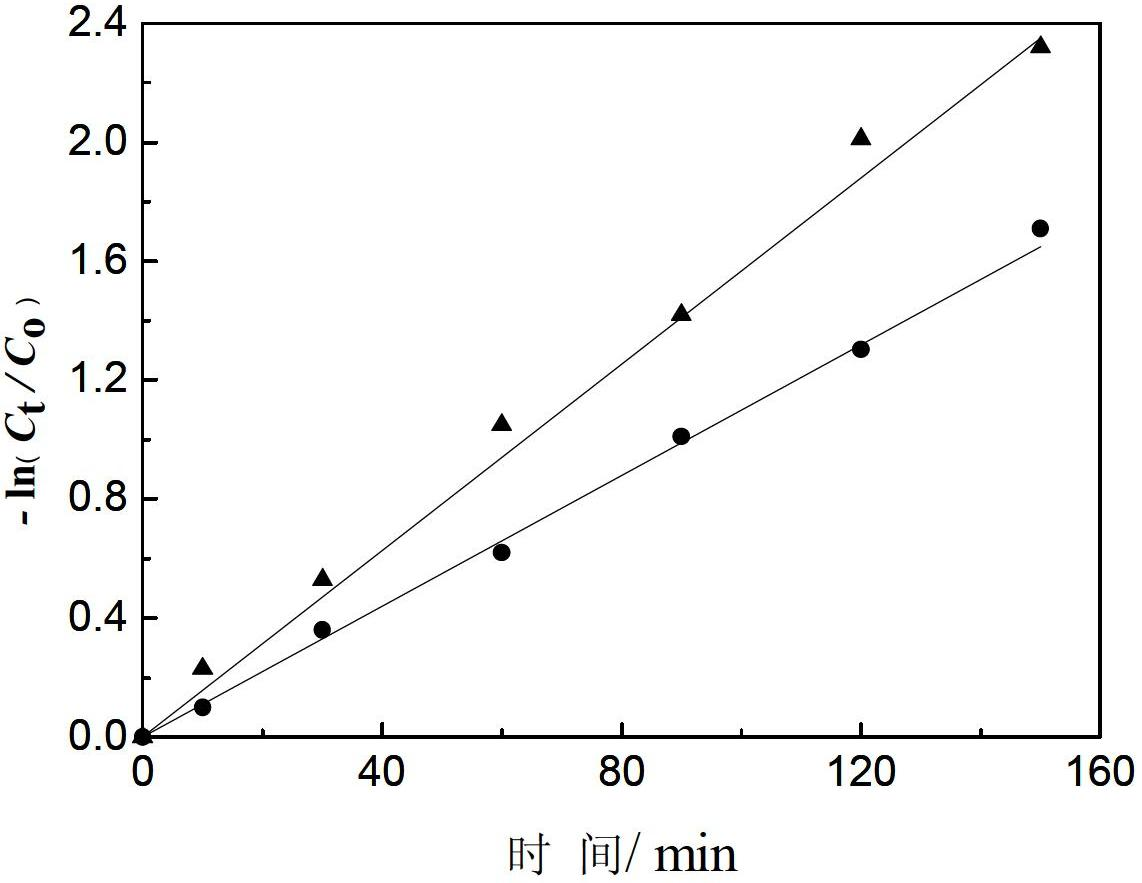

[0035] Comparative analysis of results

[0036] figure 1 It is a comparative graph of the mobility of Ni(II) for the molecularly imprinted support ionic liquid membrane system and the existing support liquid membrane system of Example 1 of the present invention, wherein c 0 and c t Respectively represent the initial concentration of Ni(II) in the liquid phase and the time t; figure 2 It is the comparative graph of the mobility of Co(II) for the molecularly imprinted support ionic liquid membrane and the existing support liquid membrane for Example 2 of the present invention, wherein c 0 and c tRepresent the initial and t concentrations of Co(II) in the feed liquid phase, respectively. It can be clearly seen from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com