Cationic-radical UV (Ultraviolet)-cured magnetic pearly-luster silk screen ink and preparation method thereof

A cationic and free radical technology, which is applied in the field of magnetic pearlescent screen ink and its preparation, can solve the problems that do not involve ink printing adaptability, achieve low solvent content, reduce VOC, and solve the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

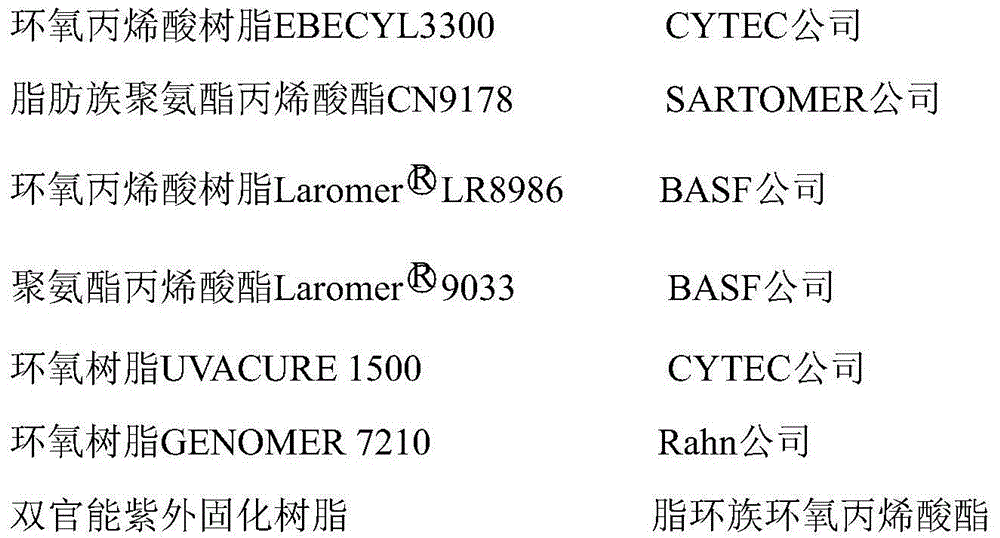

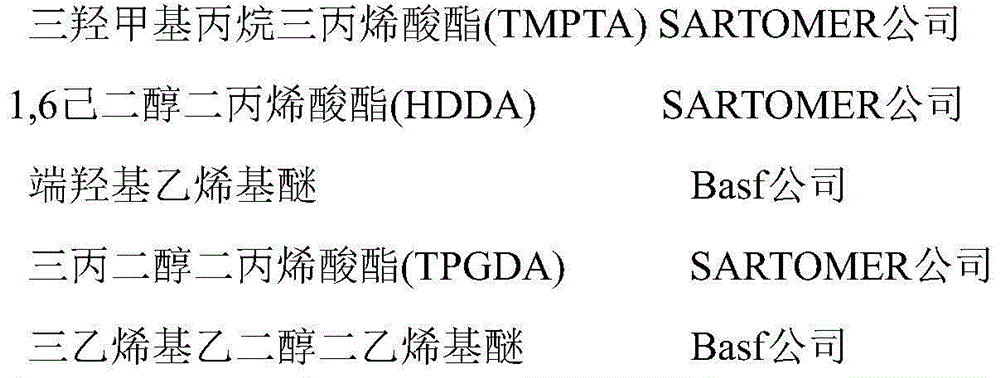

Method used

Image

Examples

Embodiment 1

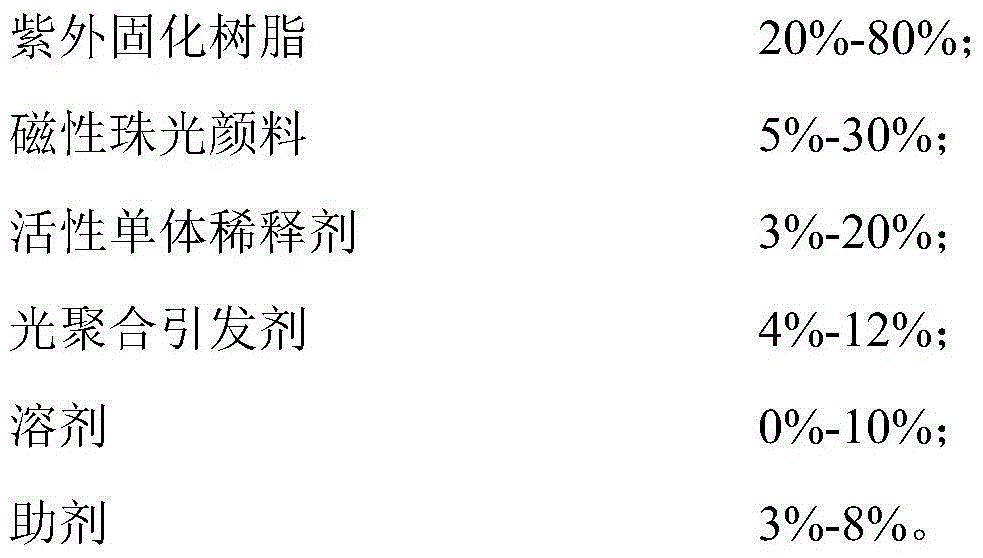

[0058] Formulation (weight percent)

[0059]

[0060] Preparation:

[0061] (1) first add the auxiliary agent to 90% of the total reactive diluent weight, then add the magnetic pearlescent pigment, disperse, and obtain solution 1;

[0062] (2) Add the remaining active diluent to the formula amount Among 9033 and CN9178, solution 2 was obtained by dispersing and dissolving evenly;

[0063] (3) Mix solution 1, solution 2 and the GENOMER 7210 of formula quantity, disperse evenly, obtain the ink composition that does not contain photopolymerization initiator;

[0064] Before the ink is printed, the photopolymerization initiator can be added to the ink composition according to the proportion;

[0065] After printing is completed, it will be tested after 72 hours.

[0066] Wrinkle resistance of the ink layer: cut to a size of 6cm*6cm, tested with IGT wrinkle resistance equipment, the front and back sides of the four sides were tested 3 times, the ink layer did not fall off c...

Embodiment 2

[0069]

[0070] Preparation:

[0071] (1) first add the auxiliary agent to a part of 30% by weight of the solvent and a part of 70% by weight of the active diluent, then add the magnetic pearlescent pigment, disperse, and obtain solution 1;

[0072] The part of the solvent is 30% of the total weight of the solvent, and the part of the reactive diluent is 70% of the weight of the reactive diluent;

[0073] (2) Add the remaining solvent and reactive diluent to the formula amount of EBECYL3300 and In LR8986, disperse and dissolve evenly to obtain solution 2;

[0074] (3) Mix the UVACURE 1500 of solution 1, solution 2 and formula quantity with cycloaliphatic epoxy acrylate, disperse evenly, obtain the ink composition that does not contain photopolymerization initiator;

[0075] Before the ink is printed, the photopolymerization initiator can be added to the ink composition according to the proportion;

[0076] Detect after 72 hours after printing.

[0077] Wrinkle resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com