Environment-coordinating method for preparing titanate piezoelectric ceramic powder

A piezoelectric ceramic and titanate technology, which is applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of expensive and impractical chelating agents, lack of practical value, and difficulty in preparing sols, etc. problems, to achieve the effect of high density, high complexation efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

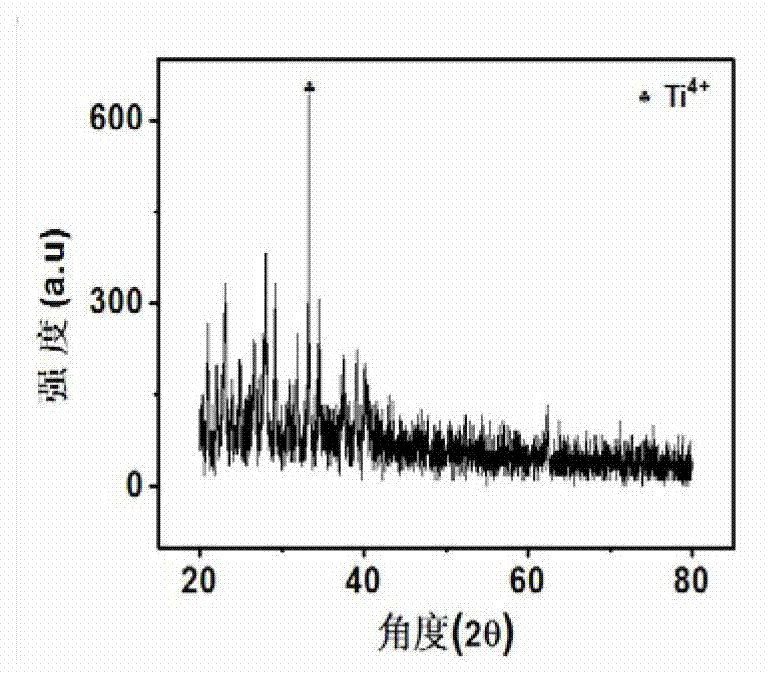

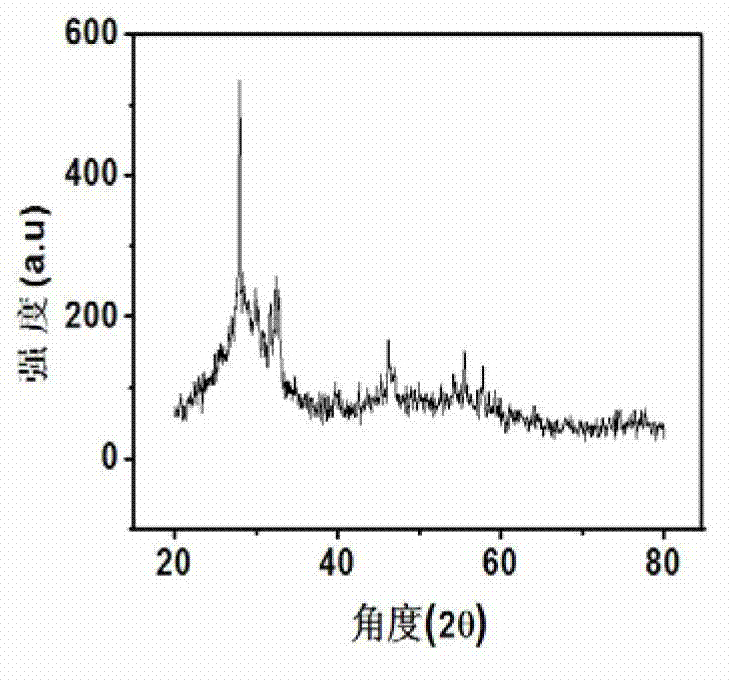

[0053] Specific embodiment 1 of the present invention, water-based sol-gel method prepares Bi 0.5 (Na 0.7 K 0.2 Li 0.1 ) 0.5 TiO 3 (BNKLT for short) The steps of nano powder and piezoelectric ceramics are as follows:

[0054] (1) The sol concentration is C sol-gel-Ti 4+ =0.15~0.25mol / L, 20 grams of sample (based on the mass of the final product BNKLT);

[0055] (2) After accurate stoichiometry, take 10.98 grams of Bi 2 o 3 (purity 99.8%) was dissolved in 45ml of concentrated nitric acid and dissolved, until it was colorless, clear and transparent, then cooled, and then 1.75 grams of Na 2 CO 3 (purity 99.8%), 0.66 g K 2 CO 3 (purity 99.0%), 0.18 g Li 2 CO 3 (purity 97.0%) aqueous solution was added thereinto to obtain liquid A;

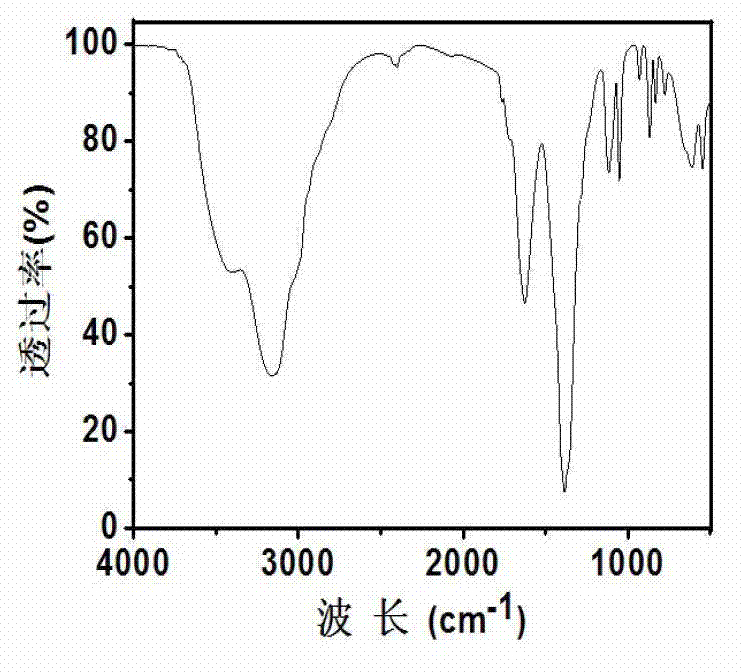

[0056] (3) According to the ratio of the amount of lactic acid to tetrabutyl titanate is 2.0~6.0, take 50ml lactic acid (purity 85~90%) and add 32.49 grams of tetrabutyl titanate (purity 98.5%, density ≈ 1.0) After fully stirring, add 5...

specific Embodiment 2

[0064] Specific embodiment 2 of the present invention, water-based sol-gel method prepares CeO 2 -[0.998Bi 0.5 (Na 0.7 K 0.2 Li 0.1 ) 0.5 TiO 3 -0.002BiFeO 3 ] (Abbreviation: C-BNKLT-BF) The steps of nano powder and piezoelectric ceramics are as follows:

[0065] (1) The sol concentration is C sol-gel-Ti 4+ =0.15~0.25mol / L, 20 grams of sample (based on the mass of the final product C-BNKLT-BF);

[0066] (2) After accurate stoichiometry, 0.20 g of CeO 2 (99.0% purity) and 10.88 grams of Bi 2 o 3 (purity 99.8%) were dissolved in 10ml and 45ml concentrated nitric acid respectively and heat-promoted, to CeO 2 A very small amount of hydrogen peroxide was added dropwise to the mixture, and fully boiled until it was colorless, clear and transparent, then cooled, then 0.08 grams of ferric nitrate nonahydrate (purity 98.5%), 1.73 grams of Na 2 CO 3 (purity 99.8%), 0.65 g K 2 CO 3 (purity 99.0%), 0.18 g Li 2 CO 3 (purity 97.0%) aqueous solution was added thereinto to o...

Embodiment 3

[0075] Specific embodiment 3 of the present invention, water-based sol-gel method prepares [0.94 Bi 0.5 (Na 0.7 K 0.2 Li 0.1 ) 0.5 TiO 3 -0.06BaTiO 3 ]-BiFeO 3 (abbreviated 0.94BNKLT-0.06BT-BF) the steps are as follows:

[0076] (1) The sol concentration is C sol-gel-Ti 4+ =0.15~0.25mol / L, 20 grams of sample (based on the mass of the final product 0.94BNKLT-0.06BT-BF);

[0077] (2) After accurate stoichiometry, to 1.11 g BaCO 3 (purity 99.8%) was added to 5ml of water, and then concentrated nitric acid was added dropwise to it until it was just clear, colorless and transparent, and 10.27 grams of Bi 2 o 3 (purity 99.8%) was dissolved in 45ml concentrated nitric acid and heat-promoted until it was colorless, clear and transparent, then cooled, mixed the above two liquids, and then mixed 0.08 grams of ferric nitrate nonahydrate (purity 98.5%), 1.60 grams of Na 2 CO 3 (purity 99.8%), 0.61 g K 2 CO 3 (purity 99.0%), 0.17 g Li 2 CO 3 (purity 97.0%) aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com