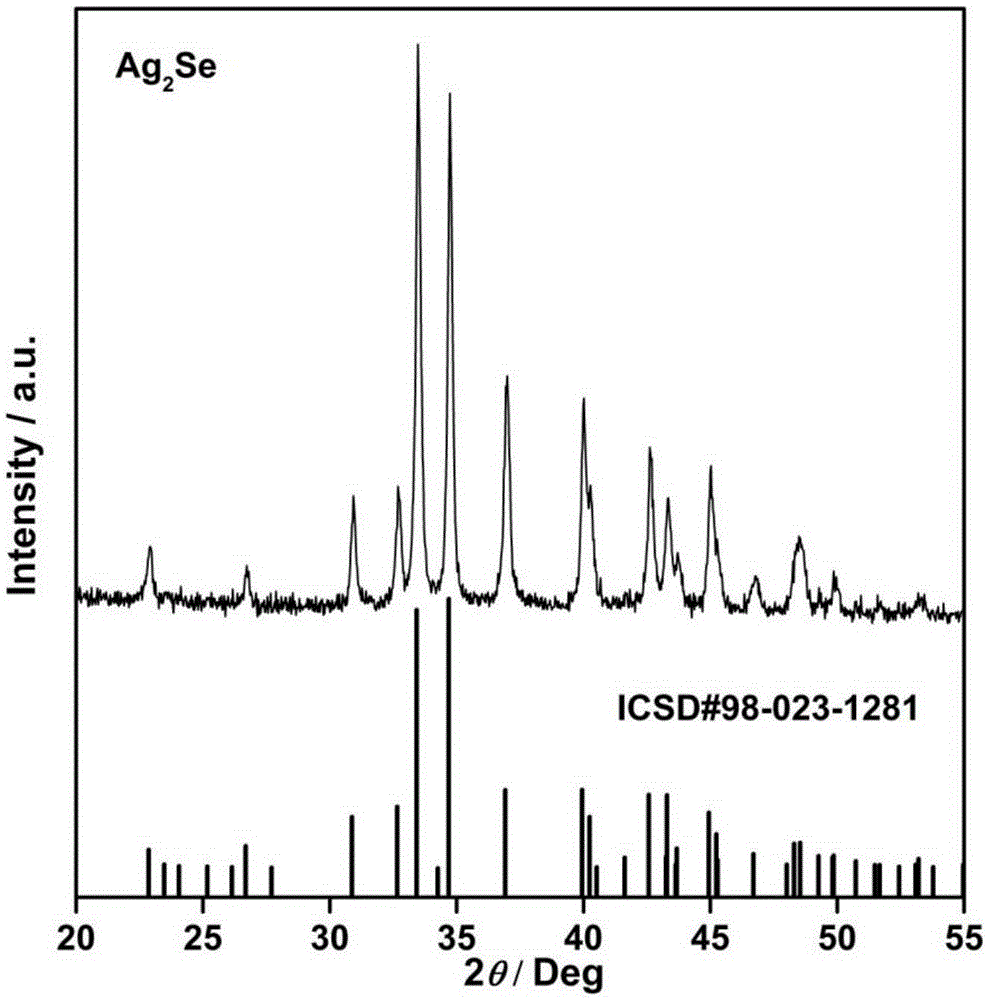

Ultrafast synthetic method of Ag2X block thermoelectric material

A technology of thermoelectric materials and synthesis methods, applied in the direction of thermoelectric device junction lead-out materials, etc., can solve the problems of strict reaction conditions, difficult to accurately control components, and harsh equipment requirements, etc., achieve simple preparation process, realize precise control, and solve volatilization problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

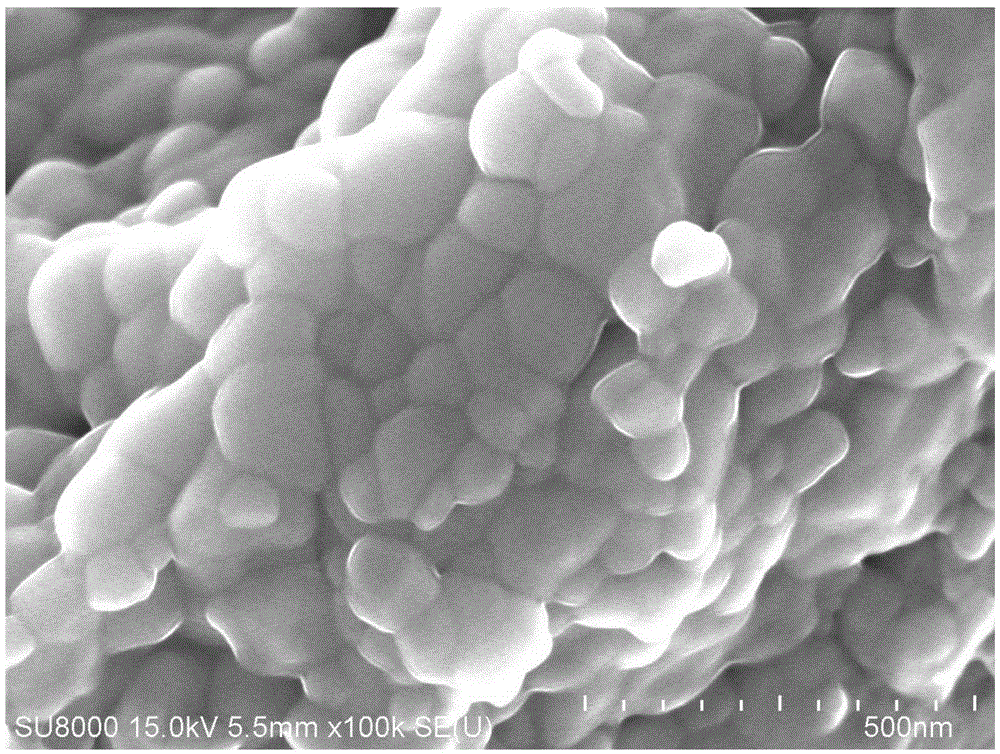

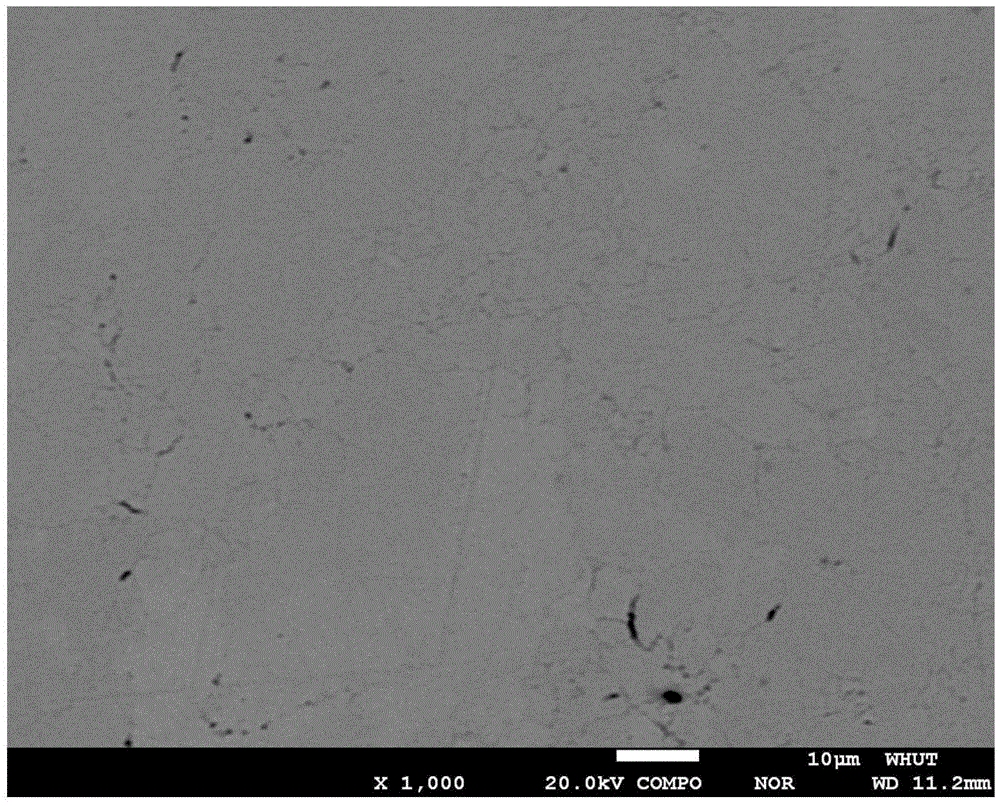

Embodiment 1

[0032] a kind of Ag 2 The ultra-fast synthesis method of Se bulk thermoelectric materials, the specific steps are as follows:

[0033] 1) Weigh Ag powder and Se powder according to the molar ratio of 2:1, a total of 5g, mix with a medicine spoon for 7 minutes, put the resulting mixed raw materials into a Φ15mm stainless steel mold, and then put the mold into a 769YP-24B manual Carry out pre-compression (10min under 5MPa under pressure) in the powder tabletting machine (24T), demoulding obtains compact;

[0034] 2) Take a large and small molybdenum "cup" container with matching size (the large cup can be fastened on the small cup to play a sealing role), fill the compact into the small "cup", and then buckle the large cup "cup";

[0035] 3) Assembling the molybdenum "cup" container filled with the compact in step 2) into the pyrophyllite pressure transmission medium;

[0036] 4) The pyrophyllite assembly obtained in step 3) is placed in the CS-IIID synthetic diamond hydrauli...

Embodiment 2

[0041] a kind of Ag 2 The ultra-fast synthesis method of Te bulk thermoelectric materials, the specific steps are as follows:

[0042] 1) Weigh Ag powder and Te powder according to the molar ratio of 2:1, and weigh 5g in total. After mixing with a medicine spoon for 7 minutes, put the mixed raw materials into a Φ15mm stainless steel mold, and then put the mold into a 769YP-24B manual Carry out pre-compression (holding pressure at 10MPa for 5min) in the powder tablet press (24T), demoulding to obtain compact;

[0043] 2) Take a large and small molybdenum "cup" container with matching size (the large cup can be fastened on the small cup to play a sealing role), fill the compact into the small "cup", and then buckle the large cup "cup";

[0044] 3) Assembling the molybdenum "cup" container filled with the compact in step 2) into the pyrophyllite pressure transmission medium;

[0045] 4) The pyrophyllite assembly obtained in step 3) is placed in the CS-IIID synthetic diamond hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com