Phenolic resin prepreg and method for preparing phenolic composite material from same

A technology of phenolic resin and composite material, which is used in the preparation of phenolic resin prepreg, the manufacture of phenolic composite material from prepreg, and the field of phenolic resin prepreg, which can solve the problem of gas is not easily discharged, material waste environment, and uneven resin content. and other problems, to achieve the effect of avoiding the decline of flame retardant performance, high product quality and small number of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

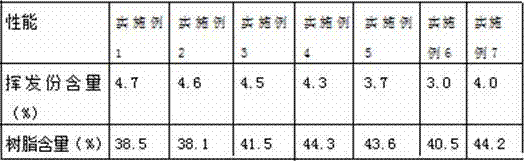

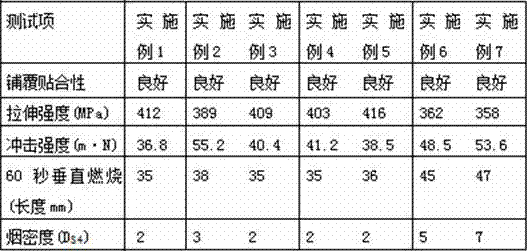

Examples

Embodiment 1)

[0042] The phenolic resin prepreg of this embodiment includes the following components in parts by weight: 58 parts of fiber fabric, 39 parts of phenolic resin, 2 parts of thickener, and 1 part of curing accelerator.

[0043] Fiber fabric in the present embodiment is 800g / m 2 Biaxial fabric.

[0044] The phenolic resin is a resole phenolic resin, the catalyst for its synthesis reaction is sodium hydroxide, and its viscosity is 300-1500 mPa·s (900 mPa·s in this embodiment).

[0045] The thickener is one or more compositions of magnesium oxide, calcium oxide, calcium sulfate, nano-scale aluminum hydroxide, white carbon black, boric acid, zinc borate, and the thickener in this embodiment is sulfuric acid calcium.

[0046] The curing accelerator is one or more combinations of imidazolidine, triazine, oxazolidine, oxazine, imidazolidine-oxazolidine hybrids, etherified resorcinol, and strong acid esters things.

[0047] The strong acid esterification product in the curing accele...

Embodiment 2)

[0053] The rest of the phenolic resin prepreg of this embodiment is the same as that of Embodiment 1, except that it also includes 2 parts of toughening agent, which is polyurethane prepolymer.

[0054] In addition to the aforementioned polyurethane prepolymer, the toughening agent can also be one of methoxysiloxane, polyvinyl alcohol, hydroxyl-terminated polybutadiene, and carboxyl-terminated polybutadiene.

Embodiment 3)

[0056] The phenolic resin prepreg of this embodiment consists of the following components in parts by weight: 55 parts of fiber fabric, 42 parts of phenolic resin, 3 parts of thickener, and 2 parts of curing accelerator.

[0057] Among them, the fiber fabric is 200g / m 2 Fiberglass satin weave.

[0058] The phenolic resin is a resole phenolic resin synthesized by catalyzing barium hydroxide with a viscosity of 1200mPa·s.

[0059] The thickener is boric acid.

[0060] The curing accelerator is the esterification of polyphosphoric acid and trimethylolpropane and oxazolidine.

[0061] The preparation method of the phenolic resin prepreg of the present embodiment all the other are identical with embodiment 1, difference is:

[0062] Step ② The temperature of the resin tank is controlled at 65°C.

[0063] Step ③ The temperature of the thickening oven is 90°C, and the time for the impregnated fabric to pass through the thickening oven is 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com