Preparation method of 3 mm Zn-Cu-Ti alloy wire for spraying

A zn-cu-ti, alloy wire technology, applied in coating, melt spraying, metal extrusion die and other directions, can solve the problem of complicated preparation process of zinc alloy wire, reduce preparation process, reduce production cost, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

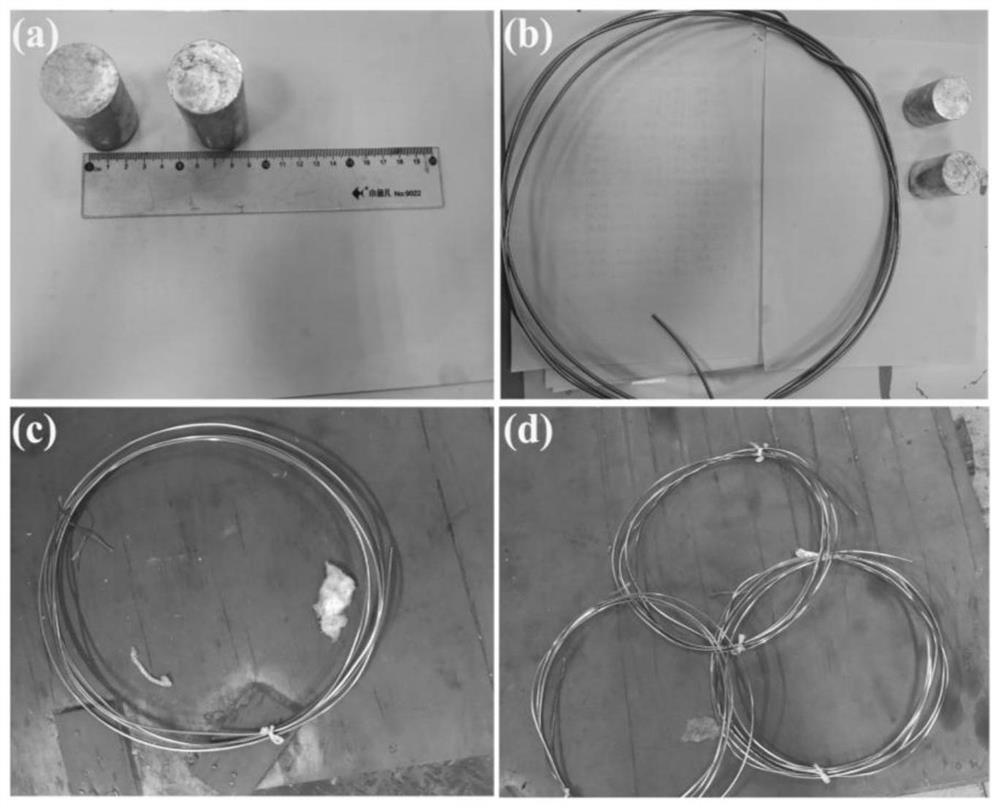

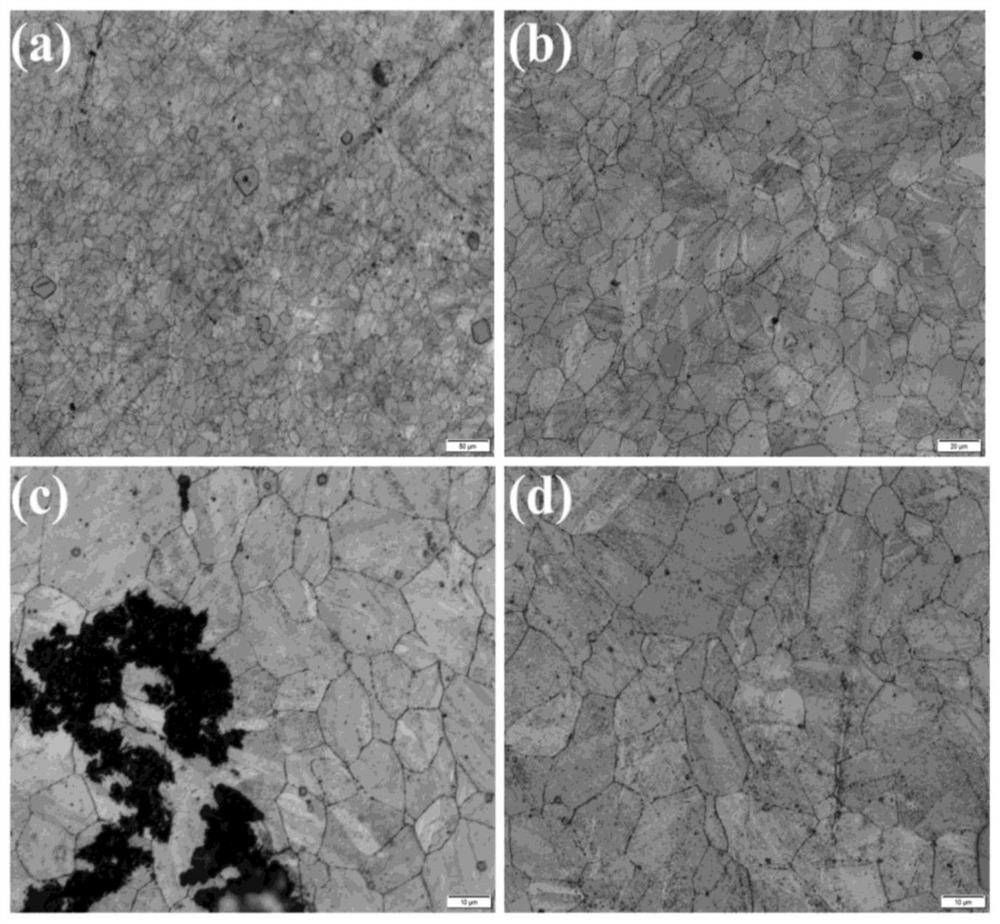

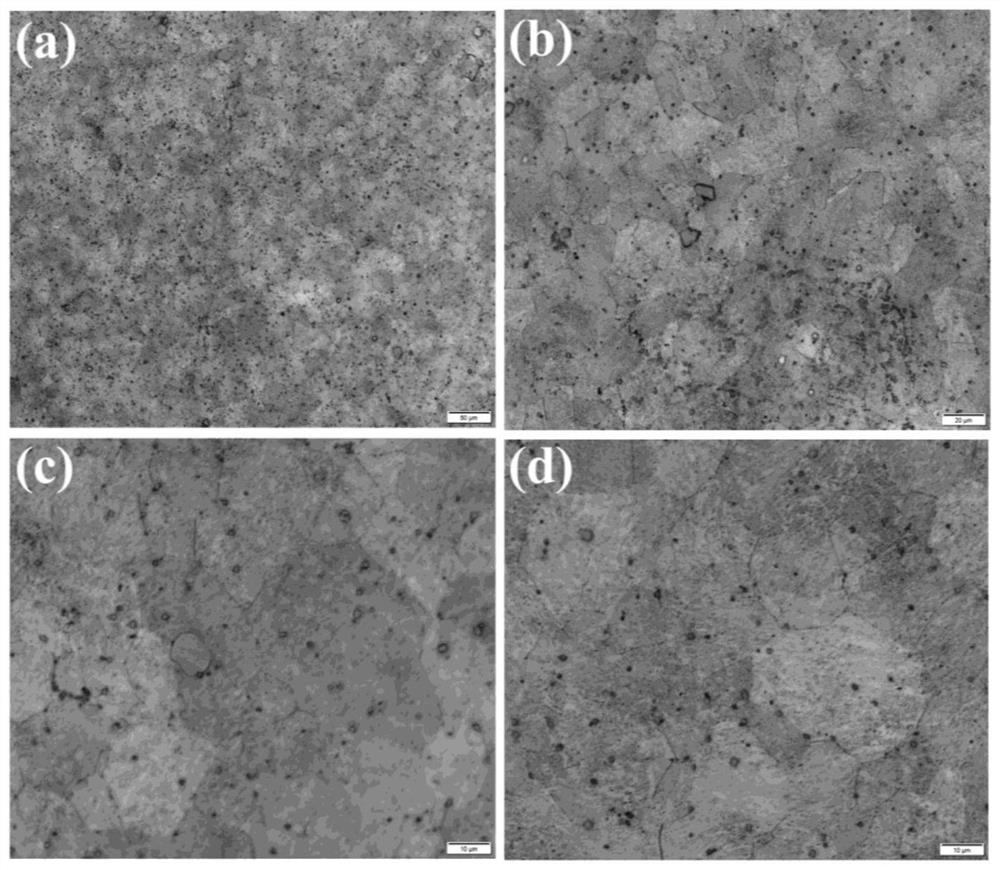

[0021] A preparation method of 3mmZn-Cu-Ti alloy wire for spraying, comprising the following steps:

[0022] (1) Weigh pure copper block and titanium sponge according to the mass ratio of 4:3, use non-consumable vacuum electric arc furnace to smelt into Cu-Ti master alloy, and carry out electromagnetic stirring treatment on the alloy melt during the smelting process, smelting The number of times is not less than 3 times. After cooling, the alloy is broken into small pieces. In order to ensure uniform dissolution and increase the contact surface, the mass of each small alloy piece does not exceed 8g;

[0023] (2) The Zn-Cu-Ti alloy is smelted in a resistance furnace, that is, the pure zinc is melted first, and then the Cu-Ti intermediate alloy is respectively put into the zinc melt. As the most preferred process parameter, the temperature of the zinc melt is controlled at 650 ℃, if the temperature is too high, the zinc element will volatilize, which will affect the composition ...

Embodiment 2

[0027] A preparation method of 3mmZn-Cu-Ti alloy wire for spraying, comprising the following steps:

[0028] (1) Weigh pure copper block and titanium sponge according to the mass ratio of 2:1, use non-consumable vacuum electric arc furnace to melt into Cu-Ti master alloy, and carry out electromagnetic stirring treatment on the alloy melt during the melting process, the number of times of melting Not less than 3 times. After cooling, break the alloy into small pieces. In order to ensure uniform dissolution and increase the contact surface, the mass of each small alloy piece should not exceed 8g;

[0029] (2) Melting the Zn-Cu-Ti alloy using a resistance furnace, that is, melting the pure zinc first, and then putting the Cu-Ti intermediate alloy into the zinc melt respectively. As an optimal process parameter, the temperature of the zinc melt is controlled at 680°C If the temperature is too high, the zinc element will volatilize, which will affect the composition of the finished...

Embodiment 3

[0033] A preparation method of 3mmZn-Cu-Ti alloy wire for spraying, comprising the following steps:

[0034] (1) Weigh the pure copper block and titanium sponge according to any ratio of mass ratio of 8:3, and melt it into a Cu-Ti master alloy in a non-consumable vacuum electric arc furnace, and electromagnetically stir the alloy melt during the melting process Processing, the number of smelting is not less than 3 times, and the alloy is broken into small pieces after cooling. In order to ensure uniform dissolution and increase the contact surface, the mass of each small alloy piece does not exceed 8g;

[0035] (2) Smelting Zn-Cu-Ti alloys using a resistance furnace, that is, melting pure zinc first, and then putting Cu-Ti intermediate alloys into the zinc melt respectively. As an optimal process parameter, the temperature of the zinc melt is controlled at 720°C If the temperature is too high, the zinc element will volatilize, which will affect the composition of the finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com