Preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 with mesoporous pore wall

A technology with three-dimensional order and hole walls, which is applied to ceramic products, household utensils, and other household utensils, etc., to achieve huge application prospects, easy access to raw materials, and good thermal stability of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

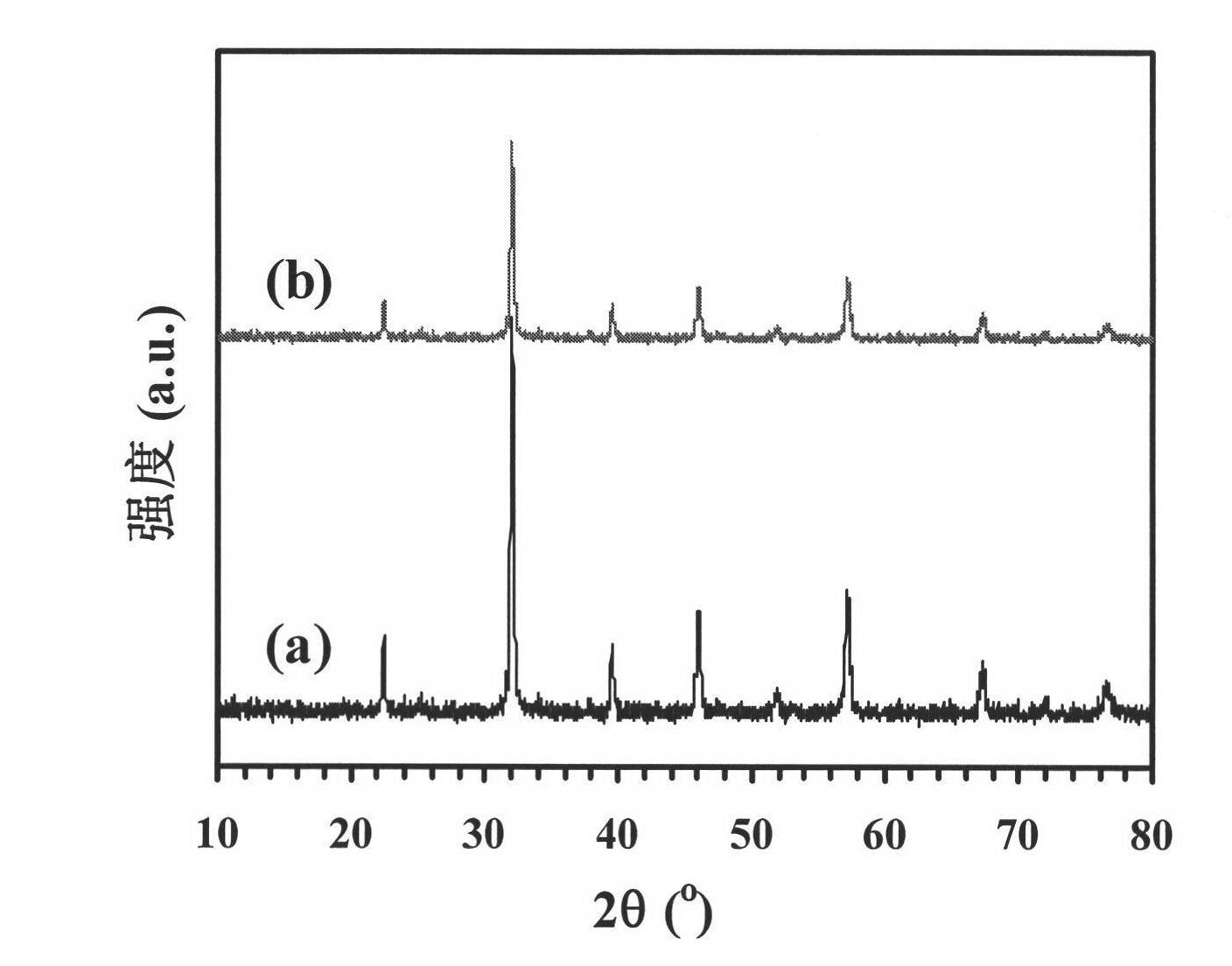

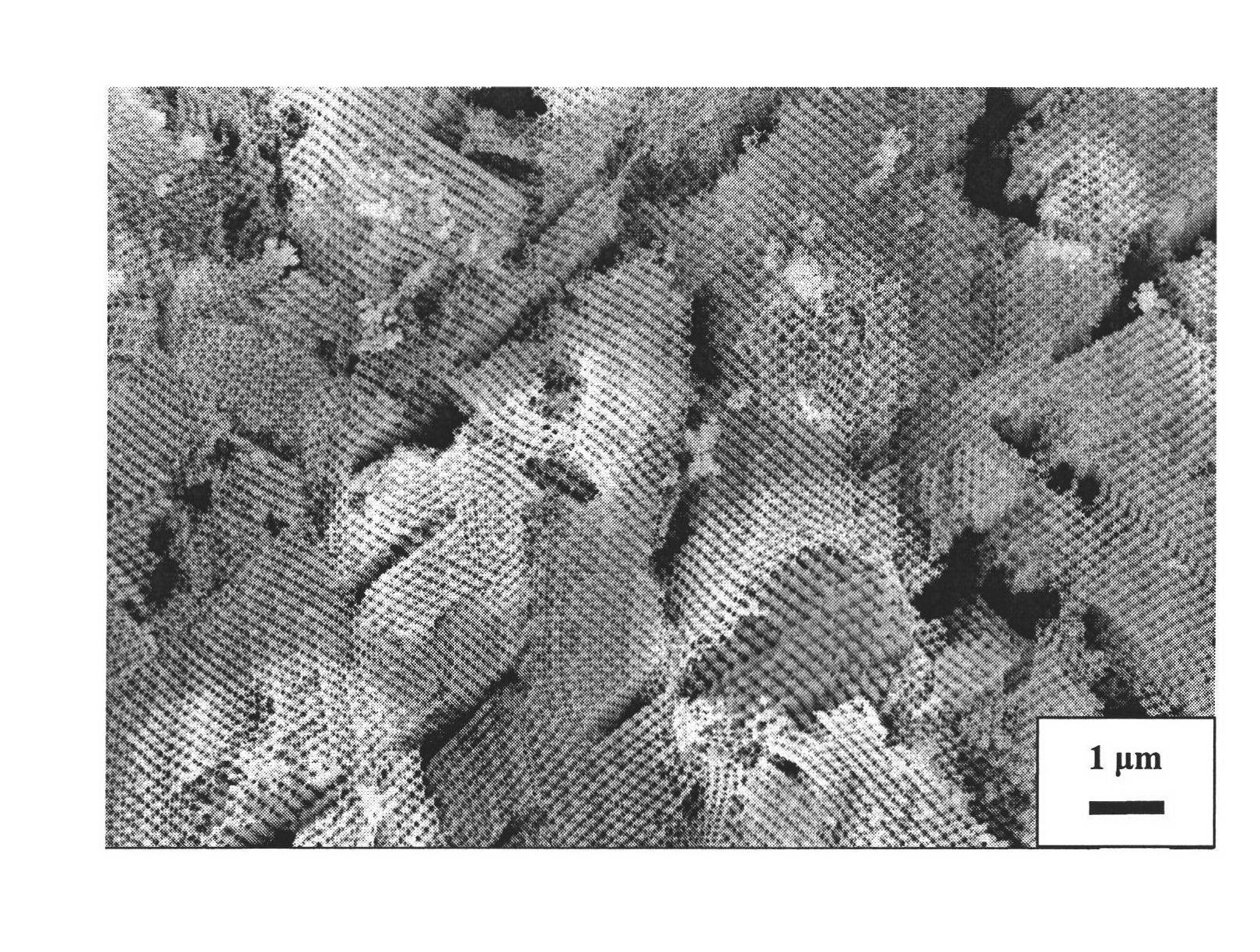

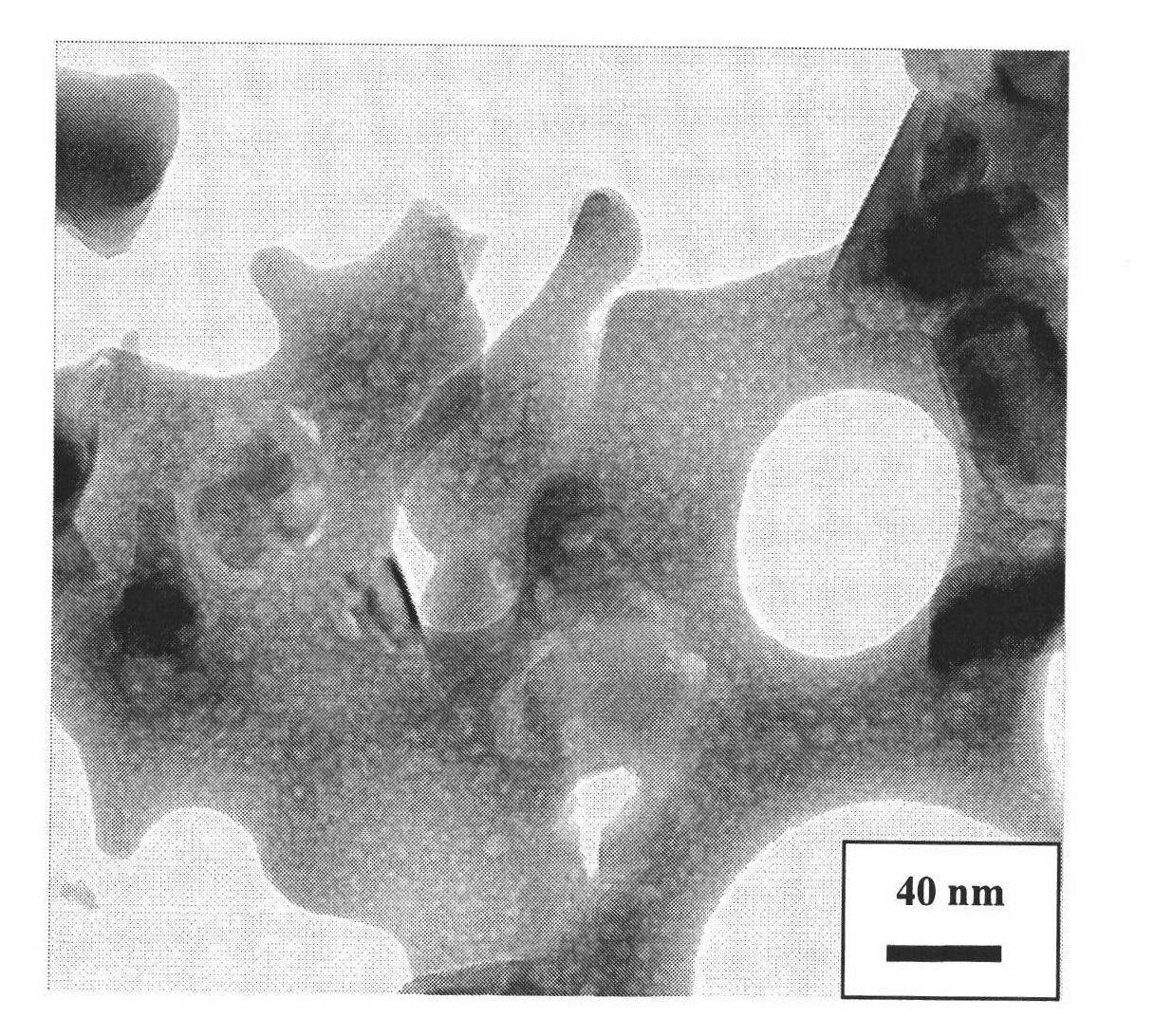

[0016] Embodiment 1: take by weighing 12.99g La(NO 3 ) 3 ·6H 2 O and 12.01g Cr(NO 3 ) 3 9H 2 O, put in a 50mL beaker, add 3.0mL polyethylene glycol 400 and 5.0mL anhydrous methanol, and magnetically stir to form a uniform precursor salt solution; add 0.03mol citric acid to it and ultrasonically disperse for 5min; weigh 1.0g three Block copolymer P123 was placed in a 50mL beaker, 10mL of anhydrous methanol was added, and after magnetic stirring for 1h, it was added to the above precursor salt solution, and ultrasonic dispersion was continued for 5min; finally, anhydrous methanol was added to make the whole solution system volume as 30mL, and continue to implement magnetic stirring for 4h; pour the above mixed solution into a 50mL beaker equipped with 1.0g PMMA hard template, in order to maintain the original orderly arrangement of PMMA, do not stir during the pouring process of the mixed solution; After impregnating PMMA for 5 h, suction filtration was performed, and the o...

Embodiment 2

[0017] Embodiment 2: take by weighing 7.79g La(NO 3 ) 3 ·6H 2 O, 2.54g Sr(NO 3 ) 2 and 12.01g Cr(NO 3 ) 3 9H 2 O, put in a 50mL beaker, add 3.0mL polyethylene glycol 400, 5.0mL anhydrous methanol and 5.0mL deionized water, magnetically stir to form a uniform precursor salt solution, add 0.03mol citric acid to it and then ultrasonically disperse 5min; Weigh 1.0g triblock copolymer P123 into a 50mL beaker, add 3.0mL anhydrous methanol and 2.0mL deionized water, stir magnetically for 1h, add it to the above precursor salt solution, and continue ultrasonic dispersion for 5min , finally add deionized water to make the whole solution system volume 30mL, and continue to implement magnetic stirring for 4h; the above-mentioned mixed solution is poured in the 50mL beaker that 1.0g PMMA hard template is housed, in order to keep the original orderly arrangement of PMMA, The mixed solution was poured without stirring; the mixed solution was impregnated with PMMA for 5 h and then fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com