ZK61M magnesium alloy conversion film treatment agent and conversion film treatment method

A ZK61M and treatment method technology, applied in the field of ZK61M magnesium alloy surface conversion coating treatment, can solve the problems of limited application promotion, poor corrosion resistance, and no environmental protection conversion coating treatment agent developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

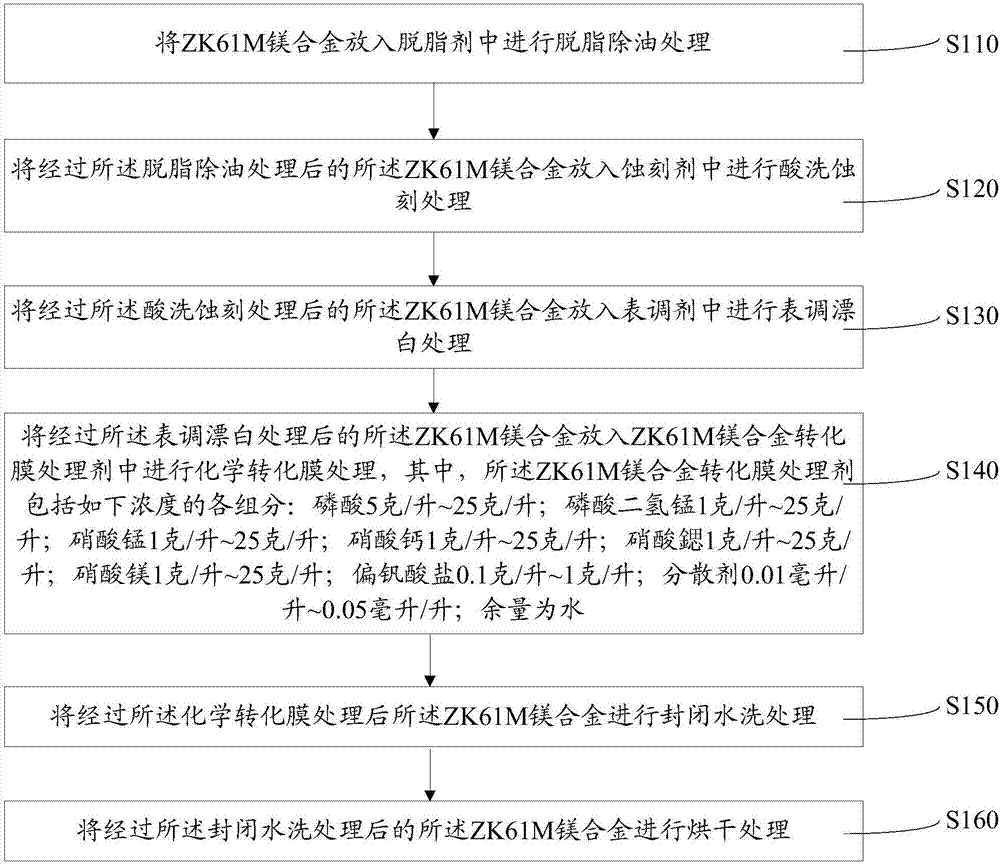

Method used

Image

Examples

Embodiment 1

[0066] 1. Degreasing: use sodium hydroxide 10 g / L, trisodium phosphate 20 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.5 g / L, temperature 60 degrees, and process for 6 minutes. After washing with water, put it into the pickling solution below;

[0067] 2. Pickling: Use 50 ml of nitric acid, 10 g / l of phosphoric acid, 0.2 ml / l of low-foaming surfactant, at a temperature of 60 degrees, for 30-60 seconds. After washing with water, put it into the table conditioning solution below;

[0068] 3. Surface adjustment: use sodium hydroxide 50-100 g / l, temperature 60 degrees, deash for 5 minutes. After washing with water, put it into the following conversion solution for processing;

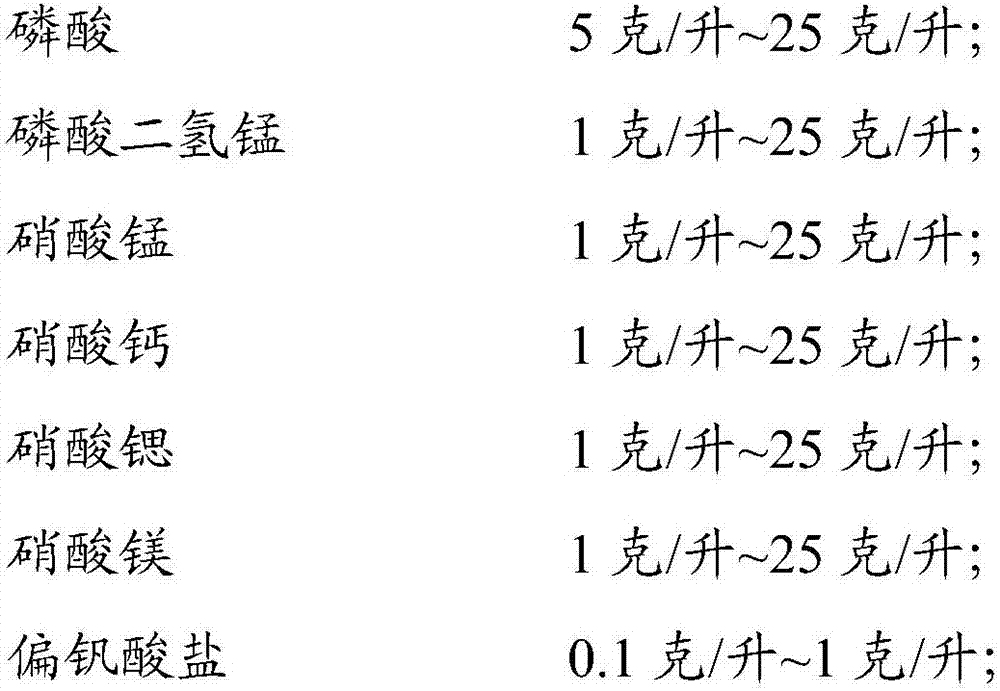

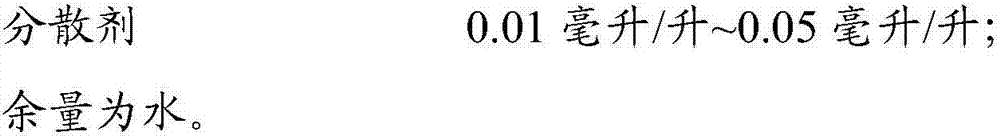

[0069] 4. Transformation: Put the ZK61M (MB15) magnesium alloy workpiece treated above into:

[0070]

[0071] pH = 1.5.

[0072] Treat in the conversion coating treatment solution at a temperature of 50-65 degrees for 3-5 minutes;

[0073] After washing with water, put it in the blocking solutio...

Embodiment 2

[0077] 1. Degreasing: use sodium hydroxide 10 g / L, trisodium phosphate 20 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.5 g / L, temperature 60 degrees, and process for 6 minutes. After washing with water, put it into the pickling solution below;

[0078] 2. Pickling: Use 50 ml of nitric acid, 10 g / l of phosphoric acid, 0.2 ml / l of low-foaming surfactant, at a temperature of 60 degrees, for 30-60 seconds. After washing with water, put it into the table conditioning solution below;

[0079] 3. Surface adjustment: use sodium hydroxide 50-100 g / l, temperature 60 degrees, deash for 5 minutes. After washing with water, put it into the following conversion solution for processing;

[0080] 4. Transformation: Put the ZK61M (MB15) magnesium alloy workpiece treated above into:

[0081]

[0082] pH = 1.5.

[0083] Treat in the conversion coating treatment solution at a temperature of 50-65 degrees for 3-5 minutes;

[0084] After washing with water, put it in the blocking solutio...

Embodiment 3

[0088] 1. Degreasing: use sodium hydroxide 10 g / L, trisodium phosphate 20 g / L, sodium gluconate 2 g / L, OP-10 emulsifier 1.5 g / L, temperature 60 degrees, and process for 6 minutes. After washing with water, put it into the pickling solution below;

[0089] 2. Pickling: Use 50 ml of nitric acid, 10 g / l of phosphoric acid, 0.2 ml / l of low-foaming surfactant, at a temperature of 60 degrees, for 30-60 seconds. After washing with water, put it into the table conditioning solution below;

[0090] 3. Surface adjustment: use sodium hydroxide 50-100 g / l, temperature 60 degrees, deash for 5 minutes. After washing with water, put it into the following conversion solution for processing;

[0091] 4. Transformation: Put the ZK61M (MB15) magnesium alloy workpiece treated above into:

[0092]

[0093] PH value = 1.5,

[0094] Treat in the conversion coating treatment solution at a temperature of 50-65 degrees for 3-5 minutes;

[0095] After washing with water, put it into the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com