Process for preparing rare-earth excited strontium aluminate long afterglow fluorescent powder

A fluorescent powder and alumina technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high reaction temperature, lower reaction temperature, poor luminescent performance of phosphor powder, etc., achieve low roasting temperature, high luminous brightness, good The effect of luminous performance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

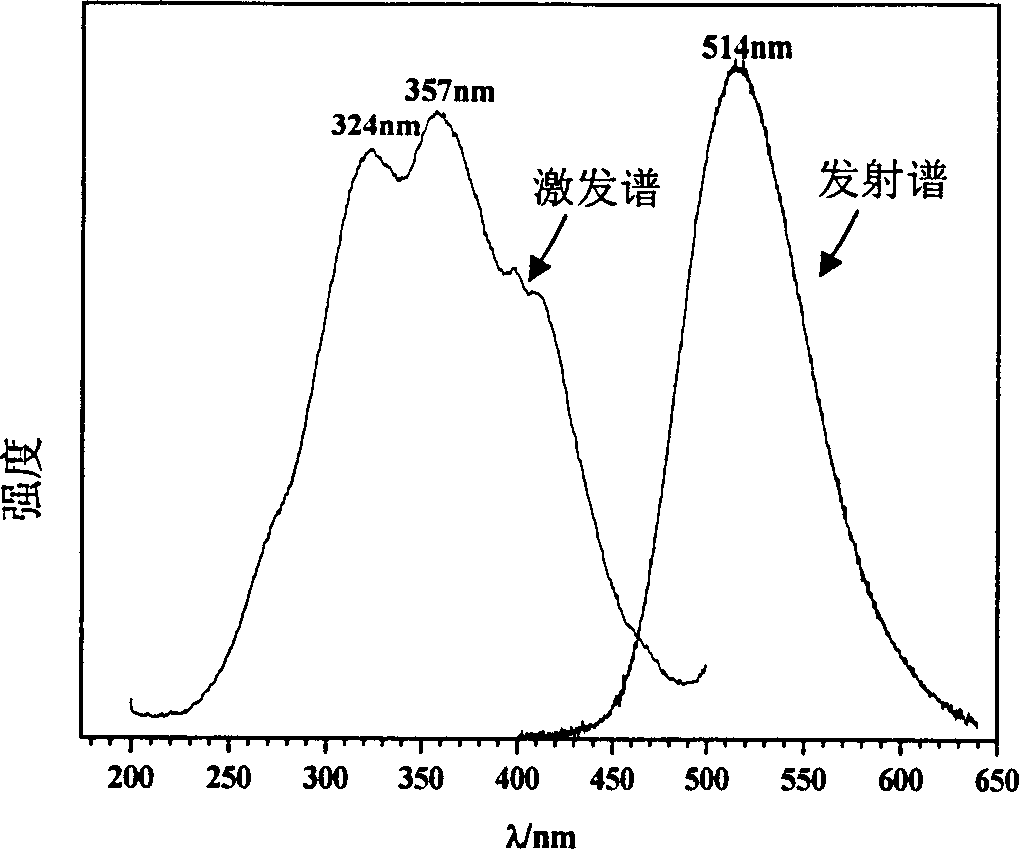

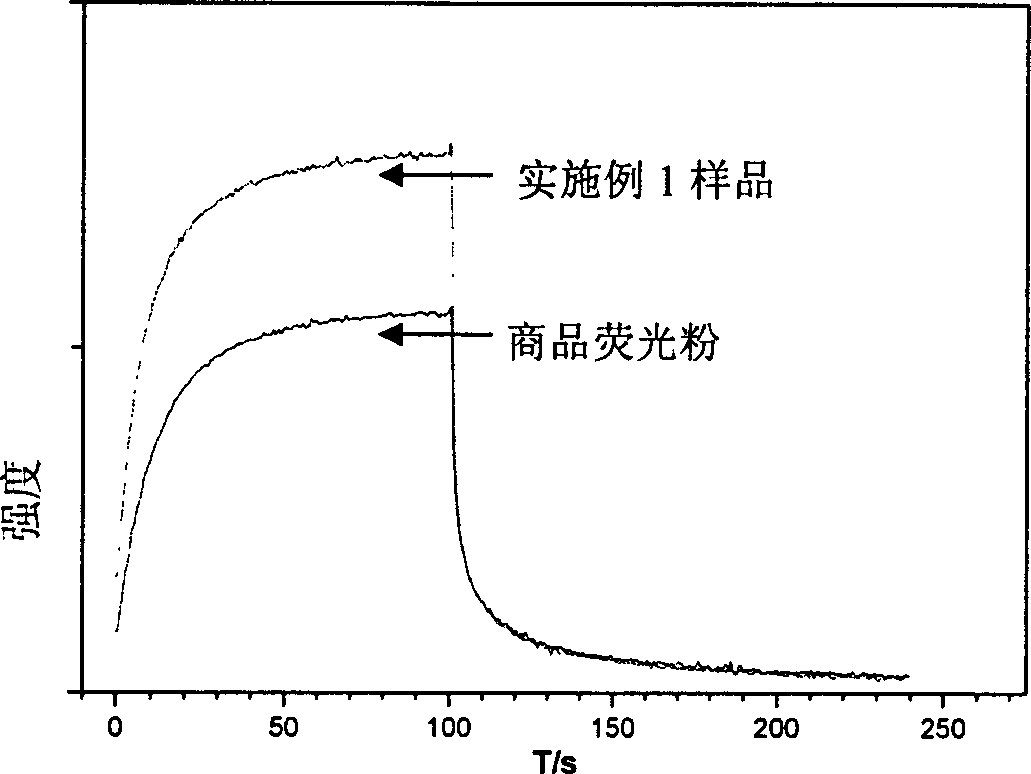

[0023] Embodiment 1, preparation SrAl 2 o 4 :Eu 0.02 , Dy 0.02 Green long afterglow phosphor

[0024] The number of moles of raw materials used is as follows:

[0025] Strontium carbonate 33.17,

[0026] Aluminum hydroxide 66.34,

[0028] Dysprosium oxide 0.33.

[0029] Its preparation steps are as follows:

[0030] 1) In a pressure vessel, aluminum hydroxide is dissolved in excess hot nitric acid to make a nitrate solution; in a heating and stirring device, strontium carbonate, europium oxide and dysprosium oxide are dissolved in hot concentrated nitric acid to make a nitrate solution; Mix the two solutions evenly to obtain a mixed solution, then adjust the pH value to 4 with ammonia water, add polyethylene glycol with a total mass of phosphor powder of 200%, and stir at a constant temperature of 80° C. for 1.5 hours to form a gel;

[0031] 2) Heating the gel at 900°C for 1.5 hours to obtain a solid-phase calcined product;

[0032] 3) A...

Embodiment 2

[0035] Embodiment 2, prepare the SrAl of different powder size 2 o 4 :Eu, Dy green long afterglow phosphor

[0036] The molar percentages of raw materials used are as follows:

[0037] Strontium carbonate 33.17,

[0038] Aluminum hydroxide 66.34,

[0039] Europium oxide 0.34,

[0040] Dysprosium oxide 0.33.

[0041] Its preparation steps are as follows:

[0042] 1) In a pressure vessel, aluminum hydroxide is dissolved in excess hot nitric acid to make a nitrate solution; in a heating and stirring device, strontium carbonate, europium oxide and dysprosium oxide are dissolved in hot concentrated nitric acid to make a nitrate solution; Mix the two solutions evenly to obtain a mixed solution, then adjust the pH value to 4 with ammonia water, add citric acid with 150% of the total mass of the phosphor powder, and stir at a constant temperature of 80° C. for 1.5 hours to form a gel;

[0043] 2) Heating the gel at 900°C for 1.5 hours to obtain a solid-phase calcined product; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com