Method for preparing nano barium-strontium titanate powder by adopting hydrothermal method

A technology of nano-titanium and hydrothermal method is applied in the field of preparation of barium strontium titanate powder, which can solve the problem of uneven particle size distribution of barium strontium titanate powder, and achieve the effect of avoiding grain growth and mixing of impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

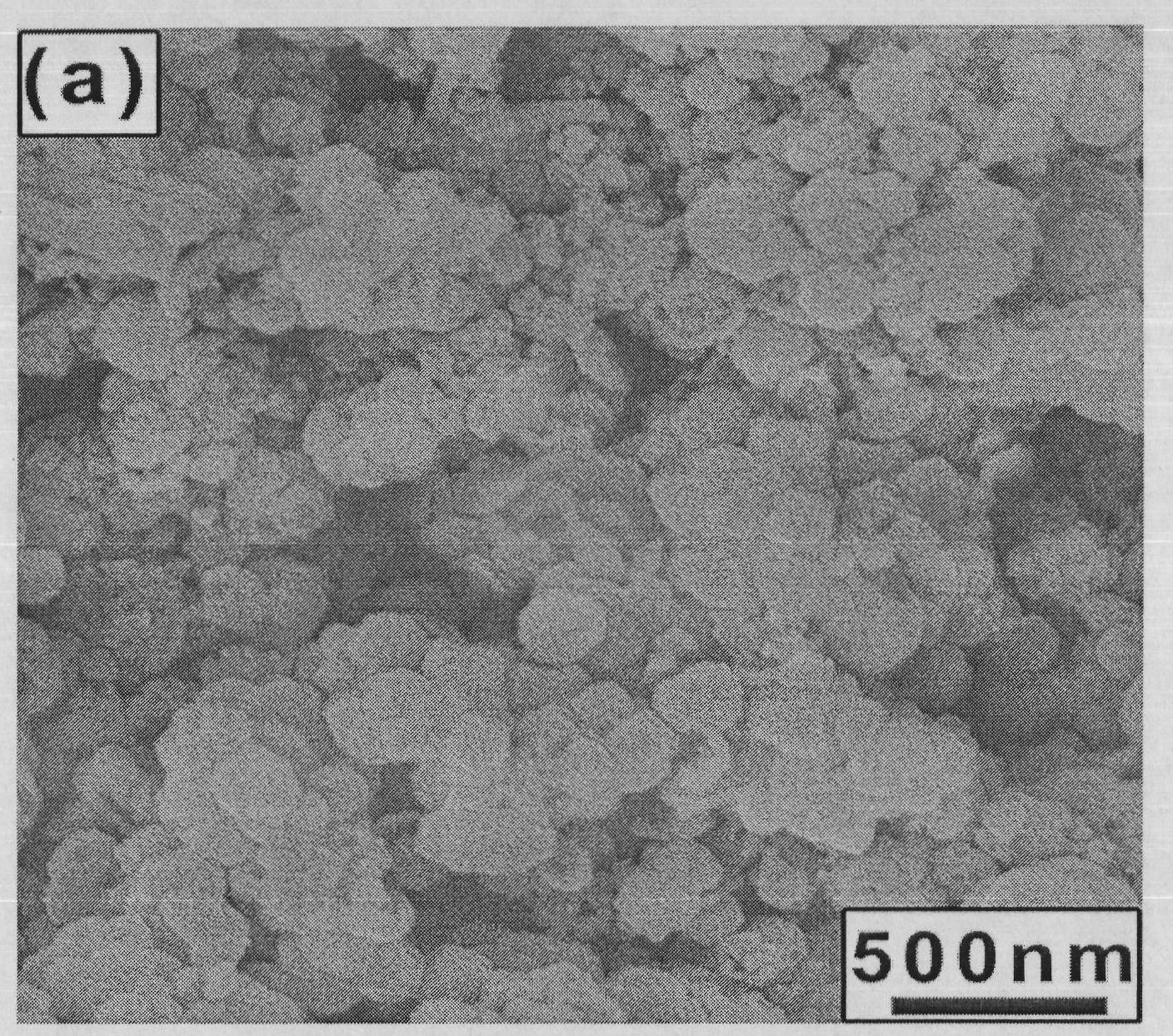

[0013] Embodiment 1, embodiment 1, weighing 1molSr (NO 3 ) 2 , 1molBa(NO 3 ) 2 , 1.2molTiO 2 , and then add 2mol / L mineralizer NaOH 50ml batching, directly into the autoclave lined with polytetrafluoroethylene, then add 31ml of deionized water, while stirring gently with a glass rod, followed by 1 ℃ / min Speed up to a hydrothermal temperature of 160°C and keep warm for 24 hours. After the heat preservation is over, cool down to room temperature with the furnace, and repeatedly rinse and filter the obtained powder with deionized water until the pH value of the filtered deionized water is neutral. Dry in oven. The microstructure of the prepared BST powder was analyzed by Hitach S-530 scanning electron microscope.

[0014] figure 1 It is the SEM photo of the BST powder obtained when r(Ba / Ti)=1.2. It can be seen from the figure that the particle size of the prepared BST powder is about 120nm, and the size is relatively uniform.

Embodiment 2

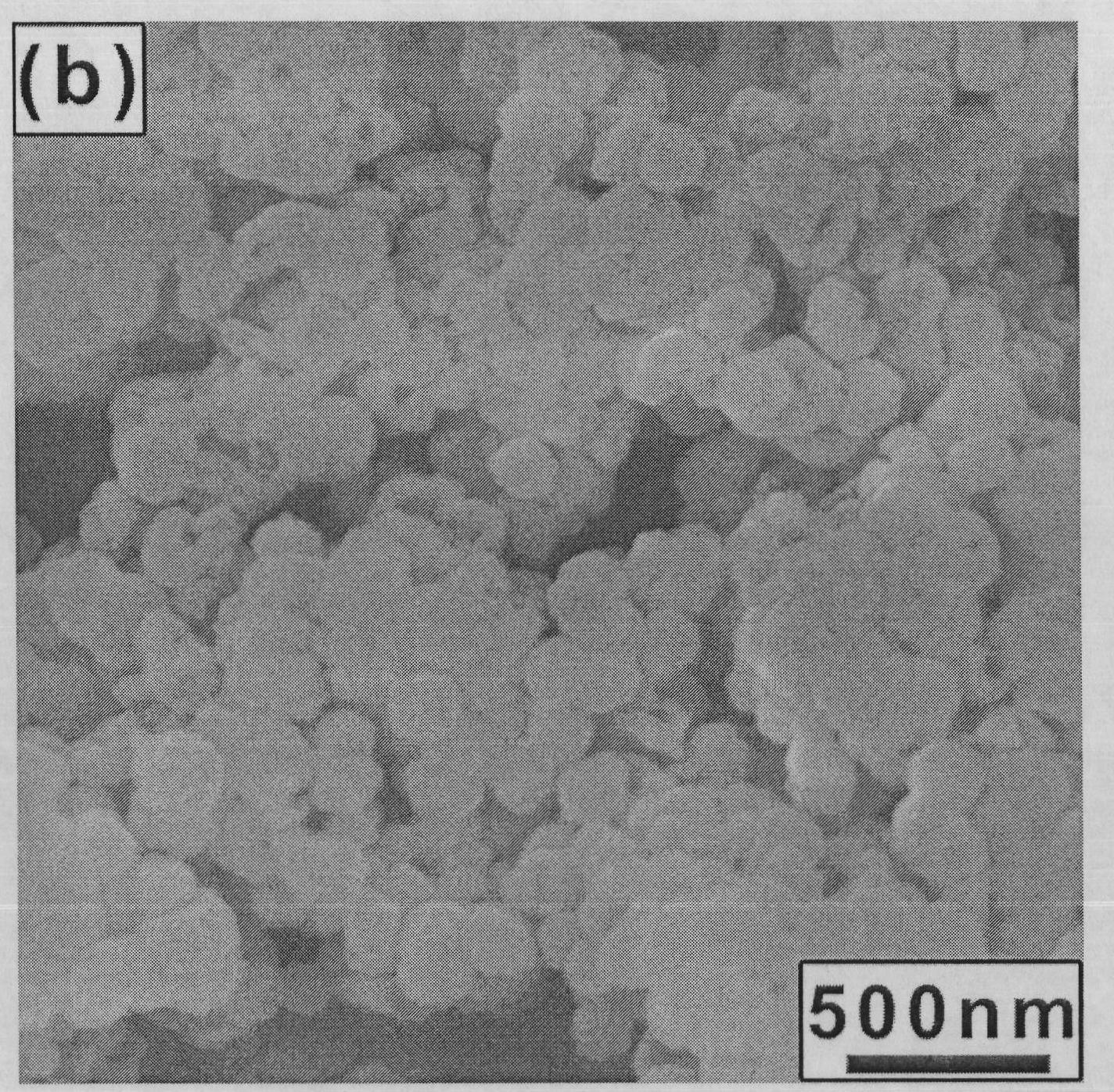

[0015] Embodiment 2, weighing 1molSr (NO 3 ) 2 , 1molBa(NO 3 ) 2 , 1.4molTiO 2 , and then add 3mol / L mineralizer KOH50ml ingredients, directly into the autoclave lined with polytetrafluoroethylene, then add 31ml of deionized water, while stirring gently with a glass rod, and then at a speed of 3°C / min Raise the temperature to a hydrothermal temperature of 140°C and keep the temperature for 12 hours. After the heat preservation is over, cool down to room temperature with the furnace, and repeatedly rinse and filter the obtained powder with deionized water until the pH value of the filtered deionized water is neutral. Dry in oven. The microstructure of the prepared BST powder was analyzed by Hitach S-530 scanning electron microscope.

[0016] figure 2 It is the SEM photo of the BST powder obtained when the Ba / Ti ratio r(Ba / Ti)=1.4. It can be seen from the figure that the particle size of the prepared BST powder is about 150nm, and the size is relatively uniform.

Embodiment 3

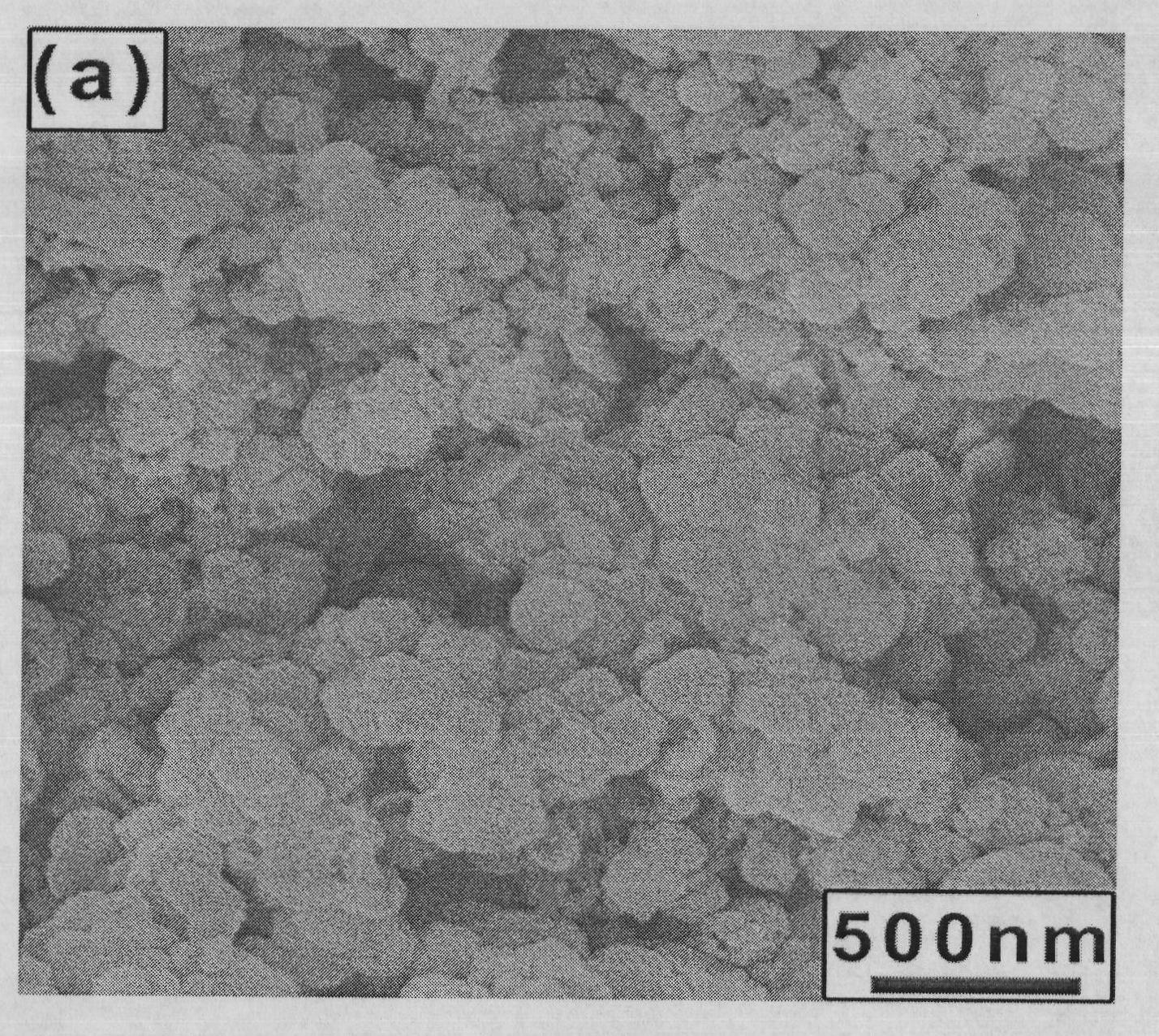

[0017] Embodiment 3, weighing 1molSr (NO 3 ) 2 , 1molBa(NO 3 ) 2 , 1.6molTiO 2 , and then add 4mol / L mineralizer NaOH 50ml batching, directly into the autoclave lined with polytetrafluoroethylene, then add 31ml of deionized water, while stirring gently with a glass rod, followed by 4 ℃ / min Speed up to a hydrothermal temperature of 120°C and keep warm for 36 hours. After the heat preservation is over, cool down to room temperature with the furnace, and repeatedly rinse and filter the obtained powder with deionized water until the pH value of the filtered deionized water is neutral. Dry in oven. The microstructure of the prepared BST powder was analyzed by Hitach S-530 scanning electron microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com