Fast synthesizing process of strontium aluminate rare earth long afterglow luminescent powder

A technology of long afterglow luminescent powder and synthesis method, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of poor luminous intensity and brightness of products, unfavorable mass production, expensive raw materials, etc. The effect of fast heating and shortening of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

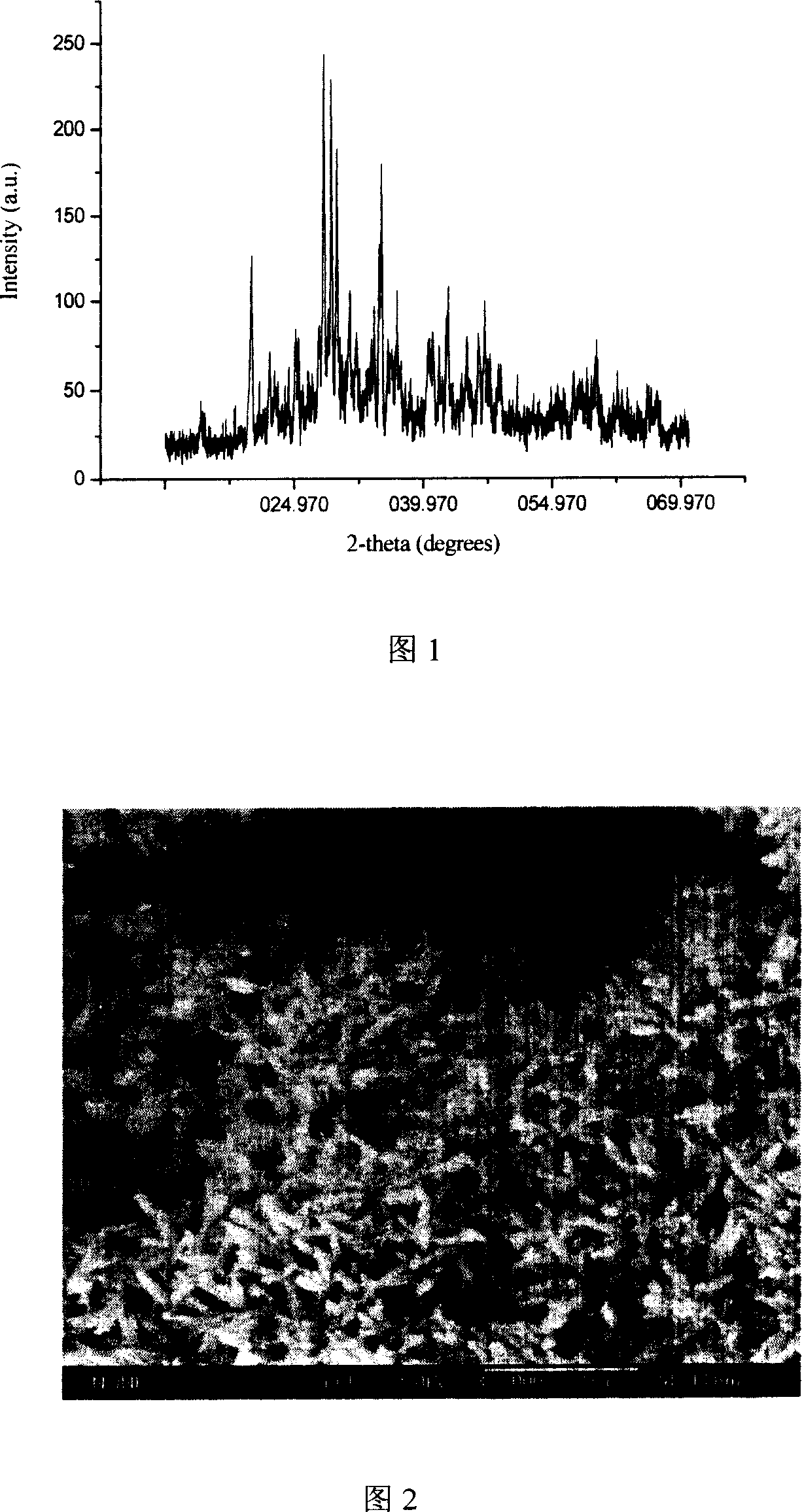

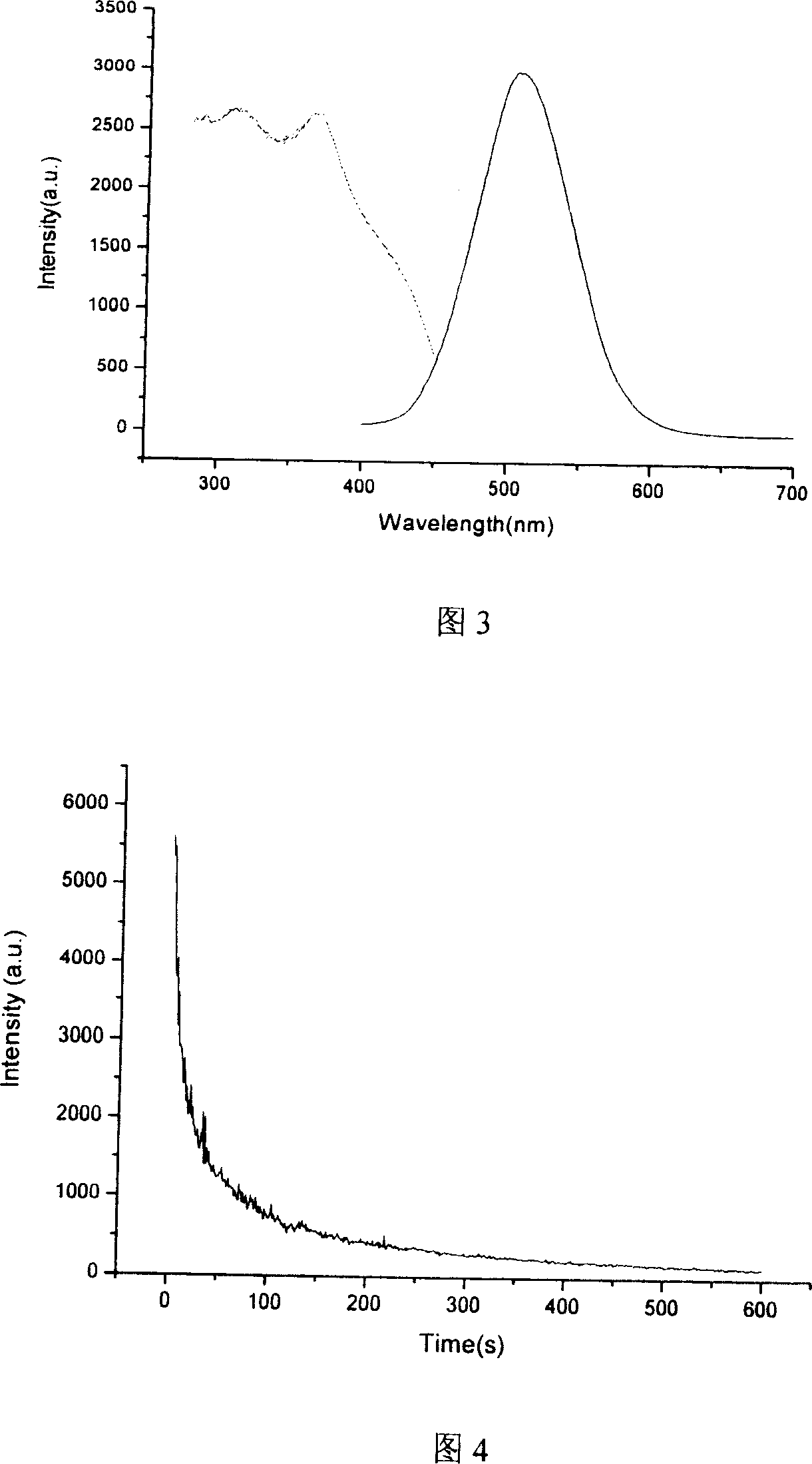

[0026] Embodiment 1: 15g Al (NO 3 ) 3 9H 2 O, 2g Sr(NO 3 ) 2 , 0.15g H 3 BO 3 , 0.025g Eu(NO 3 ) 3 ·6H 2 O and 0.025g Dy(NO 3 ) 3 ·6H 2 O was ground in a mortar for 10 min, mixed evenly and placed in a porcelain crucible, and then put into another larger porcelain crucible filled with activated carbon after being covered. Put it in a household microwave oven, control the microwave power to medium heat for 60 minutes, (1100-1300°C) to get the product.

Embodiment 2

[0027] Embodiment 2: 15g Al (NO 3 ) 3 9H 2 O, 2g Sr(NO 3 ) 2 , 0.3g H 3 BO 3 , 0.05g Eu(NO 3 ) 3 ·6H 2 O and 0.1g La(NO 3 ) 3 ·6H 2 O was ground in a mortar for 10 min, mixed evenly and placed in a porcelain crucible, and then put into another larger porcelain crucible filled with activated carbon after being covered. Put it into a household microwave oven, control the microwave power and heat it up for 20 minutes (1400-1600°C) to get the product.

Embodiment 3

[0028] Embodiment 3: 15gAl (NO 3 ) 3 9H 2 O, 2g Sr(NO 3 ) 2 , 0.6g H 3 BO 3 , 0.065g Eu(NO 3 ) 3 ·6H 2 O and 0.15g Nd(NO 3 ) 3 ·6H 2 O was ground in a mortar for 10 min, mixed evenly and placed in a porcelain crucible, and then put into another larger porcelain crucible filled with granular activated carbon after being covered. Put it in a household microwave oven, control the microwave power and heat it up for 40 minutes (1400-1600°C) to get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com