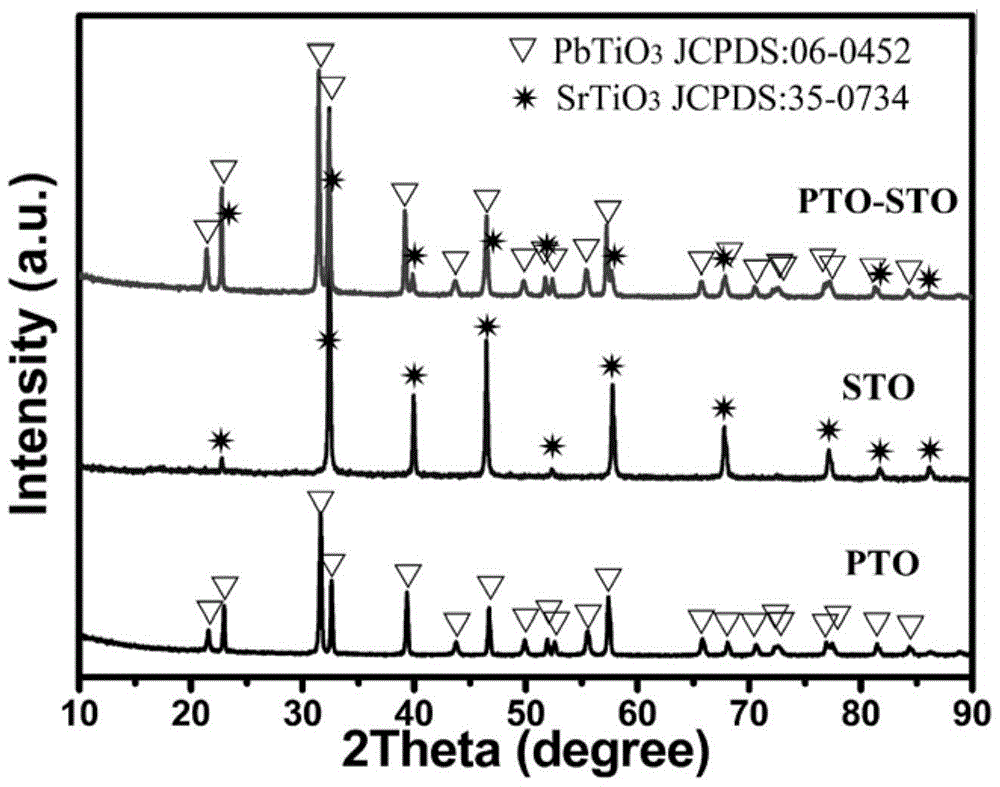

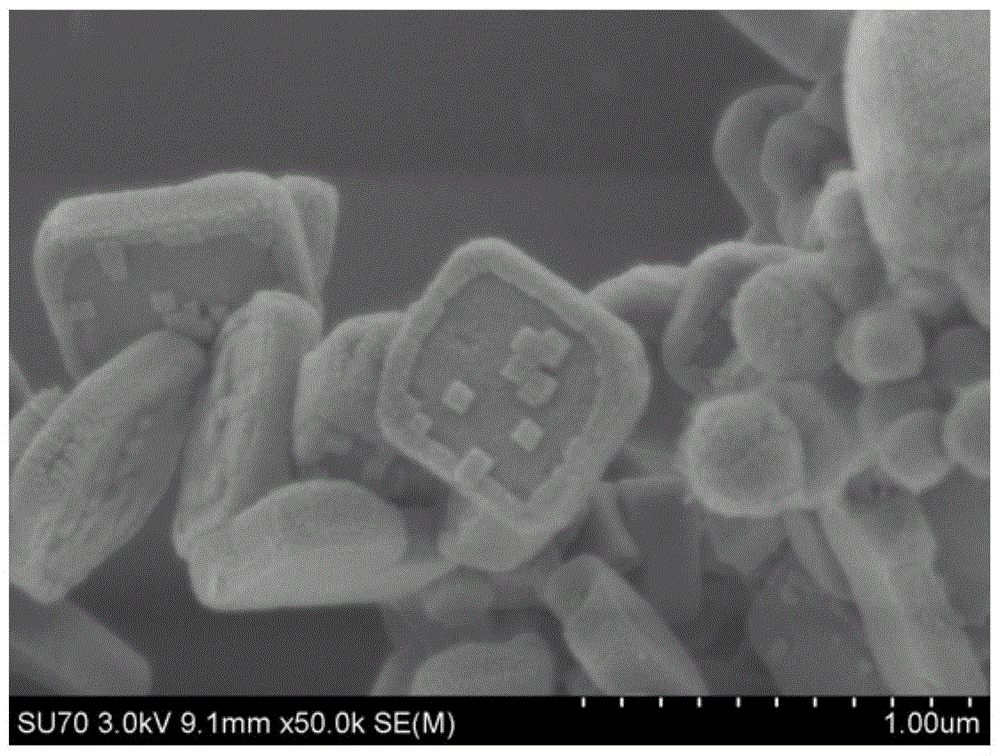

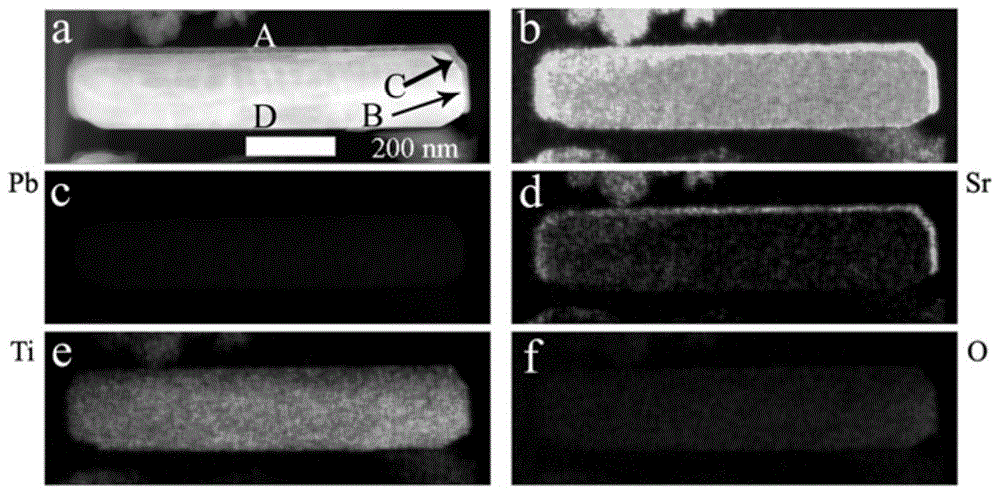

Preparation method of lead titanate-strontium titanate monocrystal nanometer material with core-shell structure

A core-shell structure and single-crystal nanotechnology, which is applied in the field of preparation of perovskite-phase lead titanate-strontium titanate single-crystal nanomaterials, can solve problems such as difficult, difficult to control material quality, high cost, etc. Simple process, low cost, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] 1) Under magnetic stirring conditions, dissolve NaOH in deionized water to prepare a 2mol / L NaOH aqueous solution;

[0026] 2) According to the chemical formula SrTiO of the perovskite structure strontium titanate to be synthesized 3 Metering ratio, weigh strontium nitrate solid powder and prepare it in deionized water to make Sr 2+ A solution with an ion concentration of 0.02mol / L, and measure tetrabutyl titanate under the condition that the molar ratio of tetrabutyl titanate and strontium nitrate is 1:1;

[0027] 3) Under magnetic stirring conditions, 20 mL of the aqueous strontium nitrate solution prepared in step 2) was added dropwise to 10 mL of the NaOH aqueous solution in step 1) to obtain a mixed solution;

[0028] 4) Under the condition of magnetic stirring, according to the molar ratio of lead titanate to strontium titanate is 1:1, weigh the perovskite phase single crystal single domain lead titanate nanosheets, and add them to the mixed solution in step 3), ...

example 2

[0032] 1) Under magnetic stirring conditions, NaOH was dissolved in deionized water to prepare a 6mol / L NaOH aqueous solution;

[0033] 2) According to the chemical formula SrTiO of the perovskite structure strontium titanate to be synthesized 3 Metering ratio, weigh strontium nitrate solid powder and prepare it in deionized water to make Sr 2+ A solution with an ion concentration of 0.02mol / L, and measure tetrabutyl titanate under the condition that the molar ratio of tetrabutyl titanate and strontium nitrate is 1:1;

[0034] 3) Under magnetic stirring conditions, 30 mL of the aqueous strontium nitrate solution prepared in step 2) was added dropwise to 5 mL of the NaOH aqueous solution in step 1) to obtain a mixed solution;

[0035] 4) Under the condition of magnetic stirring, according to the molar ratio of lead titanate to strontium titanate is 1:1, weigh the perovskite phase single crystal single domain lead titanate nanosheets, and add them to the mixed solution in step ...

example 3

[0039] 1) Under magnetic stirring conditions, NaOH was dissolved in deionized water to prepare a 4mol / L NaOH aqueous solution;

[0040] 2) According to the chemical formula SrTiO of the perovskite structure strontium titanate to be synthesized 3 Metering ratio, weigh strontium nitrate solid powder and prepare it in deionized water to make Sr 2+ A solution with an ion concentration of 0.02mol / L, and measure tetrabutyl titanate under the condition that the molar ratio of tetrabutyl titanate and strontium nitrate is 1:1;

[0041] 3) Under magnetic stirring conditions, 10 mL of the aqueous strontium nitrate solution prepared in step 2) was added dropwise to 25 mL of the NaOH aqueous solution in step 1) to obtain a mixed solution;

[0042] 4) Under the condition of magnetic stirring, according to the molar ratio of lead titanate to strontium titanate is 1:0.8, weigh the perovskite phase single crystal single domain lead titanate nanosheets, and add them to the mixed solution in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com