Thin film transistor and production method thereof and array substrate

A technology of thin film transistor and manufacturing method, which is applied in transistors, semiconductor/solid-state device manufacturing, semiconductor device and other directions, can solve problems such as poor electrical contact between source and drain and oxide semiconductor layer, and achieves solving the problem of poor electrical contact and eliminating masking. Mold process forming process, good lattice matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

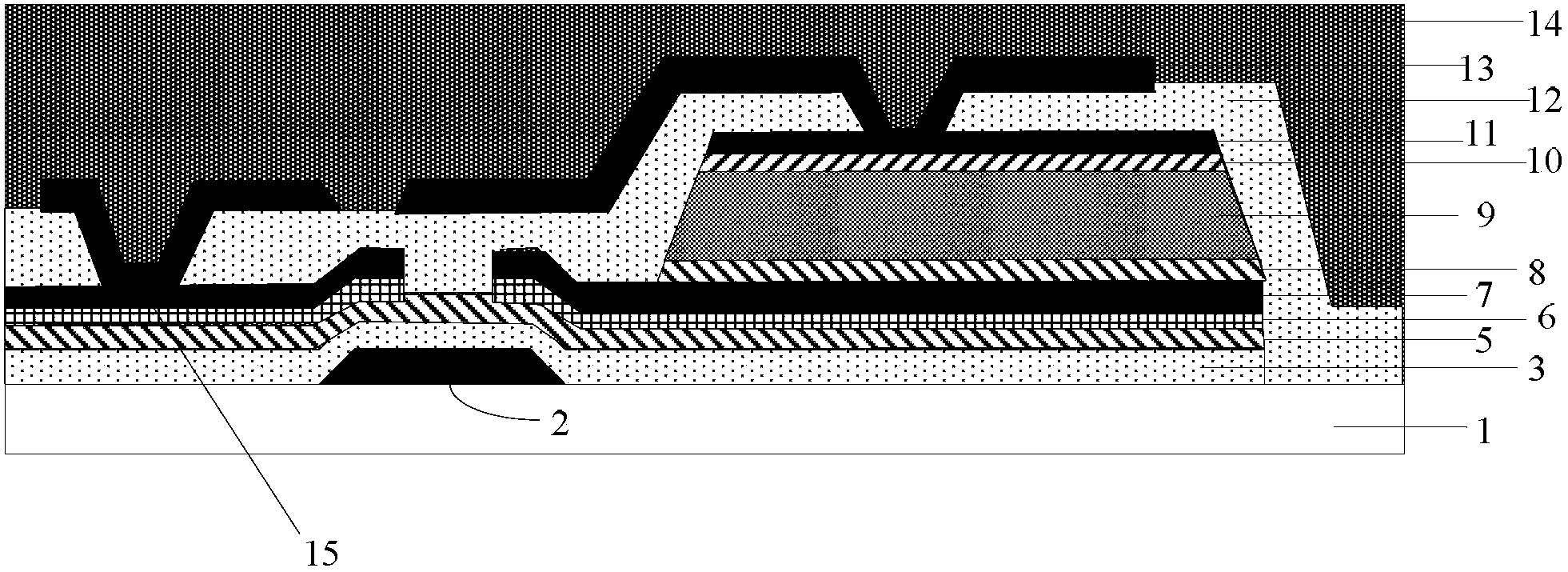

[0063] The basic idea of the present invention is: when forming the source and drain electrodes, directly deposit the highly doped amorphous silicon thin film on the oxide semiconductor thin film layers on both sides of the barrier layer to increase the carrier concentration at the oxide semiconductor interface, In this way, the oxide semiconductor can exhibit the electrical characteristics of a conductor, and the source and drain electrodes are formed.

[0064] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

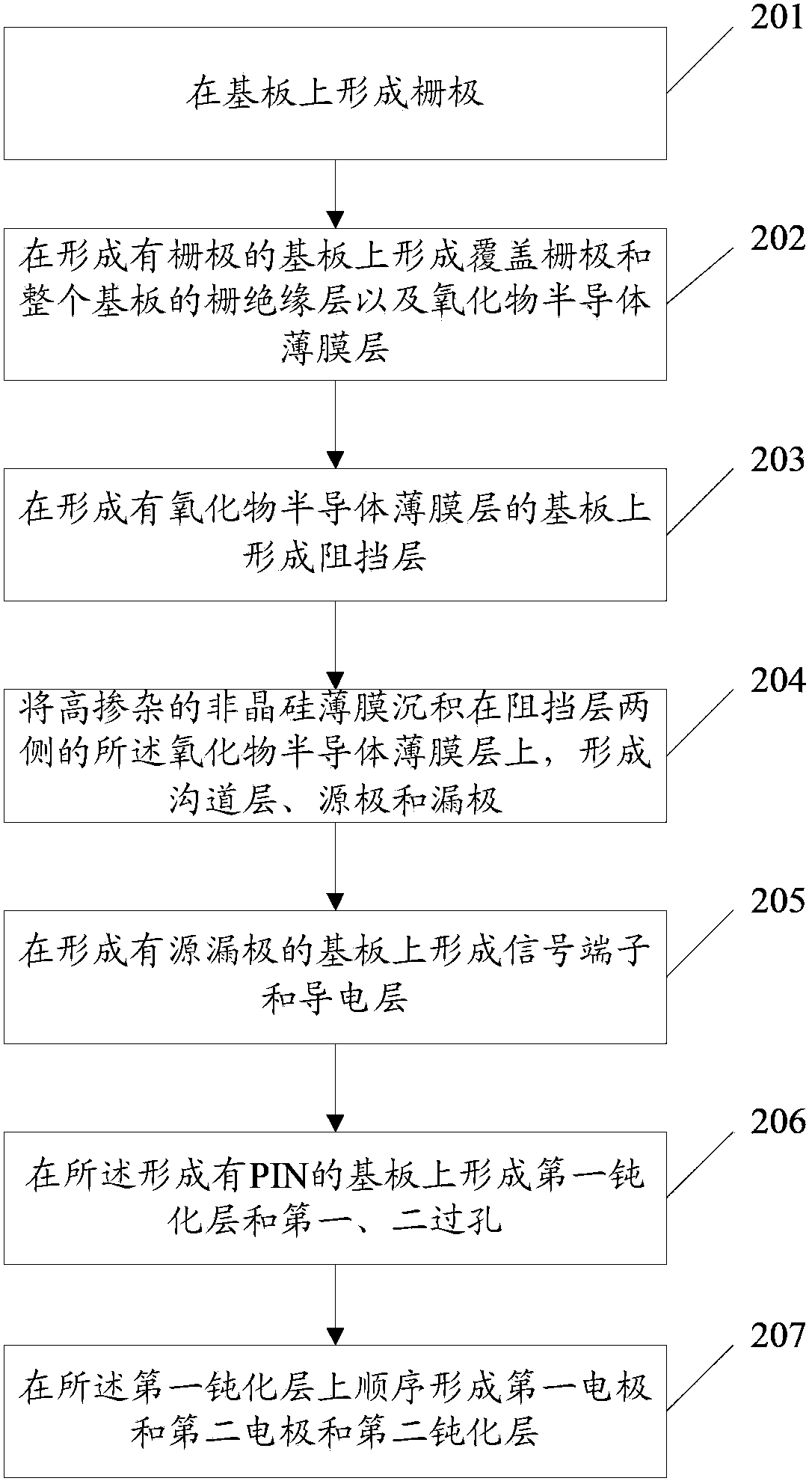

[0065] figure 2 It is a schematic flow chart of the manufacturing method of the thin film transistor of the present invention, such as figure 2 As shown, the implementation method is as follows:

[0066] Step 201: forming a gate on the substrate;

[0067] Specifically, a gate layer thin film is formed on the substrate 1 and patterned to form the gate 2 . Here, the gate can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com