Composite cathode material used for lithium-sulfur battery and having high-rate performance and preparation method

A composite cathode material, lithium-sulfur battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as not being well solved, and achieve reduced loss of active materials, excellent rate performance, and improved rate performance. The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

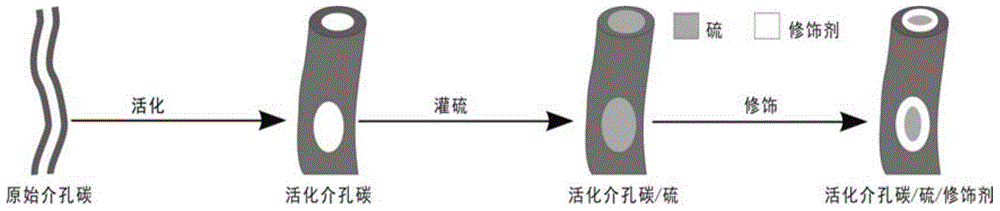

[0040] Mesoporous carbon material / sulfur composite cathode material, the preparation method of which is as follows:

[0041] 1) Take porous multi-walled carbon nanotubes (h-CNT) as the conductive carbon material (C), weigh 0.2g; weigh 0.2g of the electrochemically active substance sulfur (S);

[0042] 2) Preparation by melting method: pour the sulfur weighed in step 1) into the weighed porous multi-walled carbon nanotube (h-CNT), the setting conditions of the melting method are: 2 Under the atmosphere of protective gas, the air flow rate is set to 50mL / min, under the condition of ventilation, stand still for 30min, discharge the air in the tube furnace, then rise to 155℃ after 100℃, keep it for 10h, and then cool naturally to prepare porous multi-layer furnace. Walled carbon nanotube / sulfur composite cathode material (h-CNT / S).

[0043] The methods of preparing the positive electrode sheet, assembling the battery and testing the battery are the same as those in the comparativ...

Embodiment 2

[0045] A composite positive electrode material for a lithium-sulfur battery with high rate performance, consisting of a conductive agent, an electrochemically active substance sulfur, and a modifier ZrO 2 Composition, the conductive agent is a porous multi-walled carbon nanotube (h-CNT), the electrochemically active substance sulfur is dispersed in the pores of the porous multi-walled carbon nanotube, and the modifier is connected with the mesoporous carbon material by chemical bonding . Wherein, the amount of each composition is calculated by mass percentage: 50 wt% of the conductive agent, 49.95 wt% of the electrochemical active material, and 0.05 wt% of the modifier.

[0046] The preparation method of the composite positive electrode material of the above-mentioned high-rate performance lithium-sulfur battery, the specific steps are as follows:

[0047] 1) Take porous multi-walled carbon nanotube (h-CNT) as conductive carbon material, weigh 0.2g; electrochemically active s...

Embodiment 3

[0054] A composite positive electrode material for a lithium-sulfur battery with high rate performance, consisting of a conductive agent, an electrochemically active substance sulfur, and a modifier ZrO 2 Composition, the conductive agent is a porous multi-walled carbon nanotube (h-CNT), the electrochemically active substance sulfur is dispersed in the pores of the porous multi-walled carbon nanotube, and the modifier is connected with the mesoporous carbon material by chemical bonding . Wherein, the dosage of each composition is calculated by mass percentage: conductive agent 51wt%, electrochemical active substance 48.88wt%, modifier 0.12wt%.

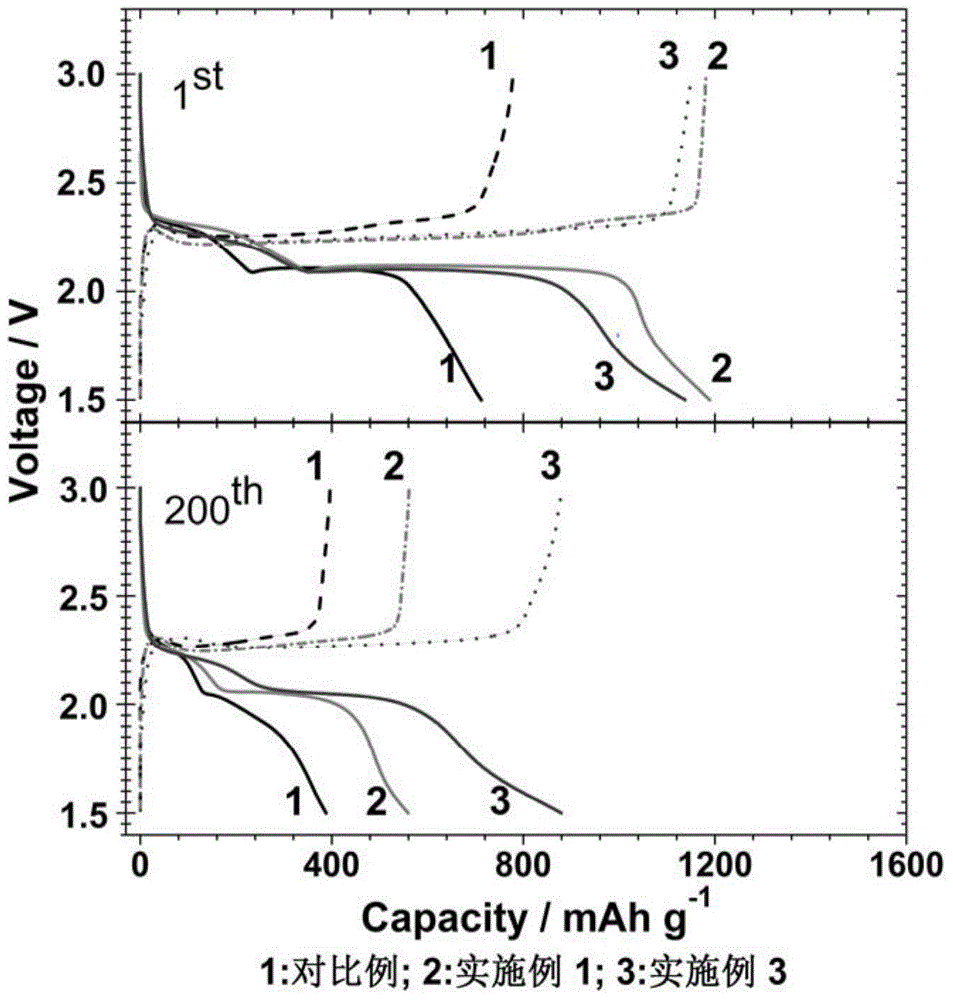

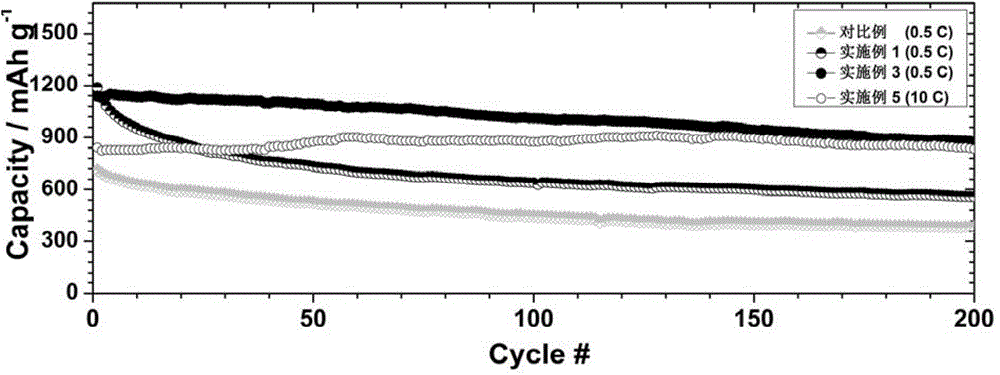

[0055] In this example, the preparation of the composite positive electrode material, the preparation of the positive electrode sheet, the method of assembling the battery and the battery test are all the same as in Example 2. The battery charge and discharge test results show that: at a rate of 0.5C, the first charge of the battery pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com