Working electrode based on carbon cloth/gallium oxynitride and supercapacitor

A supercapacitor and oxynitride technology, which is applied in the field of electrochemical energy storage, can solve the problems of low conductivity and affect the rate performance of supercapacitors, and achieve excellent rate performance, excellent electrochemical cycle stability, and good rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A carbon cloth / gallium oxynitride and a preparation method thereof, the steps are as follows:

[0055] (1) arrange the carbon in 6mol L -1 Nitric acid solution, sonicate at room temperature for 2 h, and dry.

[0056] (2) Cut the carbon cloth into a rectangular strip of 1cm×4cm, place the carbon cloth strip in 1mol L -1 The gallium trichloride-benzene solution was dipped and pulled 12 times, and the time interval between two adjacent dips and pulled was 5 minutes.

[0057] (3) Arrange the impregnated and pulled carbon in a fume hood, place it in ambient air at room temperature for 12 hours, then place the carbon in a 60°C oven to dry for 6 hours, then place the carbon in a tube furnace, and turn on the ammonia gas bottle, the ammonia flow rate was set at 48mL min -1 , Ammonia gas enters the tube furnace after passing through 25-28% concentrated ammonia water.

[0058] (4) Programmed heating, the heating rate is 10°C min -1 , when the temperature reaches 750°C, keep ...

Embodiment 2

[0061] Change the 750°C in step (4) of Example 1 to 800°C, and keep the rest of the conditions unchanged. The obtained carbon cloth / gallium oxynitride is denoted as S2.

Embodiment 3

[0063] Change the 750°C in step (4) of Example 1 to 850°C, and keep the rest of the conditions unchanged. The obtained carbon cloth / gallium oxynitride is denoted as S3.

[0064] Result analysis

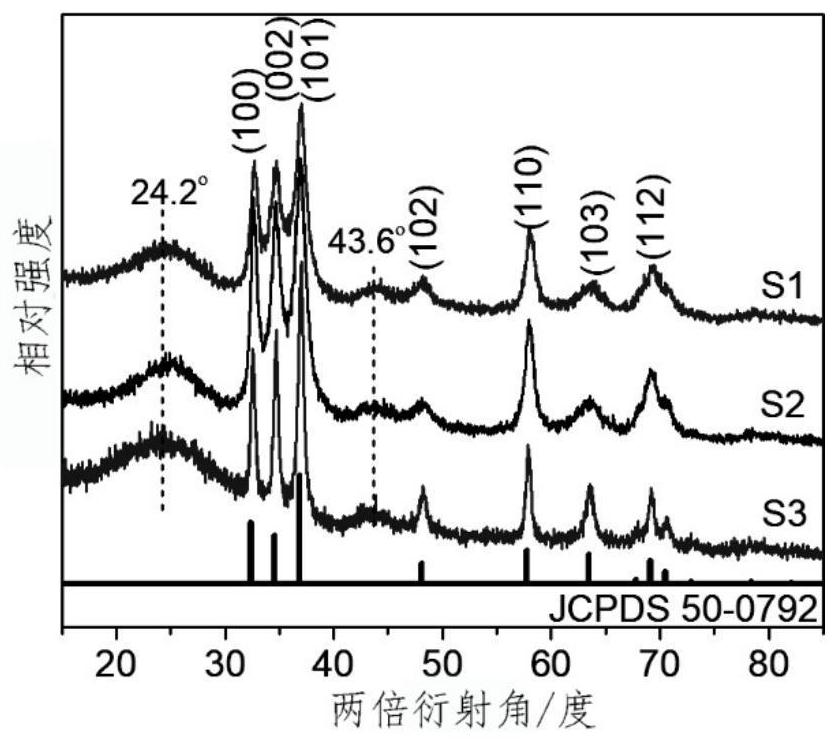

[0065] figure 1 is the XRD pattern of samples S1, S2 and S3. The two weak peaks at 24.2° and 43.6° in the figure come from carbon cloth, and the positions of the remaining diffraction peaks are similar to those of (100), (002), (101), (102), (110), (103) and (112) crystal planes correspond. Compared with S1 and S2, the width of the diffraction peak corresponding to the (100) / (002) / (101) crystal plane in the spectrum of S3 is narrower, and there is obvious splitting. This shows that the increase of nitriding temperature is beneficial to improve the crystallinity of sample particles.

[0066] The structural information of the sample can be obtained by Rietveld fitting. Table 1 gives the unit cell parameters of different samples. It can be seen from Table 1 that as the nitriding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com