Method for preparing sulfur positive electrode of lithium-sulfur battery from tubular mineral

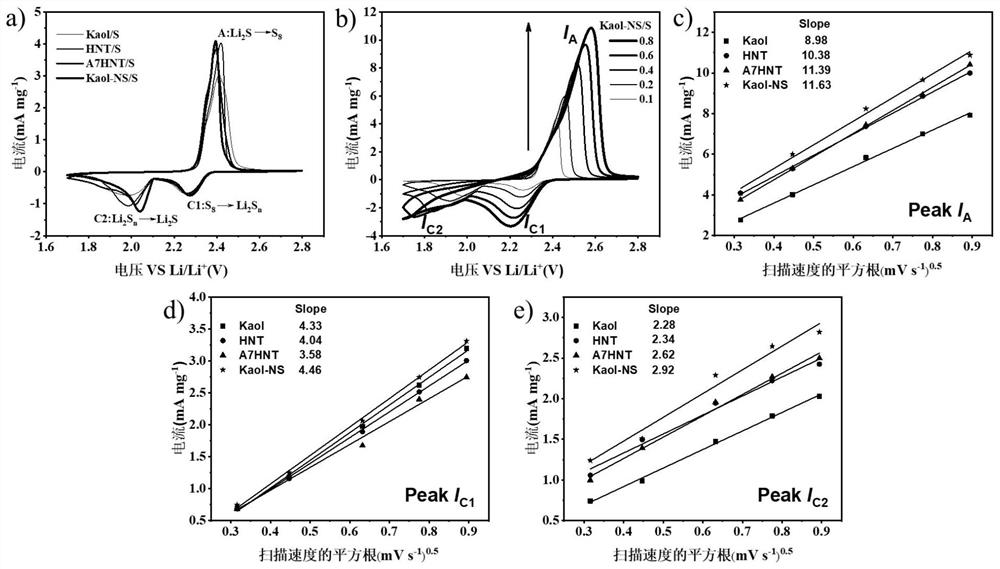

A lithium-sulfur battery and sulfur cathode technology, which is applied in the field of preparing the lithium-sulfur battery sulfur cathode from tubular minerals, can solve the problems of slow electrochemical reaction kinetics, poor rate performance, poor cycle stability, etc., so as to suppress the shuttle effect and improve the Reaction kinetics, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method for preparing a lithium-sulfur battery sulfur positive electrode from a tubular mineral, which specifically includes the following steps:

[0034] Step 1: Disperse the kaolin in a mixed solution of DMOS and deionized water, stir in an oil bath at 90°C for 3 hours, separate the solid by centrifugation, and dry at 60°C for 24 hours to obtain pretreated kaolin. Preferably, the centrifugation rate is 3500rpm / min, and the centrifugation time is 5min; preferably, the mass ratio of kaolin, DMSO and deionized water is 1:(5-9):(1-2).

[0035] Step 2: Add pretreated kaolin to anhydrous AlCl 3 The mixed solution with methanol was magnetically stirred for 12 hours, the solid was separated by centrifugation, then HCl was added, stirred in a water bath at 85°C for 1 hour, washed with methanol for several times, and air-dried naturally to obtain the preliminary treated kaolin. Preferably, pretreated kaolin, anhydrous AlCl 3And the mass rat...

Embodiment 1

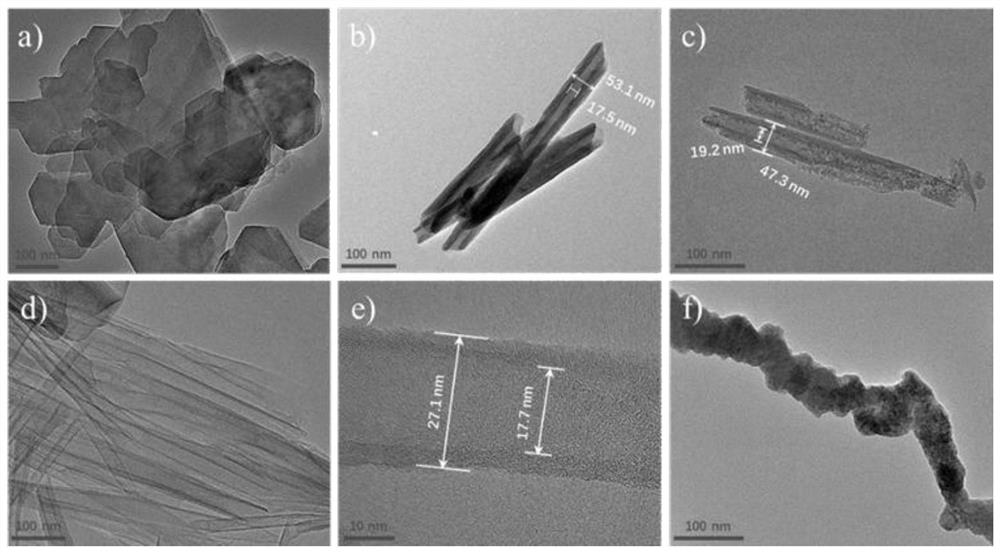

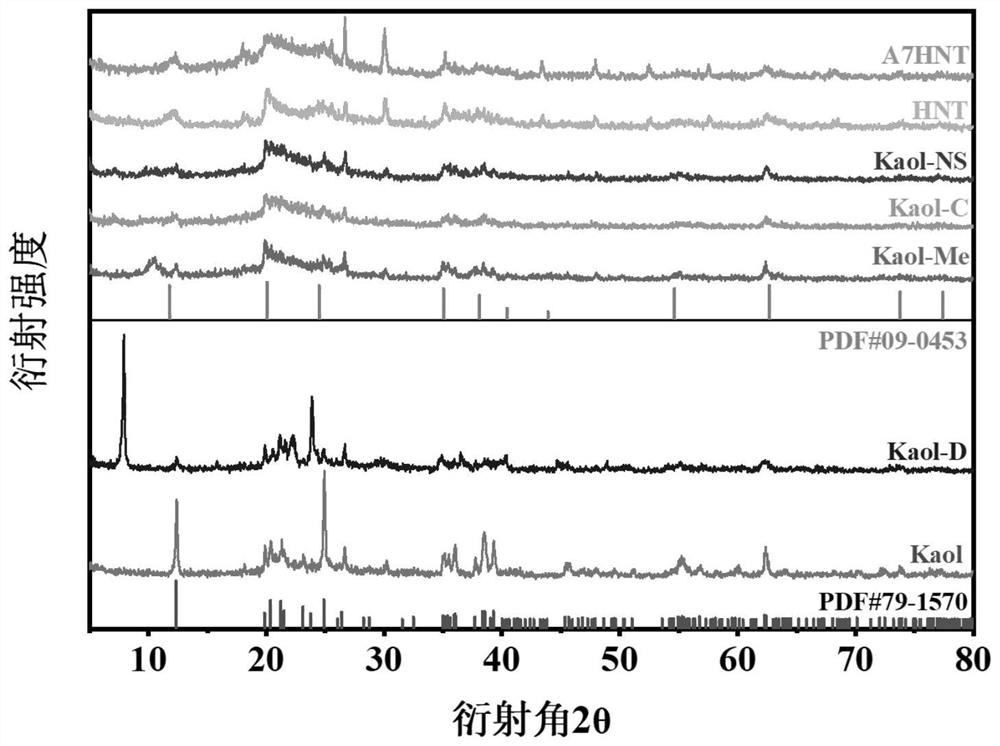

[0064] (1) Treatment of kaolin

[0065] Disperse 10 g of kaolinite powder in a mixture of 90 mL of DMSO and 10 mL of deionized water, stir in an oil bath at 90 °C for 3 h, centrifuge to separate the solid, and then dry at 60 °C for 24 h to obtain pretreated kaolin (Kaol-D). Take 5g Kaol-D powder and add it to 50mL of 1mol / L AlCl 3 In the methanol mixed solution, magnetically stirred for 12 h, centrifuged to separate the solid, then added 15 mL of 1 mol / L HCl, stirred in a water bath at 85 °C for 1 h (under airtight conditions), washed with methanol 5 times, and air-dried naturally to obtain the preliminary treatment kaolin (Kaol-Me). Add 2 g of Kaol-Me to 40 mL of 1 mol / L CTAB methanol mixed solution, condense and reflux for 24 h at 85 °C, filter, wash with methanol for several times, and dry at 60 °C for 24 h to obtain reprocessed kaolin (Kaol-C). Take 1 g of Kaol-C and add it to 40 mL of 0.5 mol / L CTAB solution, and use an ultrasonic cell disintegrator for ultrasonication. ...

Embodiment 2

[0075] (1) Treatment of kaolin

[0076] Disperse 10 g of kaolinite powder in a mixture of 90 mL of DMSO and 20 mL of deionized water, stir in an oil bath at 90 °C for 3 h, centrifuge to separate the solid, and then dry at 60 °C for 24 h to obtain pretreated kaolin (Kaol-D). Take 5g Kaol-D powder and add it to 50mL 2mol / L AlCl 3 In the methanol mixed solution, magnetically stirred for 12 h, centrifuged to separate the solid, then added 15 mL of 1 mol / L HCl, stirred in a water bath at 85 °C for 1 h (under airtight conditions), washed with methanol 5 times, and air-dried naturally to obtain the preliminary treatment kaolin (Kaol-Me). 2g Kaol-Me was added to 20mL 1mol / L CTAB methanol mixed solution, condensed and refluxed for 24h at 85°C, stirred for 24h, filtered and washed with methanol for several times, and dried at 60°C for 24h to obtain reprocessed kaolin (Kaol-C). Take 1 g of Kaol-C and add it to 40 mL of 1.5 mol / L CTAB solution, and use an ultrasonic cell disintegrator to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com