High-performance alkaline zinc battery cathode material and preparation method thereof

A cathode material, zinc battery technology, applied in the direction of alkaline storage battery, battery electrode, carbon preparation/purification, etc., can solve the problems of poor controllability, tedious time-consuming, not enough environmental protection, etc., to achieve mild and controllable reaction, The effect of low production cost and high area specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

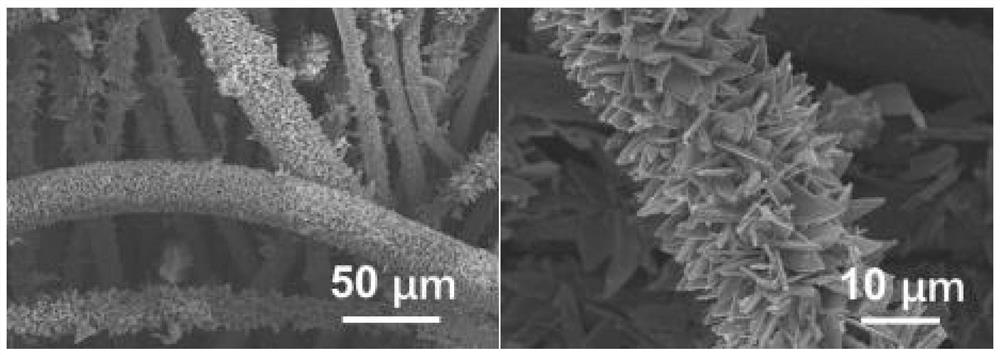

[0023] (1) Using cobalt nitrate hexahydrate and dimethylimidazole with a mass ratio of 1:2.5 as the precursor, the acid-treated hydrophilic carbon cloth was suspended in the aqueous solution of the precursor, and the sheet-like cobalt-based metal-organic framework (ZIF- 67) Uniformly grow on the carbon cloth in situ, the reaction temperature is controlled at 20°C, the reaction time is controlled at 6h, and the resulting material is dried under vacuum. For the specific structure, see figure 1 ;

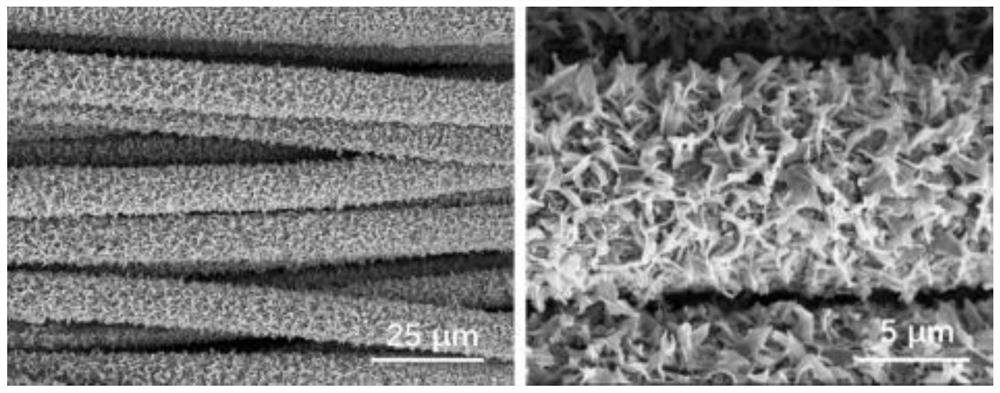

[0024] (2) Under the protection of argon, the material obtained in step (1) was heat-treated in a tube furnace, and the heating rate was controlled at 1.5°C min -1 , the treatment temperature is 500°C, the treatment time is controlled at 2h, ZIF-67 is converted into carbon-coated cobalt nanoparticles, and the material is obtained. For the specific structure, see figure 2 ;

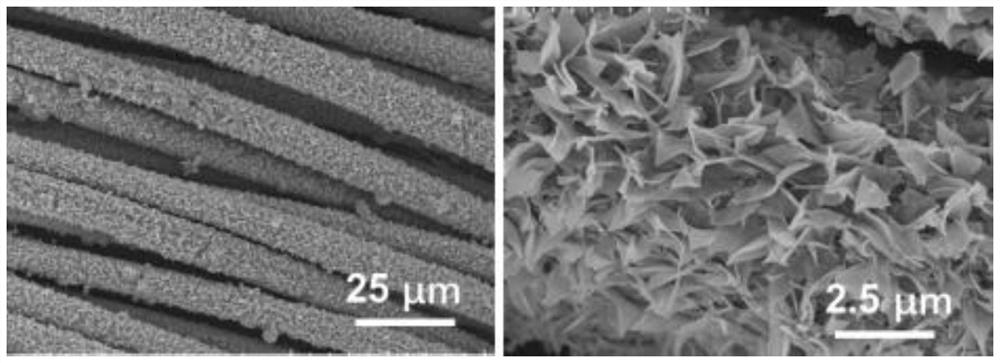

[0025] (3) Place the commercial selenium powder on the upstream of the gas path, put it into the tube furnace...

Embodiment 2

[0028] (1) Using cobalt nitrate hexahydrate and dimethylimidazole with a mass ratio of 1:3.5 as the precursor, the acid-treated hydrophilic carbon cloth was suspended in the aqueous solution of the precursor, and the sheet-like cobalt-based metal-organic framework (ZIF- 67) In-situ uniform growth on the carbon cloth, the reaction temperature is controlled at 15°C, the reaction time is controlled at 10h, and the obtained material is dried under vacuum;

[0029] (2) Under the protection of argon, the material obtained in step (1) was heat-treated in a tube furnace, and the heating rate was controlled at 5°C min -1 , the treatment temperature is 600°C, the treatment time is controlled at 5h, and the ZIF-67 is converted into carbon-coated cobalt nanoparticles;

[0030] (3) Place the commercial selenium powder on the upstream of the gas path, put it into the tube furnace together with the material obtained in step (2), and pass a hydrogen-argon gas mixture with a hydrogen content o...

Embodiment 3

[0033] (1) Using cobalt nitrate hexahydrate and dimethylimidazole with a mass ratio of 1:2 as the precursor, the acid-treated hydrophilic carbon cloth was suspended in the aqueous solution of the precursor, and the sheet-like cobalt-based metal-organic framework (ZIF- 67) In-situ uniform growth on the carbon cloth, the reaction temperature is controlled at 30°C, the reaction time is controlled at 4h, and the obtained material is dried under vacuum;

[0034] (2) Under the protection of argon, the material obtained in step (1) was heat-treated in a tube furnace, and the heating rate was controlled at 1°C min -1 , the treatment temperature is 400°C, the treatment time is controlled at 1h, and the ZIF-67 is converted into carbon-coated cobalt nanoparticles;

[0035] (3) Place the commercialized selenium powder on the upstream of the gas path, put it into the tube furnace together with the material obtained in step (2), and pass a hydrogen-argon gas mixture with a hydrogen content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com