Natural graphite, modified natural graphite material prepared from natural graphite, preparation method and application

A natural graphite, modified technology, applied in the field of negative electrode materials, can solve the problems of poor rate performance and first Coulombic efficiency of composite materials, poor Coulombic efficiency and rate performance, etc., achieve excellent cycle performance, excellent rate performance, and improve anisotropy same-sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

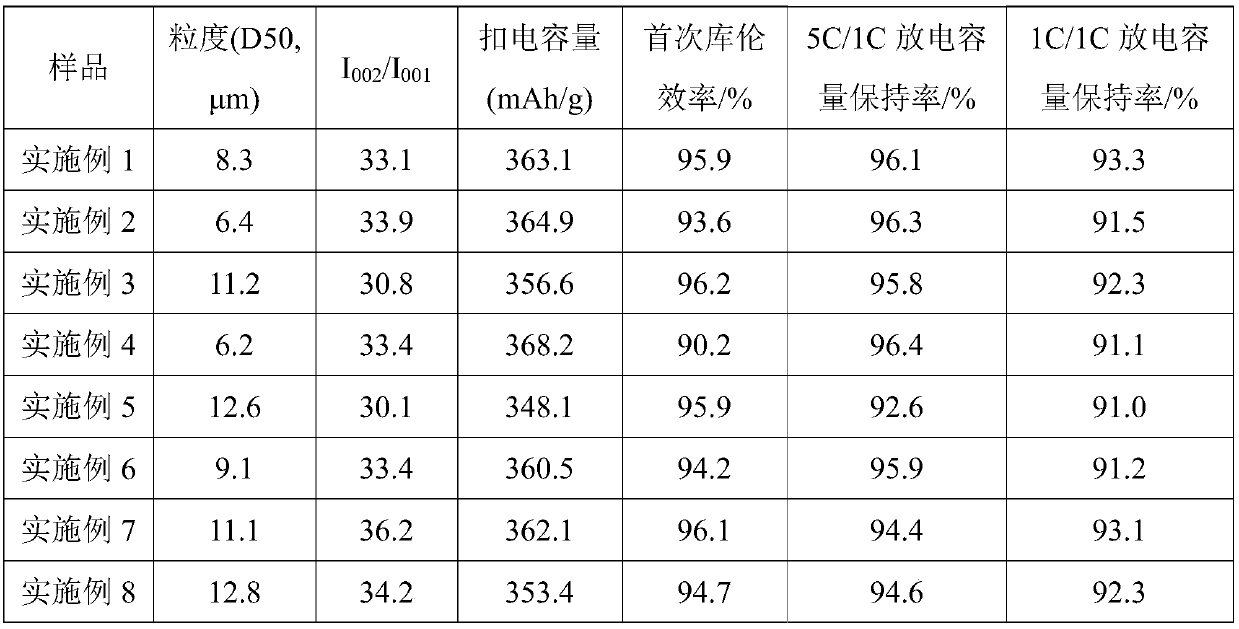

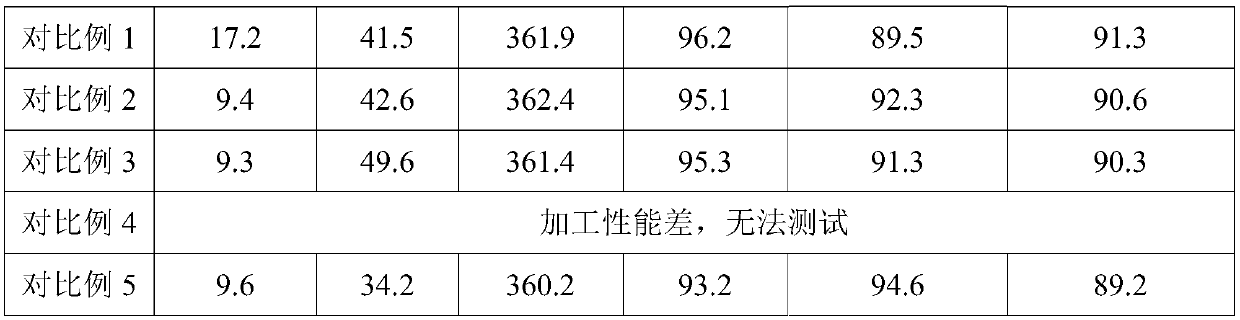

Embodiment 1

[0046] A modified natural graphite material, the preparation method is as follows:

[0047] Natural graphite (D50=6μm, D90 / D10=2.48, I 002 / I 110 ≤33.2, saturated tap density is 0.62g / cc, specific surface area is 9.4m 2 / g) and petroleum asphalt (softening point: 140°C) are mixed at a ratio of 1:0.25, and then the mixed material is put into a specific reaction kettle for stirring and heating. The heating temperature is 360°C and kept for 3 hours. After heating The material is subjected to cold isostatic pressing treatment, the treatment pressure is 120MPa, and the time is 2min. The product after isostatic pressing is carbonized at 2800°C, and then the material is crushed to the approximate particle size of the raw material, and sieved to obtain a modified natural graphite material with a D50 of 8.3 μm.

Embodiment 2-5

[0049] The only difference with Example 1 is that in the present example, the mass ratio of natural graphite and coal tar pitch is 1:0.05 (Example 2), 1:1 (Example 3), 1:0.01 (Example 4 ), 1:2 (embodiment 5).

Embodiment 6

[0051] The only difference from Example 1 is that in this example, the solidifying agent is phenolic resin (softening point is 110° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com