Preparation method of dry-method microwave composite medium board

A composite medium, dry mixing technology, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of complex collection and treatment, high manufacturing cost, large amount of waste water, etc., to save the preparation cycle, Stable product quality and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

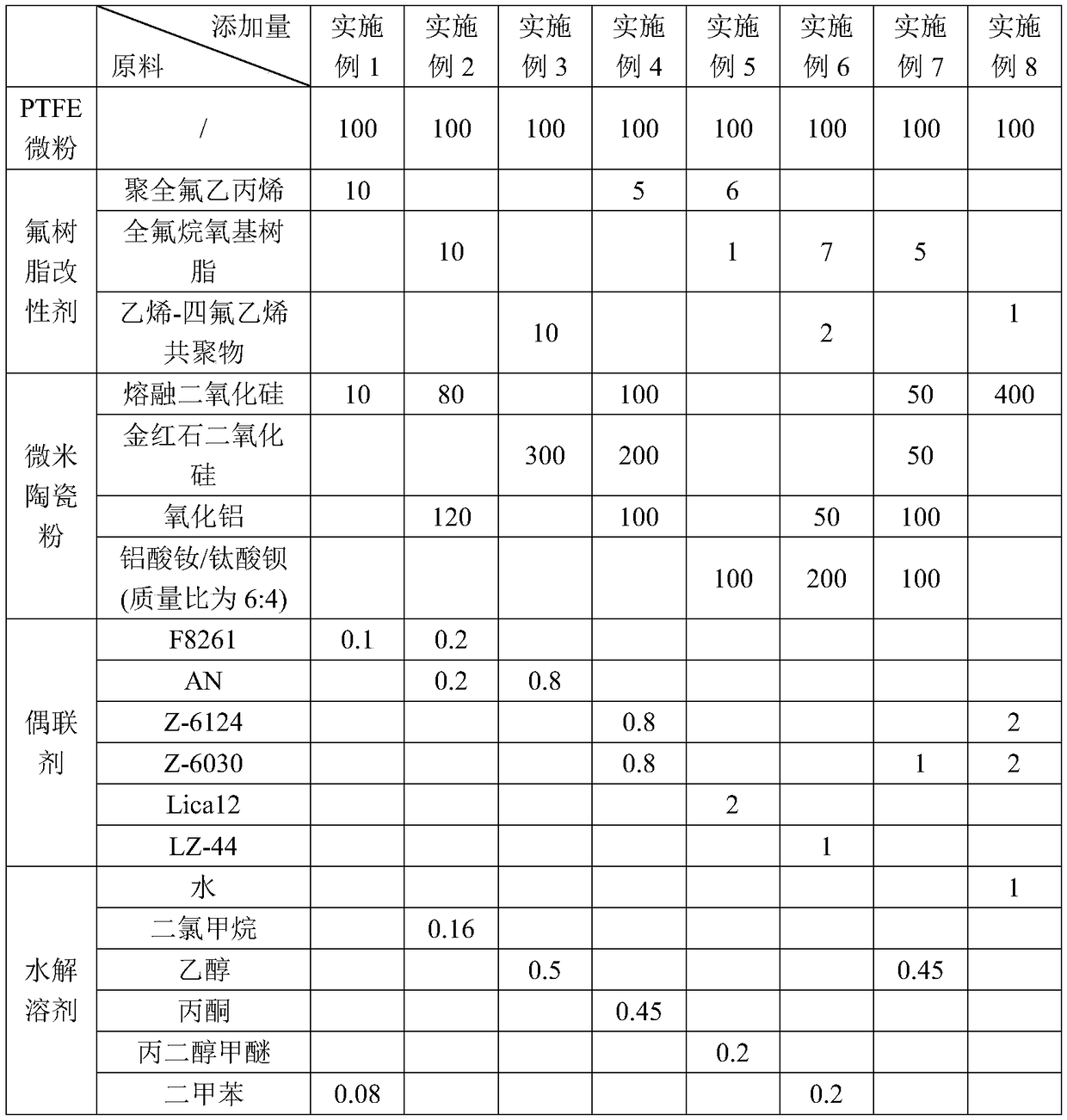

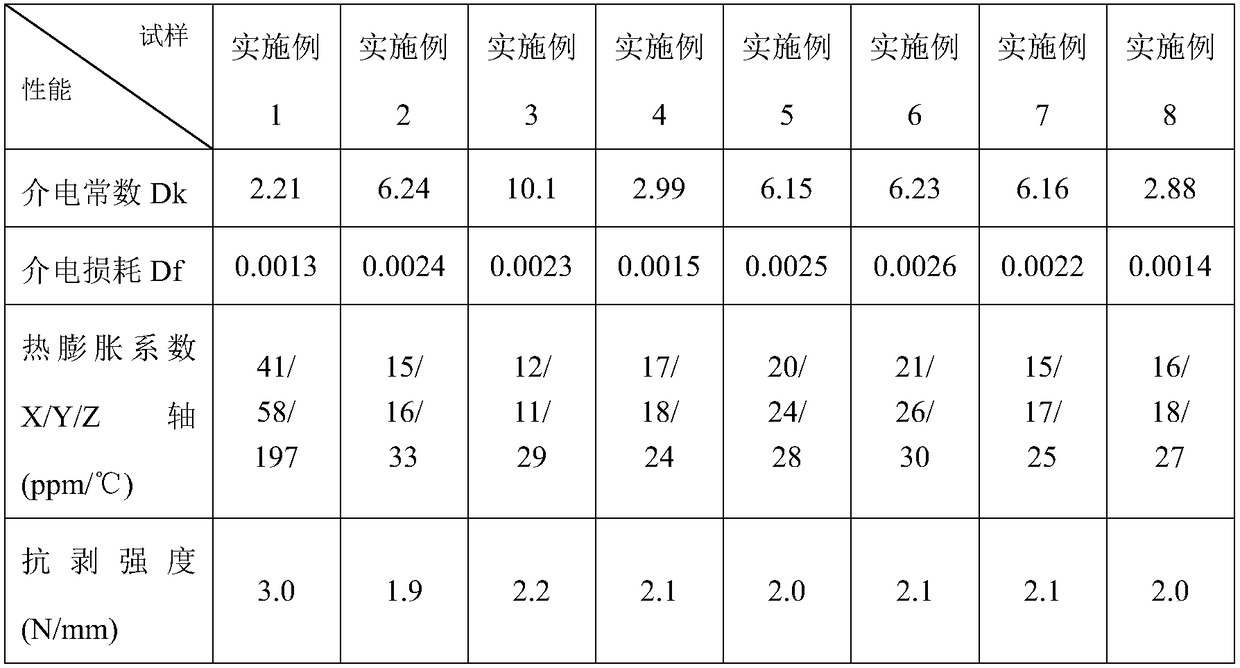

[0041] The materials used in this example are described as follows:

[0042] 0.01Kg coupling agent F8261, 0.008Kg hydrolysis solvent xylene, 10Kg PTFE micropowder, 1Kg polyperfluoroethylene propylene (fluororesin modifier), 1Kg fused silica (micron ceramic powder). D50 of PTFE micropowder = 5 μm; D50 of micron ceramic powder = 0.1 μm; D50 refers to the corresponding particle size when the cumulative particle size distribution percentage of the sample reaches 50%.

[0043] The specific preparation steps of the dry microwave composite dielectric board are as follows:

[0044] (1) Raw material pretreatment

[0045] Add 0.008Kg of hydrolysis solvent xylene to 0.01Kg of coupling agent F8261 to hydrolyze to obtain a modified coupling agent; add the modified coupling agent and 1Kg of fused silica into a ball mill, and ball mill at 60°C for 2 hours, Obtain modified ceramic powder.

[0046] (2) dry mixing

[0047] Mix the modified ceramic powder prepared in step (1), 1Kg PTFE micro...

Embodiment 2

[0060] The materials used in this example are described as follows:

[0061] 0.1Kg coupling agent F8261, 0.1Kg coupling agent AN, 0.08Kg hydrolysis solvent dichloromethane, 50Kg PTFE micropowder, 5Kg perfluoroalkoxy resin (fluororesin modifier), 40Kg fused silica (micron ceramic powder ), 60Kg alumina (micron ceramic powder).

[0062] D50 of PTFE micropowder = 5 μm; D50 of micron ceramic powder = 0.1 μm; D50 refers to the corresponding particle size when the cumulative particle size distribution percentage of the sample reaches 50%.

[0063] The specific preparation steps of the dry microwave composite dielectric board are as follows:

[0064] (1) Raw material pretreatment

[0065] Mix 0.1Kg coupling agent F8261 and 0.1Kg coupling agent AN evenly to obtain a mixed coupling agent; add 0.08Kg hydrolysis solvent methylene chloride to the mixed coupling agent, and hydrolyze to obtain a modified coupling agent; The coupling agent, 40Kg of fused silica and 60Kg of alumina were ad...

Embodiment 3

[0080] The materials used in this example are described as follows:

[0081] 0.08Kg coupling agent AN, 0.05Kg hydrolysis solvent ethanol, 10Kg PTFE micropowder, 1Kg ethylene-tetrafluoroethylene copolymer (fluororesin modifier), 30Kg rutile silica (micron ceramic powder).

[0082] D50 of PTFE micropowder = 5 μm; D50 of micron ceramic powder = 0.1 μm; D50 refers to the corresponding particle size when the cumulative particle size distribution percentage of the sample reaches 50%.

[0083] The specific preparation steps of the dry microwave composite dielectric board are as follows:

[0084] (1) Raw material pretreatment

[0085] Add 0.05Kg of hydrolysis solvent ethanol to 0.08Kg of coupling agent AN, and hydrolyze to obtain a modified coupling agent; add the modified coupling agent and 30Kg of rutile silica into a ball mill, and ball mill for 2 hours at 80°C to obtain Modified ceramic powder.

[0086] (2) dry mixing

[0087] Mix the modified ceramic powder prepared in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com