Preparation method of carbon-based nano composite material electrode of lithium ion battery

A lithium-ion battery and composite material technology, which is applied in the field of preparation of carbon-based nanocomposite electrodes for lithium-ion batteries, can solve the problems of lithium-ion battery rate performance and energy density, poor adhesion between active materials and metal current collectors, and battery problems. Electrochemical performance degradation and other problems, to achieve the effect of light weight, high energy density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, the CVD method is used to grow high-purity carbon nanocoil CNCs. Under an argon protective atmosphere, acetylene is used as a carbon source with an amount of 10 sccm, and iron-tin solution is used as a catalyst to grow and prepare high-purity carbon nanocoils at a high temperature of 650°C. Coil CNCs.

[0026] Next, add the obtained high-purity CNCs into concentrated nitric acid for acidification treatment, add 5 g of CNCs for every 10 ml of concentrated nitric acid, ultrasonically disperse for two hours, then carry out suction filtration, wash with deionized water three times, and place in an oven to dry for 2 hours. Get acidified CNCs.

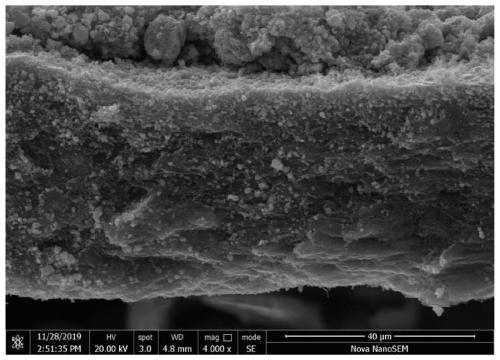

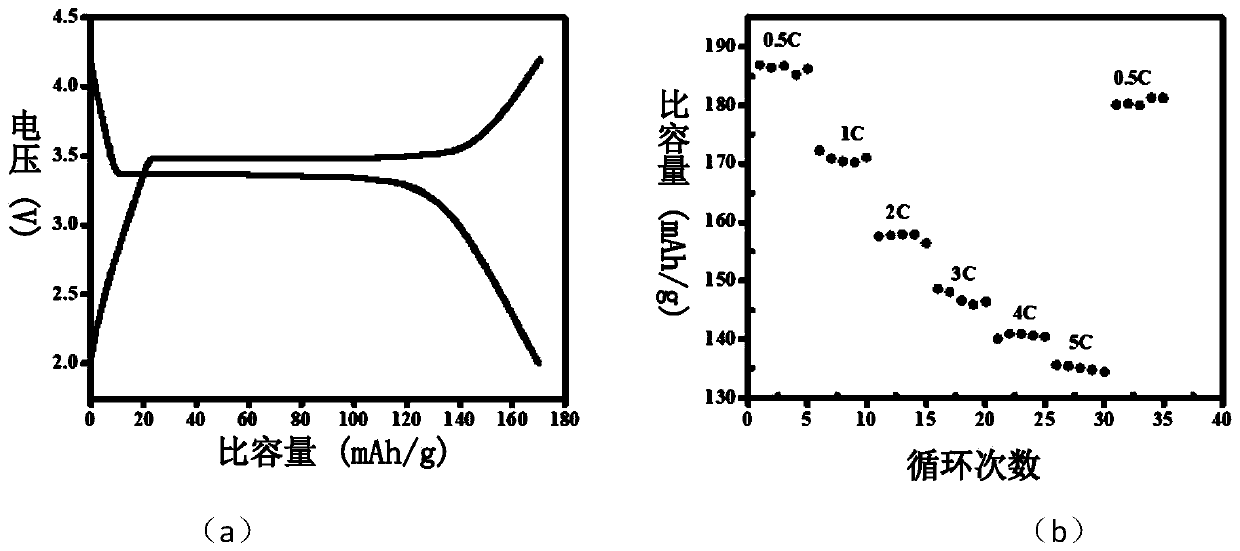

[0027] Finally, disperse 22.5mg CNT and 7.5mg CNCs in 30ml deionized water, add 200μl dispersant Triton X-100, at room temperature, ultrasonic cleaning machine ultrasonic 40min, ultrasonic cell pulverizer ultrasonic 40min, get CNT and CNC Mix the solutions, and then use a vacuum pump and a suction filtration device to obtain a...

Embodiment 2

[0031] First, the CVD method is used to grow high-purity carbon nanocoil CNCs. Under the protective atmosphere of argon, acetylene is used as the carbon source, and the dosage is 30 sccm. The iron-tin solution is used as the catalyst, and high-purity carbon nanocoils are grown at a high temperature of 650 ° C. Coil CNCs.

[0032] Next, add the obtained high-purity CNCs into concentrated nitric acid for acidification treatment, add 5 g of CNCs for every 10 ml of concentrated nitric acid, ultrasonically disperse for two hours, then carry out suction filtration, wash with deionized water three times, and place in an oven to dry for 2 hours. Get acidified CNCs.

[0033]Finally, 30mg of CNT and 10mg of CNCs were dispersed in 40ml of deionized water, 250μl of dispersant Triton X-100 was added, and after ultrasonication at room temperature for 20min, ultrasonic cell pulverizer was ultrasonicated for 60min to obtain a mixed solution of CNT and CNC, and then vacuum pump and filter dev...

Embodiment 3

[0039] First, the CVD method is used to grow high-purity carbon nanocoil CNCs. Under the protective atmosphere of argon, acetylene is used as the carbon source, and the dosage is 20 sccm. The iron-tin solution is used as the catalyst, and the high-purity carbon nanocoils are grown at 650 ° C. Coil CNCs.

[0040] Next, add the obtained high-purity CNCs into concentrated nitric acid for acidification treatment, add 5 g of CNCs for every 10 ml of concentrated nitric acid, ultrasonically disperse for two hours, then carry out suction filtration, wash with deionized water three times, and place in an oven to dry for 2 hours. Get acidified CNCs.

[0041] Finally, 30 mg of CNT and 10 mg of CNCs were dispersed in 40 ml of deionized water, 250 μl of dispersant Triton X-100 was added, and after ultrasonication at room temperature for 60 minutes, ultrasonic cell pulverizer was used for ultrasonication for 20 minutes to obtain a mixed solution of CNT and CNC. filter device to obtain CNT-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com