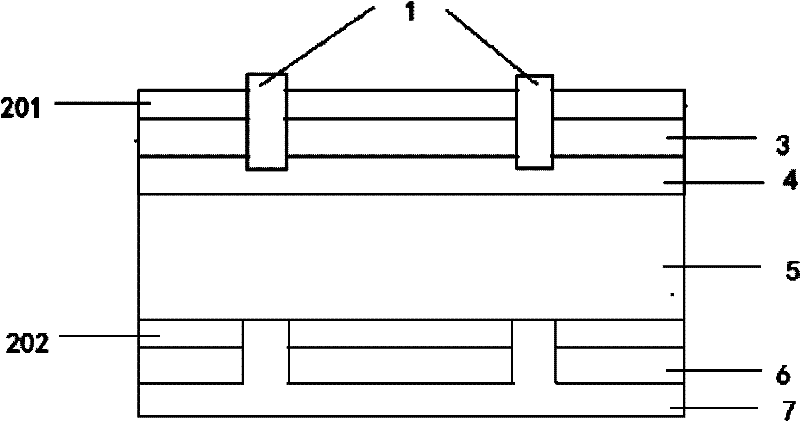

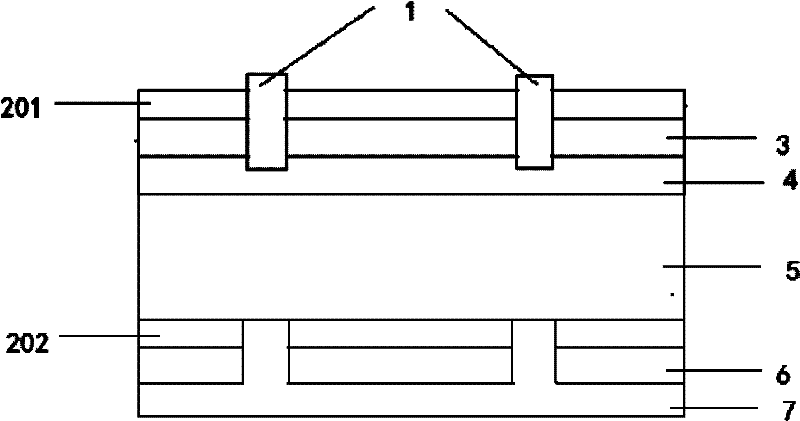

A kind of rear point contact crystalline silicon solar cell and its preparation method

A technology of point contact on the back and solar cells, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of suboptimal passivation effect, easy overflow of silicon nitride hydrogen, weakened passivation effect, etc., to achieve enhanced anti-corrosion Effects of UV radiation performance, reduction of reflection, and improvement of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

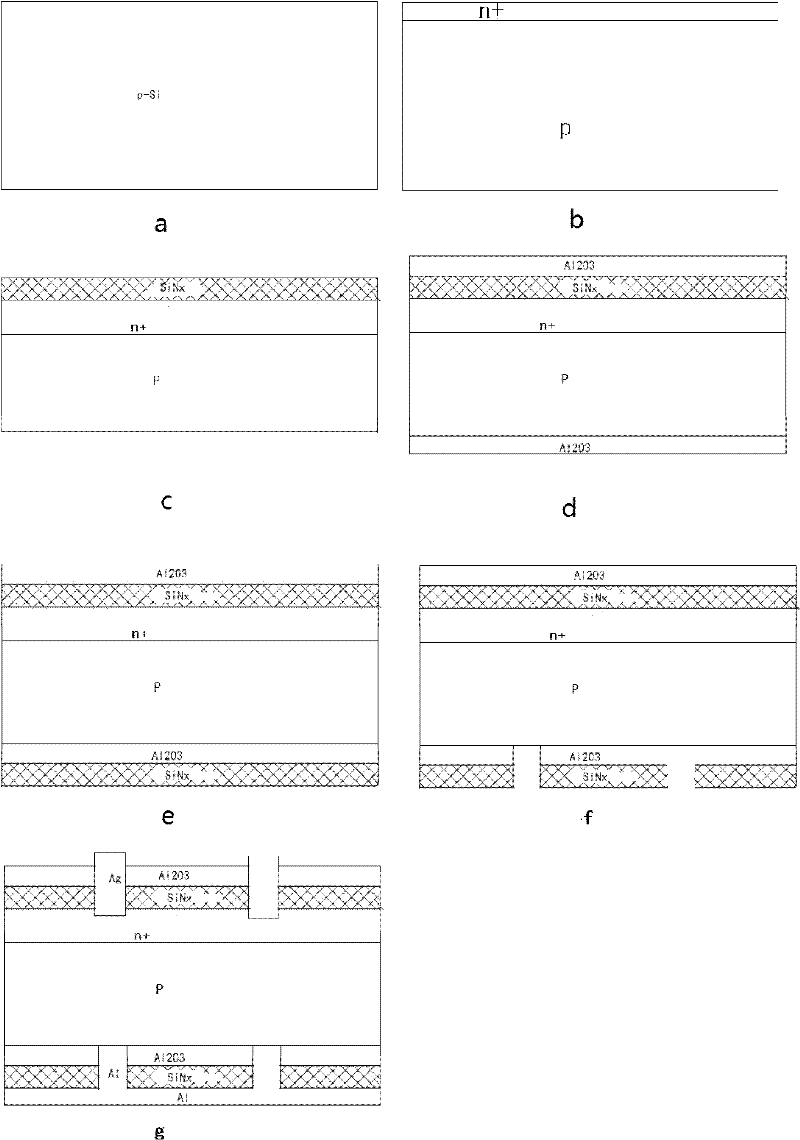

[0039] Steps §1, §2, §3, §5, §7 and §8 are all traditional crystalline silicon cell preparation processes, and the process parameters are different.

[0040] §1 figure 2 a, Use the general single crystal silicon cleaning method, that is, sodium hydroxide + isopropanol (NaOH + IPA) solution to remove the surface damage of P-type CZ silicon and make texture to form an anti-reflection structure and chemical cleaning; P-type CZ silicon wafer 125 monocrystalline silicon wafers for industrial use, resistivity 0.5-5Ωcm, thickness 180-220um;

[0041] §2 figure 2 b, Diffusion in a POCl3 atmosphere to form an n+ emitter and remove the surrounding pn junction and phosphosilicate glass to form a pn+ junction silicon substrate with a pn+ structure;

[0042] §3 figure 2 c, a 70nm amorphous silicon nitride film with a refractive index of 2.3 was deposited on the surface of the n+ emitter by conventional direct PECVD;

[0043] §4 Use HF acid to clean the surface of the structure obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com