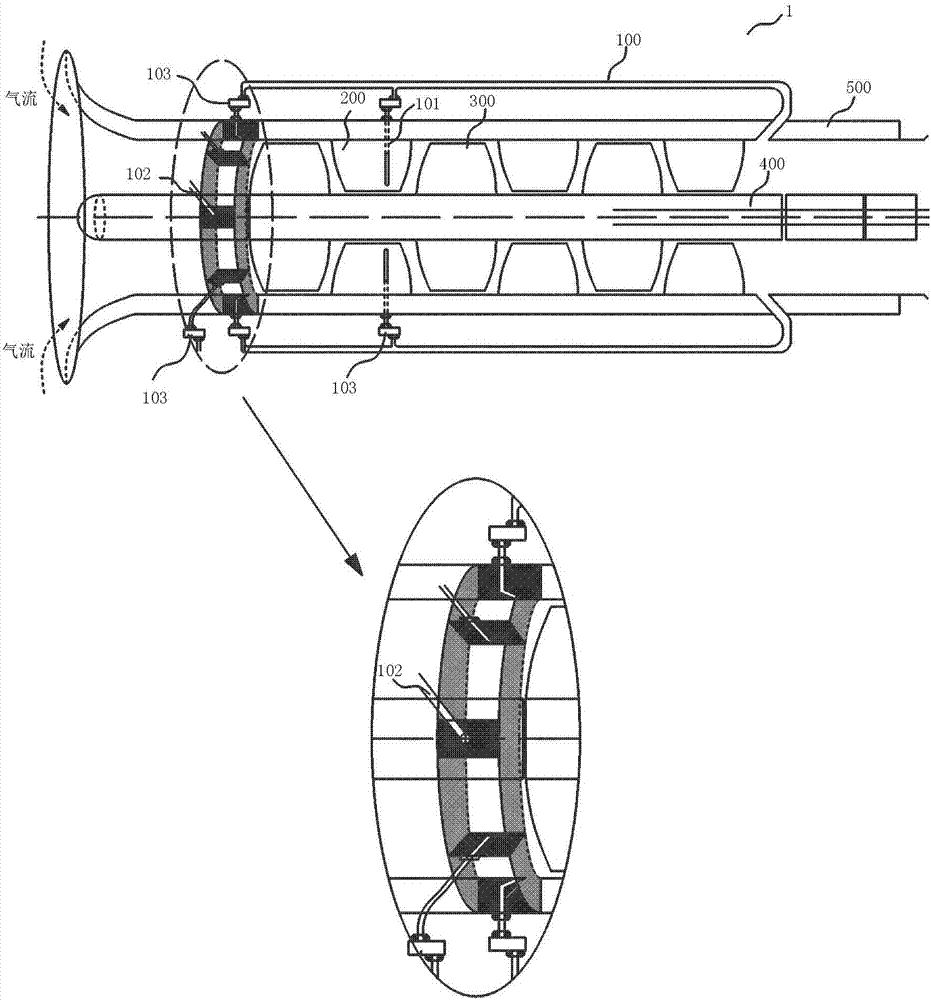

Gas compressor, gas turbine and gas compressor stability enhancement and efficiency improvement method

A technology of compressors and hubs, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., to achieve the effects of small loss, good sealing performance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

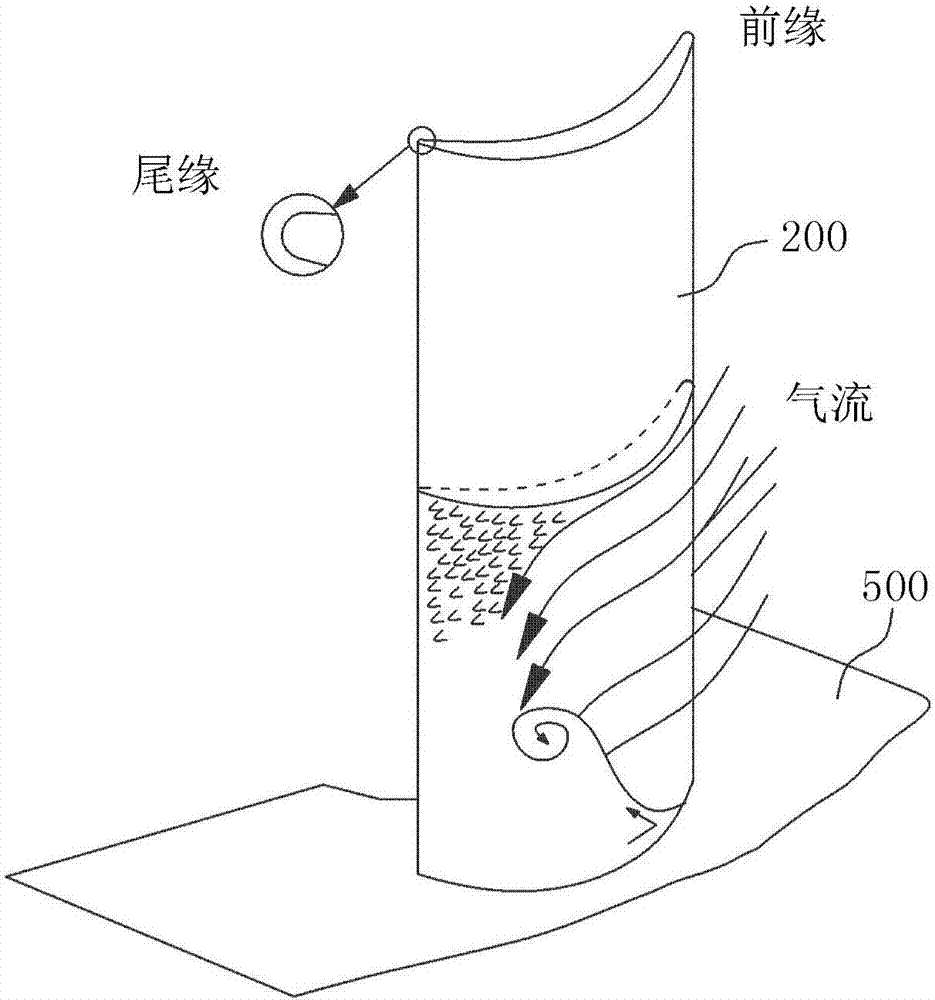

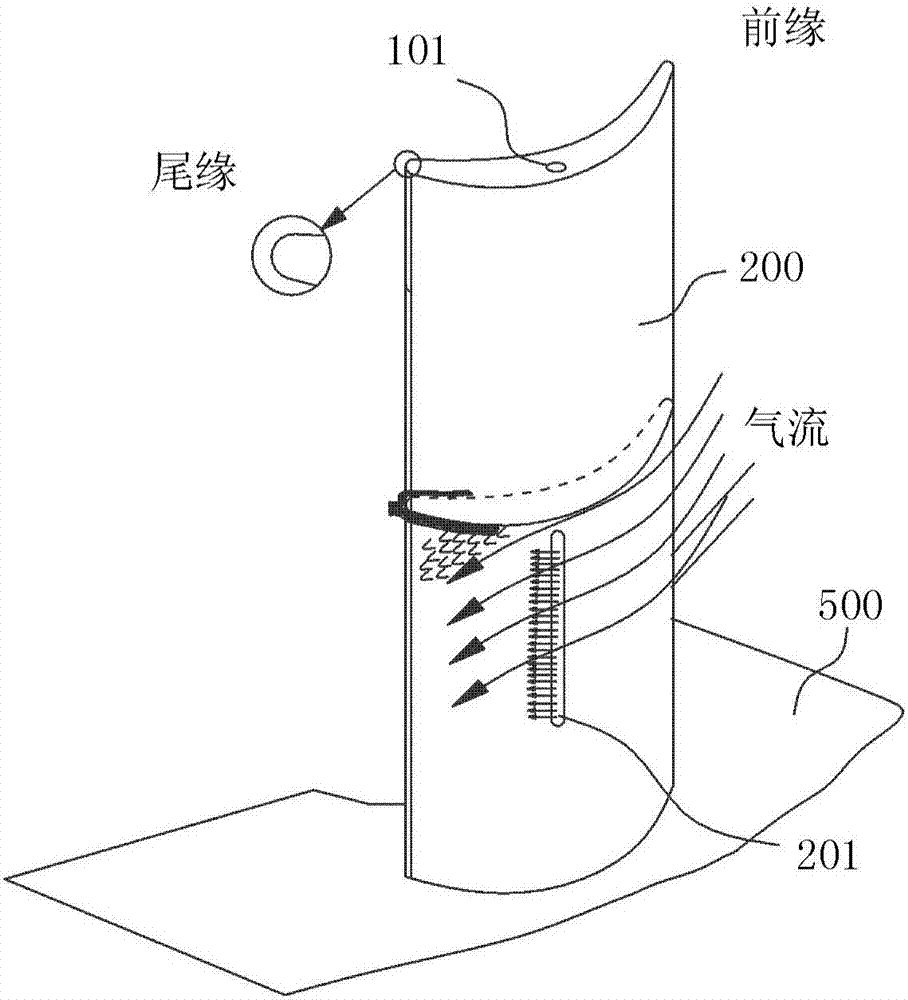

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0024] In order to improve the thrust-to-weight ratio and reduce fuel consumption, modern turbofan engines pursue high bypass ratio, high pressure ratio and high temperature before the turbine. The total pressure ratio of the entire compressor is one of the key performance indicators. For example, the pressure ratio of GE9x can reach 60 (including the root of the fan)! A certain type of commercial aeroengine CJx being developed in my country has a design total pressure ratio of 43. The supercharging of the gas turbine is completed by three parts. First, the root of the fan matches the connotation channel, followed by the low-pressure compressor (also known as Booster, often translated as supercharging stage), and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com