Upright magnetorheological polishing device and method

A technology of magnetorheological polishing and magnetorheological fluid, which is applied in the field of polishing, can solve the problems of pollution and corrosive damage, high surface roughness requirements of pipe fittings, high chemical activity, etc., and achieve easy control and adjustment, continuous working efficiency High, with simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

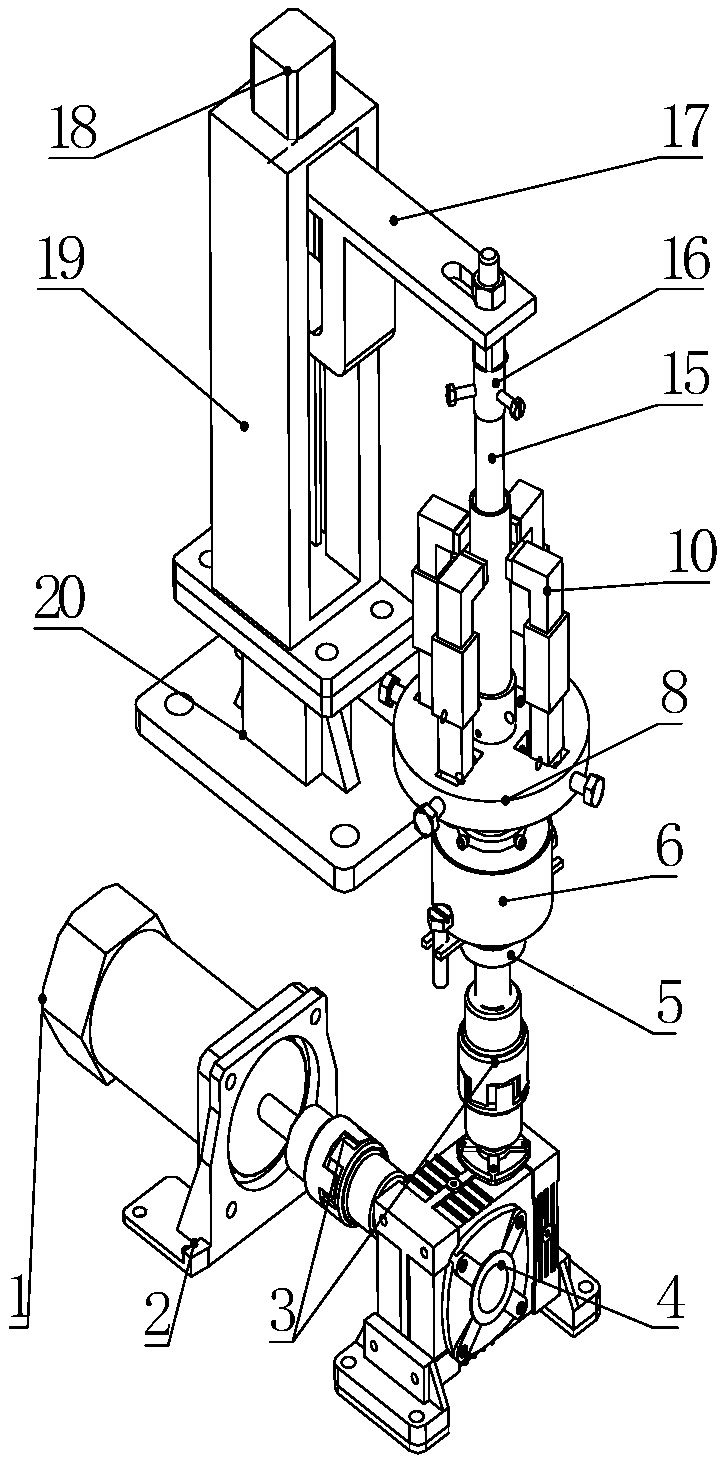

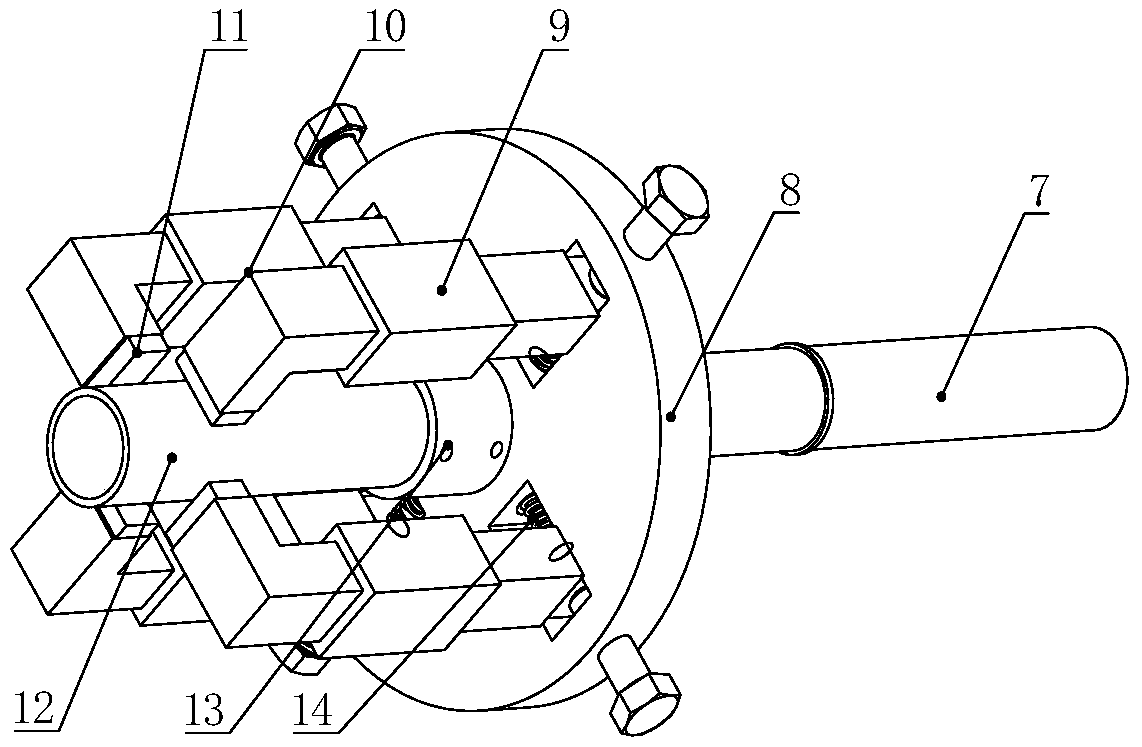

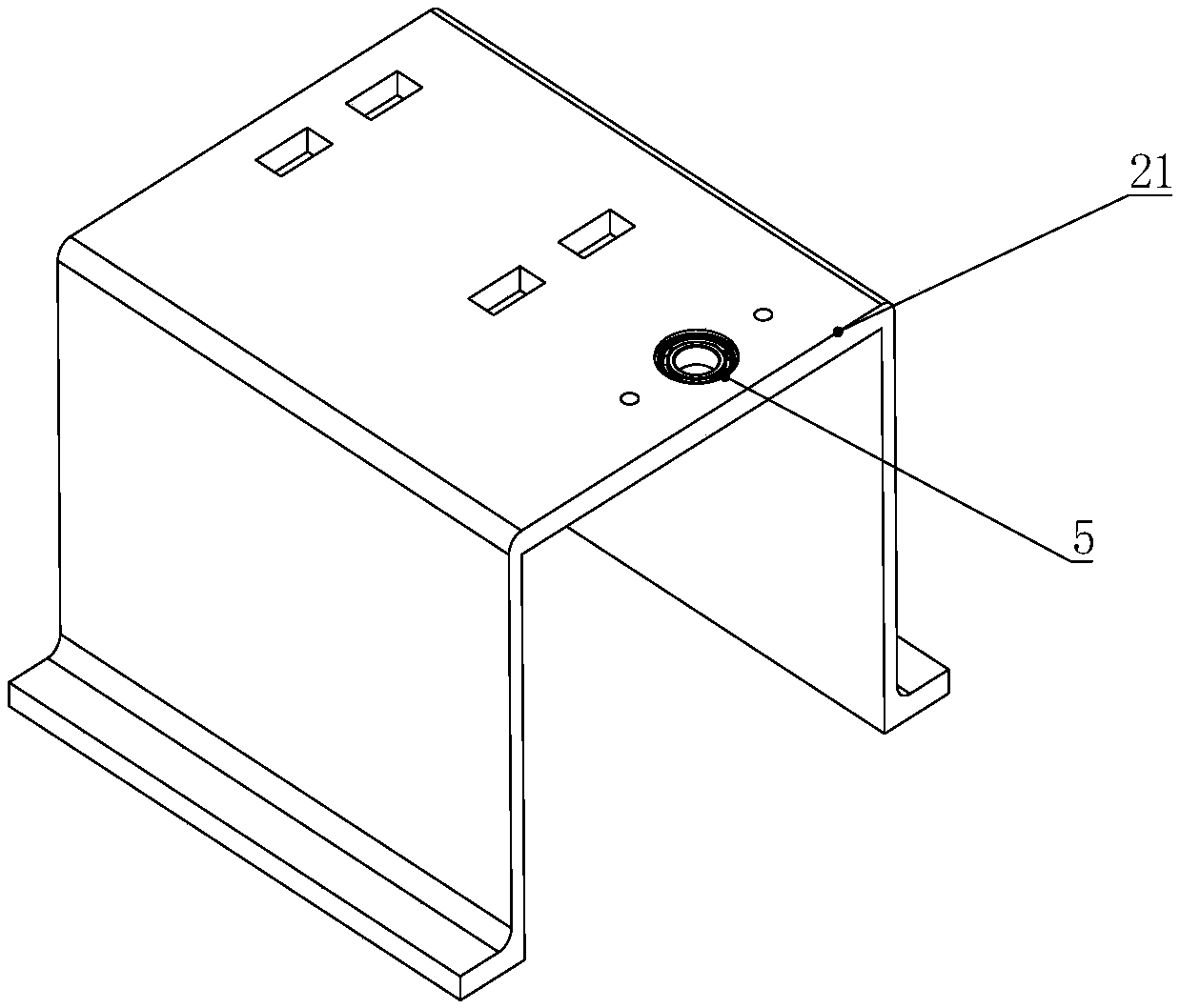

[0035] Such as figure 1 , figure 2 As shown, the magnetic frame 8 is fixedly connected to the rotating shaft 7 of the driving mechanism and rotates with it. The magnetic frame 8 is provided with four iron core supports 10 , and the outer ring of the iron core support 10 is provided with a coil 9 . The rotating shaft 7 passes through the conductive slip ring 6 and is supported by the bearing 5 . The rotor of the conductive slip ring 6 is fixed to the rotating shaft 7 and electrically connected to the coil 9; the stator of the conductive slip ring 6 is relatively fixed and electrically connected to an external power supply. specific reference image 3 , the support member 21 is fixedly arranged relative to the ground, and its upper part is fixed to the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com