Experimental device for asphalt rotational shear failure

A technology of rotating shearing and destructive experiments, which is applied in the direction of applying stable shearing force to test the strength of materials, etc. It can solve the problems of large torque sensor range, inapplicability, and difficulty in guaranteeing experimental accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

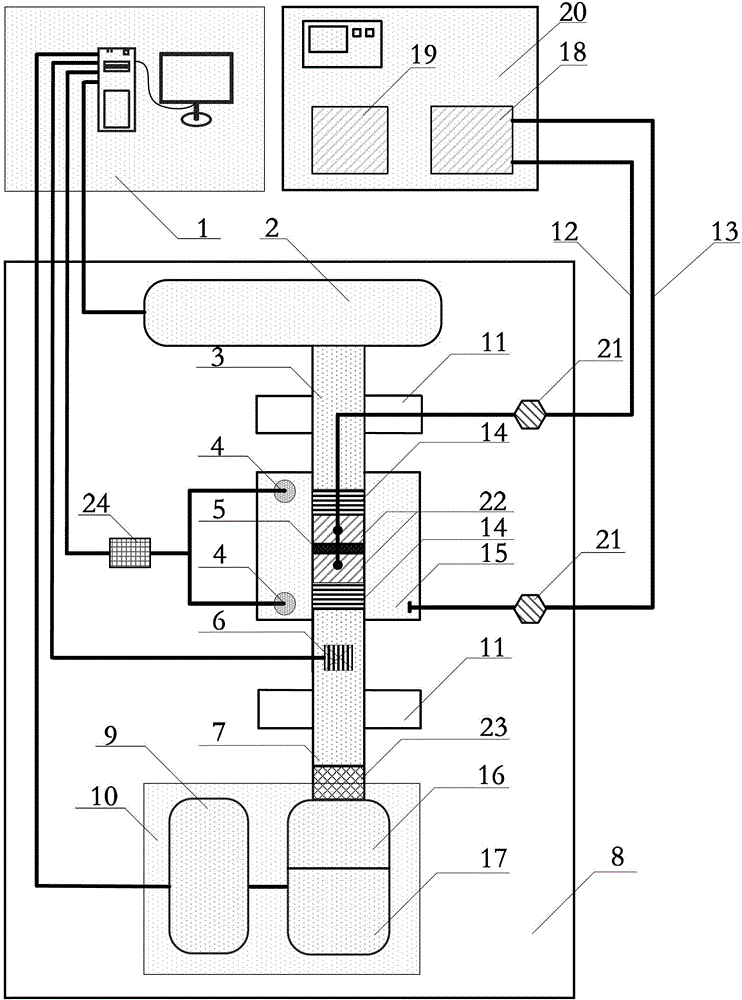

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0027] The asphalt rotational shear failure experimental device consists of an experimental platform 8 , an experimental specimen, a loading facility 10 , a temperature control system and a computer control system 1 . The computer control system 1 automatically controls the loading facility 10 according to the set target parameters and real-time collected data information, performs rotational shear loading on the experimental specimen, and controls the experimental process; the temperature control system controls the experimental temperature.

[0028] The experimental platform 8 consists of a base steel plate, a bearing support 11, a fixed shaft 3, a rotating shaft 7, an experimental specimen, a fixture 14, a shaft coupling 23, a loading facility 10, a torque sensor and an encoder 2, and an angular displacement sensor and an encoder 6 Composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com