Method for analyzing rotary forging effect based on 3D constitutive model under alternating load

A constitutive model, alternating load technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems of element node division and point selection errors, insufficient iterations, affecting calculation accuracy, etc., to reduce energy. consumption, obvious process advantages, and the effect of improving product forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

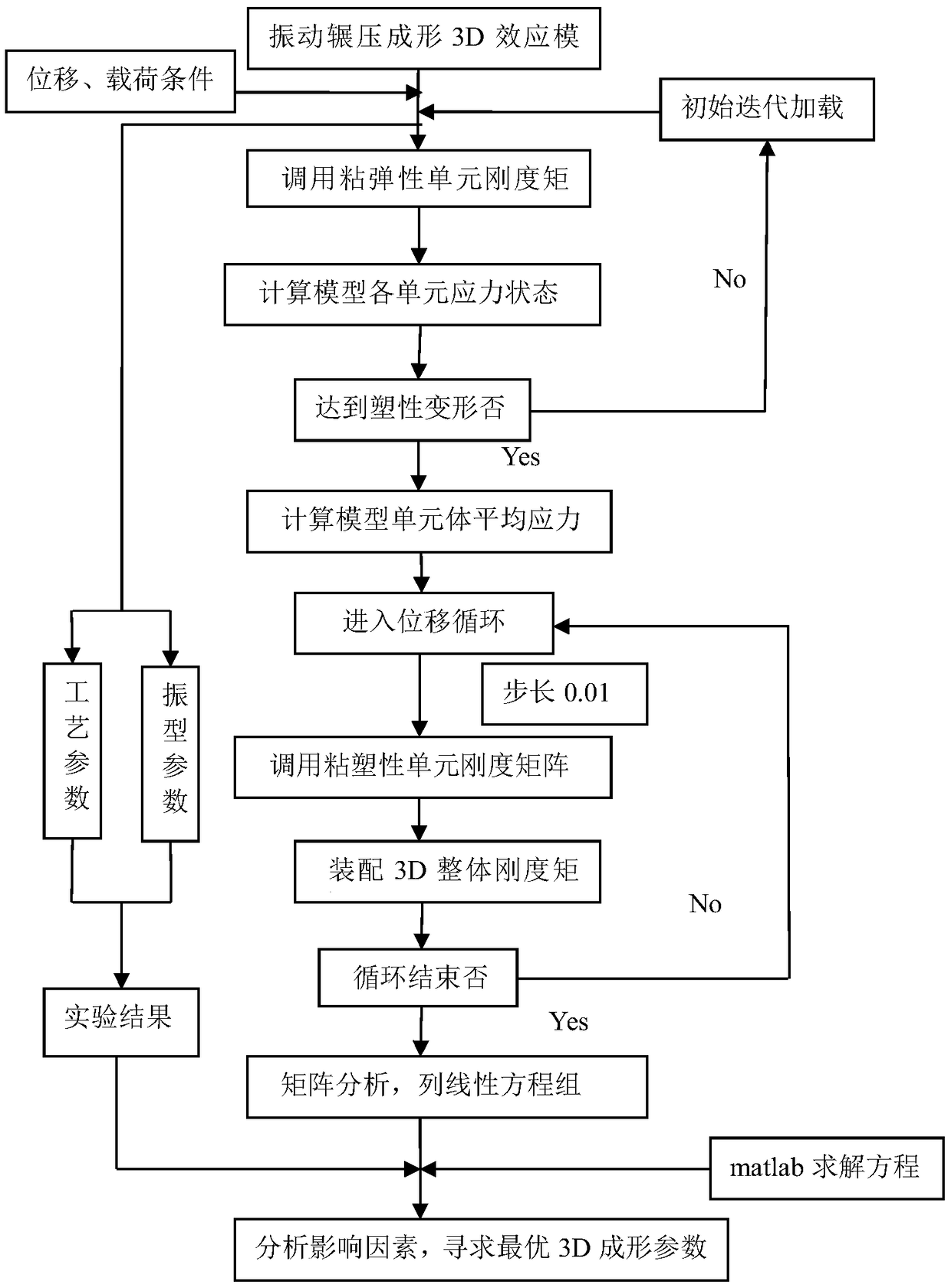

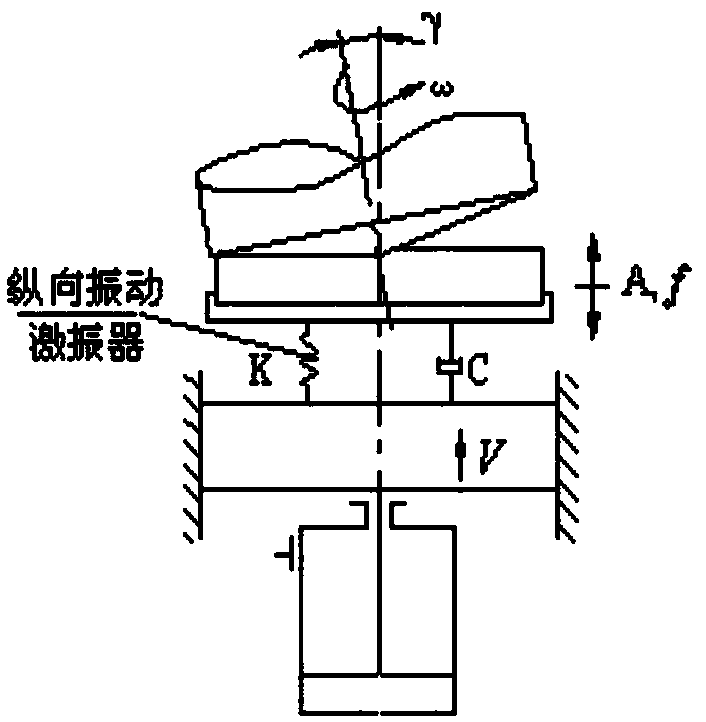

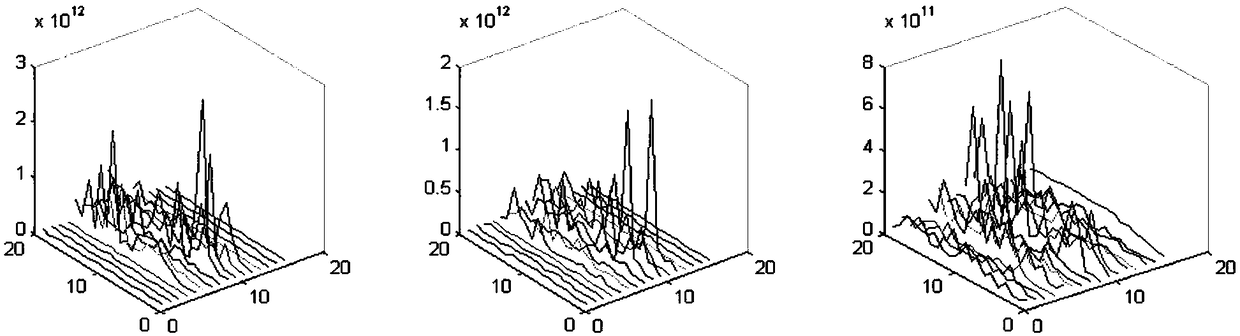

[0068] Taking metal materials as the experimental research object, the vibration rolling forming experiment is carried out, and the appropriate vibration parameters (exciting force, amplitude, frequency), rolling force, loading speed, displacement parameters and boundary load parameters are selected as the experimental parameters. Through the calculation of the contact boundary of the vibrating rolling profile, the shape of the simulated contact boundary obtained is basically consistent with the shape of the actual contact boundary between the swing head and the blank during the forming process. On the basis of this, a hypo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com