Patents

Literature

34results about How to "Obvious technological advantages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

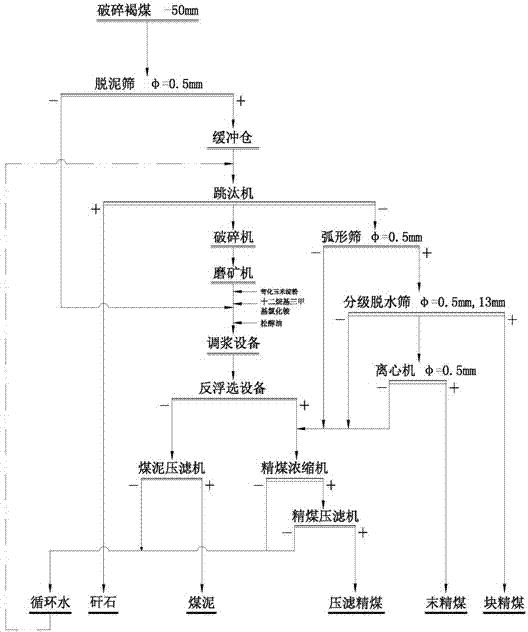

Lignite separation process

The invention relates to a lignite separation process, and belongs to coal washing methods. The lignite separation process comprises the following steps of: desliming broken lignite; putting obtained screen underflows into size mixing equipment to perform size mixing; outputting obtained waste rocks, crushing obtained middling coal in a crusher, putting the crushed middling coal into an ore grinding machine, putting a product after ore grinding into the size mixing equipment to perform size mixing, putting obtained cleaned coal into a sieve bend and a grading and dewatering screen for dewatering and grading, and putting screening water into a cleaned coal thickener; outputting lumpish cleaned coal obtained by the grading and dewatering screen, and putting fine cleaned coal into a centrifuge for dewatering again; outputting low-water fine cleaned coal obtained by the centrifuge, and putting centrifugate into the cleaned coal thickener; putting foams obtained through reverse flotation into a coal slime pressure filter for pressure filtering, and putting underflow into the cleaned coal thickener for thickening; putting filtrate obtained by the coal slime press filter into a circulating pool, and outputting filter cakes as coal slimes; putting overflow of the thickener into the circulating pool, and putting the underflow into a cleaned coal pressure filter for pressure filtering; and putting the filtrate into the circulating pool. The lignite separation process integrates desliming, jigging, dewatering, regrinding of the middling coal, reverse floating and coal slime water purifying, and is concise, low in investment and operation cost, and high in economic benefit.

Owner:CHINA UNIV OF MINING & TECH

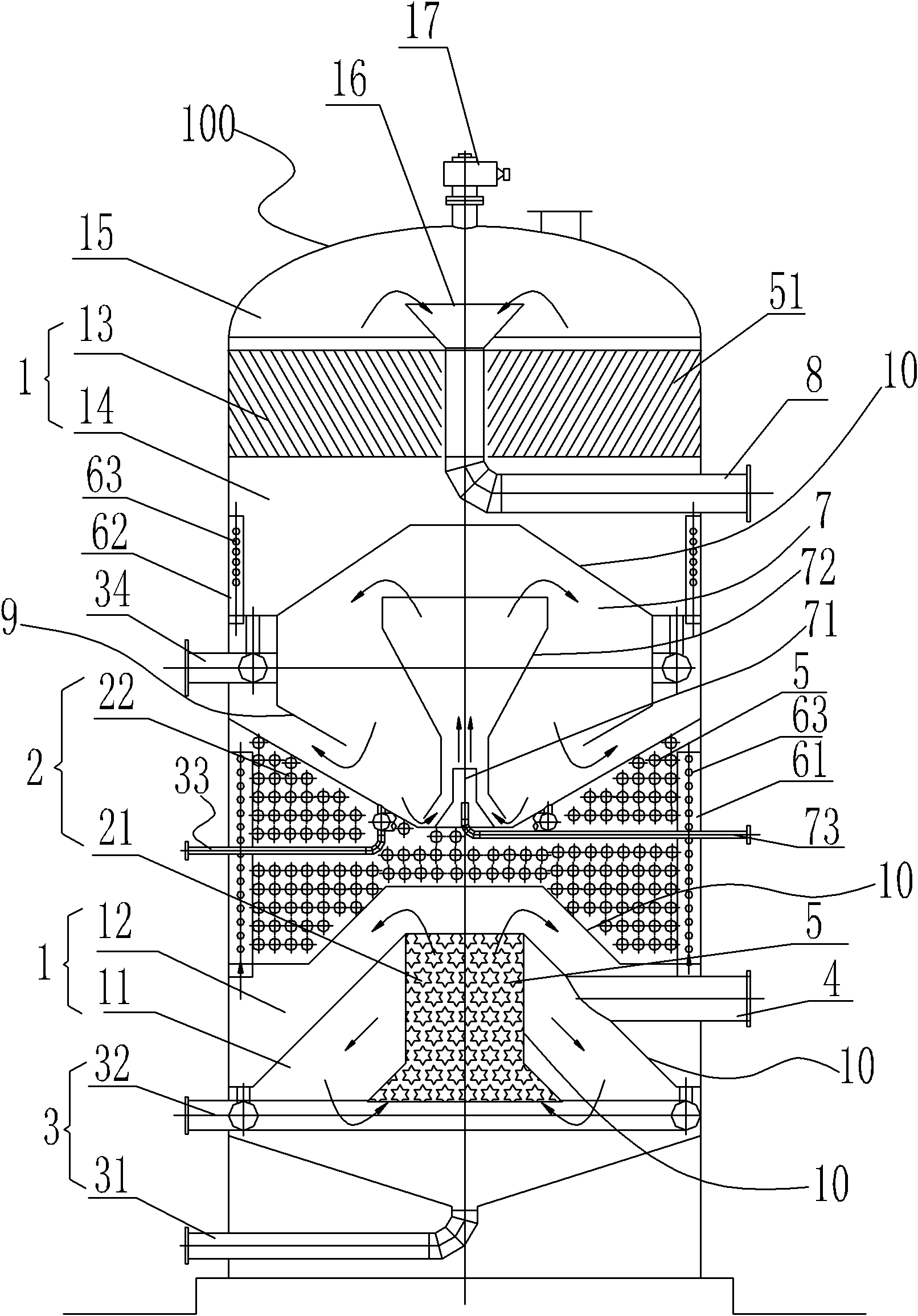

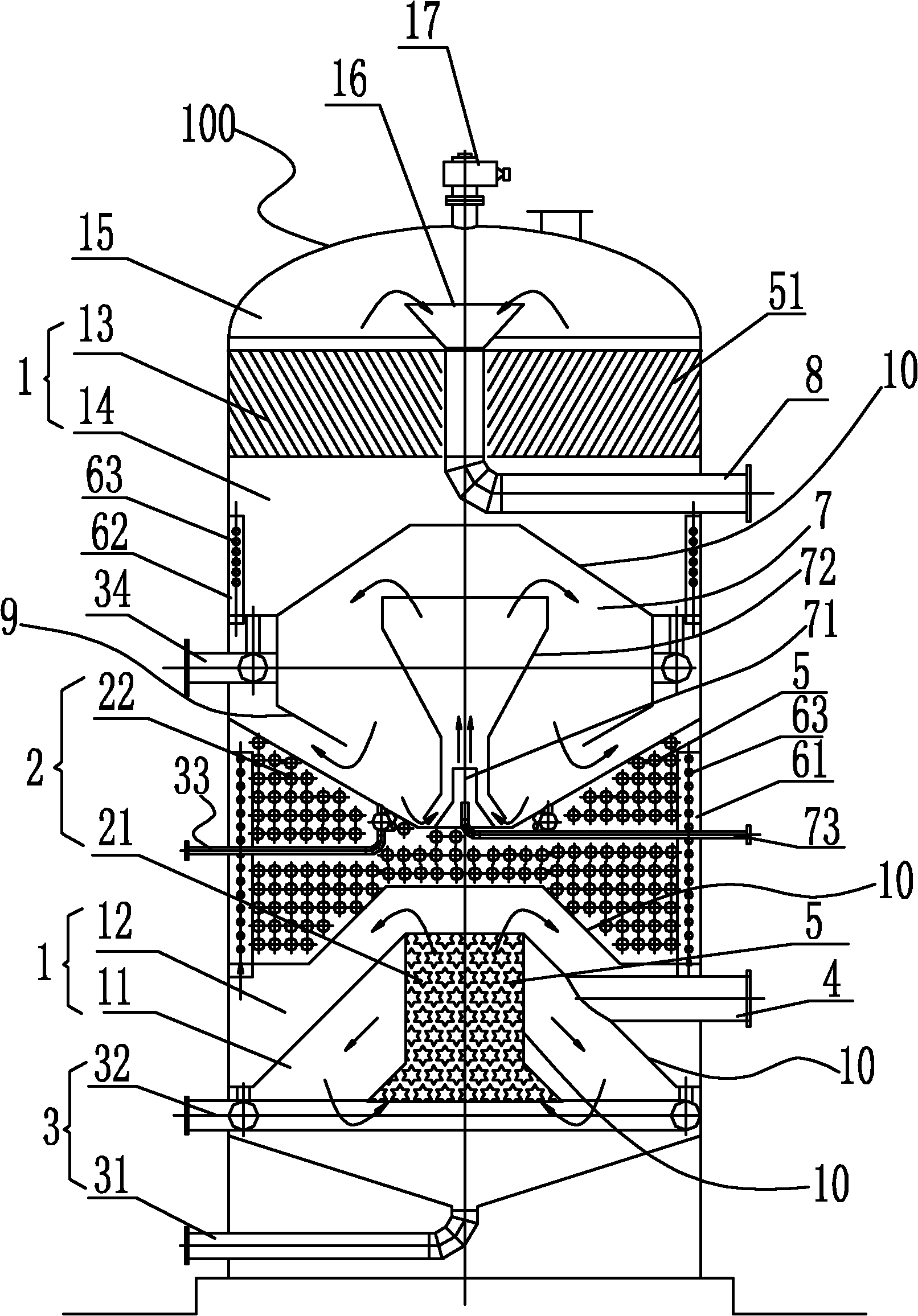

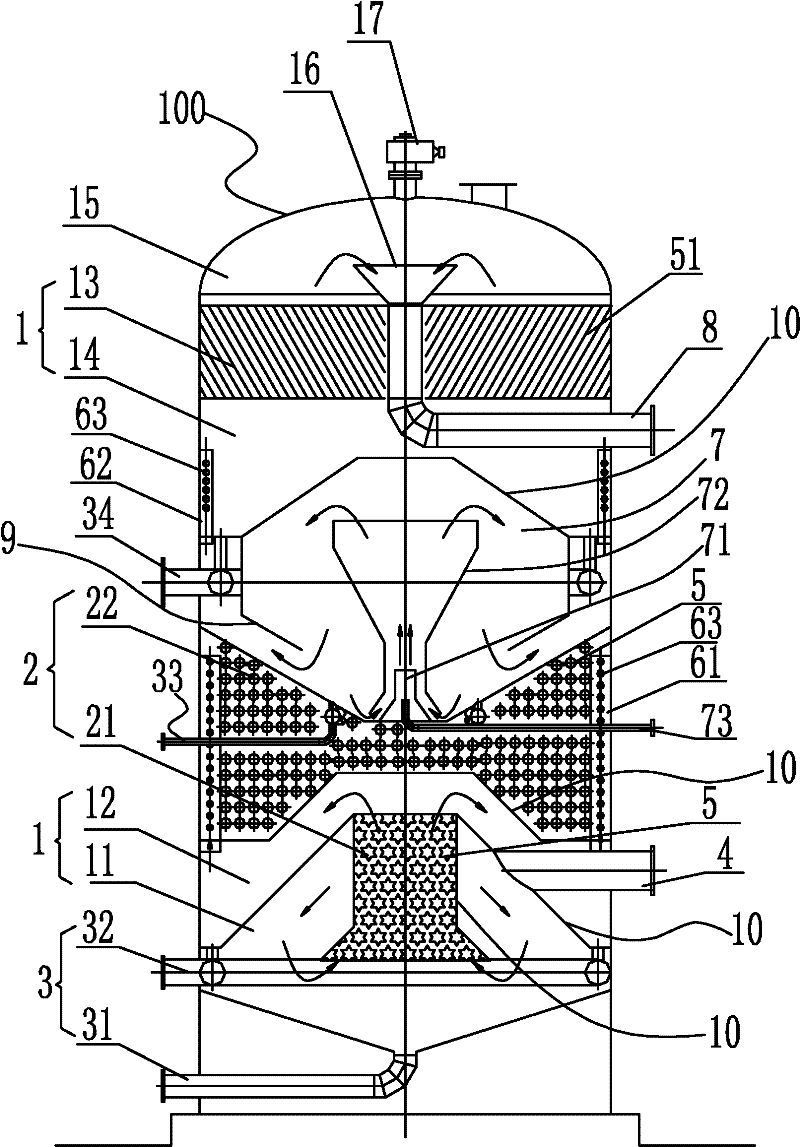

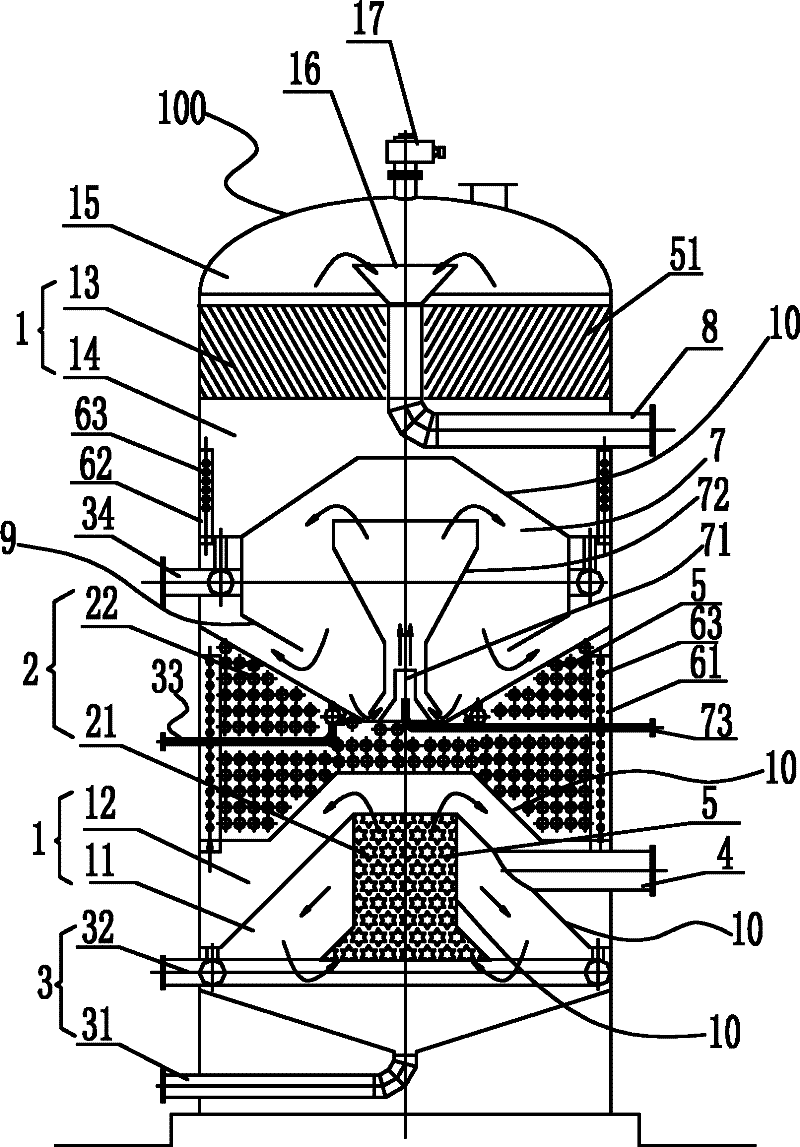

Pressure-bearing integral metallurgy sewage purifying treatment device

ActiveCN102010088AObvious technological advantagesCompact structureMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationCooling tower

The invention discloses a pressure-bearing integral metallurgy sewage purifying treatment device comprising a sealed pressure-bearing shell, wherein the shell is provided with at least two settling chambers, at least two flocculation reaction chambers and a hydraulic circulating clarifying chamber, and the settling chambers and the flocculation reaction chambers are staggered from bottom to top and are communicated in sequence; the lower end of each settling chamber is respectively connected with a blow-off pipe which extends to the outside of the shell; and the upper part and lower part of the shell are respectively provided with a discharging pipe and a water inlet pipe which extend to the outside of the shell. The treatment device can ensure stable purification effect and strong water impact resistance, has less possibility of being blocked, and is simple and convenient for maintenance; and the fully-sealed pressure-bearing integral metallurgy sewage purifying treatment device can fully utilize the residual pressure of coming water, and water produced by the device can be sent to a pressure filter or a cooling tower with no need of a secondary pressurizing pump station.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

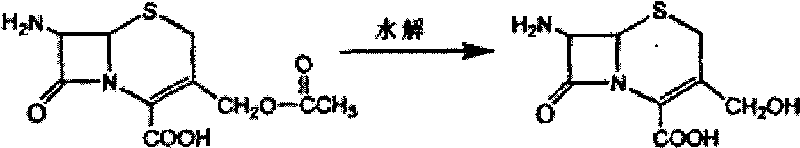

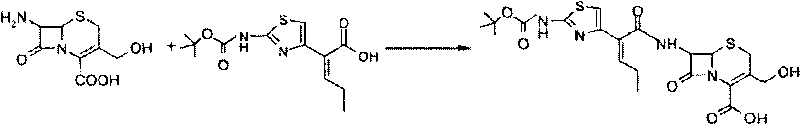

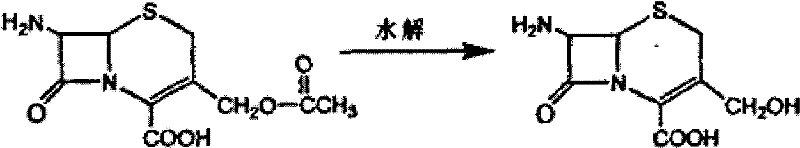

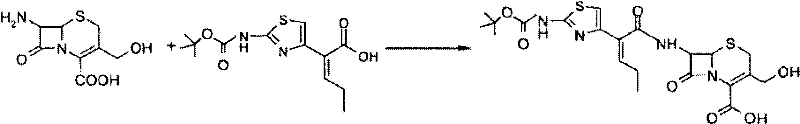

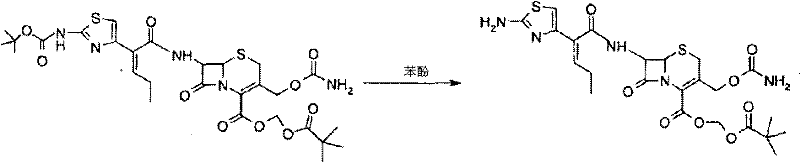

Synthesis Method of cefcapene pivoxil hydrochloride

ActiveCN101747344AEasy to operateMild reaction conditionsOrganic chemistrySynthesis methodsSocial effects

The invention belongs to the technical field of antibiotic drug synthesis, in particular to a synthesis methodof cefcapene pivoxil hydrochloride. The invention is mainly used for process improvement and optimization of cefcapene pivoxil, and the advantage of the synthesis process of cefcapene pivoxil are obvious; new catalytic agents are used, such as phenol, boric acid and other reagents, thereby improving the product quality, increasing the yield, simplifying the operating steps and realizing greater productivity effect and social effect.

Owner:SHANDONG RUNZE PHARMA

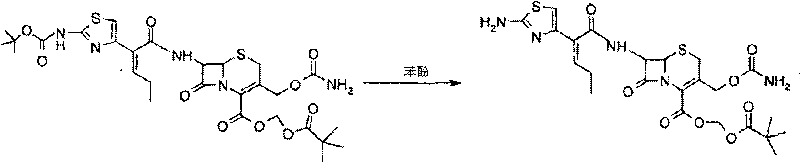

Beneficiation method for improving micro-fine particle refractory iron ore flotation ore-concentrate production rate and recovery rate

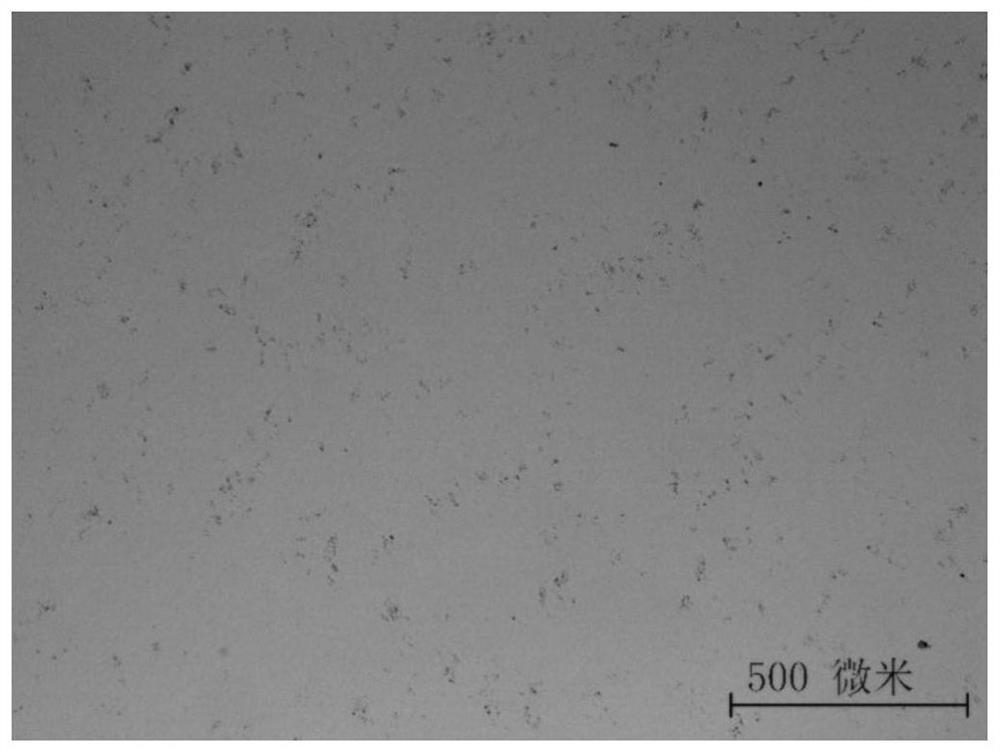

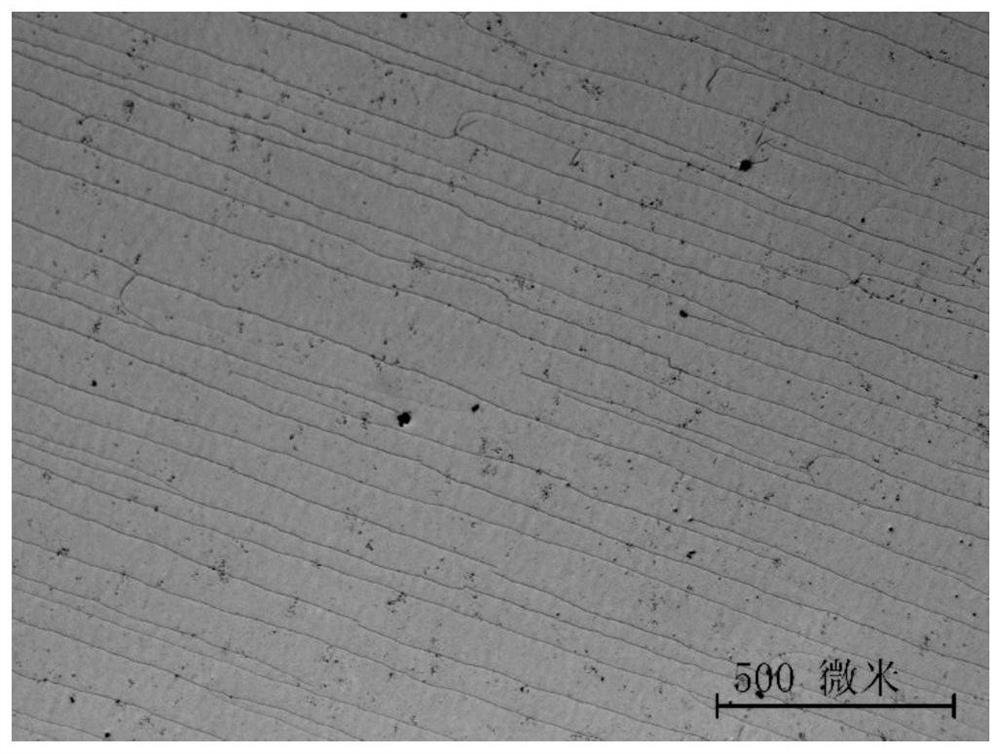

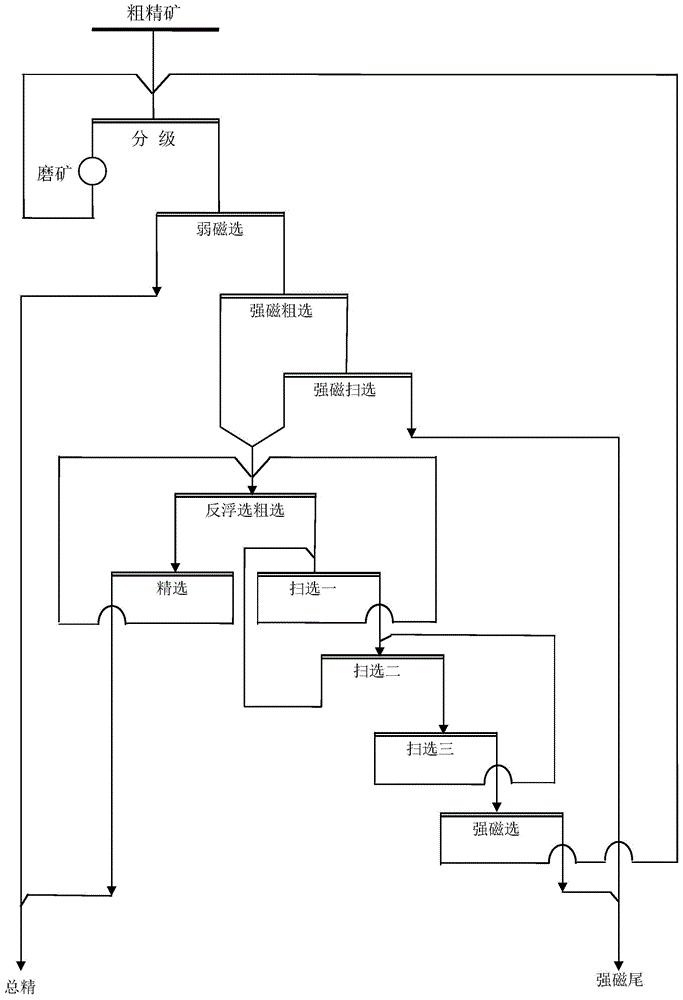

The invention discloses a beneficiation method for improving the micro-fine particle refractory iron ore flotation ore-concentrate production rate and the recovery rate. The method includes the following steps that pre-treated micro-fine particle rough concentrate is sent to a closed circuit grinding grading system, so that most of the rough concentrate undergoes monomer separation; obtained ground ore products which undergo monomer separation sequentially undergo low-intensity magnetic separation, high-intensity magnetic rough flotation and high-intensity magnetic scavenging carried out at least once, and ultimately, low-intensity magnetic ore-concentrate and high-intensity magnetic rough ore-concentrate are obtained, the obtained high-intensity magnetic rough ore-concentrate is concentrated, concentration bottom currents are involved in a reverse flotation operation, and accordingly reverse flotation ore-concentrate is obtained; the low-intensity ore-concentrate and the reverse flotation ore-concentrate are combined to form a finished ore-concentrate product, foam after reverse flotation enters a high-intensity magnetic floatation procedure for re-flotation, the ore-concentrate after high-intensity magnetic flotation treatment returns to the closed circuit grinding grading system, and the preceding steps are repeated. The method has the advantages that procedure operations are easy and controllable, the iron grade of flotation tailings is low, and the recovery rate of the ore-concentrate is high.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

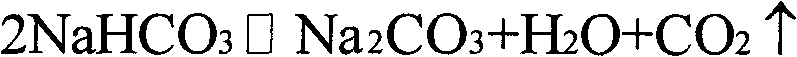

Preparation method of nano SiO2

InactiveCN102633267AReduce manufacturing costEmission reductionSilicaNanotechnologyOrganic solventNano sio2

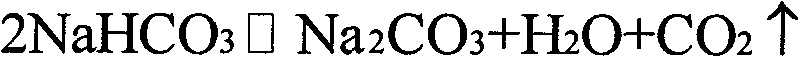

The invention discloses a preparation method of nano SiO2. The preparation method is characterized by taking soluble silicate M2O.nSiO2 and hydrocarbonate MHCO3 as raw materials to obtain hydrate SiO2 through precipitation, separating out filtrate through filtration, then washing the filter cake, displacing the filter cake with an organic solvent and drying and grinding the product to obtain the nano SiO2 product, wherein the filtrate mainly contains carbonate M2CO3 and little hydrocarbonate MHCO3; and M in the soluble silicate M2O.nSiO2, hydrocarbonate MHCO3 and carbonate M2CO3 is an alkali metal Na or K. The preparation method has the following beneficial effects: the filtrate mainly contains carbonate M2CO3 and little hydrocarbonate MHCO3 and the reaction raw materials can be obtained through different processing modes, so the materials can be recycled, thus the preparation cost is reduced, fewer resources are consumed, emission is reduced, and the problems of environmental pollution and the like because plenty of inorganic acids need to be consumed in the prior art are avoided.

Owner:ZHEJIANG YUDA CHEM IND

Synthesis method for disperse dye intermediate

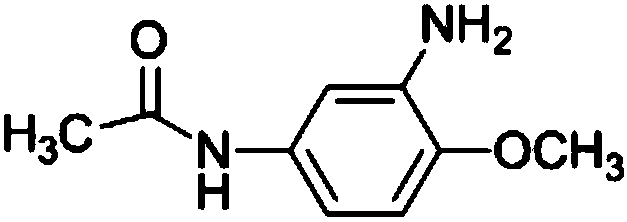

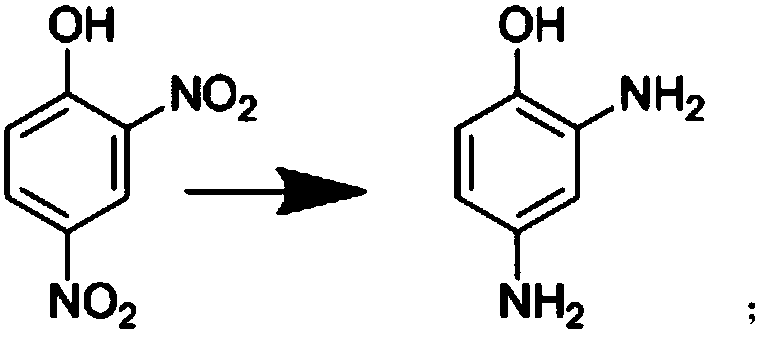

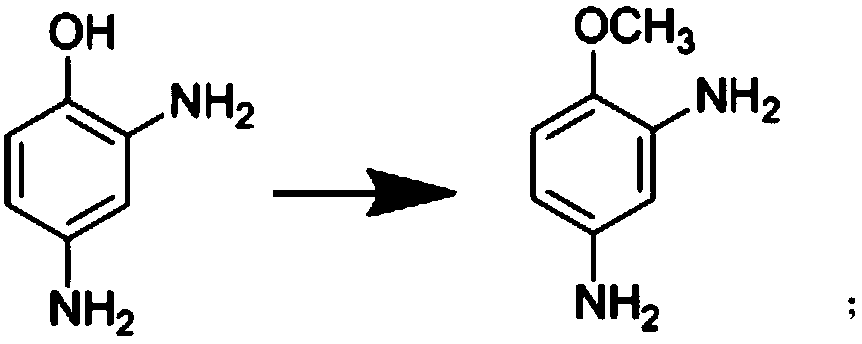

InactiveCN108440333AHigh reduction conversion rateImprove conversion rateOrganic compound preparationCarboxylic acid amides preparationDinitrophenolDisperse dye

The invention discloses a synthesis method for a disperse dye intermediate. The synthesis method comprises the following steps: preparing 2,4-diaminophenol through reduction reaction of 2,4-dinitrophenol and hydrogen gas; enabling 2,4-diaminophenol and iodomethane to generate etherification reaction under action of a catalyst tributyl methyl ammonium carbonate to prepare 2,4-diaminoanisole; and enabling 2,4-diaminoanisole and acetic anhydride to generate acylation reaction to prepare a target product 3-amino-4-methoxya-cetanilide. Compared with a 2,4-diaminoanisole hydrogenation reduction process, the 2,4-dinitrophenol hydrogenation reduction process is adopted, so that the conversation rate is high and the side reactions are fewer.

Owner:JIANGSU DAOBO CHEM

Preparation method of silica sol

The invention discloses a preparation method of silica sol, comprising the following steps: reacting with NaHCO3 or NH4HCO3 and sodium silicate Na2O.nSiO2 as raw materials to obtain hydrated SiO2 sediment; filtering to remove filtrate; washing, peptizing, grain-increasing and concentrating filter cake to obtain the silica sol. In the preparation method, the filtrate mainly contains Na2CO3; when NaHCO3 is used as the raw material, a small amount of NaHCO3 is contained; and when NH4HCO3 is used as the raw material, NH3.H2O and a small amount of NH4HCO3 are contained. As the main ingredient of the filtrate can be regenerated into reaction materials by different processing modes, the preparation method disclosed by the invention has the characteristic of cycle use, thereby reducing the production cost of the silica sol, the resource consumption, the emission and the environment damage and avoiding the problems that a great amount of inorganic acid is consumed so as to cause the environmental pollution in the prior art, and the like.

Owner:ZHEJIANG YUDA CHEM IND

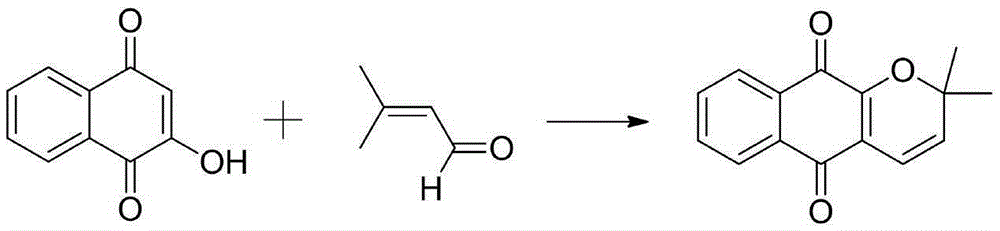

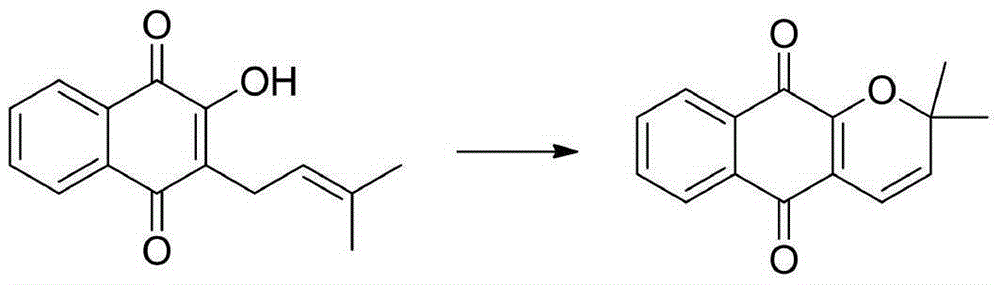

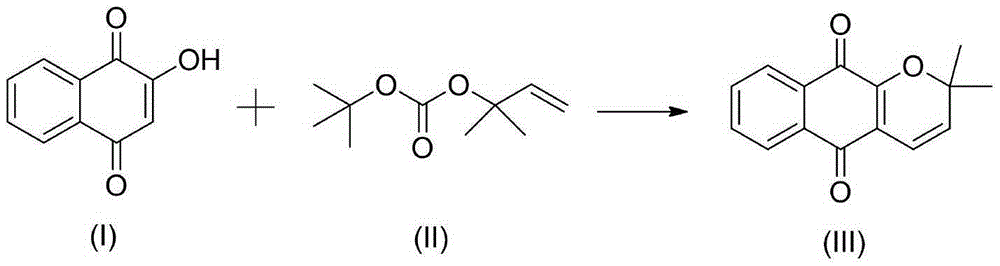

Catalyzed synthesis method of dehydrogenated alpha-lapachol

The invention relates to a catalyzed synthesis method of dehydrogenated alpha-lapachol. According to the method, a novel carbonate reaction raw material is adopted, a multiplex catalyst system is creatively used, mild and high-efficiency conversion of materials is realized, and the reaction yield is greatly improved. The process has the advantages of high reaction speed, mild reaction conditions, excellent reaction yield and the like, the production cost is saved, and the method has a great benefit to medicinal synthesis and is wide in industrial application prospects.

Owner:CHENGDU KECHUANG JIASI TECH

Precipitated calcium carbonate seed crystal containing aragonite crystalline phase and preparation method thereof

ActiveCN105819483AHigh aragonite contentHigh phase contentCalcium/strontium/barium carbonatesPrecipitated calcium carbonateMedicinal chemistry

The invention provides precipitated calcium carbonate seed crystal containing an aragonite crystalline phase and a preparation method thereof. The precipitated calcium carbonate seed crystal containing the aragonite crystalline phase is characterized in that weight content of an aragonite phase is greater than 80%, and the particle size of the seed crystal D50 is greater than or equal to 0.1 [mu]m and less than or equal to 0.2 [mu]m. The precipitated calcium carbonate seed crystal can be used for preparing the precipitated calcium carbonate containing a metastable crystalline phase, and also can be directly used in the corresponding industrial field. The method has the advantages of low cost and obvious process advantage, and the technology bias that strontium salts such as strontium chloride cannot be used to prepare the precipitated calcium carbonate seed crystal containing the aragonite crystalline phase in the prior art is overcome. The provided technology has wide application prospect based on the above advantages.

Owner:建德华明科技有限公司

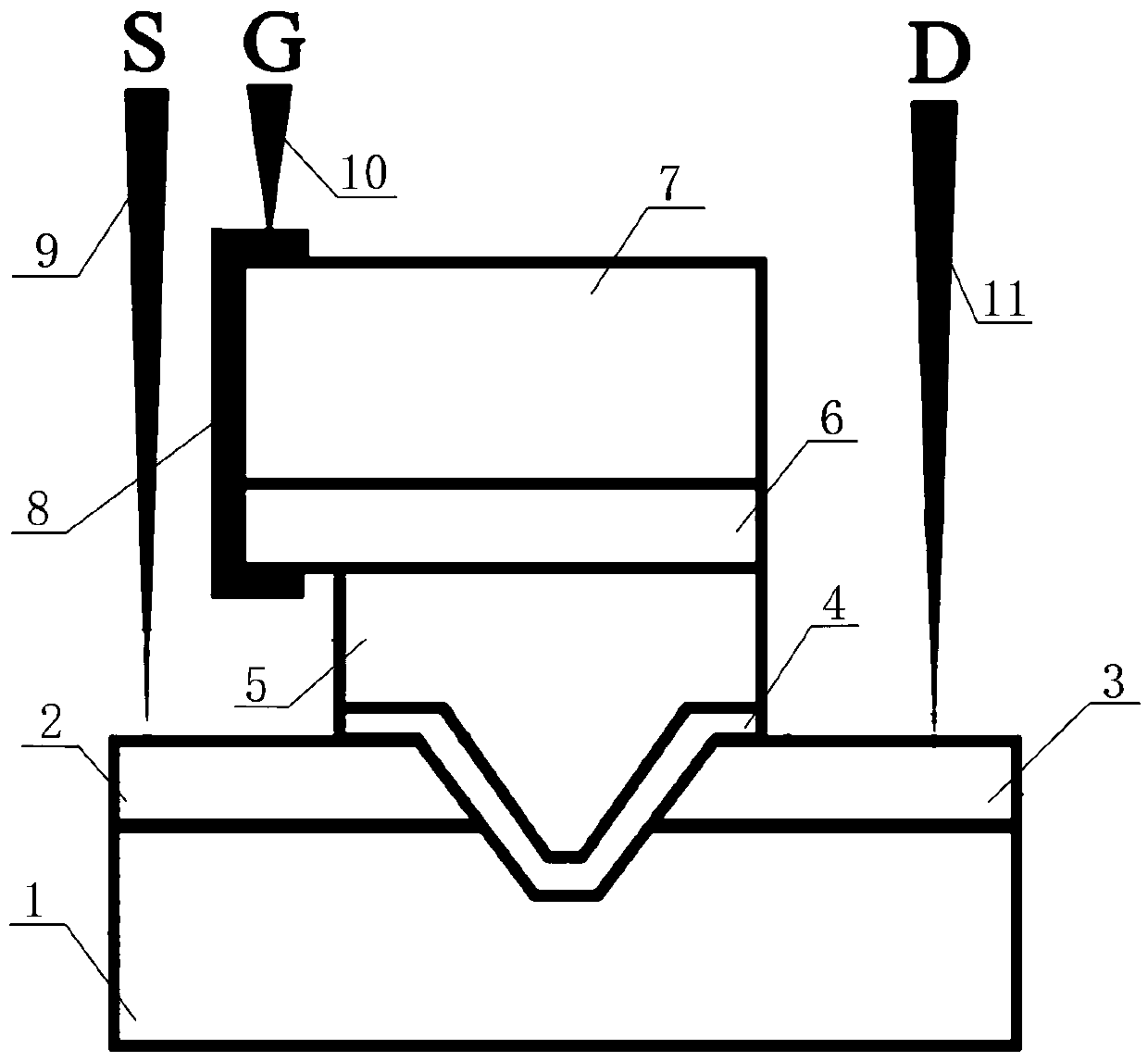

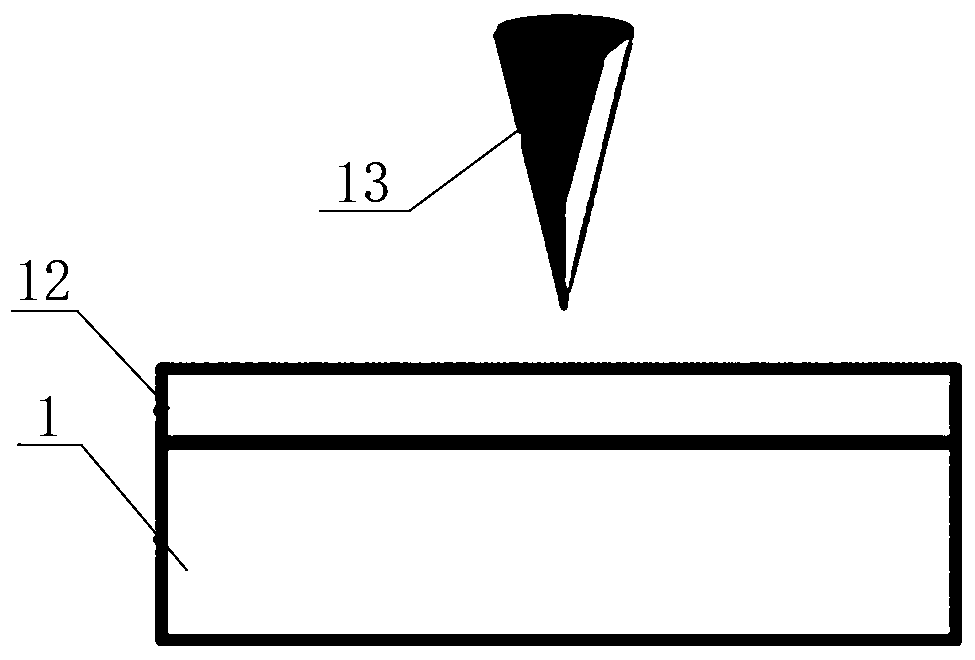

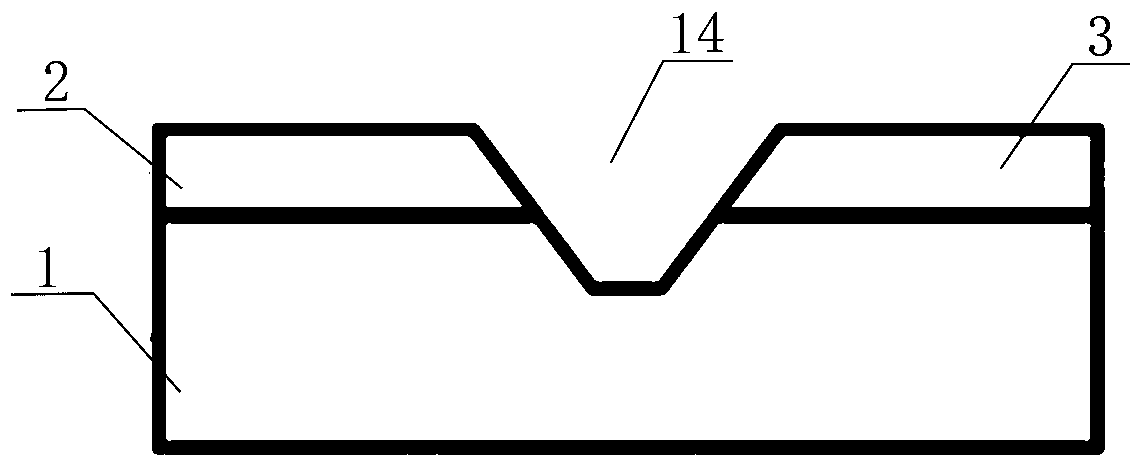

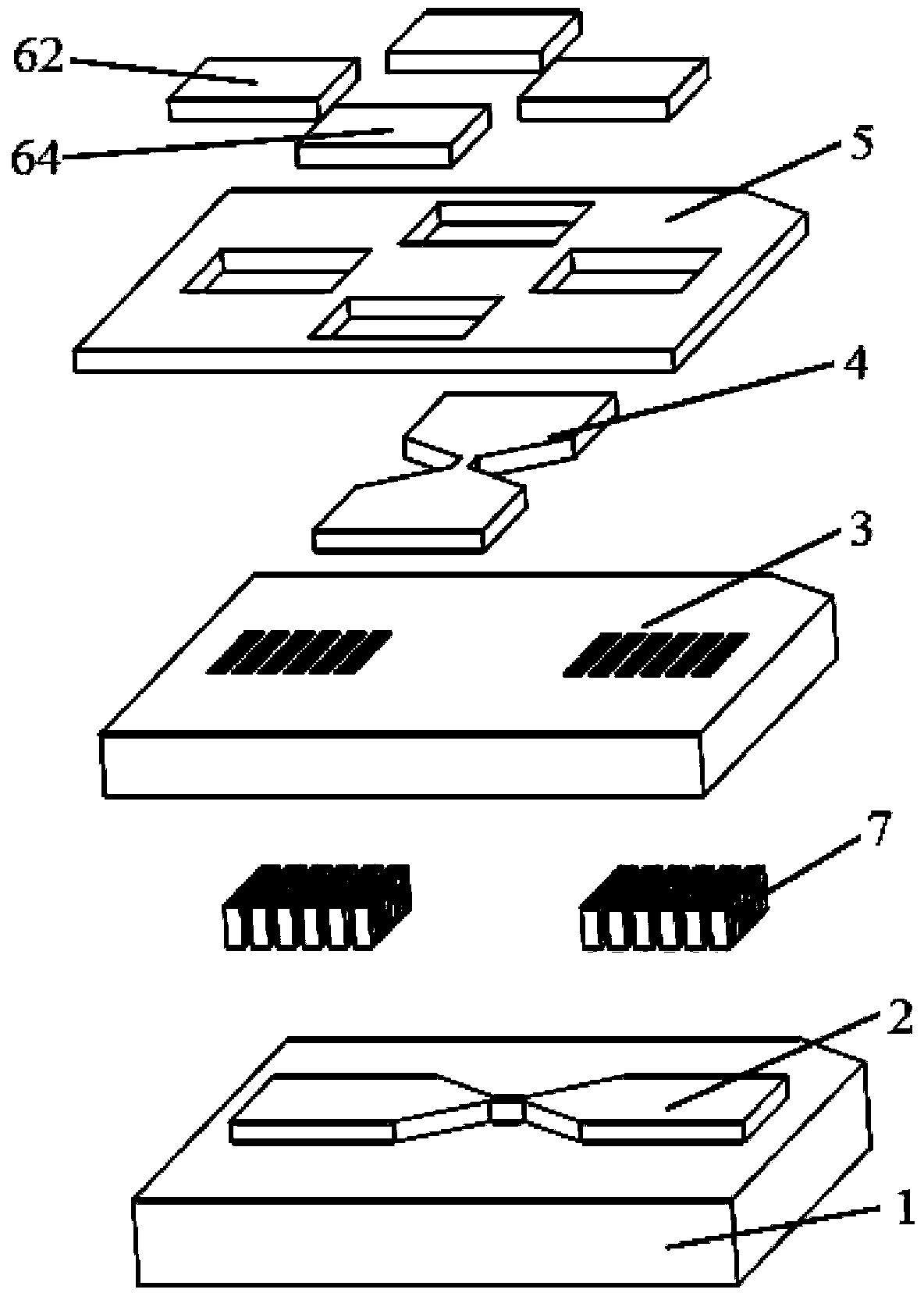

Low-cost technology for preparing double electrode layer thin film transistor

PendingCN110767547ALow costEase of mass productionSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricThin membrane

A low-cost technology for preparing a double electrode layer thin film transistor in the present invention comprises: a). substrate and electrode material selection; b). source and drain electrode patterning (carving); c). sample cleaning; d). active layer preparation; e). gate substrate and electrode material selection and gate patterning (cutting); f). gate dielectric layer preparation; and g).flip-chip bonding. According to the technology for preparing the double electrode layer thin film transistor in the present invention, a simple low-cost method for preparing a double electrode layer thin film transistor is provided, and a "carving, cutting, and flip-chip bonding (CCFB for short)" technology is developed. The technology has advantages of low costs, timesaving, environmental protection and easy large-scale production, and can be used for various substrates, for example, rigid substrates such as glass, silicon slices, mica and the like, and flexible substrate such as plastic, paper and the like. The excellent technology advantages and device performance indicate that, the technology has an extremely high application promotion prospect.

Owner:济南嘉源电子有限公司

Pressure-bearing integral metallurgy sewage purifying treatment device

ActiveCN102010088BObvious technological advantagesCompact structureMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationCooling tower

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

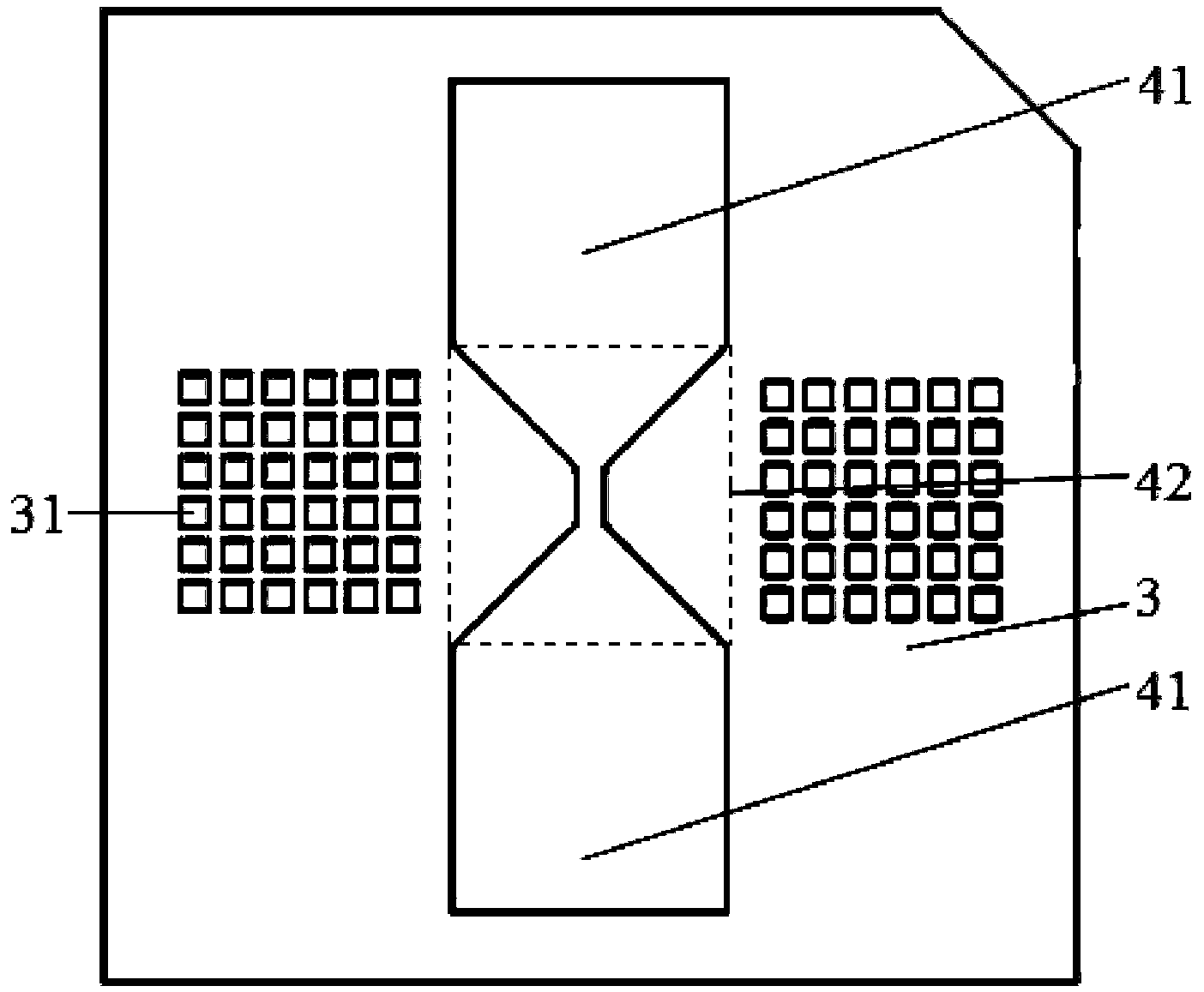

Assembling method of low-energy exploding foil initiator

Provided is an assembling method of a low-energy exploding foil initiator. A detonating unit comprises a ceramic substrate, a composite metal film layer, an insulating layer, an upper electrode Ti / W / Ti / Cu / Au, a Schottky diode or a high-pressure pipe and an accelerating chamber. The assembling method is characterized by including the following steps that 1, a PCB is ground and cleaned; 2, the processed substrate is bonded to an appropriate position of the PCB by adopting an insulation paste and is cured; 3, the Schottky diode is reversely bonded to the upper electrode Ti / W / Ti / Cu / Au or the high-pressure pipe is bonded to the high-pressure pipe by adopting the insulation paste and is cured; 4, the Schottky diode and a PCB bonding pad are connected through aluminum strip wedge bonding; 5, the upper electrode and the PCB bonding pad are connected through copper strip hand welding. The method adopts a thin film process, the precision and integration level are high, a manufactured detonating system is smaller in size and is safer and more reliable, the impedance of a detonating circuit is reduced, firing energy of the detonating system is low, and independent components and parts can be reworked multiple times to achieve multiple times of use of exploding foil experiment samples.

Owner:苏州亿禾永利新能源有限公司 +1

Preparation method of voglibose impurity vinyl voglibose

InactiveCN108276298ASimple processEasy to operateOrganic compound preparationAmino-hyroxy compound preparationVogliboseValienamine

The invention relates to a preparation method of voglibose impurity vinyl voglibose. According to the preparation method, valienamine and 1,3-dihydroxy acetone are adopted, one kettle method is adopted to prepare vinyl voglibose through reduction using a reducing agent. The preparation method is simple; operation is convenient; subsequent process is simple; technology advantages are obvious; and purity and yield are high.

Owner:SHANDONG XINHUA PHARMA CO LTD

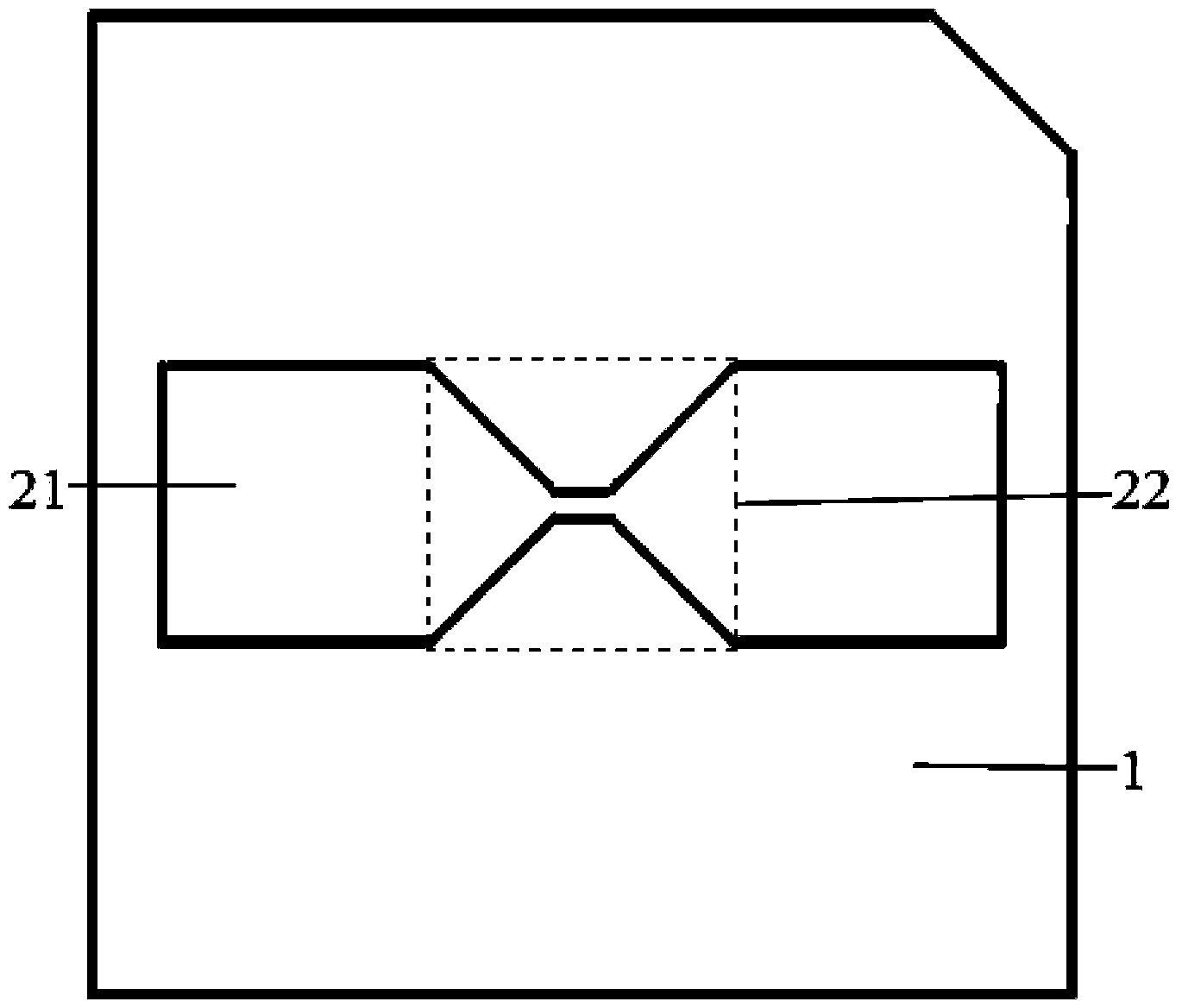

Solid-state electronic switch with characteristic of conversion from normally-open state to normally-closed state and preparation method thereof

InactiveCN104168007ABistableImprove antistatic performanceElectronic switchingControl signalEngineering

The invention discloses a solid-state electronic switch with characteristic of conversion from a normally-open state to a normally-closed state and a preparation method thereof. The solid-state electronic switch consists of a substrate, a control bridge, an insulating layer, a metal interconnection unit, a controlled bridge, a passivation layer, a pair of control electrode welding pads and a pair of controlled electrode welding pads. The control bridge is connected to a control circuit by the pair of control electrode welding pads, thereby receiving a control signal from the control circuit; and the controlled bridge is connected to a controlled circuit by the pair of controlled electrode welding pads. According to the invention, the solid-state electronic switch only consumes the electric energy at the moment of state conversion and does not consume electric energy in states of connection maintaining and disconnection, so that the switch has the bistable state characteristic; bidirectional conduction can be realized and no movable component is contained, so that the switch can work in a severe environment; the switch has the excellent anti-statistic and anti-electromagnetic interface characteristics; on the basis of the semiconductor technology of the integrated circuit, the switch has the high compatibility with the semiconductor technology of the integrated circuit; and the switch can be used as the short-circuit safety switch of an electric explosive device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Improved process for synthesizing omethoate

The invention discloses an improved process for synthesizing omethoate. In the process of preparation of omethoate by using a post aminolysis method, coarse prepared omethoate crude oil is first dried, and then desolvation is conducted so as to obtain omethoate crude oil. Through improvement of multiple processes, improvement of the reaction environment, improvement of the progress of a main reaction and reduction of hydrolysis are achieved to the greatest extent, the reaction yield is improved, and the post-treatment of salt-containing compounds is more convenient. By using the process, the yield of refined ester of oxygen sulfur phosphorus ester can be increased to 86% or above, and the purity is also increased to 90% or above; the purity of ammonium chloride can reach 99% or above, andthe ammonium chloride can be directly sold as a by-product first-grade product; the total yield of the omethoate crude oil can be increased to 79% or above, the purity of the crude oil is also improved, the overall process is greatly improved, and the social and economic benefits are huge.

Owner:兰博尔开封科技有限公司

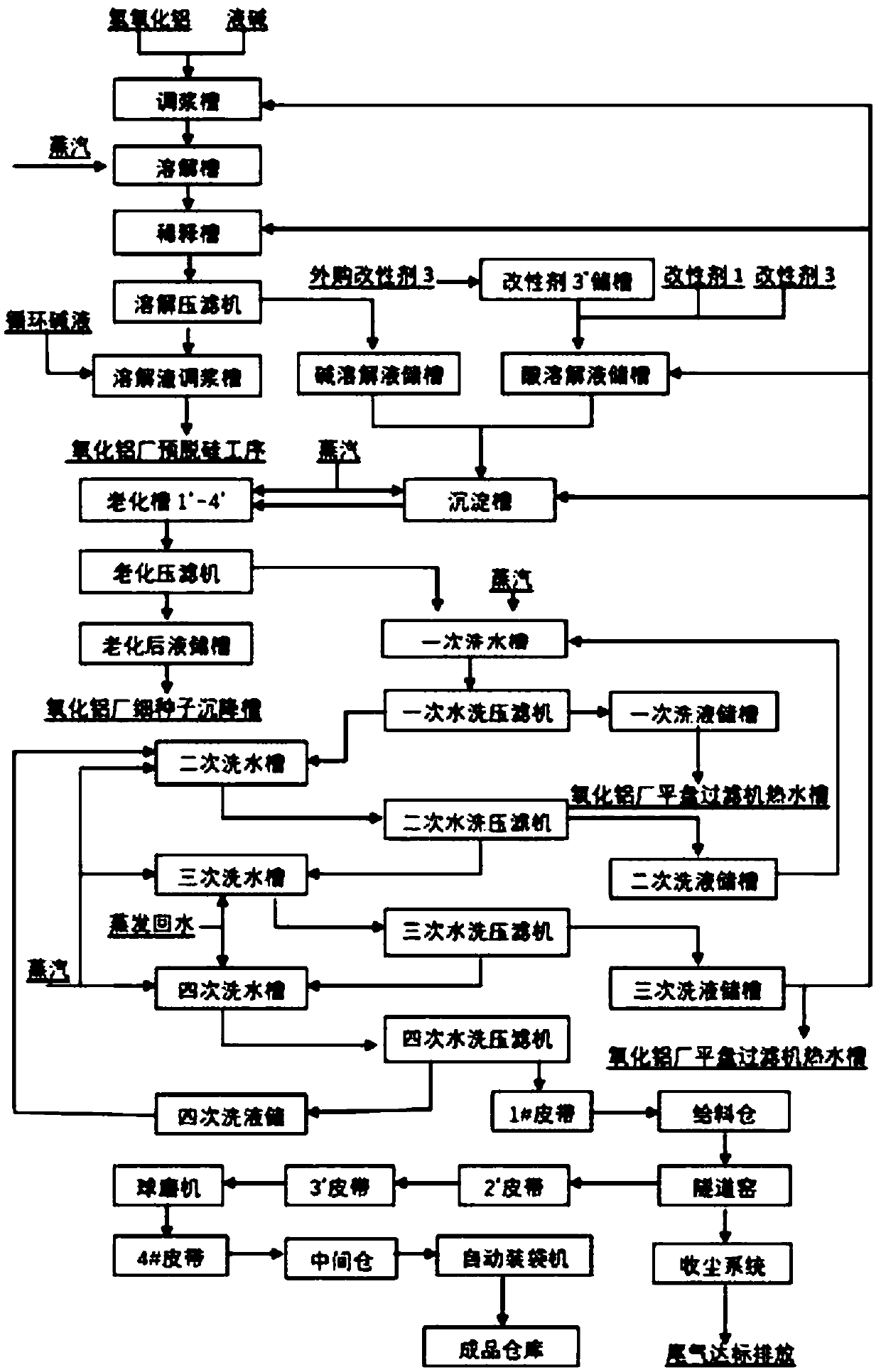

Modified gamma-Al2O3 and processing method thereof

InactiveCN109607585ALow costImprove high temperature resistanceAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideSodium aluminate

The invention discloses a method for processing modified gamma-Al2O3. Sodium aluminate, a dispersing agent, a modifier and pseudo-boehmite washing liquor are mixed, and a mixture A is obtained; the mixture A is sequentially subjected to sedimentation, ageing and roasting, and the modified gamma-Al2O3 product is obtained, wherein roasting is carried out for 2 h to 40 h at the temperature of 90 DEGC to 170 DEG C, and then roasting is carried out for 1 h to 4 h at the temperature of 600 DEG C to 900 DEG C. According to the process, industrial aluminum hydroxide is adopted as the raw material, steam heating and high alkali concentration dissolving out are adopted, a sodium aluminate solution is generated, diluting, filtering and purifying are carried out, the sodium aluminate solution and salpeter solution to which a modifying agent is added are subjected to coprecipitation, and pseudo-boehmite is obtained. The pseudo-boehmite is subjected to ageing, washing, adhesive water and crystal water high-temperature removal and smashing and levigating, and then qualified modified aluminum oxide is obtained. The process raw material cost is low, the production process is environmentally friendly, the product is good in high temperature resisting performance, sewage generated in the project can be adopted as water for an aluminum oxide producing system of an aluminum oxide plant, no waste water is drained out, and the advantages are more obvious.

Owner:YUNNAN WENSHAN ALUMINUM

Preparation method of precipitated silicon dioxide

InactiveCN102633272AReduce manufacturing costWill not increase investmentSilicaManufacturing cost reductionResource consumption

The invention discloses a preparation method of precipitated silicon dioxide. The preparation method comprises the steps of reacting by using soluble silicate M2O.nSiO2 and NH4HCO3 as raw materials in a molar ratio of M2O.nSiO2 to NH4HCO3 of 1:(1.0-1.15), and precipitating out hydrated SiO2; removing filtrate through filtration; and washing and drying filter cake to obtain the precipitated silicon dioxide product, wherein M in the soluble silicate M2O.nSiO2 and carbonate M2CO3 is alkali metal element Na or K. According to the scheme, as the filtrate mainly contains M2CO3 and NH3, MHCO3 and NH4HCO3 can be generated via reaction with CO2, and MHCO3 can react with M2O.nSiO2 to precipitate out hydrated SiO2. Thus, in the preparation method, chemicals other than the silicon source can be reused, so that the production cost, the resource consumption and the environment damage are reduced.

Owner:ZHEJIANG YUDA CHEM IND

New process for synthesizing 1-hydroxycyclohexanecarboxylic acid and application

InactiveCN109053410AIncrease hot meltGood reaction temperaturePreparation from nitrilesCarboxylic compound separation/purificationAmmonium chloride mixtureAmmonium

The invention discloses a new process for synthesizing 1-hydroxycyclohexanecarboxylic acid and an application. During the synthesis of the 1-hydroxycyclohexanecarboxylic acid, an anhydrous system is adopted. According to the process, due to an anhydrous reaction processing technology, a reaction enviroment is improved to the maximum, the progress of a main reaction is improved, adverse factors toreactions caused by a solid-liquid reaction are solved, the reaction yield is increased, and the aftertreatment of salt-bearing compounds becomes more convenient. By using the new process disclosed bythe invention, the yield of the 1-hydroxycyclohexanecarboxylic acid can reach 87% or more, the purity of the 1-hydroxycyclohexanecarboxylic acid can reach 97% or more, the purity of ammonium chloridecan reach 99% or more, and thus, the ammonium chloride can be sold directly as firsts of byproducts; the total yield of spirodiclofen prepared by using the 1-hydroxycyclohexanecarboxylic acid can reach 64% or more. Compared with the traditional processes, the process and the application have the advantages that the whole effect is greatly improved, and the social and economic benefits are huge.

Owner:兰博尔开封科技有限公司

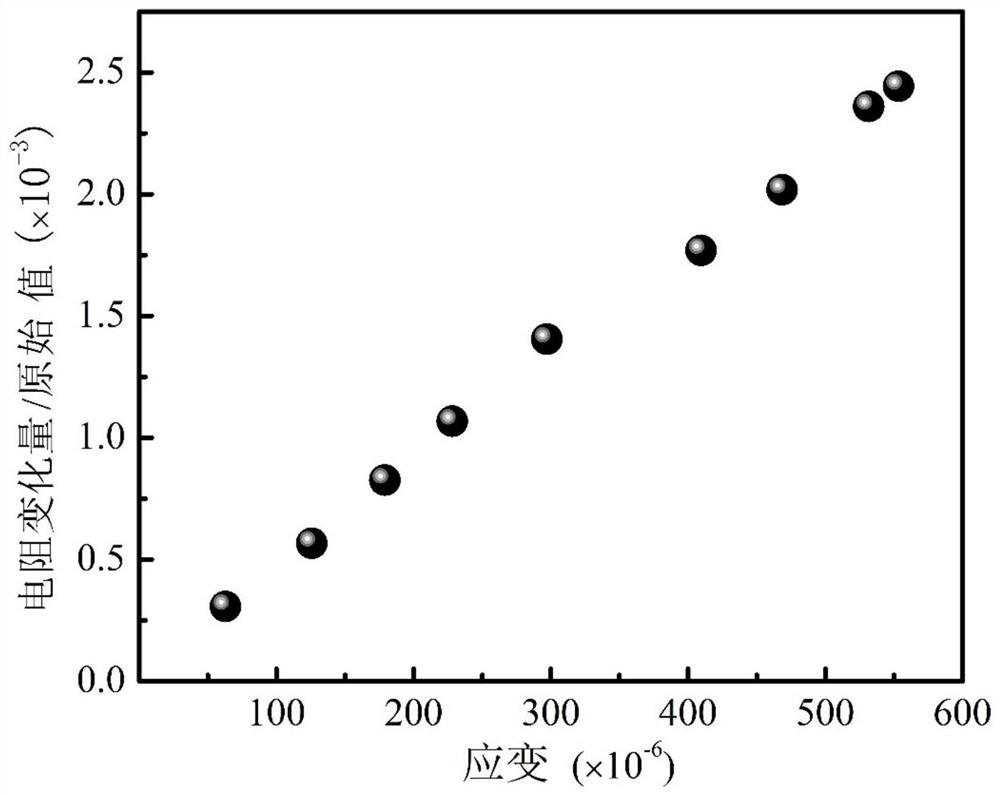

Preparation method and application of amorphous carbon film with piezoresistive properties and toughness on flexible substrate surface

ActiveCN110184577BEasy to manufactureImprove piezoresistive coefficientVacuum evaporation coatingSputtering coatingCarbon filmGraphite

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A beneficiation method that can improve the flotation concentrate rate and recovery rate of fine-grained refractory iron ore

The invention discloses a beneficiation method for improving the micro-fine particle refractory iron ore flotation ore-concentrate production rate and the recovery rate. The method includes the following steps that pre-treated micro-fine particle rough concentrate is sent to a closed circuit grinding grading system, so that most of the rough concentrate undergoes monomer separation; obtained ground ore products which undergo monomer separation sequentially undergo low-intensity magnetic separation, high-intensity magnetic rough flotation and high-intensity magnetic scavenging carried out at least once, and ultimately, low-intensity magnetic ore-concentrate and high-intensity magnetic rough ore-concentrate are obtained, the obtained high-intensity magnetic rough ore-concentrate is concentrated, concentration bottom currents are involved in a reverse flotation operation, and accordingly reverse flotation ore-concentrate is obtained; the low-intensity ore-concentrate and the reverse flotation ore-concentrate are combined to form a finished ore-concentrate product, foam after reverse flotation enters a high-intensity magnetic floatation procedure for re-flotation, the ore-concentrate after high-intensity magnetic flotation treatment returns to the closed circuit grinding grading system, and the preceding steps are repeated. The method has the advantages that procedure operations are easy and controllable, the iron grade of flotation tailings is low, and the recovery rate of the ore-concentrate is high.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

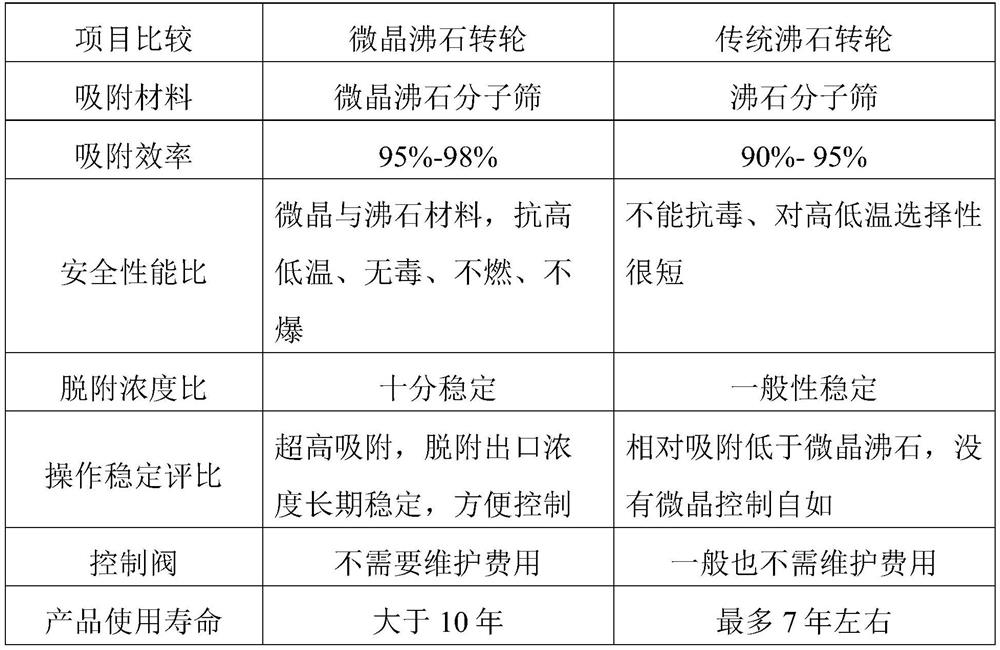

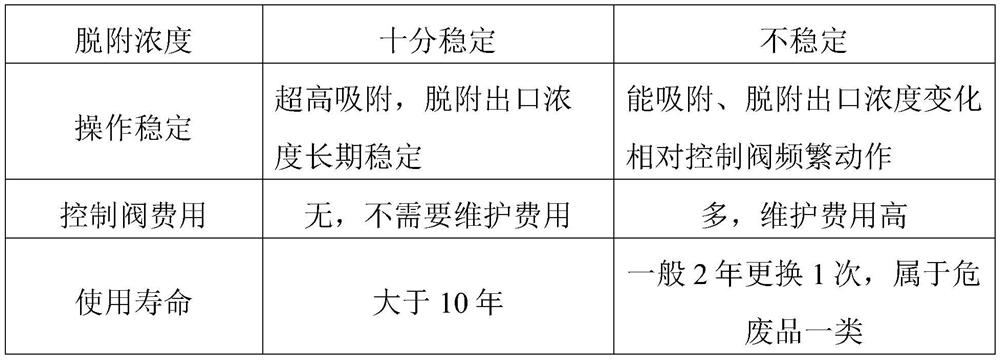

Microcrystal rotating wheel zeolite molecular sieve for efficiently removing VOCs and preparation method of microcrystal rotating wheel zeolite molecular sieve

PendingCN113797709AObvious technological advantagesFlexible reaction temperatureGas treatmentOther chemical processesMolecular sieveZeolite

The invention relates to a microcrystal rotating wheel zeolite molecular sieve for efficiently removing VOCs and a preparation method of the microcrystal rotating wheel zeolite molecular sieve, and belongs to the technical field of VOCs removal treatment. The microcrystal rotating wheel zeolite molecular sieve comprises, in percentage by mass, 25%-35% of a microcrystal material, 30%-50% of a natural zeolite material and 20%-30% of a mud making material. The molecular sieve comprises an adsorption zone, a regeneration zone and a cooling zone, and the technical problems that in the prior art, thiophene removal is not ideal, adsorbent blockage is easily caused, and catalyst poisoning is easily caused are solved.

Owner:江西省杰夫环保科技有限公司

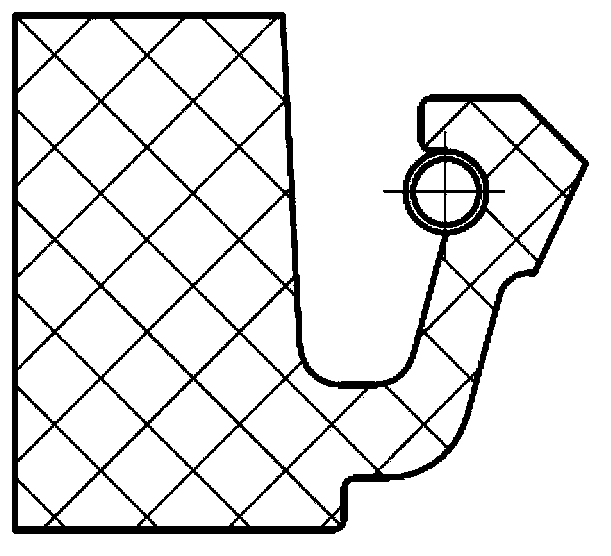

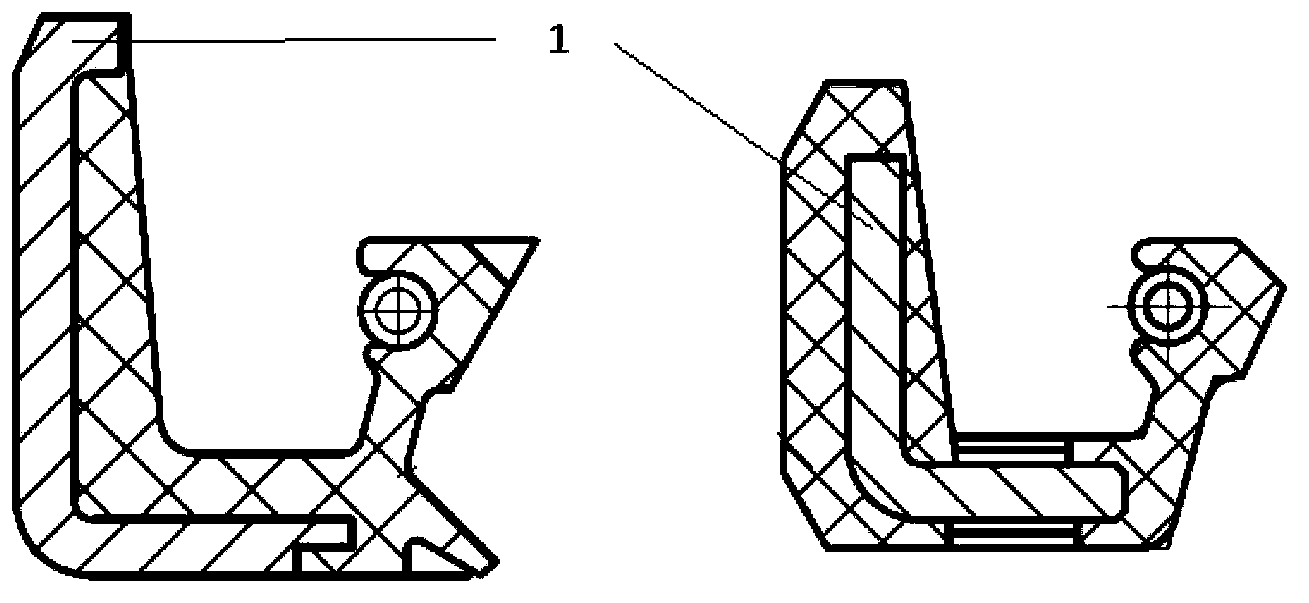

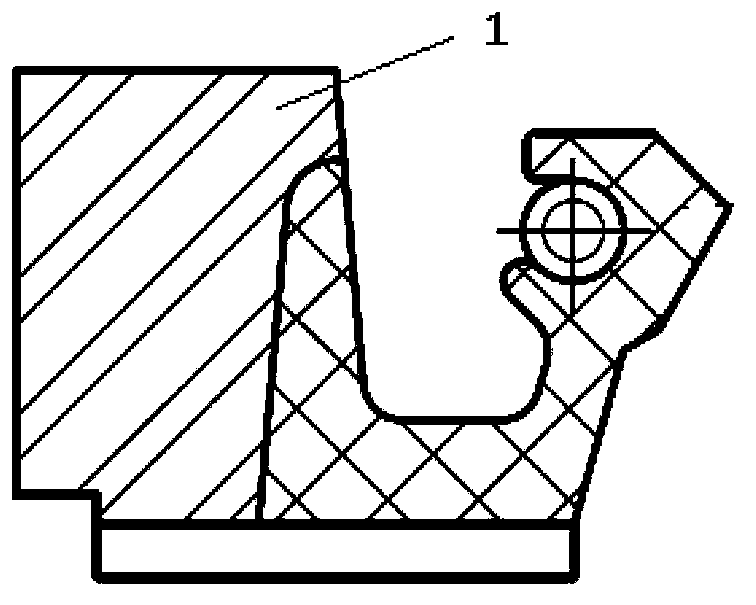

Lip-type seal ring framework material for rotary shaft, as well as preparation method and application of lip-type seal ring framework material

The invention discloses a lip-type seal ring framework material for a rotary shaft, as well as a preparation method and an application of the lip-type seal ring framework material, and belongs to the field of rubber-plastic seal. The lip-type packing framework material for the rotary shaft is formed by compounding a chemigum system, an epoxy resin system and an aramid pulp system. The preparation method comprises the steps as follows: pre-processing the aramid pulp system; carrying out glue mixing to the chemigum system, the epoxy resin system and the pre-processed aramid pulp on an open type mixing machine, so as to obtain the lip-type packing framework material for the rotary shaft. The lip-type packing framework material subjected to extruding and the semi-finished product of lip-type glue are subjected to mould pressing and vulcanizing, so as to obtain the lip-type sealing ring for the rotary shaft. Test results show that the lip-type seal ring disclosed by the invention is simple in production process, proper in difficulty at installation, and high in capacity of keeping the sealing force of an external circle.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Synthesis method of flucloxacillin sodium

ActiveCN102964356BEasy to operateMild reaction conditionsOrganic chemistryOctanoic AcidsAklanonic acid

The invention particularly discloses a synthesis method of flucloxacillin sodium and belongs to the field of synthesis of antibiotic medicines. The synthesis method comprises the following steps: reacting 3-(2-chloro-6-fluorobenzene)-5-methyl isoxazole-4-formic acid as a raw material with phosphorus oxychloride under the catalysis of organic amine to generate acyl chloride; dissolving 6-APA (6-aminopenicillanic acid) and inorganic alkaline in water, dripping an acyl chloride solution obtained in the previous step, acidizing by using hydrochloric acid after the reaction is completed, and then layering; concentrating under a reduced pressure, adding residues into an alcohols solvent for dissolution, dripping water to separate out flucloxacillin crystals; and dissolving flucloxacillin acid in an organic solvent, dripping a sodium iso-octoate solution for reaction to produce a product, namely flucloxacillin sodium monohydrate. The synthesis method disclosed by the invention has the advantages that the process advantages are obvious, the product quality is promoted, the yield is improved, and the operation steps are simplified so as to achieve greater production benefits and social benefits.

Owner:HEZE RUIZHI TECH DEV

Synthesis Method of cefcapene pivoxil hydrochloride

ActiveCN101747344BEasy to operateMild reaction conditionsOrganic chemistrySynthesis methodsCefcapene Pivoxil

The invention belongs to the technical field of antibiotic drug synthesis, in particular to a synthesis methodof cefcapene pivoxil hydrochloride. The invention is mainly used for process improvement and optimization of cefcapene pivoxil, and the advantage of the synthesis process of cefcapene pivoxil are obvious; new catalytic agents are used, such as phenol, boric acid and other reagents, thereby improving the product quality, increasing the yield, simplifying the operating steps and realizing greater productivity effect and social effect.

Owner:SHANDONG RUNZE PHARMA

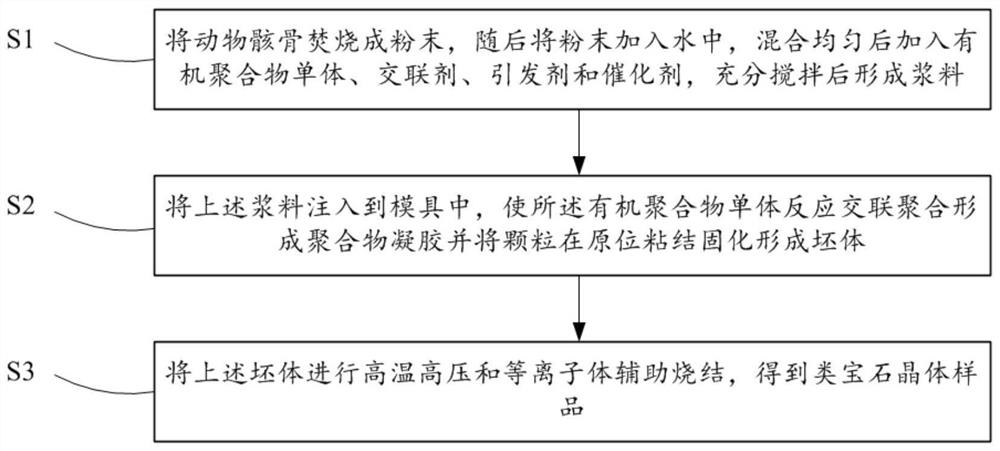

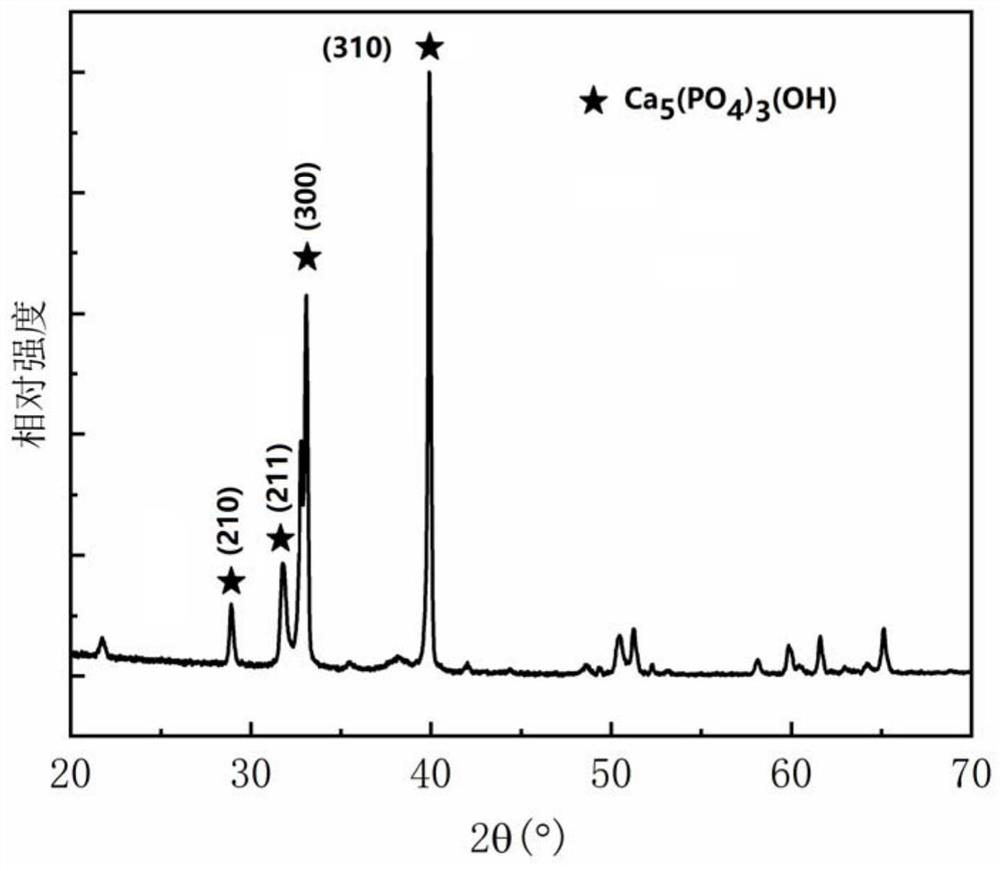

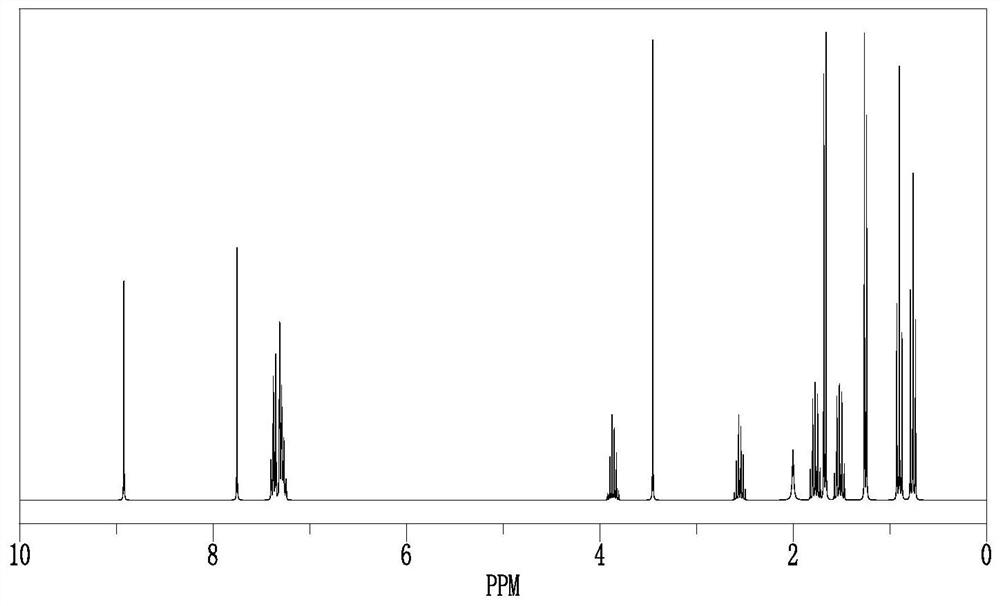

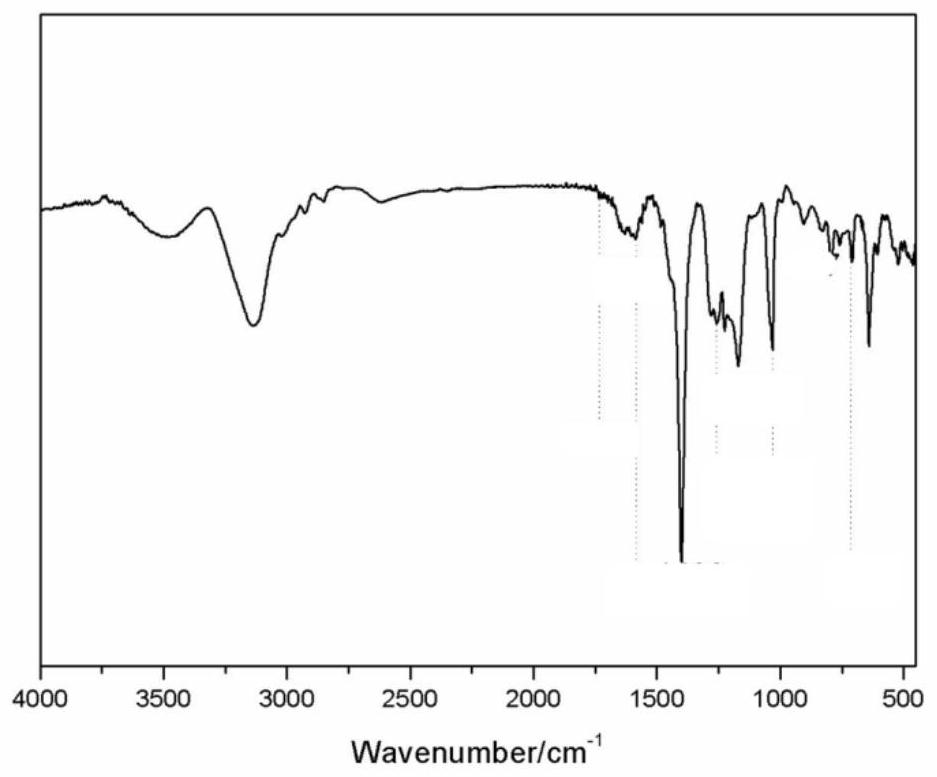

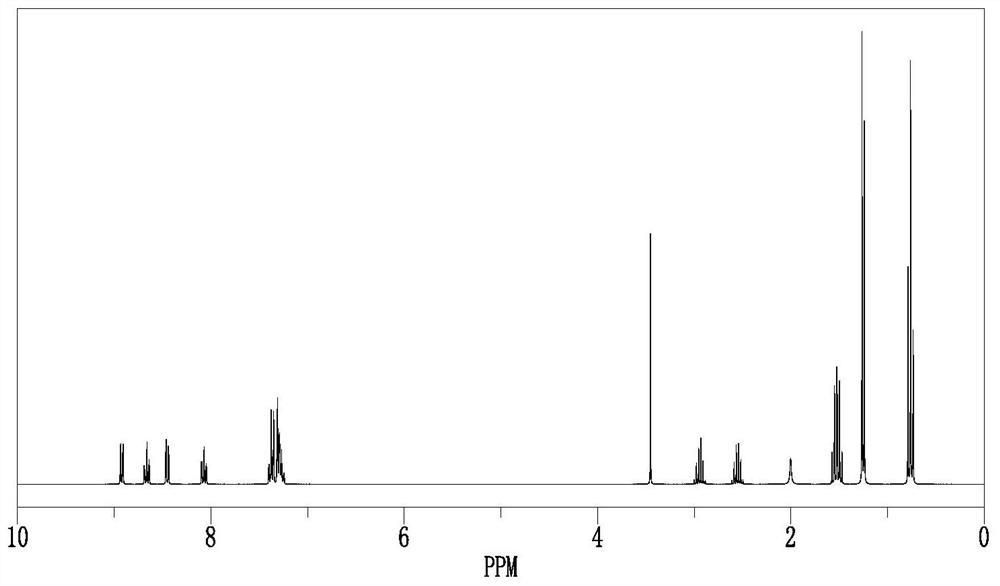

Jewel-like crystal based on animal skeletons and preparation method of jewel-like crystal

The invention relates to a jewel-like crystal based on animal skeletons and a preparation method of the jewel-like crystal. The preparation method comprises the following steps of burning animal skeletons into powder, then adding the powder into water, uniformly mixing, then adding an organic polymer monomer, a cross-linking agent, an initiator and a catalyst, and fully stirring to form slurry, injecting the slurry into a mold, enabling the organic polymer monomer to react, crosslink and polymerize to form polymer gel, and bonding and curing the particles in situ to form a green body, and carrying out high-temperature and high-pressure plasma-assisted sintering on the green body to obtain the jewel-like crystal. The technical means of material synthesis and crystal reconstruction are adopted, and the natural dead pet skeletons are subjected to atom recombination to form jewel-like crystals containing elements such as carbon, calcium, phosphorus, magnesium and oxygen; on the basis of the traditional hot pressing sintering technology, the plasma auxiliary sintering technology is combined, multi-field coupling of a thermal field, a force field and an electric field is achieved, energy needed by reaction is reduced, and the reaction rate and the production efficiency are improved.

Owner:福建省泉州市半岛建材有限公司

Precipitated calcium carbonate seed crystal containing aragonite crystal phase and preparation method thereof

ActiveCN105819483BHigh phase contentHigh aragonite contentCalcium/strontium/barium carbonatesPrecipitated calcium carbonateAragonite

The present invention provides a precipitated calcium carbonate seed crystal containing aragonite crystal phase and a preparation method thereof. The precipitated calcium carbonate crystal seed containing aragonite crystal phase is characterized in that the weight content of the aragonite phase is >80%, and the seed crystal grain Diameter 0.1μm≤D50≤0.2μm. The precipitated calcium carbonate seed crystal containing aragonite crystal phase can be used to prepare metastable crystal phase precipitated calcium carbonate, and can also be directly applied to corresponding industrial fields. The invention has low cost and obvious technological advantages, and overcomes the technical prejudice that strontium salts such as strontium chloride cannot be prepared into precipitated calcium carbonate with high aragonite phase content in the prior art. Because of the above advantages, the technology provided by the present invention has broad application prospects.

Owner:建德华明科技有限公司

Method for removing trace aldehyde group impurities in 1, 3-propylene glycol

ActiveCN114805028ASuitable for dealdehyde refiningEasy to separate and recycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterFiber

The invention relates to a method for removing trace aldehyde group impurities in 1, 3-propylene glycol. The method comprises the following steps: adding a sulfonic acid functionalized polymeric acidic ionic liquid into a dehydrated concentrated solution obtained in the preparation of 1, 3-propylene glycol, carrying out dealdehyding treatment at a certain temperature, carrying out reduced pressure rectification on the dealdehyded 1, 3-PDO solution, and condensing the distillate to obtain a high-purity fiber-grade 1, 3-PDO product. According to 1, 3-PDO produced by a common acrolein hydration route, after the method is adopted, the content of residual aldehyde group impurities can be reduced to 5 ppm or below, a product with the purity higher than 99.9%, the ultraviolet absorbance (260 nm) smaller than 0.04 and the chromaticity smaller than 5 Hazen is obtained, and the requirement for raw material quality in synthesis of high-quality polyester PTT is met. The treatment method is simple to operate, green in process, high in catalytic efficiency and good in dealdehyding effect, and the catalyst is convenient to separate and recover.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of nano SiO2

The invention discloses a preparation method of nano SiO2. The preparation method is characterized by taking soluble silicate M2O.nSiO2 and NH4HCO3 as raw materials to react to obtain hydrate SiO2 through precipitation, separating out filtrate through filtration, then washing the filter cake, displacing the filter cake with an organic solvent and drying the product to obtain the nano SiO2 product, wherein the filtrate mainly contains carbonate M2CO3 and NH3 and also contains little NH4HCO3; and M is an alkali metal Na or K. The preparation method has the following beneficial effects: the filtrate mainly contains M2CO3 and NH3 which can generate MHCO3 and NH4HCO3 through reaction with CO2, and MHCO3 can react with M2O.nSiO2 to obtain the hydrate SiO2 through precipitation, i.e. several components in the filtrate can regenerate the required reaction raw materials through reaction with CO2, so the materials can be recycled, thus the preparation cost of precipitated SiO2 is reduced, simultaneously fewer resources are consumed and emission is reduced.

Owner:ZHEJIANG YUDA CHEM IND

Preparation method of metastable crystal phase precipitated calcium carbonate

ActiveCN105819482BReduce manufacturing costLow costCalcium/strontium/barium carbonatesCarbonizationStrontium hydroxide octahydrate

The invention discloses a method for preparing metastable crystal phase precipitated calcium carbonate, which comprises the following steps: (1) adding additive 1 and additive 2 into calcium hydroxide suspension and mixing, and the carbonization initial temperature is 40-60°C; 1 is more than one of group IA metal bicarbonate, group IA metal carbonate, group IA metal hydroxide, barium hydroxide or ammonia water, additive 2 is strontium hydroxide, strontium oxide, strontium chloride or strontium acetate One or more of them, feed carbon dioxide-containing gas, and when the pH of the suspension drops to 7.0 to 7.5, continue to ventilate for 10 to 30 minutes, and then collect the seed crystals from the suspension; (2) the crystal seeds of step (1) The mixture is added to the calcium hydroxide suspension and mixed with carbon dioxide-containing gas. The initial carbonization temperature is 25-50°C. When the pH of the suspension drops to 7.0-7.5, continue to ventilate for 10-30 minutes, and then remove the carbon dioxide from the suspension. The metastable crystal phase precipitated calcium carbonate is collected. The invention has low cost, obvious technological advantages and wide application prospects.

Owner:湖北国鼎华明纳米新材料有限公司

A kind of technique of synthetic omethoate important intermediate oxathion

ActiveCN108864187BObvious technological advantagesRaise the ratioGroup 5/15 element organic compoundsDimethoateBiochemical engineering

The invention discloses a new process for synthesizing an important intermediate oxinothiophospholipid of omethoate. The process comprises the steps of adopting an anhydrous system to synthesize the oxinothiophospholipid, drying an oxinothiophospholipid coarse ester, and preparing the oxinothiophospholipid. According to the anhydrous reaction process technology provided by the invention, the reaction environment is maximally improved, the progress of main reaction is improved, the adverse factors brought by solid-liquid reaction are solved, the hydrolysis is reduced, the reaction yield is improved, and a salt-containing compound is convenient to post-treat. By using the new process provided by the invention, the purity of the oxinothiophospholipid can reach to more than 89 percent, the yield of the oxinothiophospholipid can reach to more than 86 percent, the purity of ammonium chloride can reach to more than 99 percent, and the ammonium chloride can be directly used as a by-product first-grade product for sales. Compared with the traditional process, the overall effect is greatly improved, and the social benefit and the economic benefit are great.

Owner:兰博尔开封科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com