Pressure-bearing integral metallurgy sewage purifying treatment device

A technology of sewage purification and treatment device, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. problems, to achieve the effect of strong hydraulic shock resistance, saving power input, and simple operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

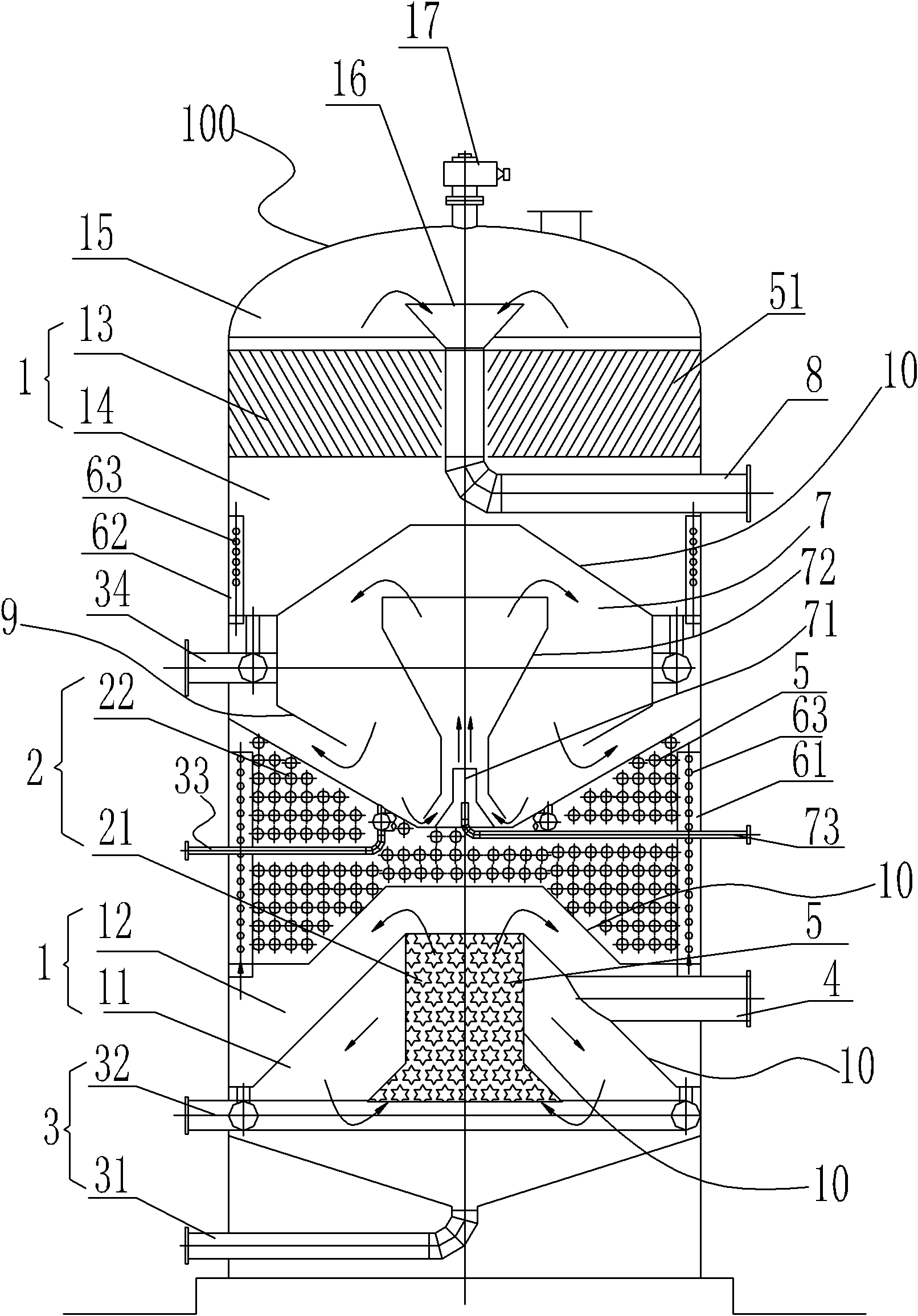

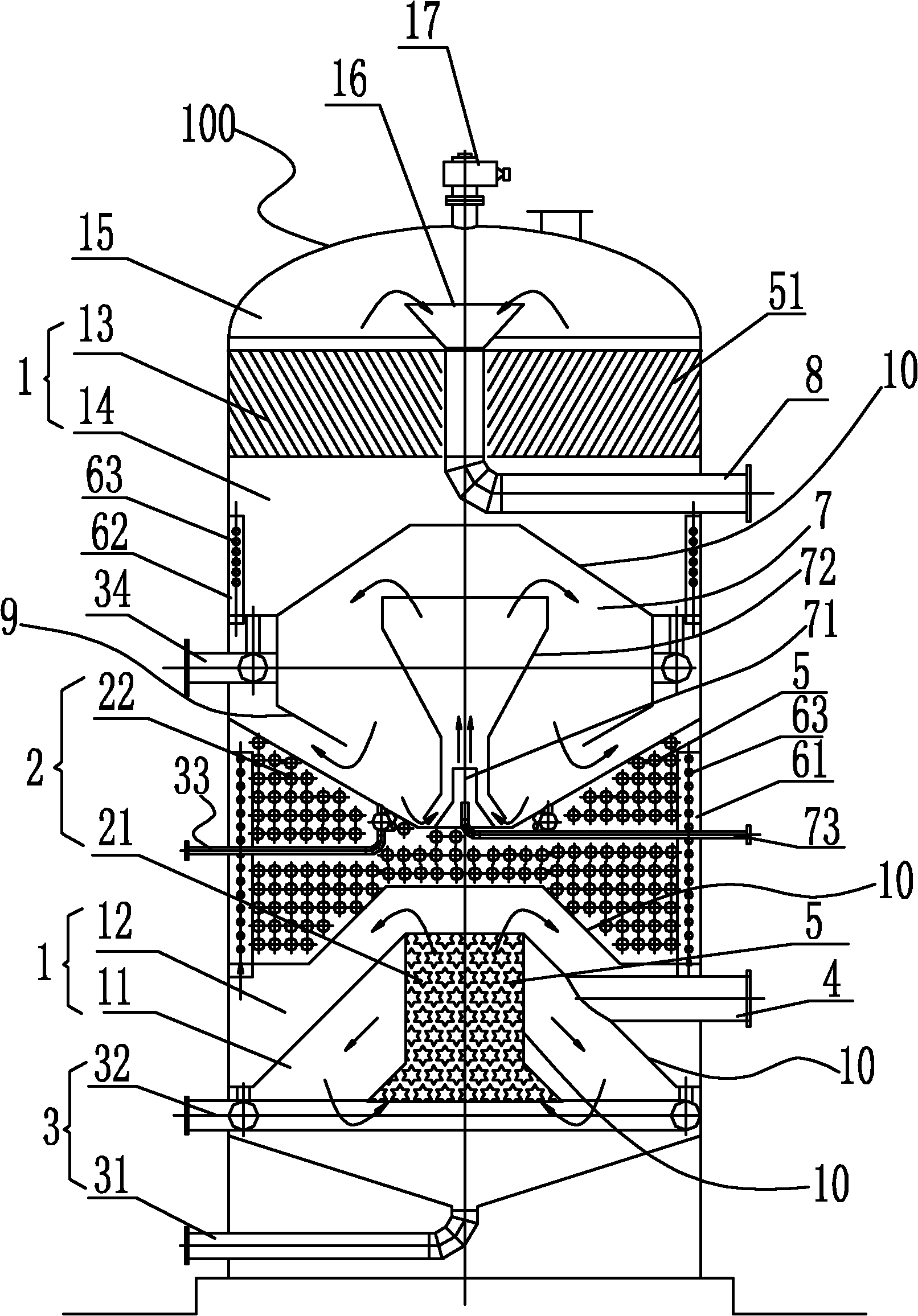

[0030] Please refer to figure 1 , is a structural schematic diagram of the pressure-bearing integrated metallurgical sewage purification treatment device of the present invention. As shown in the figure, the pressure-bearing integrated metallurgical sewage purification treatment device proposed by the present invention is used to purify the pressurized slag flushing sewage (pressurized turbid ring water) from the production line. The purification treatment device includes: a closed pressure-bearing housing 100, in which at least two sedimentation chambers 1 and at least two flocculation reaction chambers 2 are arranged from bottom to top, and the sedimentation chamber 1 is connected with the flocculation reaction chamber. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com