Preparation method of nano SiO2

A nano-silicon dioxide and silicate technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of environmental pollution, the inability to recycle or recycle salt-containing and acid-containing wastewater, and the consumption of inorganic acids. The effect of reducing manufacturing costs, reducing direct production costs, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

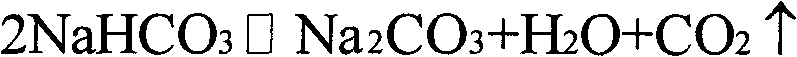

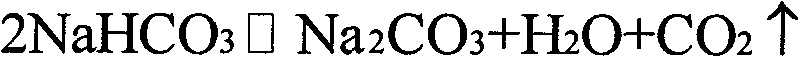

[0060] Take a sodium silicate with a Baume degree of 37°Be' (20°C, the same below), add 4 times the amount (weight, the same below) of water to dilute, filter, and measure the diluent containing SiO 2 %=5.0%, Na 2 O%=1.4%, its modulus n=3.7, weighs 600g of this dilute solution, mixes with 600g 3.8% NaHCO under stirring 3 The solution is mixed (the reaction molar ratio is 1:2.0), until there is basically no SiO in the test liquid phase 2 , continue to stir for about 15 minutes, filter, wash the precipitate with water until the washing water is nearly neutral, drain, wash the precipitate with ethanol, drain, dry in an oven, and then pulverize to obtain about 27.5g of nano-silica finished product .

[0061] The clear water is tap water or deionized water.

Embodiment 2

[0063] Take a sodium silicate with a Baume degree of 40°Be', add 3 times the amount of water to dilute, filter, and measure that the diluted solution contains SiO 2 % = 7.3%, Na 2 O%=2.3%, its modulus n=3.3, take by weighing 400g of this dilute sodium silicate solution, mix with 450g NaHCO containing 6.1% under stirring 3 The solution is mixed (the reaction molar ratio is 1:2.2), until there is basically no SiO in the test liquid phase 2 , continue to stir for about 15 minutes, filter, wash the precipitate with water 2-3 times, and then use a small amount of NH 4 HCO 3 Wash the precipitate with water for 2-3 times, then wash the precipitate with clean water until the washing water is nearly neutral, drain, then wash the precipitate with isopropanol several times, drain, dry in an oven, and then pulverize to obtain nano-dioxide The silicon finished product is about 27.5g.

Embodiment 3

[0065] Take a sodium silicate with a Baume degree of 50°Be', add 4 times the amount of water to dilute, filter, and measure that the diluted solution contains SiO 2 %=5.8%, Na 2 O% = 2.6%, its modulus n = 2.3, weigh 500g of this kind of dilute sodium silicate solution, mix it with 500g of NaHCO containing 7.4% under stirring 3 The solution is mixed (the reaction molar ratio is 1:2.1), until there is basically no SiO in the test liquid phase 2 , continue to stir for about 15 minutes, filter, wash the precipitate with water 2-3 times, and then use a small amount of H 2 SO 4 Wash the precipitate with water for 2-3 times, then wash the precipitate with water until the washing water is nearly neutral, drain it, add it to n-butanol, use azeotropic distillation to remove the water contained in the filter cake, stop heating after the distillation is completed, and cool After reaching normal temperature, use a Buchner funnel to suction filter, put the filter cake in an oven to dry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com