Patents

Literature

53results about How to "Continuous and stable process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

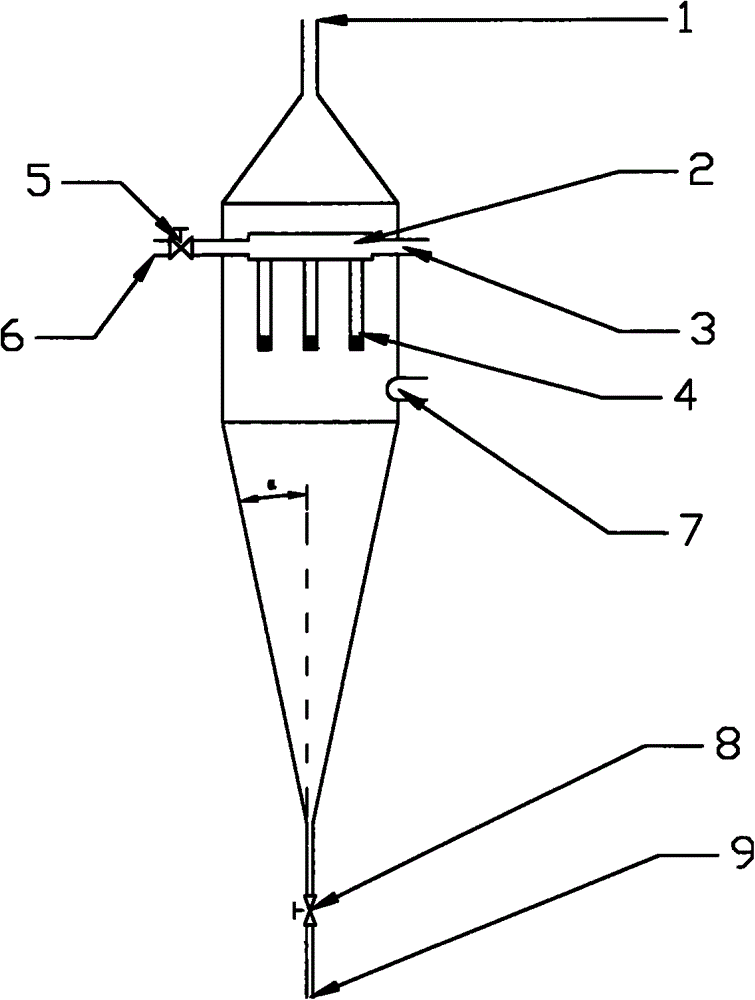

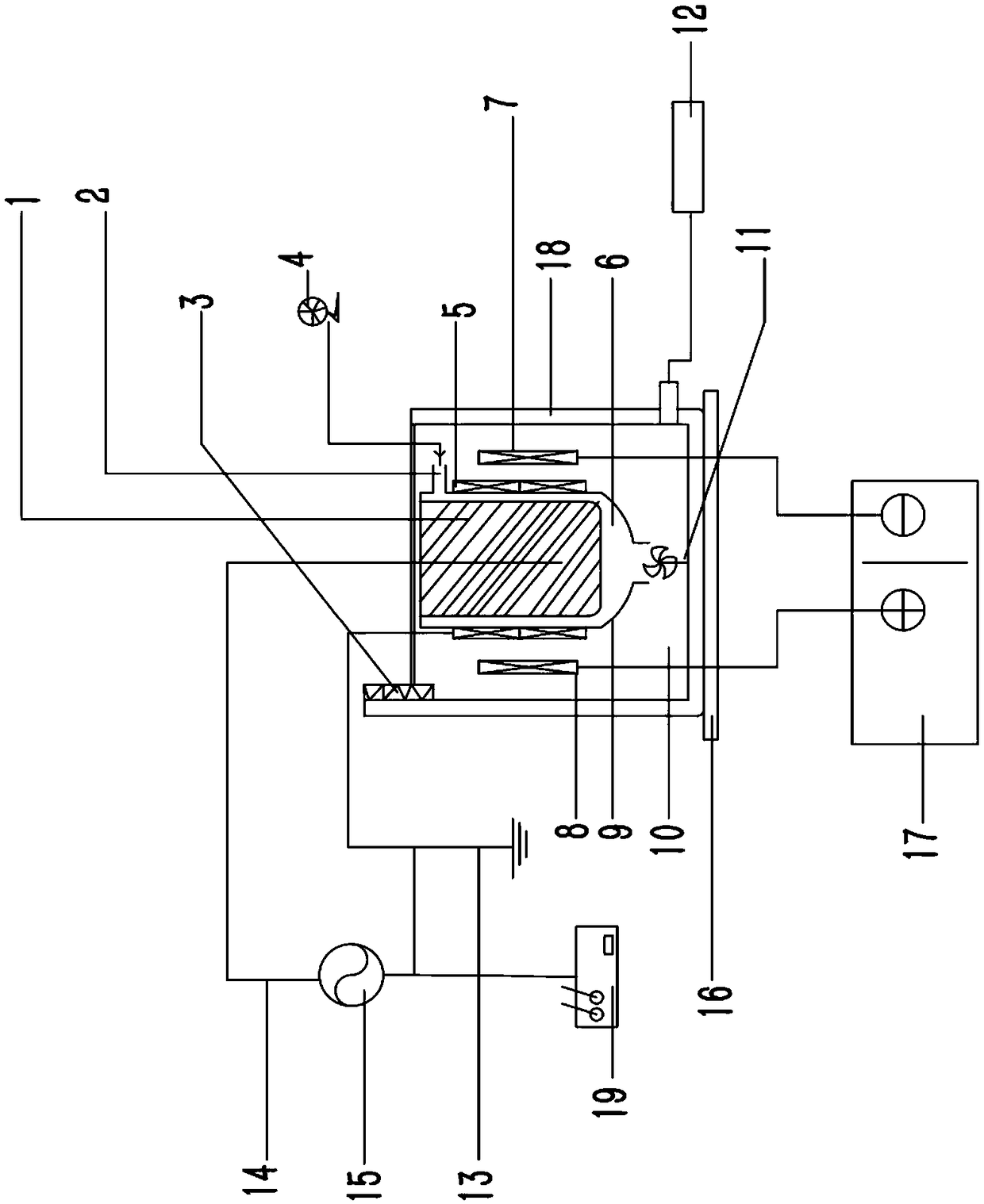

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995AThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustProcess design

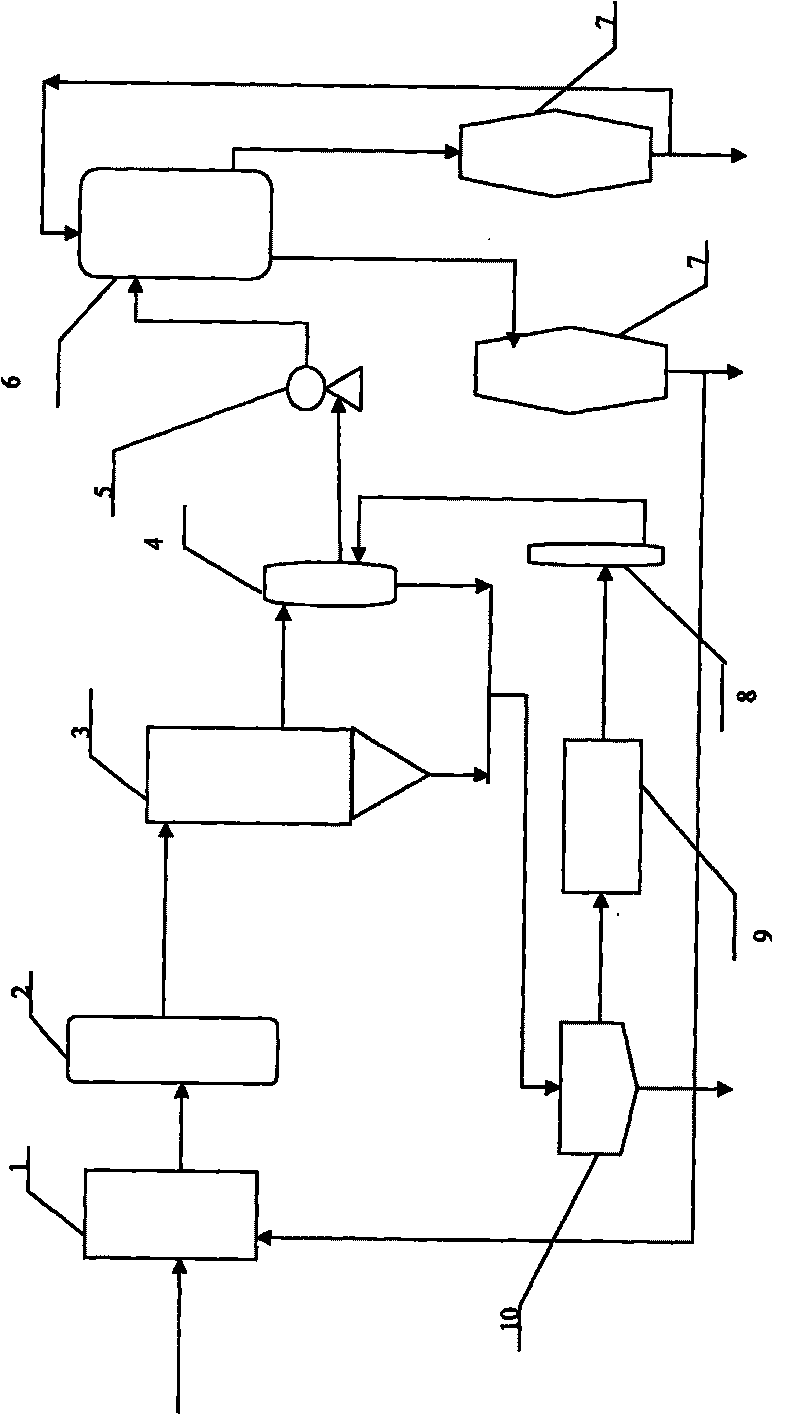

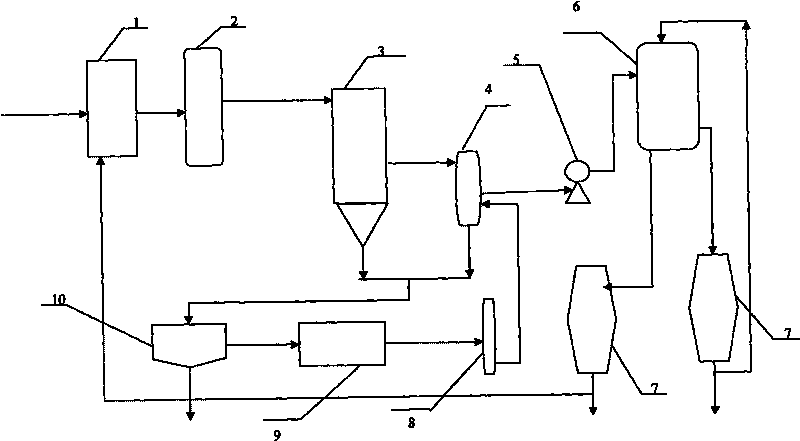

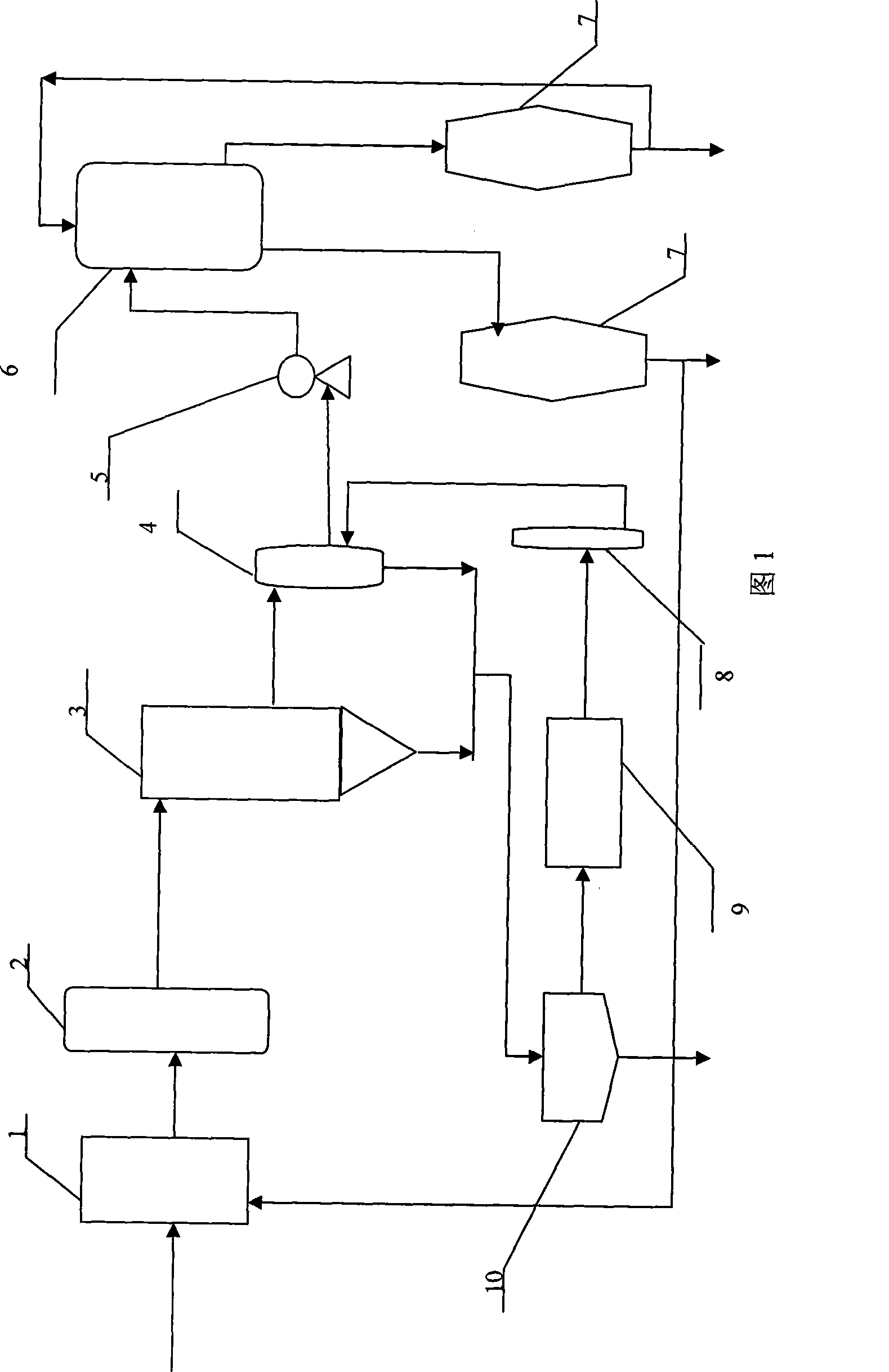

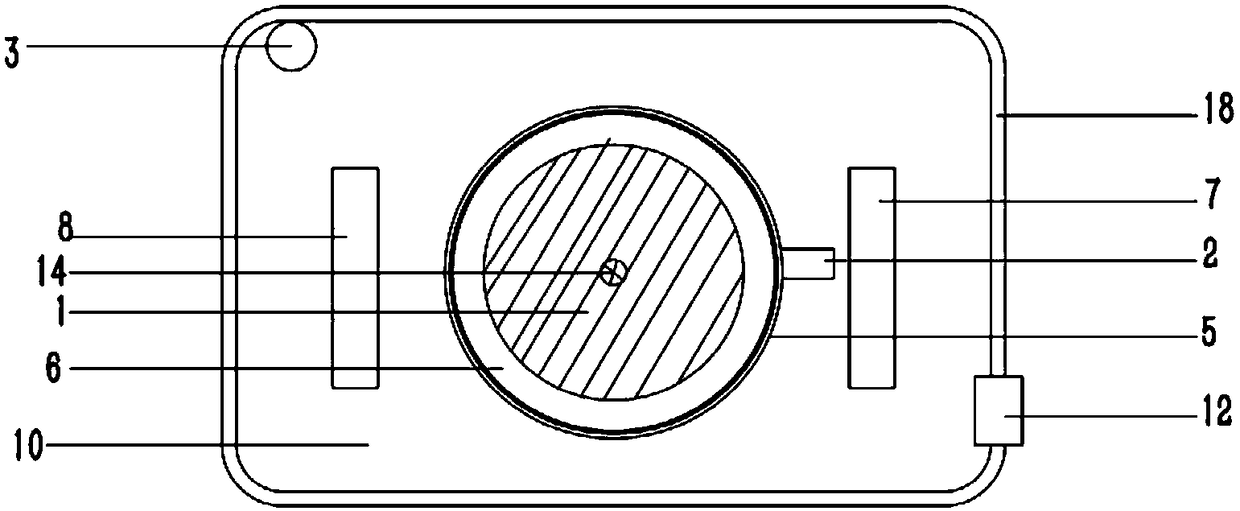

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

Distributed control type steam-light discharge process for desulfurizing fume by semi-wet method

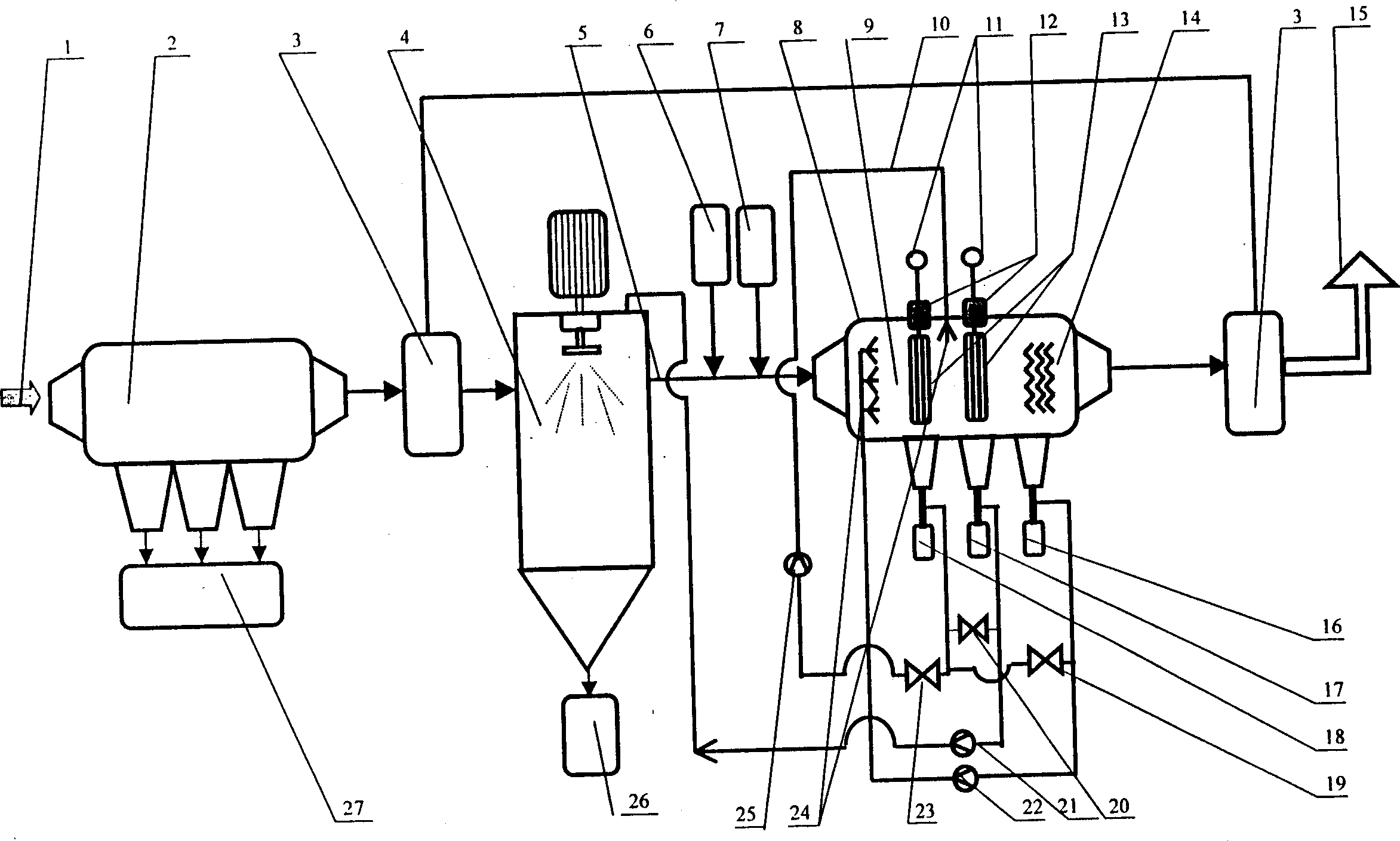

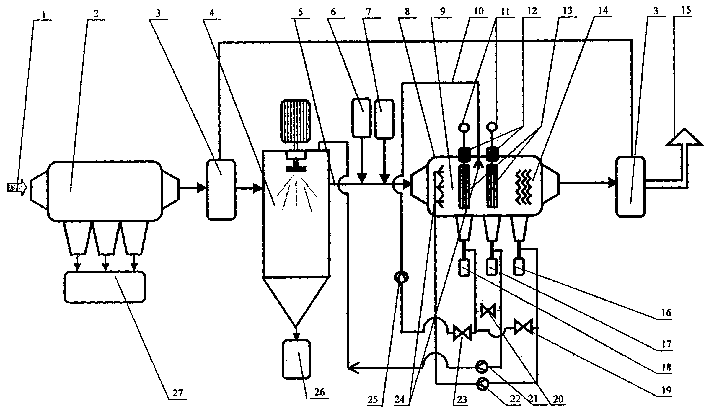

InactiveCN1390630ALow audio noiseOptimizing spatiotemporal distribution parametersDispersed particle separationLow noiseChemical reaction

A distributed control type stream-light discharge process for desulfurizing fume is disclosed. Its wet discharge reactor is composed of thermal chemical reaction region and discharge plasma chemical reaction region with discharging electrode and receiving electrode. Said discharging electrode is connected with high-voltage power supply to generate stream-light discharge. Said power supply is controlled in distributed mode. After boiler fume goes through thermal chemical reaction and discharge plasma chemical reaction, the gas pollutant is removed and the liquid by-product is generated and dried to obtain dry powder. Its advantages are high power and long service life of power supply, low noise, and low cost.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

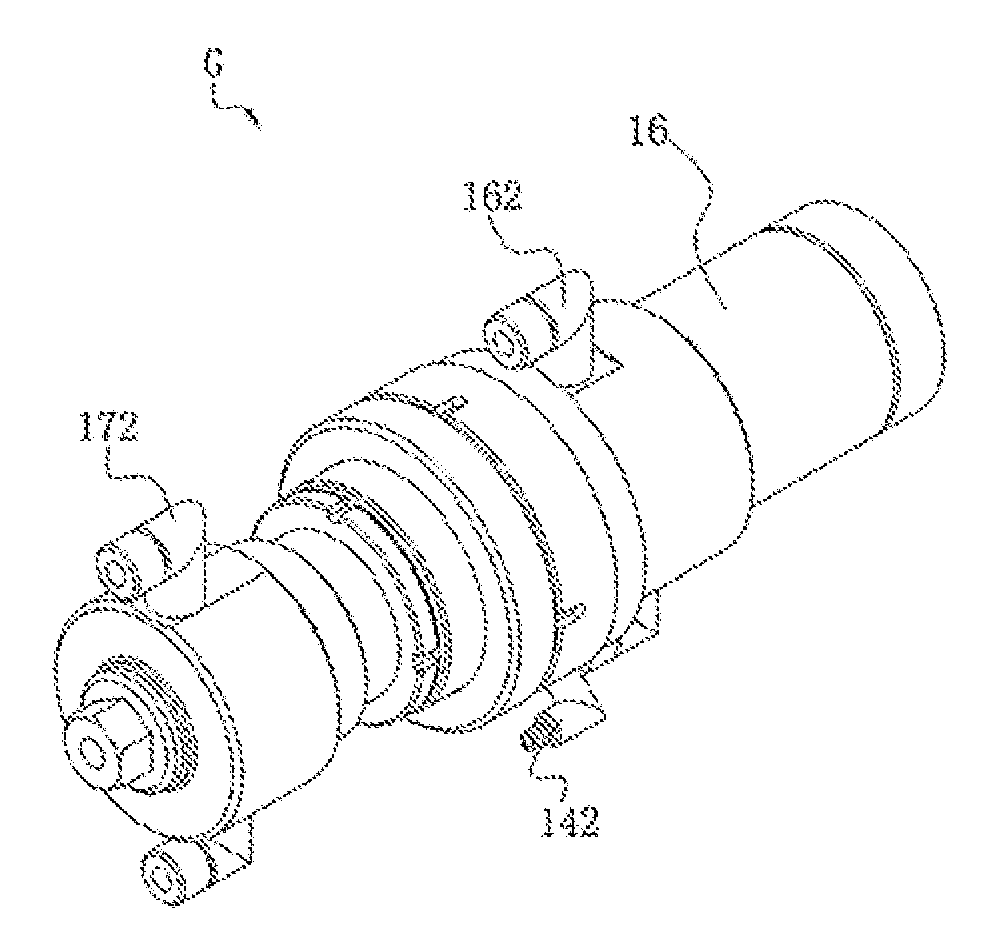

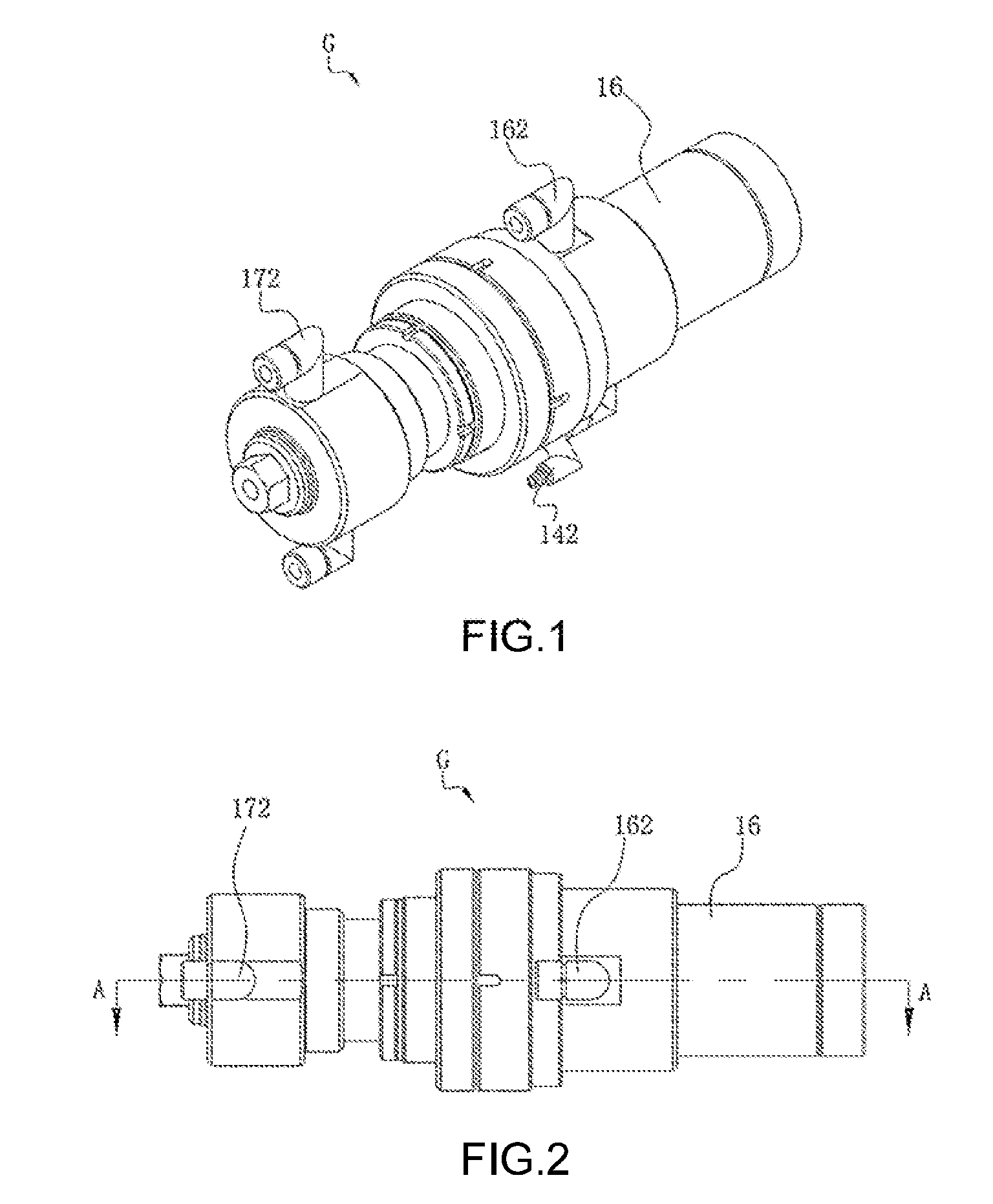

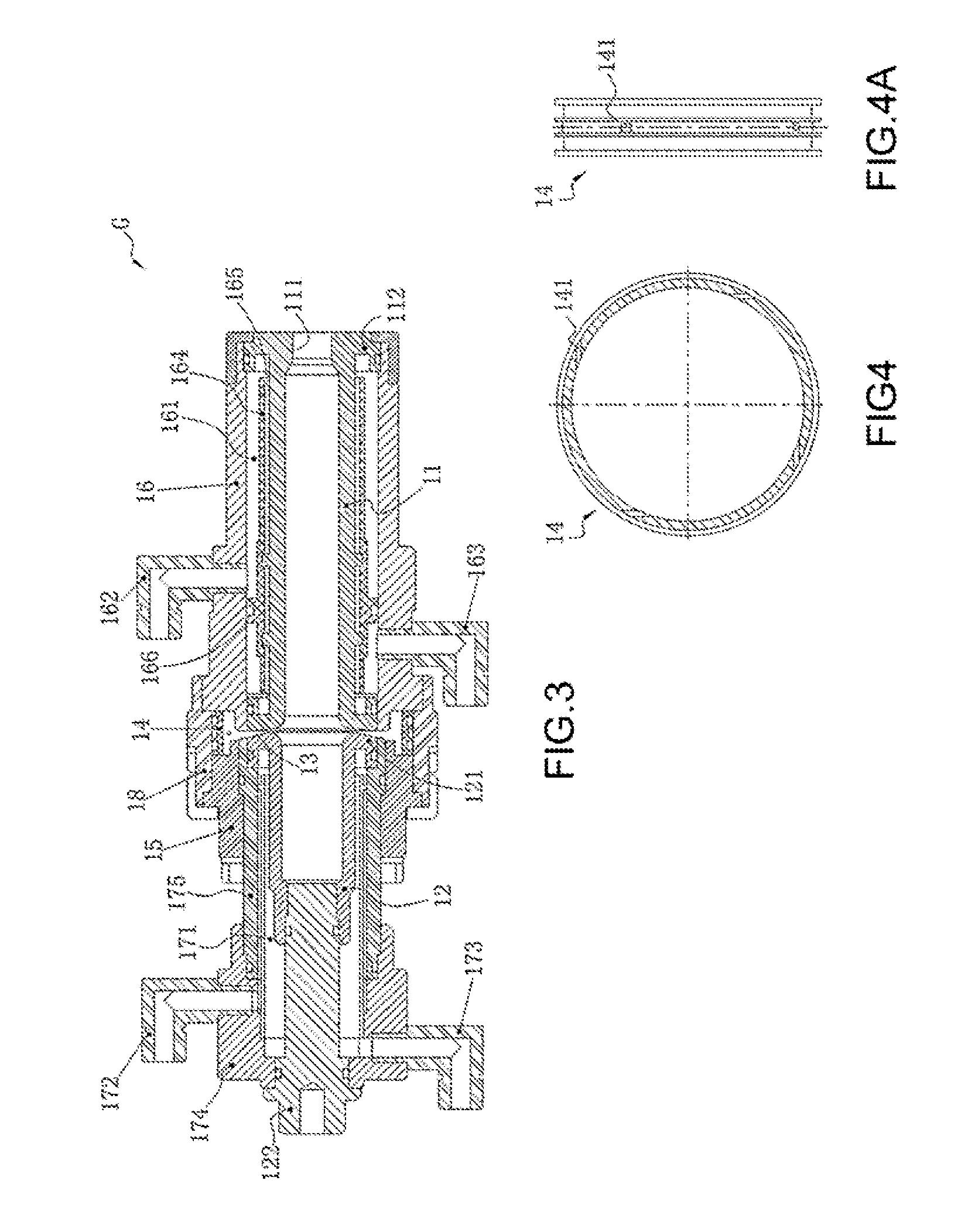

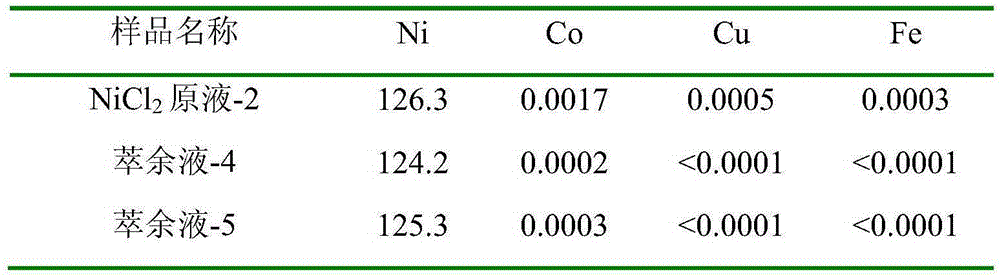

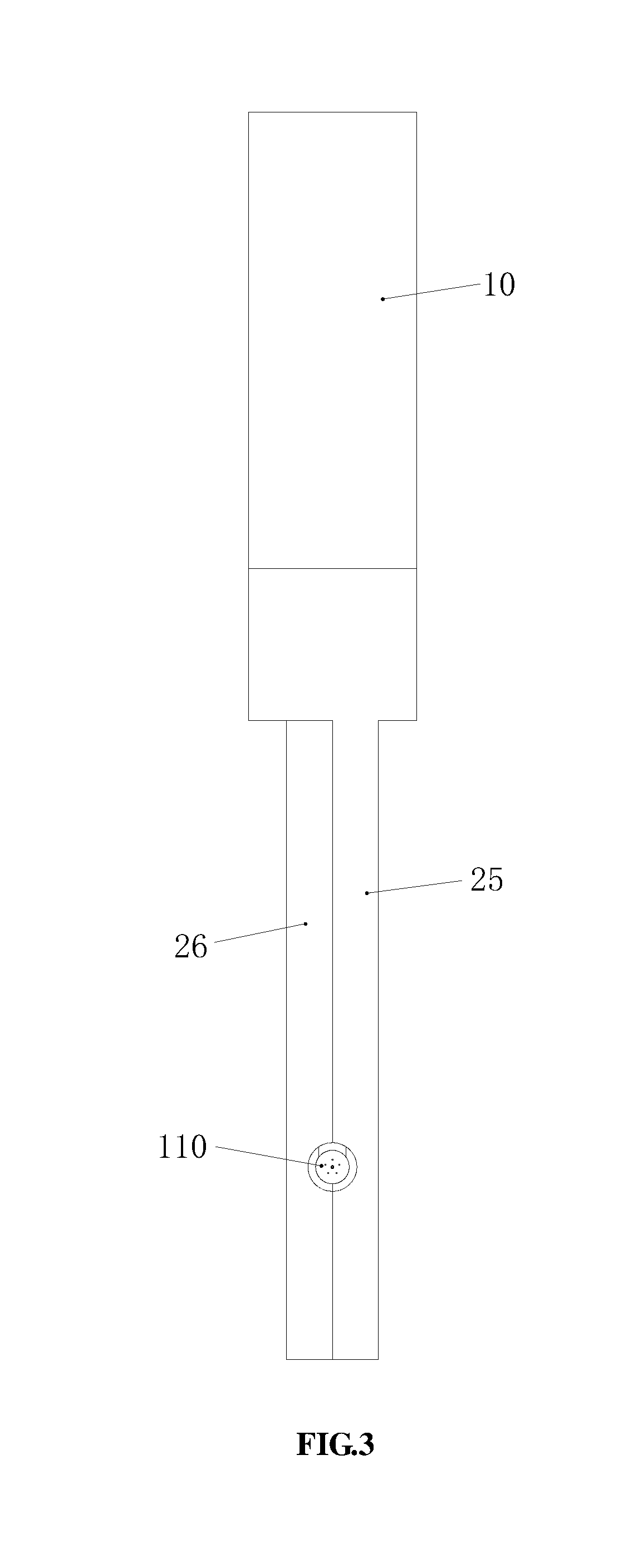

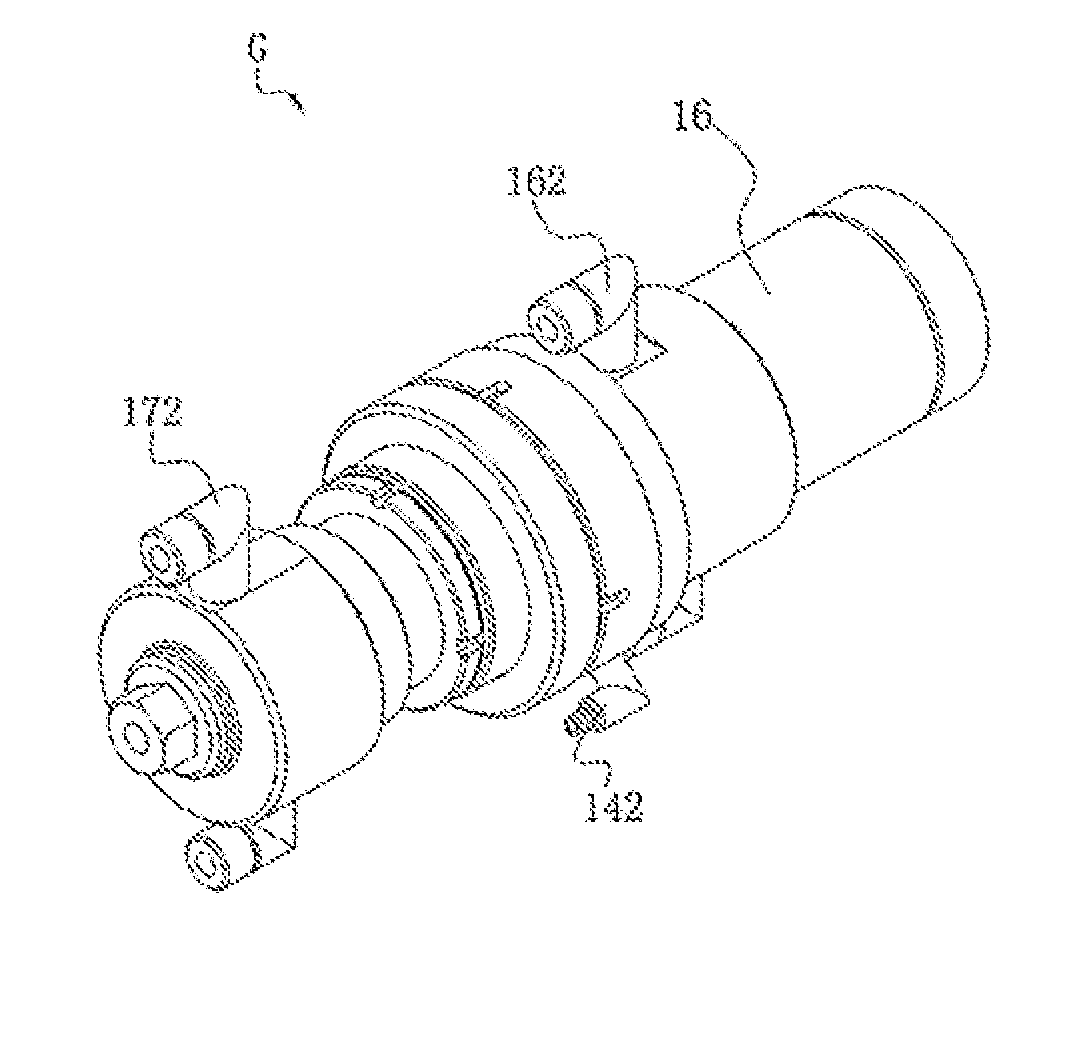

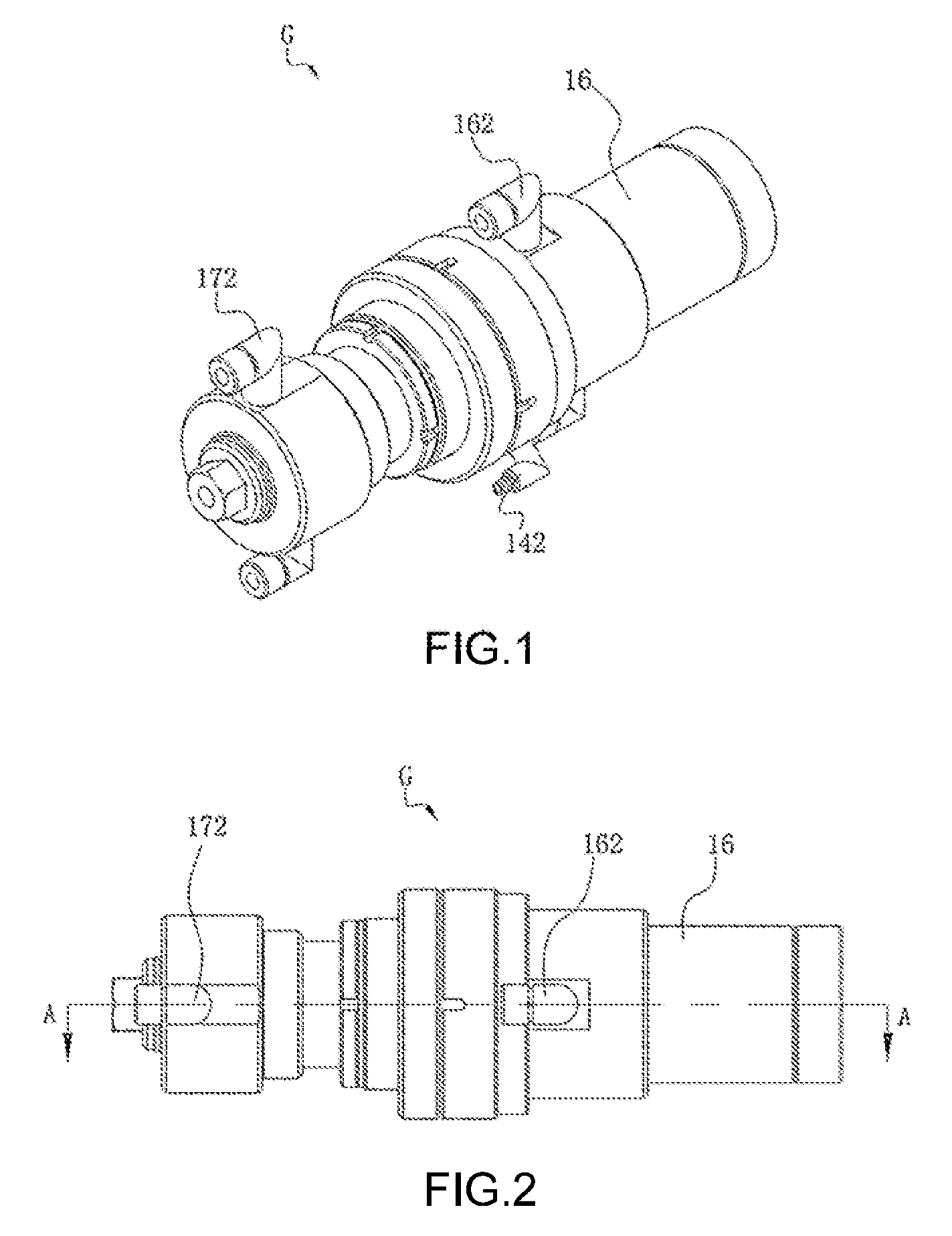

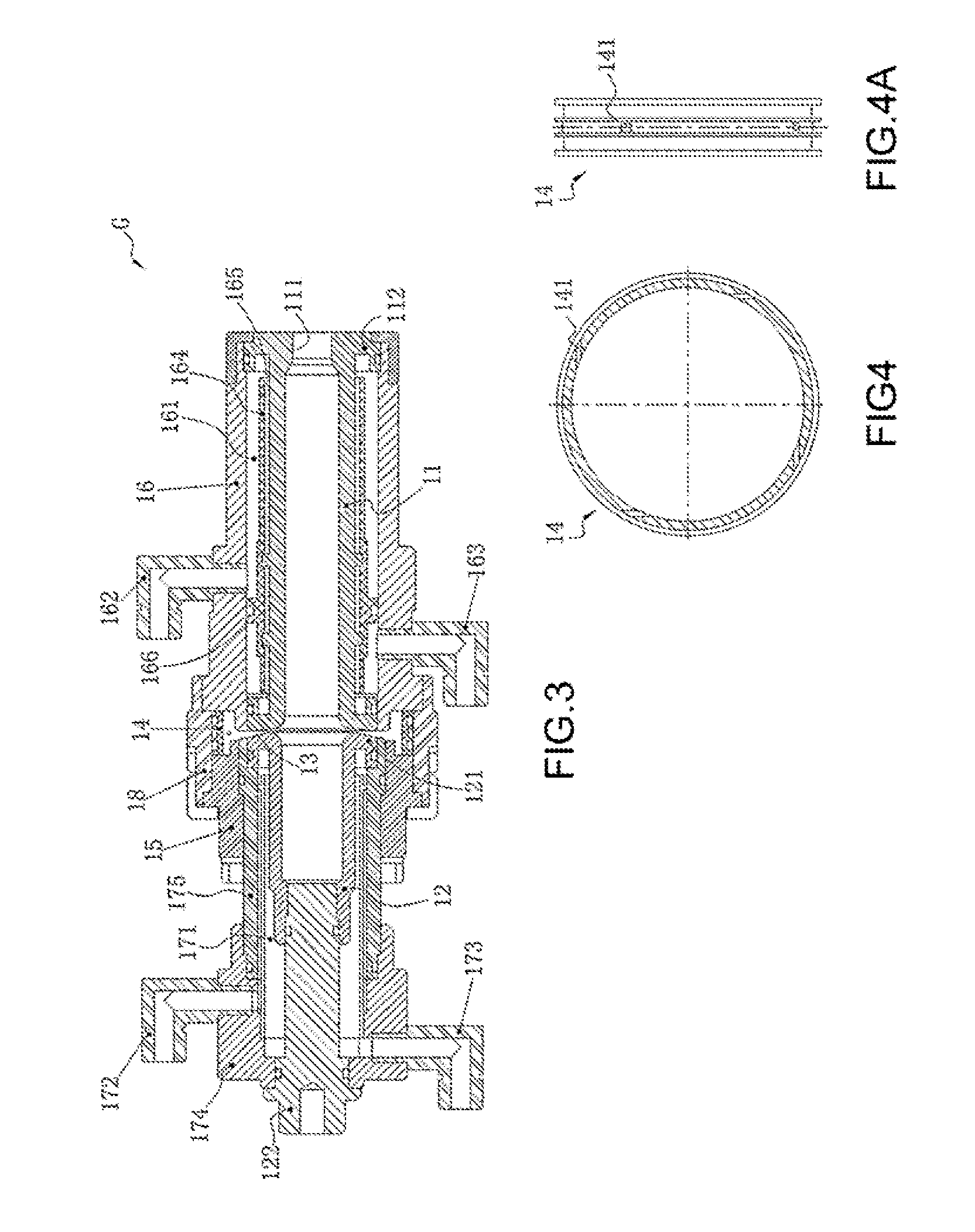

AC Plasma Ejection Gun, the Method for Supplying Power to it and Pulverized Coal Burner

ActiveUS20100300335A1Small currentIncrease motivationPulverulent fuel combustion burnersSolid cathode detailsElectricityEngineering

An AC plasma ejection gun, the method for supplying power to the gun and a pulverized coal burner are provided. The ejection gun comprising: a power supply device, having a live wear and a null wear; an electric front electrode, inside of which a front chamber is set, a nozzle connected with said front chamber is set at the outlet of the front electrode, an air inlet pipe connected with said front chamber is set at the inlet of the front electrode, and the front electrode is connected with said null wire; an electric rear electrode, connected with the inlet of said front electrode by an insulated ring, there is a gap between the electric rear electrode and said front electrode, said rear electrode is connected with the live wire, a spinning air inlet ring is set at the outside of the gap between said front electrode and said rear electrode, compressed air from the air inlet pipe passes the spinning air inlet ring and enters into the front chamber; wherein, the arc between said front electrode and said rear electrode discharges, ionizing the compressed air into plasma in the gap between said front electrode and said rear electrode, and the plasma is ejected out of the nozzle from the front chamber. The ejection gun in present invention can work with small current and large power, so that the life of the plasma ejection gun is prolonged.

Owner:BEIJING GUNGYAO ELECTRICITY EQUIP CO LTD

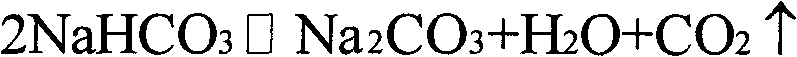

Preparation method of nano SiO2

InactiveCN102633267AReduce manufacturing costEmission reductionSilicaNanotechnologyOrganic solventNano sio2

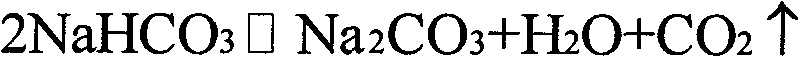

The invention discloses a preparation method of nano SiO2. The preparation method is characterized by taking soluble silicate M2O.nSiO2 and hydrocarbonate MHCO3 as raw materials to obtain hydrate SiO2 through precipitation, separating out filtrate through filtration, then washing the filter cake, displacing the filter cake with an organic solvent and drying and grinding the product to obtain the nano SiO2 product, wherein the filtrate mainly contains carbonate M2CO3 and little hydrocarbonate MHCO3; and M in the soluble silicate M2O.nSiO2, hydrocarbonate MHCO3 and carbonate M2CO3 is an alkali metal Na or K. The preparation method has the following beneficial effects: the filtrate mainly contains carbonate M2CO3 and little hydrocarbonate MHCO3 and the reaction raw materials can be obtained through different processing modes, so the materials can be recycled, thus the preparation cost is reduced, fewer resources are consumed, emission is reduced, and the problems of environmental pollution and the like because plenty of inorganic acids need to be consumed in the prior art are avoided.

Owner:ZHEJIANG YUDA CHEM IND

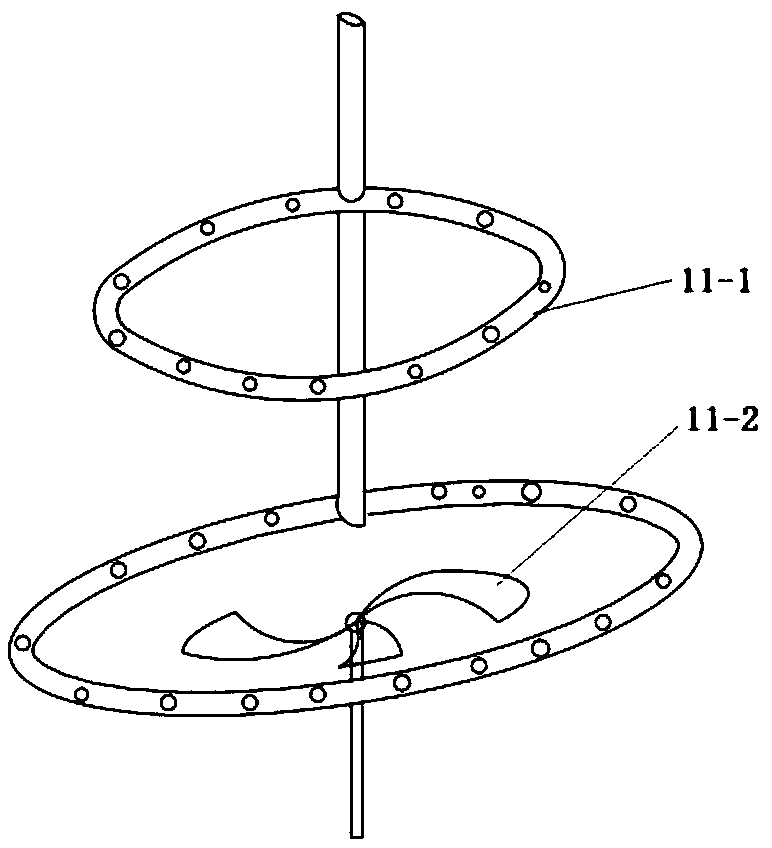

Multi-Pitch Screw, And Manufacturing Method And Manufacturing Apparatus Of Multi-Pitch Screw

InactiveUS20080010807A1Difficult to manufactureRolled easily and efficientlyAutomatic/semiautomatic turning machinesNutsScrew threadHelix

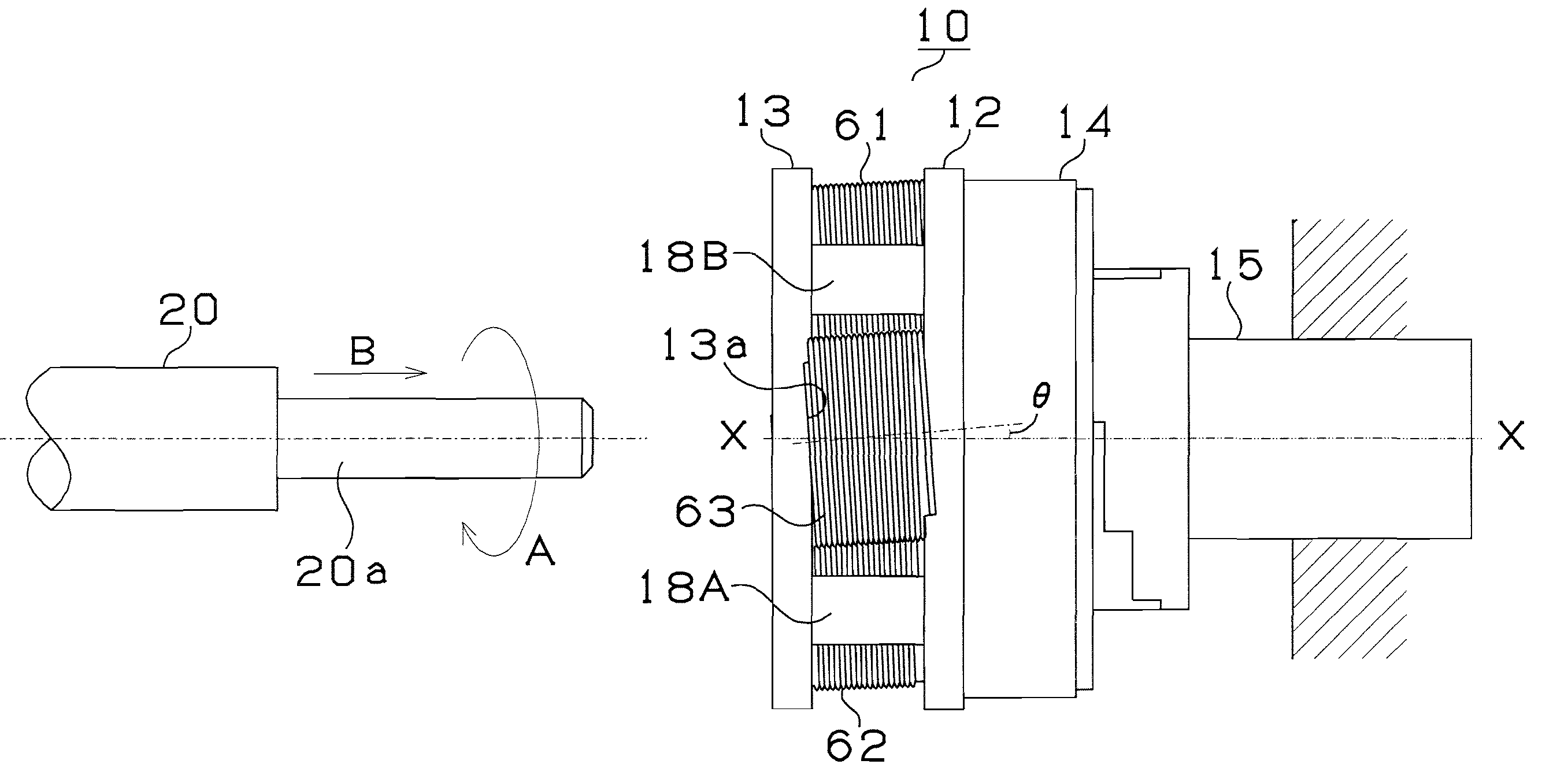

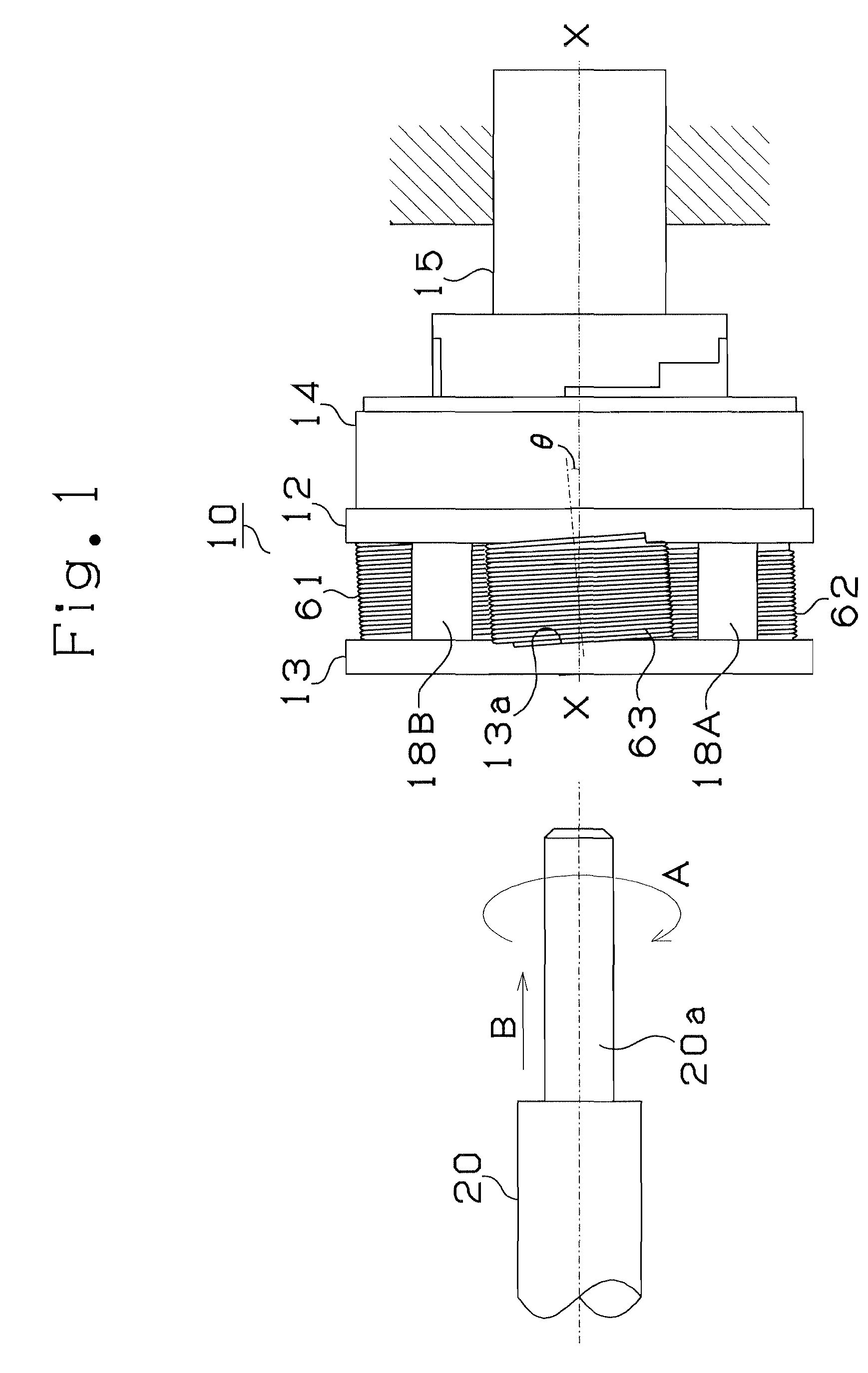

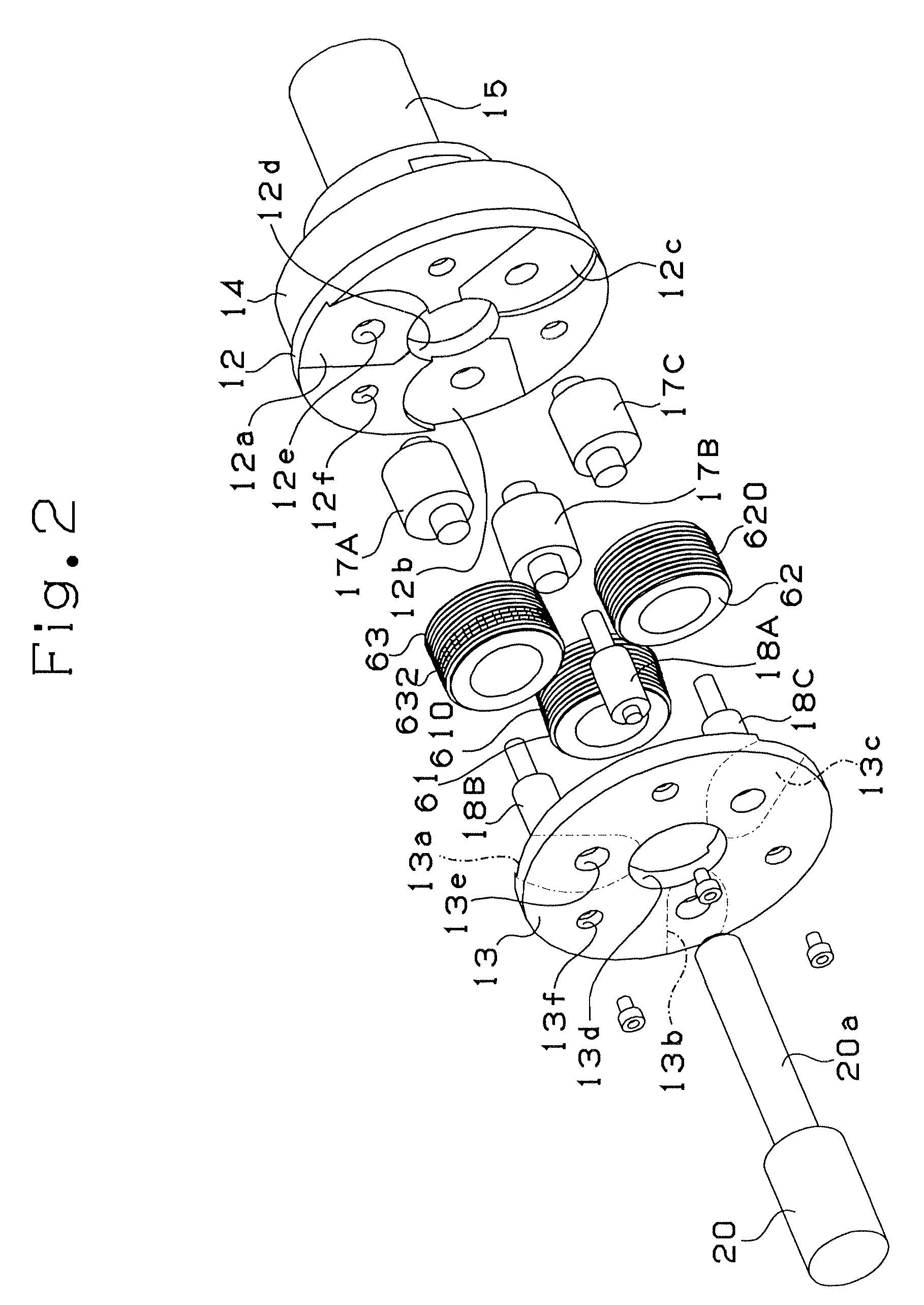

The invention presents a method of manufacturing a multi-pitch screw having desired threads and pitches by rolling. A trace of general (even lead angle) spiral screw is formed by even pitch protrusions 610 and 620 of an existing rotating dies 61 and 62, and it is combined with a trace of stair step screw formed by stair step protrusions 632 of a rotating die 63 of uneven lead angle, and multi-pitch screw threads are formed efficiently. Herein, only one rotating die 61 of uneven lead angle is used, and screw threads are not flattened out by stair step protrusions of the plurality of rotating dies of uneven lead angles.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

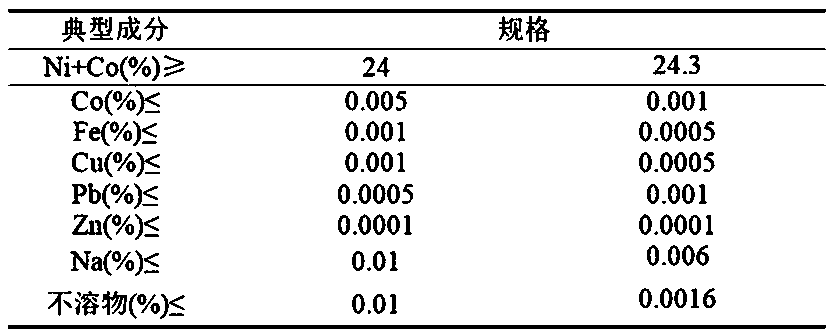

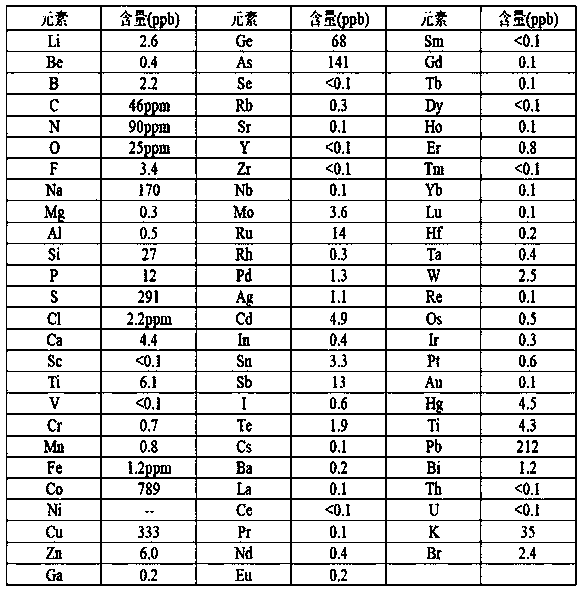

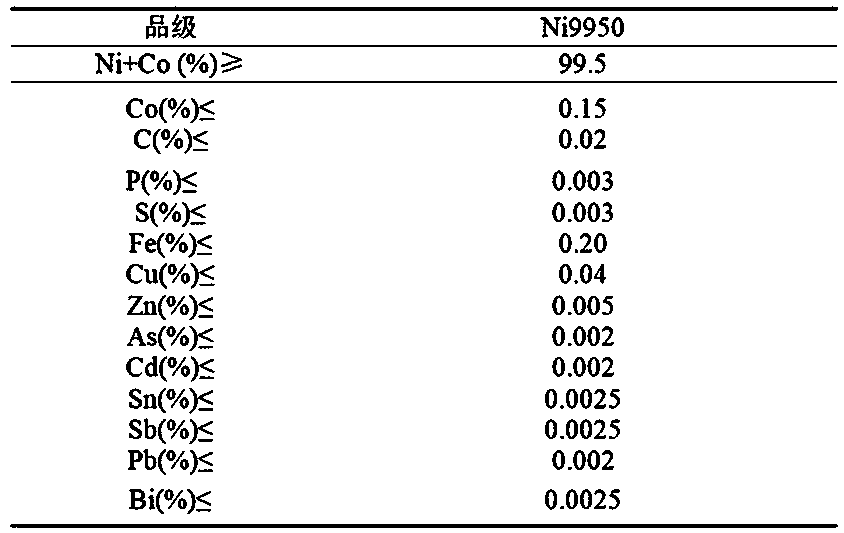

Purification method for nickel electric accumulated liquid for manufacturing high-purity nickel plate

InactiveCN105349780ASimple processGood effect of removing impuritiesPhotography auxillary processesProcess efficiency improvementPurification methodsOrganic solvent

The invention provides a purification method for nickel electric accumulated liquid for manufacturing a high-purity nickel plate, relates to high-purity nickel plate manufacturing, in particular to a purification method for a nickel solution for manufacturing the high-purity nickel plate. The method is characterized in that the nickel electric accumulated liquid for manufacturing the high-purity nickel plate is a nickel chloride solution, and an organic solvent extraction method is adopted for purifying the nickel chloride solution for manufacturing the high-purity nickel plate till the content ratio of nickel and cobalt in the solution is larger than 400000. The sample purity of the a high-purity nickel plate produced through the electric accumulated liquid purified through the method is 99.999%, the content of the cobalt and the content of the nickel are both smaller than 1 ppm, and the content of iron is smaller than 2 ppm. By the adoption of the method, the process is simple and feasible, the product quality is high, and stability is good; and the nickel chloride solution with impurities removed meets the requirements for manufacturing high-purity nickel and producing other high-purity nickel products.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

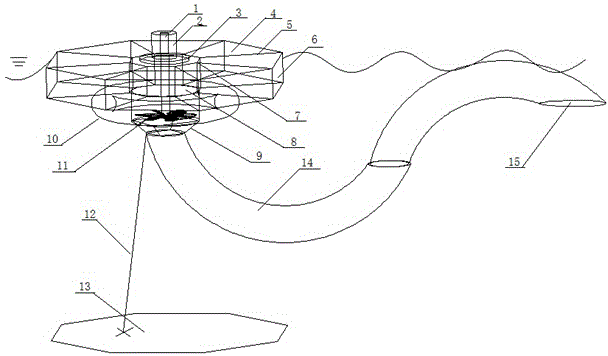

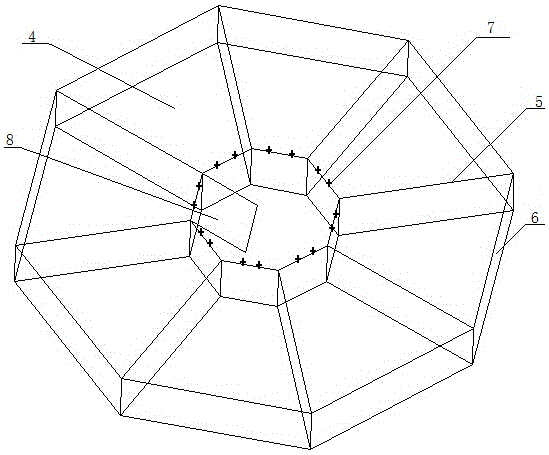

Vertical axis wave energy power generation device

InactiveCN104806435AImprove conversion efficiencyContinuous and stable processHydro energy generationMachines/enginesWater flowIncident wave

The invention discloses a vertical axis wave energy power generation device. The vertical axis wave energy power generation device comprises a rotary shaft, a power generator, a flow guide device, an inner cavity and blades, wherein the flow guide device has a flow guide acceleration effect and can accept waves with different inflowing directions; the inner cavity is arranged under the flow guide device and is used for accepting a water flow from the flow guide device; the rotary shaft is fixedly connected with a central rotary shaft of the power generator and the blades are fixed on the rotary shaft along the peripheral direction; the blades are located in the inner cavity and can rotate in a single direction along the center of the rotary shaft under the action of the water flow, and the water flow with the different inflowing directions is converted into the water flow with the single direction, so that the rotary shaft is driven to enable the power generator to work. By virtue of the special flow guide device, the seaborne arrangement of the device is unrelated to an incident wave direction; the blades drive the rotary shaft to rotate so as to directly drive the power generator to generate power; the conversion efficiency of wave energy can be effectively improved, the electric energy output is continuous and stable, and a lot of construction costs are reduced; an S-shaped tail water pipe is arranged so that the power generation efficiency can be improved.

Owner:HOHAI UNIV

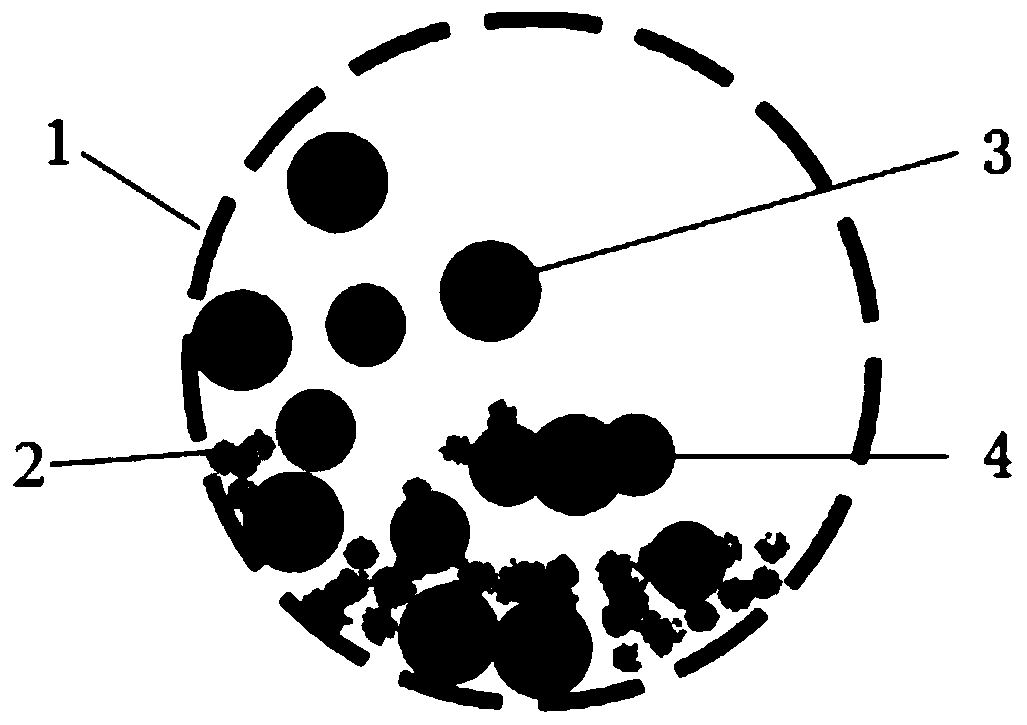

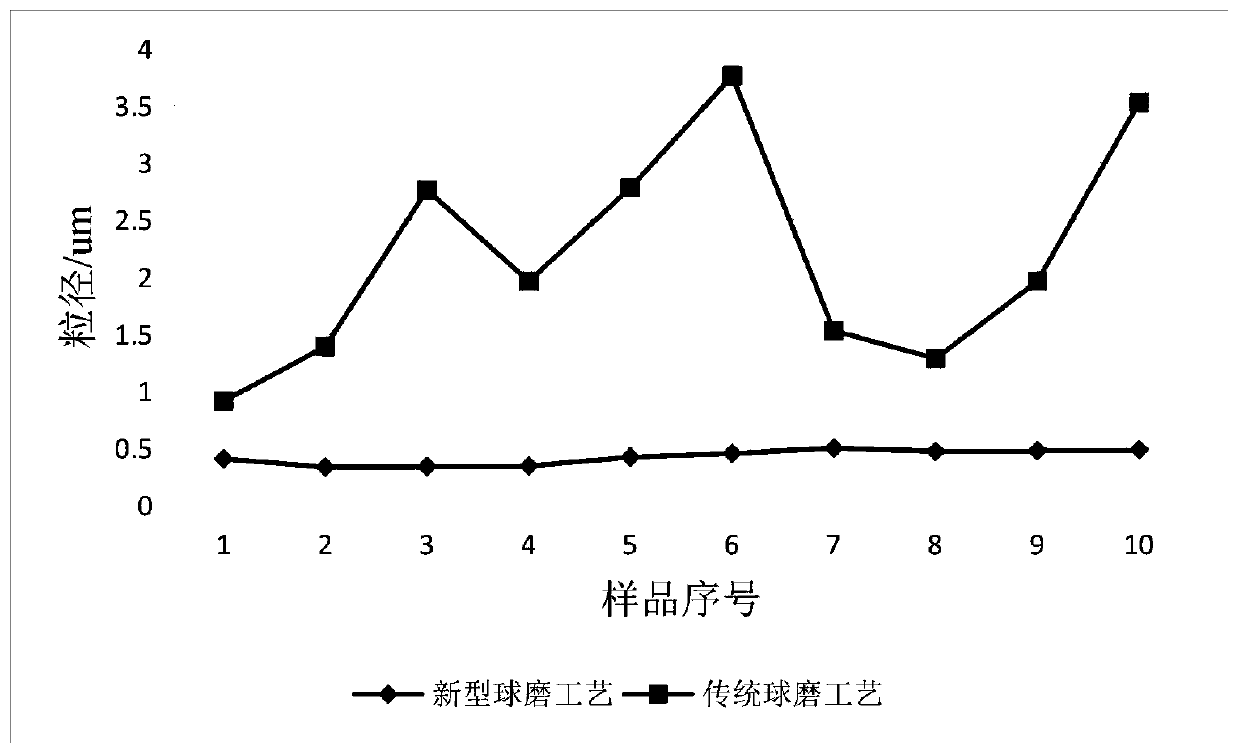

Method for preparing nano-powder by ball milling

The invention relates to the technical field of nano-powder materials, and provides a method for preparing nano-powder by ball milling. According to the method, a raw material is ground and stirred byusing grinding balls with different hardness in a ball milling process; the reaction activation energy can be obviously reduced; grains can be refined; the activity of the powder can be enhanced; thesintering capacity can be improved; finally, micro-raw material powder is crushed into the nano-powder; the obtained nano-powder is stable in quality, uniform in particle size and high in conglomeration rate, has high apparent density, can ensure smooth progress of subsequent forming and sintering processes of the nano-powder, and realizes continuous stable industrial production; and in addition;and the method provided by the invention does not require two-step ball milling, and is easy to operate and low in energy consumption.

Owner:SHANGHAI UNIV

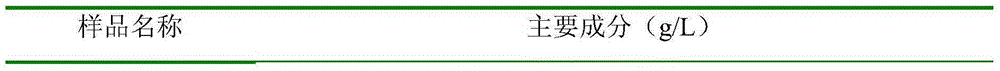

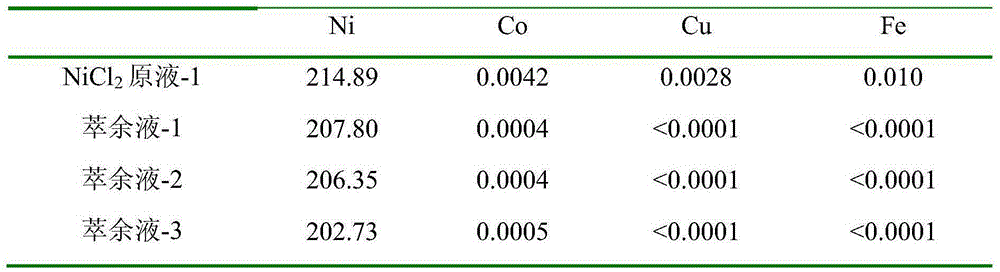

Removal method of trace cobalt in nickel chloride solution

InactiveCN109518006ASimple processGood effect of removing impuritiesPhotography auxillary processesProcess efficiency improvementSolventCopper

The invention provides a removal method of trace cobalt in a nickel chloride solution. A solution obtained through 99.95% nickel board electrodissolution is adopted as the nickel chloride solution ora commercially available pure nickel chloride crystal is used for preparing the nickel chloride solution; the nickel chloride solution is subjected to extraction deep purification through an extraction agent Cyanex272 matched with solvent oil with the proper proportion, and cobalt, copper and iron are removed; after impurity removal, the pure nickel chloride solution is obtained, the content of cobalt is reduced to 0.001 g / L, meanwhile, the content of copper and iron is reduced to 0.0001 g / L, and the aim of removing three impurity elements in one working procedure is achieved. The method is applied to the high-purity nickel production, the purity of the obtained nickel plate product is 99.999%, the contents of the cobalt and the copper are both smaller than 1 ppm, the content of iron is smaller than 2 ppm, the process is simple and easy to operate, the product quality is high, stability is good, industrial production is easy, and treatment capacity is large; the nickel chloride solution obtained after impurity removal can meet the need of preparing high-purity nickel and other high-purity nickel products.

Owner:JINCHUAN GROUP LIMITED +1

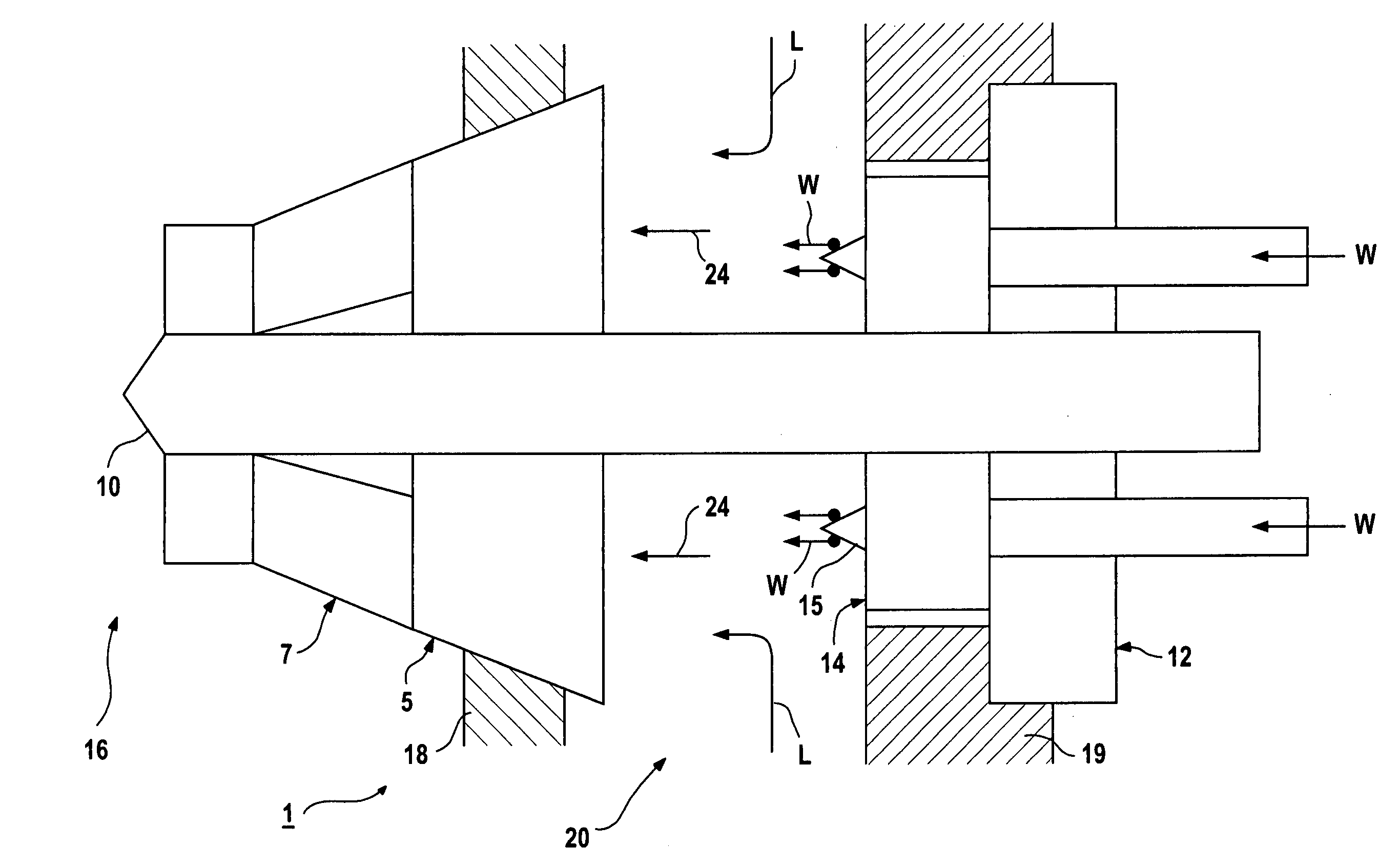

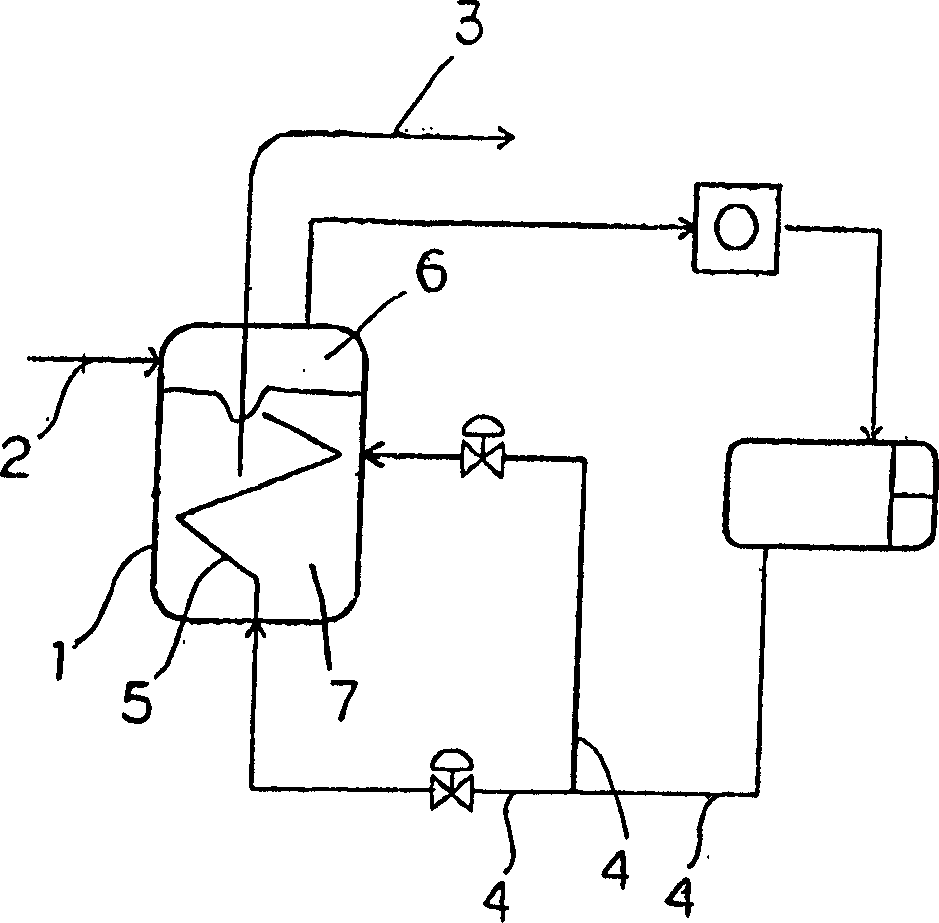

Method for operation of a burner and burner in particular for a gas turbine

InactiveUS7143582B2Avoids disadvantageContinuous and stable processBurnersContinuous combustion chamberAutomotive engineeringGas turbines

The invention relates to a method for operation of a burner, whereby a mixture used for burning is supplied to the burner in a two-stage process. In a first step atomised water is mixed with combustion air and said mixture is mixed with a fuel in a second step and then supplied to the burner. Said burner comprises means for carrying out the above method.

Owner:SIEMENS AG

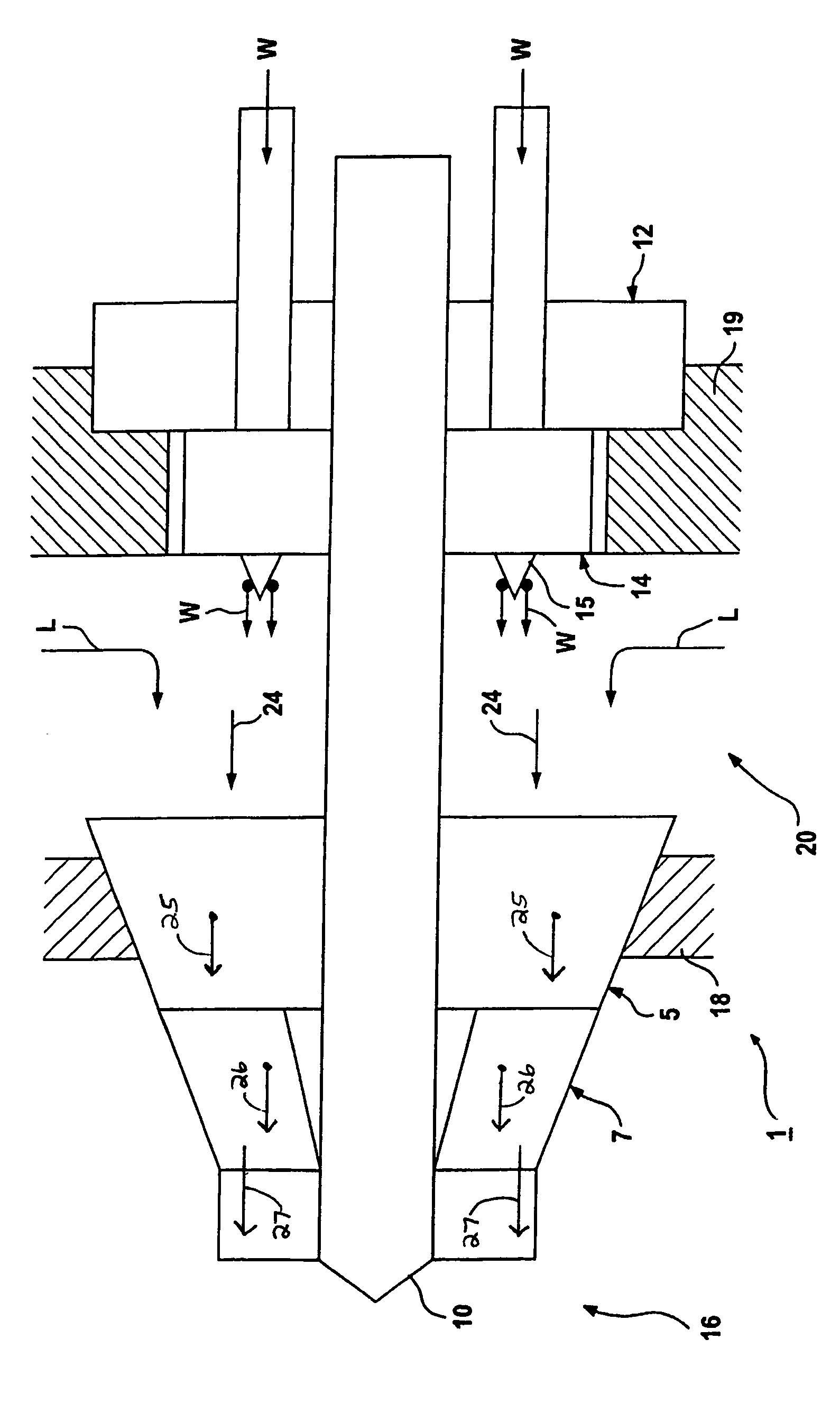

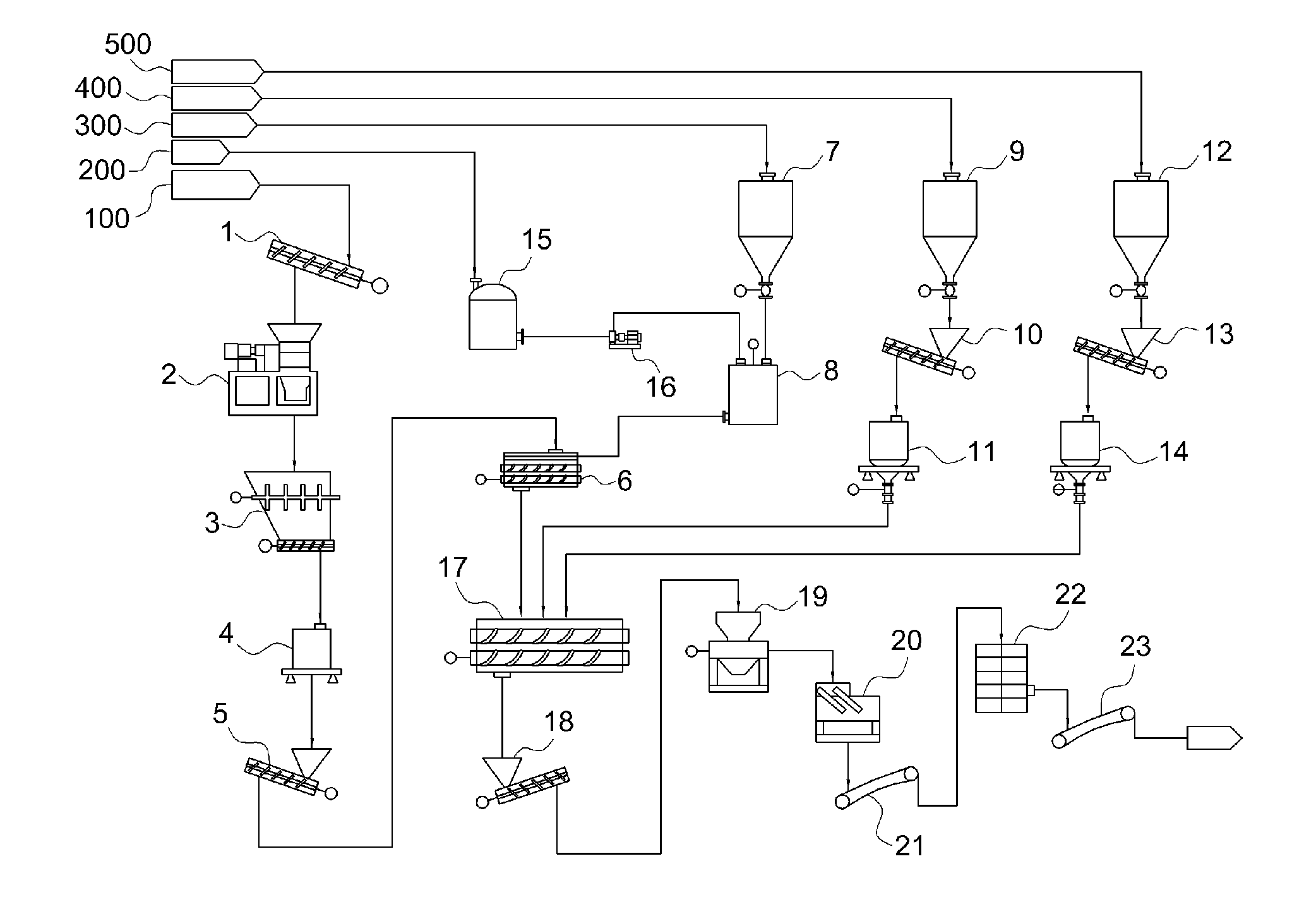

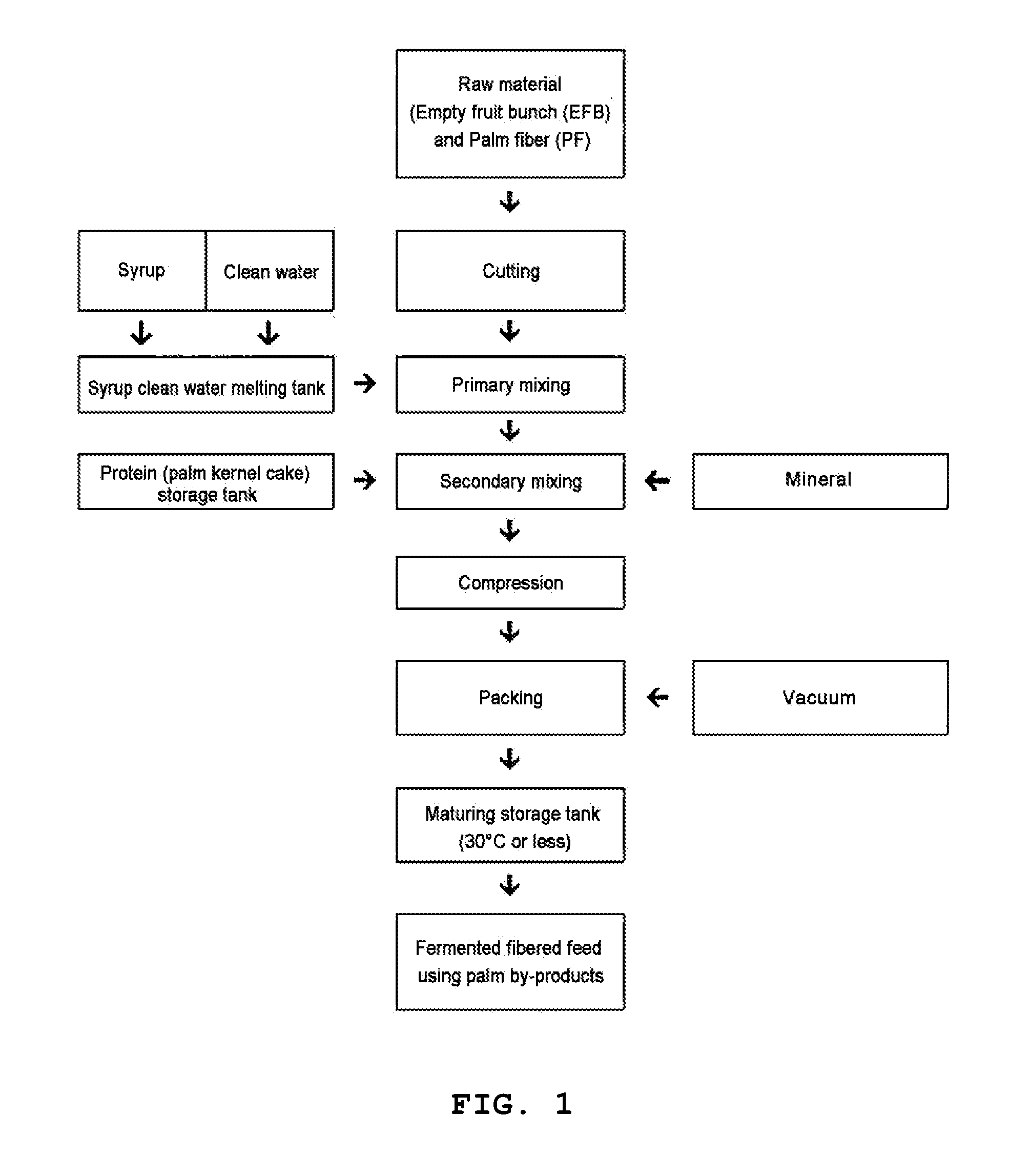

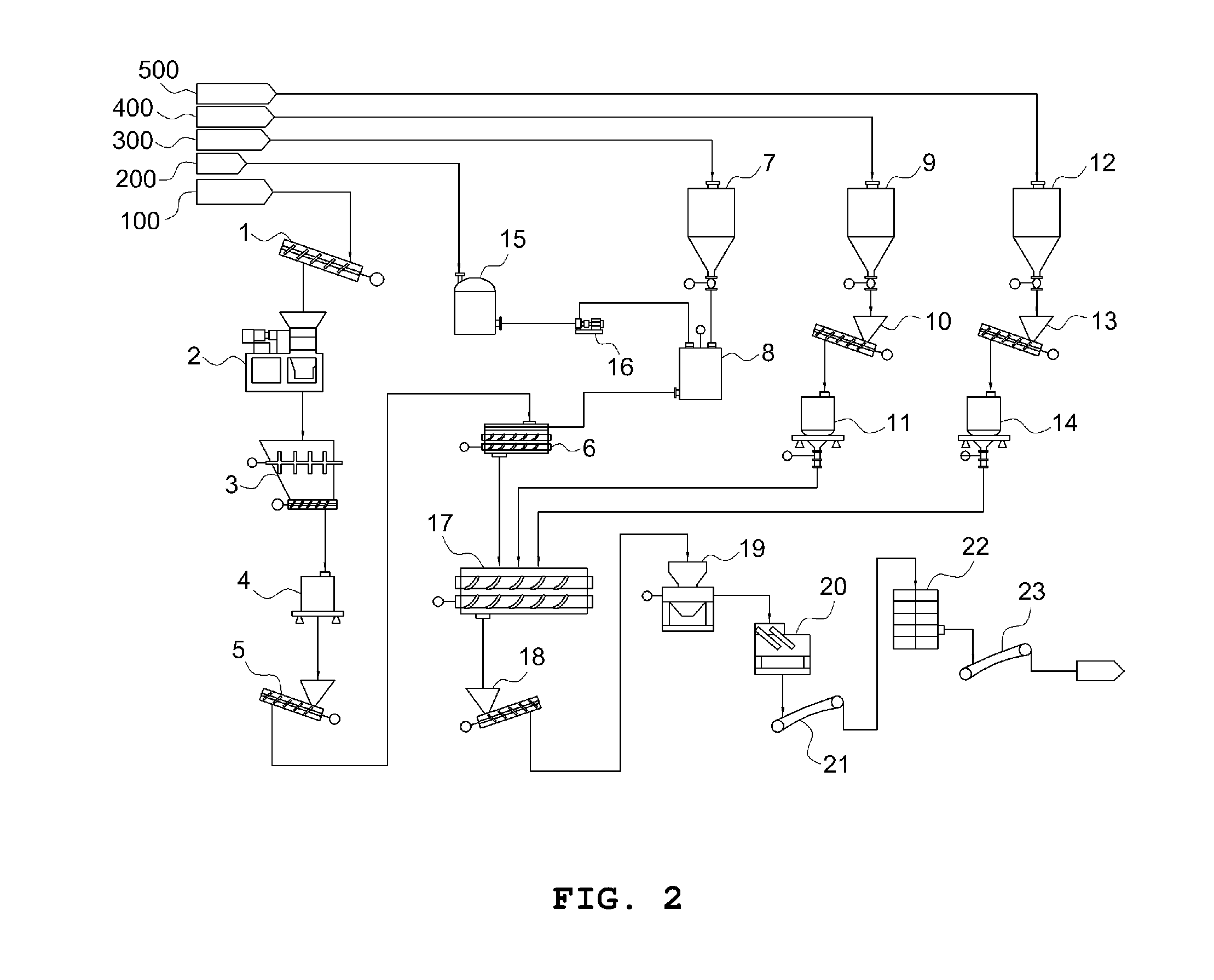

Equipment and method for producing fiber feed by using palm-processing by-products

ActiveUS20160192695A1Economical efficiency is highContinuous and stable processFeeding-stuffFood processingFiberSugar

The present invention uses empty fruit bunch (EFB) and fiber so as to crush and cut over a crushing process, adds water, adds soluble sugar and protein and mixes the same in an appropriate ratio, compresses the same to remove air, seals and leaves the same alone at a temperature of approximately 25 DEG C for at least 30 days, and supplies process-completed products as fiber and energy feed for ruminants.

Owner:BAE HEE DONG +1

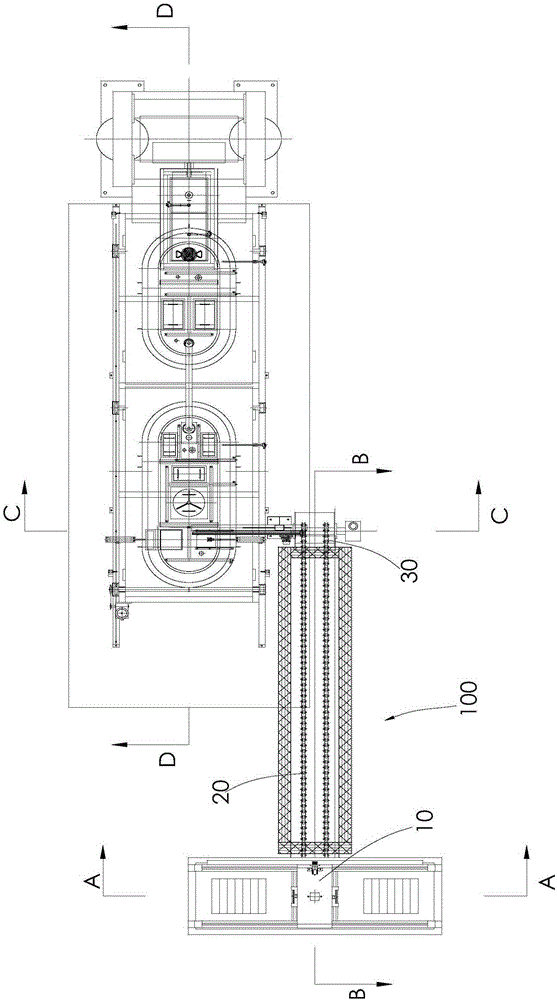

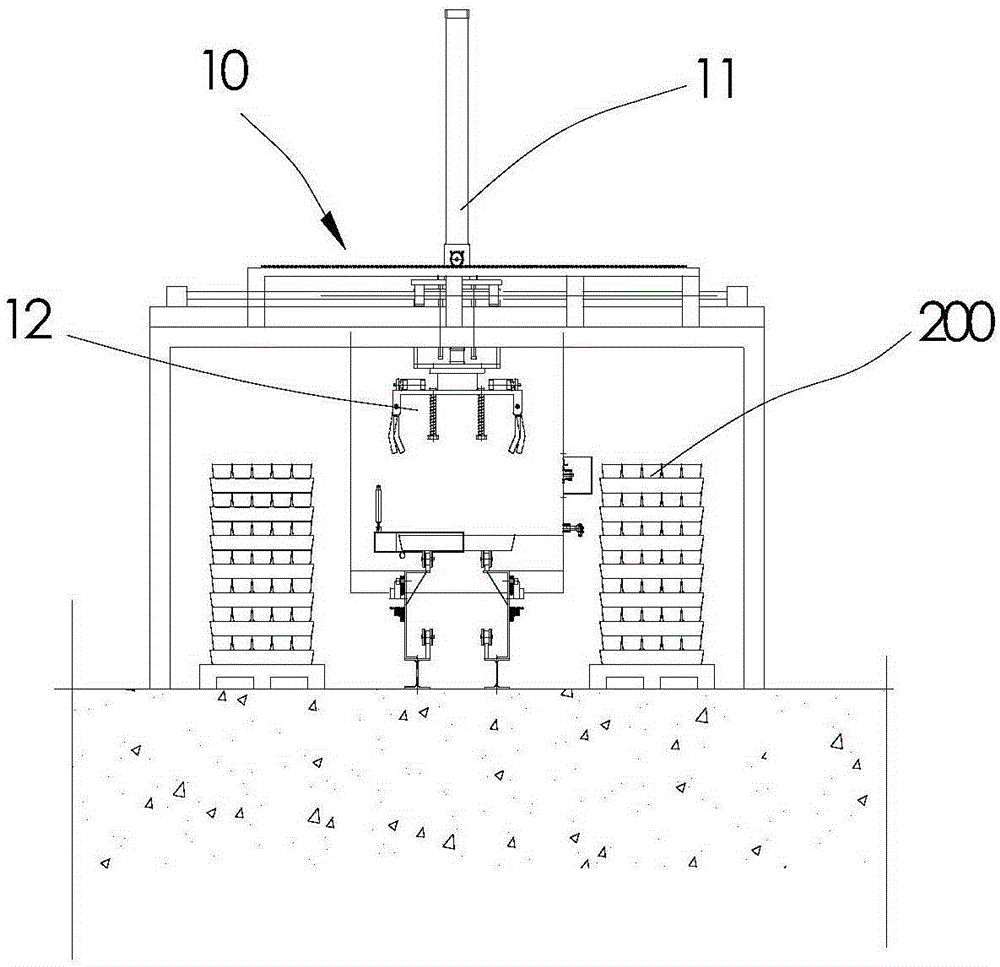

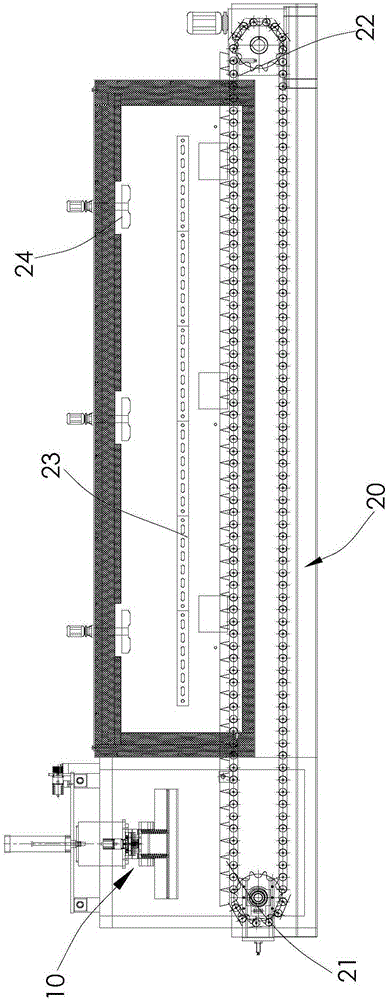

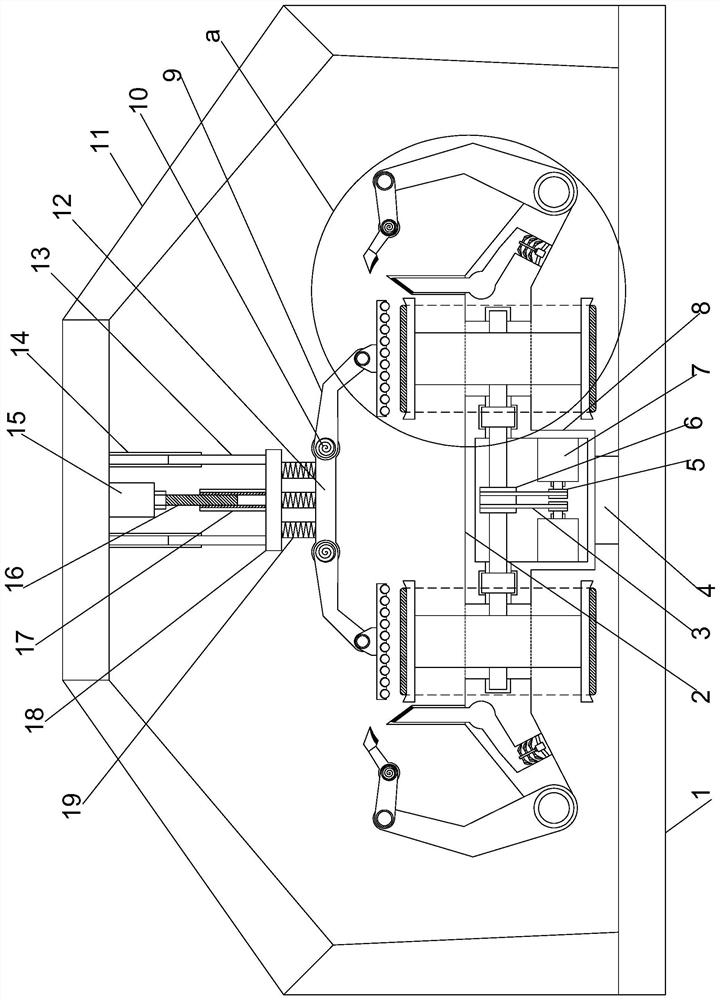

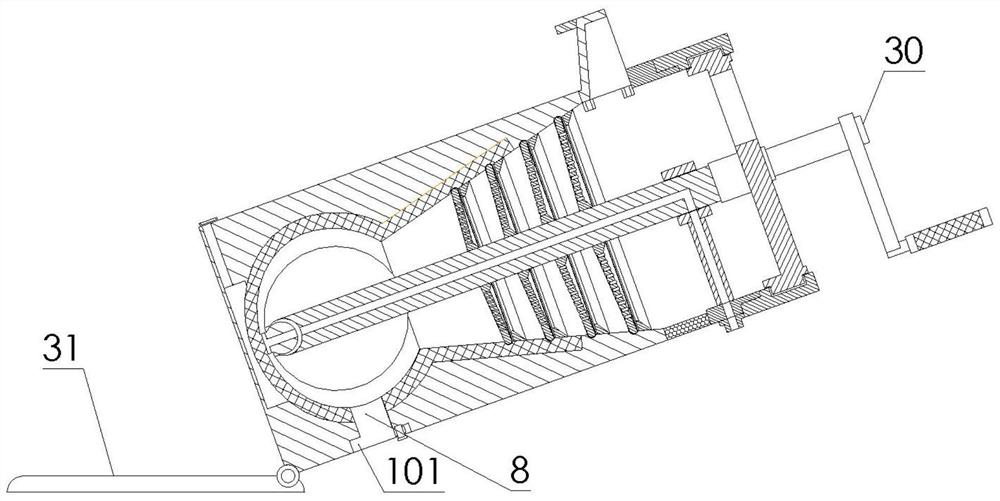

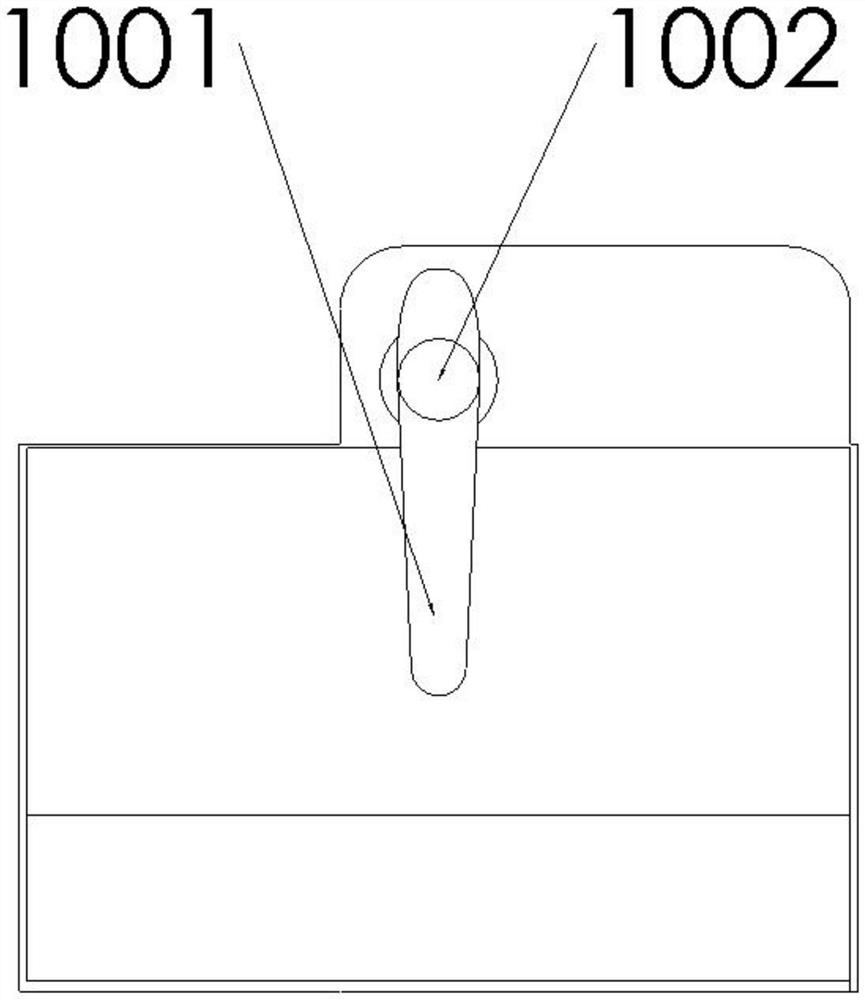

Automatic liquid supply device for magnesium alloy cast rolling

An automatic liquid supply device for magnesium alloy cast rolling comprises a cast rolling machine, a front liquid box, a heat preservation holding furnace, a melting furnace and a magnesium ingot conveying device. The front liquid box is used for storing magnesium liquid, and an outlet of the front liquid box is communicated with a casting mouth of the cast rolling machine. An outlet of the heat preservation holding furnace is communicated with an inlet of the front liquid box. The melting furnace and the heat preservation holding furnace are communicated through an automatic siphon. The magnesium ingot conveying device is used for conveying magnesium ingots to the melting furnace. According to the automatic liquid supply device for magnesium alloy cast rolling, the magnesium ingots are conveyed to the melting furnace by the magnesium ingot conveying device, the magnesium liquid sequentially passes through the melting furnace, the heat preservation holding furnace and the front liquid box to enter the cast rolling machine, the whole process is continuous and stable, the quality of a cast-rolled plate is improved, the labor intensity of workers is lowered, and production efficiency is improved; and real-time liquid supply control can be carried out over the melting furnace, the heat preservation holding furnace and the front liquid box, continuous liquid supply is achieved, and production efficiency, continuous production stability and production safety are improved.

Owner:CHINA MAGNESIUM IND

Deburring device for bamboo mat production capable of instantly recycling waste materials

InactiveCN111618970ASmooth transmissionPlenty of torqueMechanical surface treatmentCane mechanical workingAgricultural engineeringWaste material

The invention relates to the field of summer sleeping mat production, in particular to a waste instant recovery type bamboo summer sleeping mat production deburring device. The device comprises a horizontally-arranged supporting mounting plate, a supporting mounting frame is vertically arranged at the upper end of the supporting mounting plate, an operation mounting plate is horizontally arrangedover the supporting mounting plate, a transmission mounting cylinder is vertically and downwards arranged in the middle of the operation mounting plate, the lower end of the transmission mounting cylinder is fixed to the supporting mounting plate through a supporting mounting column, and through transmission driving of a synchronous belt, the device is sufficient in material guiding torque, stablein transmission and capable of achieving stable material guiding operation and two-stage rotating adjustment in cooperation with a material pressing structure above the device. The device has good angle adjustment and is matched with the limiting elastic rotating shaft, so that the deburring process is continuous and stable, the operation efficiency and quality are remarkably improved, meanwhile,machining waste can be sucked in and guided out in time through the air draft structure arranged right opposite to the device, and the tidiness of the operation face is guaranteed.

Owner:湖南省春龙竹艺有限公司

Drying equipment for Chinese herbal medicine

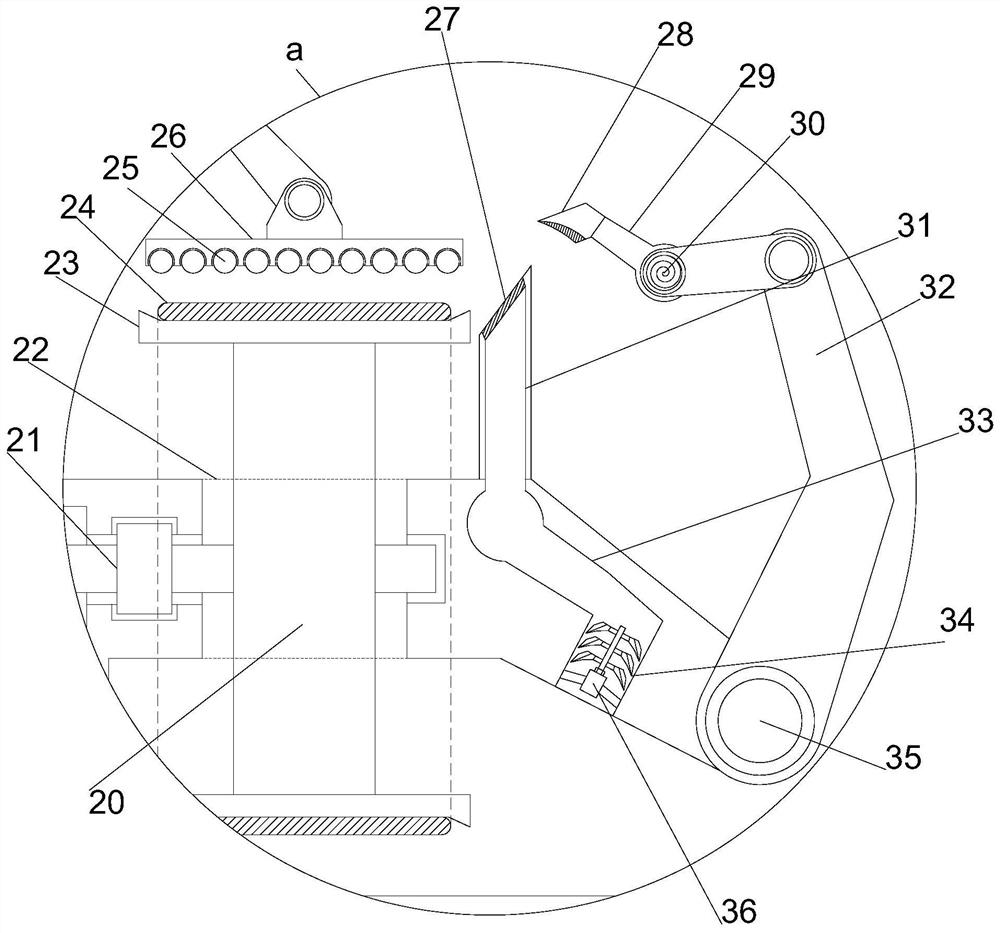

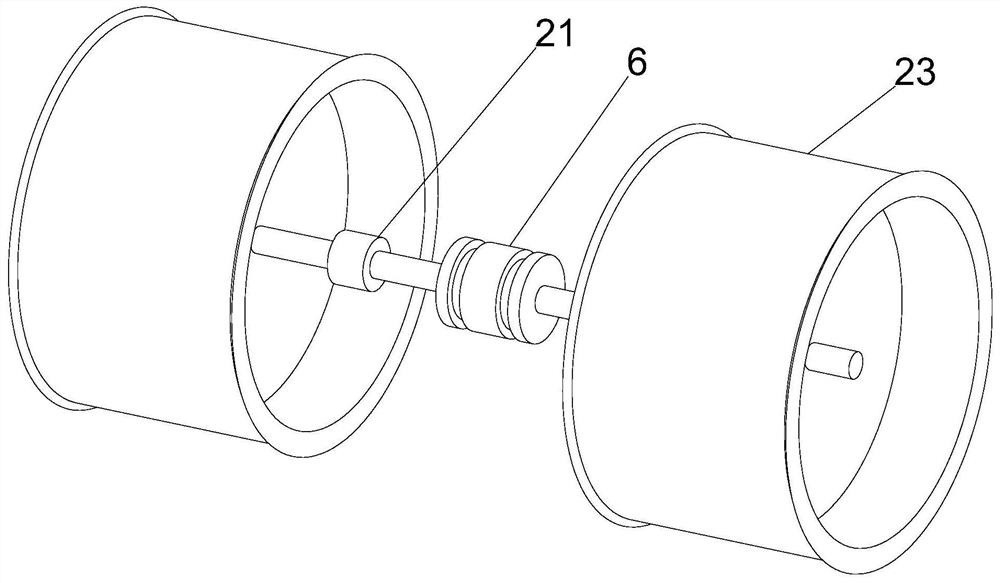

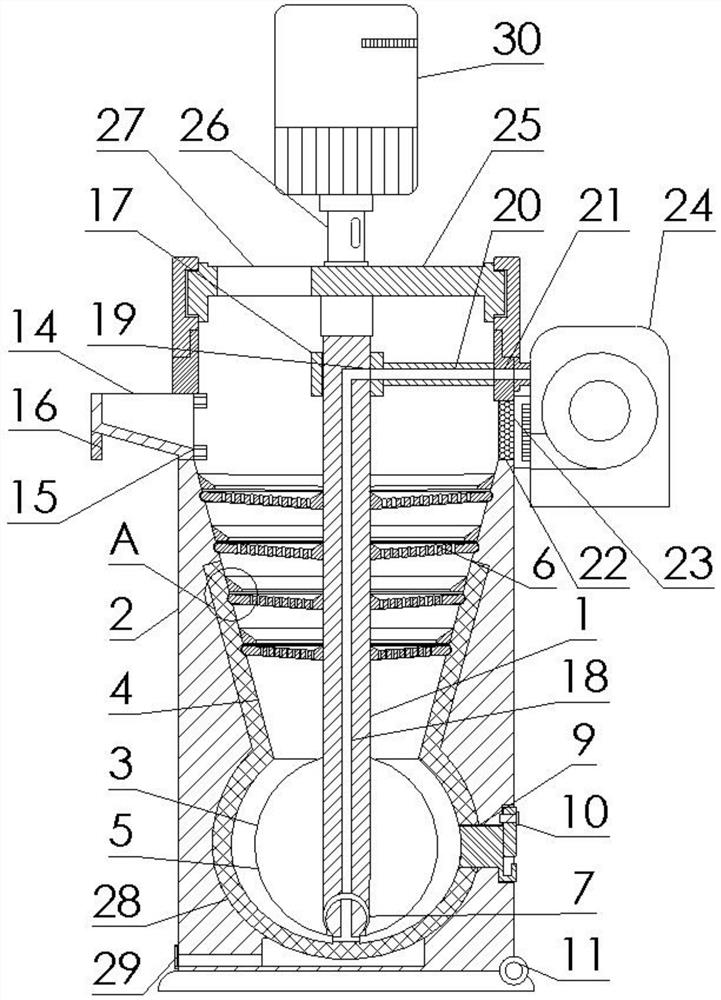

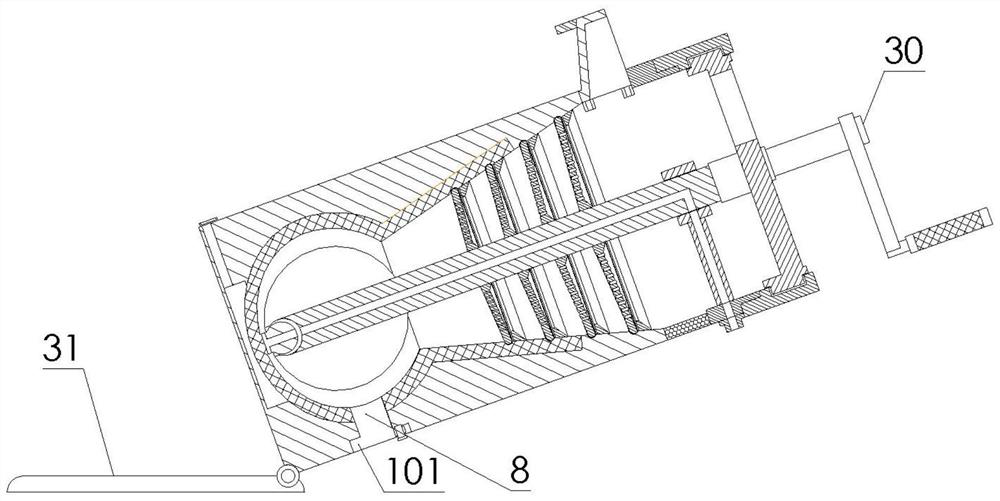

ActiveCN112044564AContinuous and stable processImprove grinding and drying qualityDrying gas arrangementsDrying solid materialsChinese herbsMechanical engineering

The invention discloses drying equipment for Chinese herbal medicine. The drying equipment comprises a barrel, a rotating rod is arranged in the barrel, and a grinding area and a drying area are arranged in the barrel from top to bottom. Grinding parts are arranged on the rotating rod in the grinding area, annular edges are arranged on the inner wall of the grinding area and located above the outer edges of the grinding parts, and annular grooves are formed below the annular edges and matched with the grinding parts; material turning plates are arranged on the rotating rod in the drying area;and a feeding hopper is arranged on one side of the upper portion of the barrel, and a discharging port is formed in one side of the bottom of the barrel. According to the drying equipment for the Chinese herbal medicine, the separation and rapid drying of damp, granulated and caked Chinese herbal medicine can be realized, material turning and drying can be conducted while grinding and refining are conducted, and the whole operation process is efficient, convenient, fast, stable and reliable.

Owner:湖南康易达绿茵科技有限公司

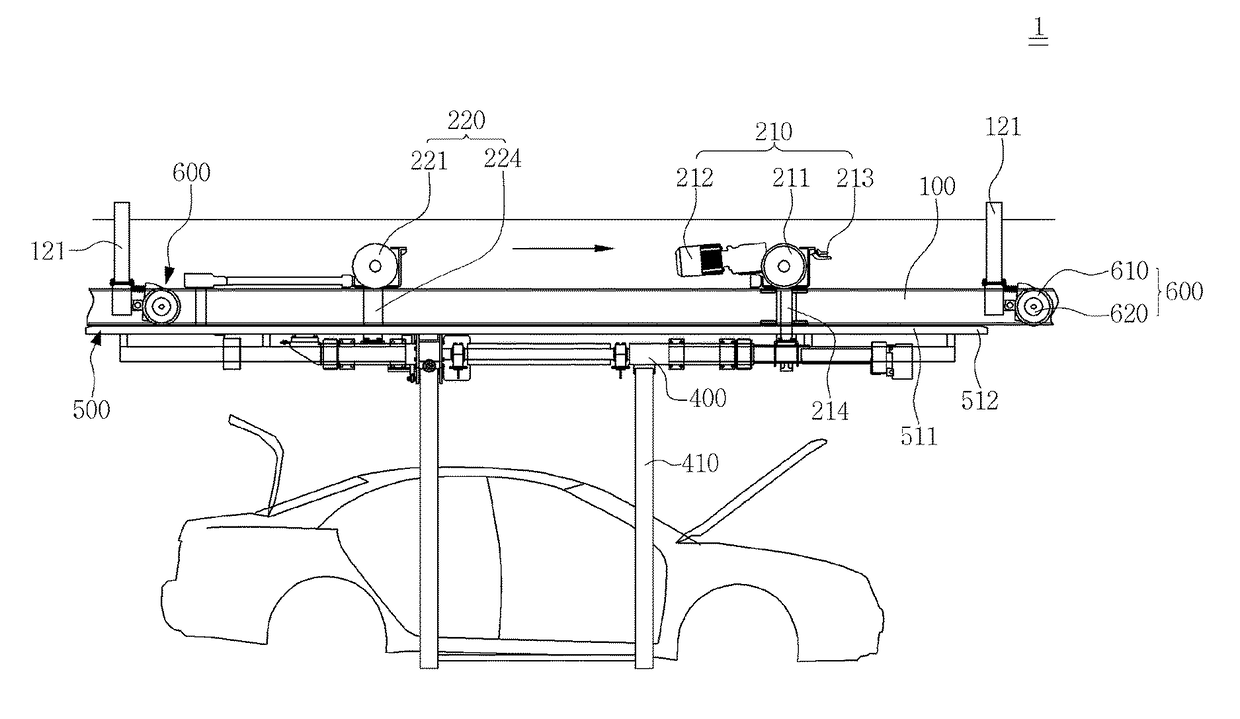

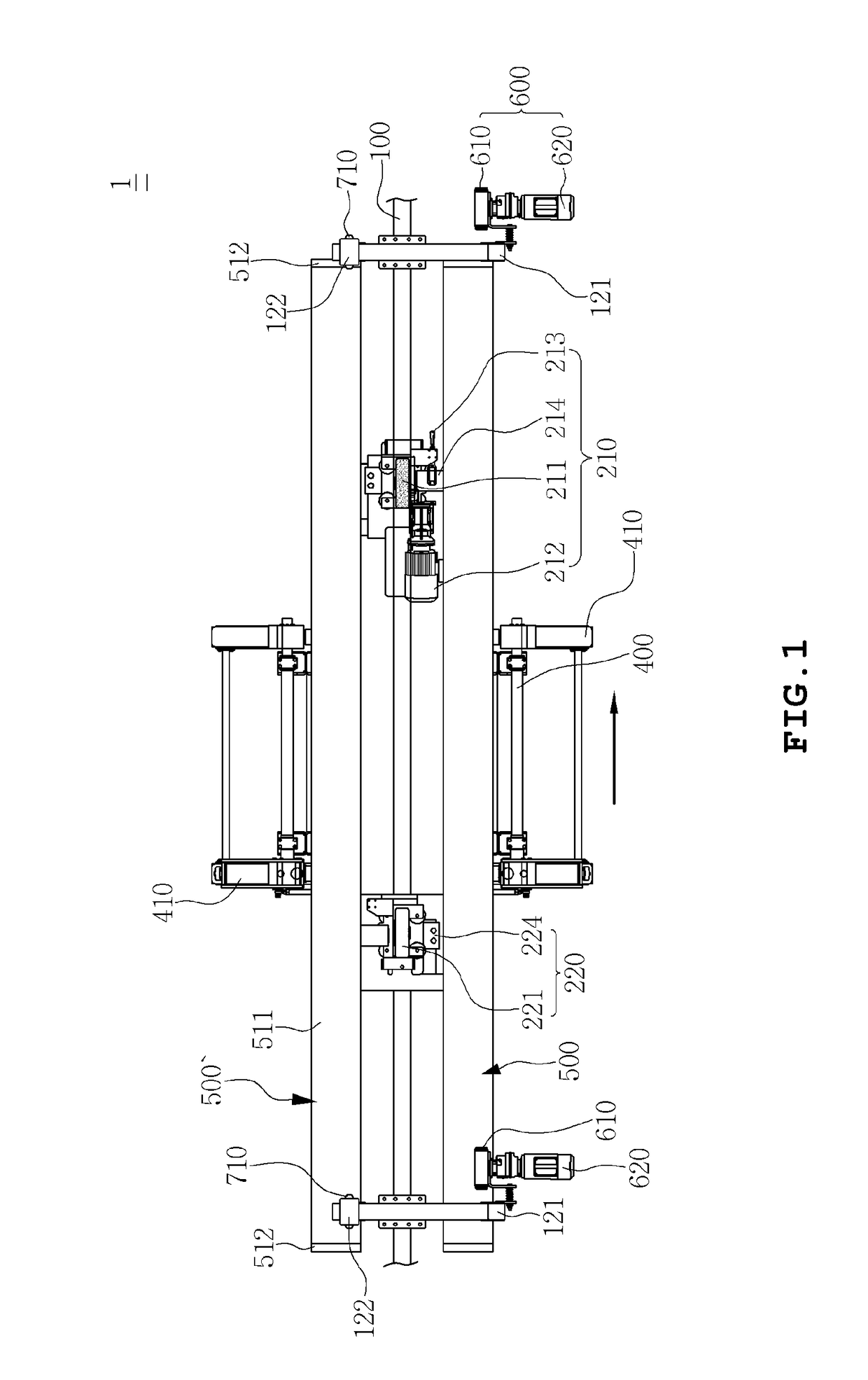

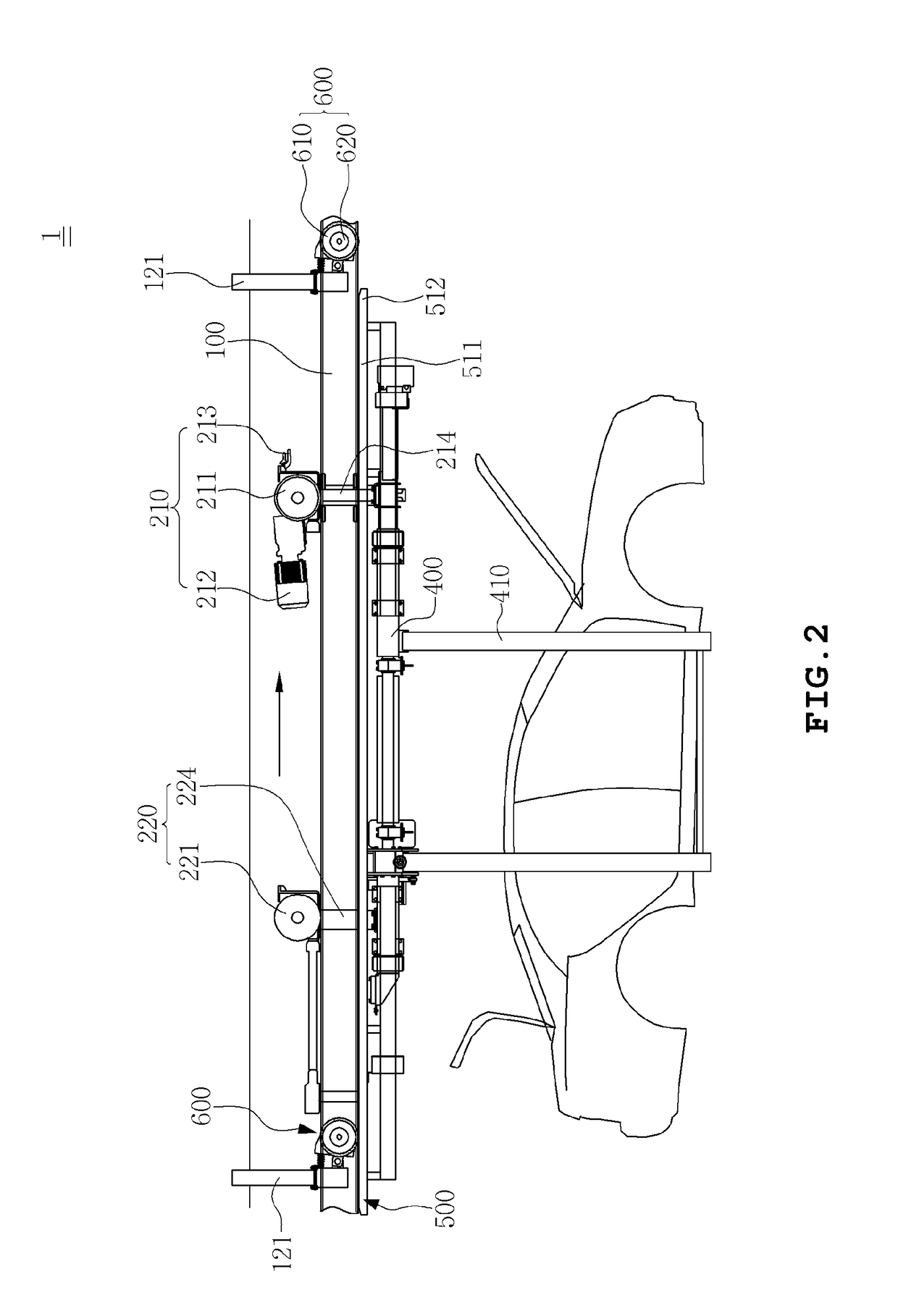

Overhead conveyor

InactiveUS20170282937A1Simple configurationContinuous and stable processMonorailsElevated railway with suspended vehicleDrive wheelMotor drive

An overhead conveyor includes a monorail, a driving trolley having a drive wheel rolling along the monorail and a motor driving the drive wheel, a driven trolley disposed to be spaced apart from the driving trolley on the monorail and having a driven wheel rolling along the monorail, a hanger operatively suspended from the monorail, a first friction plate disposed on the hanger, a plurality of first jigs extending towards the first friction plate along the monorail, and a friction drive unit having a friction drive wheel disposed on the first jig so as to convey the first friction plate in a running direction and a drive motor driving the friction drive wheel.

Owner:SE WOONG MACHINERY

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995BThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustDust control

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

Self-regulation-membrane bicirculation-condensation-activated carbon adsorption-low temperature catalytic oxidation combination device

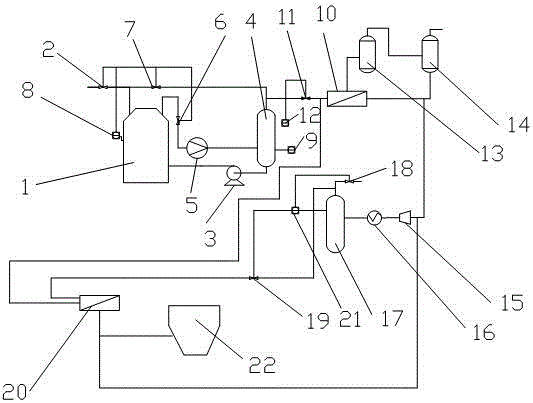

ActiveCN105797544AContinuous and stable processSimple and gentle operating conditionsGas treatmentDispersed particle separationActivated carbonAutomatic control

The invention discloses a self-regulation-membrane biciruclation-condensation-activated carbon adsorption-low temperature catalytic oxidation combination device. The device is formed by connecting a storage tank, a buffer tank-membrane processor-alkali adsorption tower-activated carbon adsorption tower assembly and a buffer tank-membrane processor-incinerator assembly and used for controlling various parameters. The device is high in safety, low in pressure and temperature and small in size, the process is continuous and stable, no heating process exists, the pressure drop of a connecting pipeline is small, automatic control and module design are achieved, no operation worker needs to be added.

Owner:北京瑞惠环保科技有限公司

Screen plunger piston flow electrolyzing device and method for treating organic wastewater

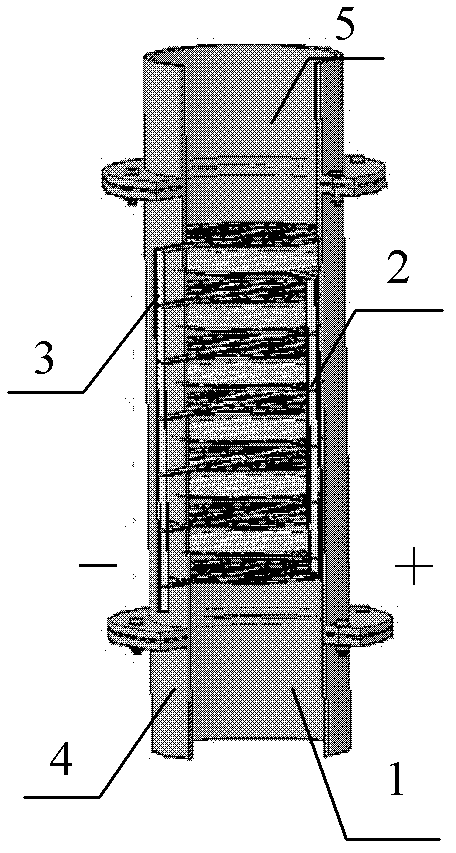

ActiveCN102583662BReduce spacingHigh catalytic activityWater contaminantsWater/sewage treatmentElectrolysisEngineering

The invention provides a screen plunger piston flow electrolyzing device and a method for treating organic wastewater. The screen plunger piston flow electrolyzing device mainly comprises a tank body of an electrolyzing tank; two ends of the tank body are respectively provided with a water flow inlet region and a water flow outlet region; the tank body is internally provided with cathodes and anodes; the cathodes and the anodes are of screen-type structures and are placed along the direction of the cross section of the tank body; when the device operates, water flow passes through a cathode plate and an anode plate; each anode is a net-shaped titanium-based plated metal oxide electrode plate and each cathode is a net-shaped lead or stainless steel electrode plate; a plurality of cathodes and anodes are alternately and uniformly distributed in the tank body; and the quantity of cathodes is one more than that of anodes. The screen plunger piston flow electrolyzing device and the method for treating the organic wastewater, disclosed by the invention, have the main beneficial effects that: (1) the device is small in size, gaps among the electrodes is small and the power consumption islow; (2) the flow direction of the wastewater is vertical to an electrode surface and the process is continuous and stable; (3) other novel screen active electrodes can be adopted and have higher catalytic activity; and (4) the mass transferring performance is good and the electrolyzing efficiency is high.

Owner:ZHEJIANG UNIV OF TECH

Method and system for producing anaerobic biogas slurry concentrated fertilizer

PendingCN111217491AConcentration effect is goodPromote crop growthWater treatment parameter controlBio-organic fraction processingBiogasFertilizer

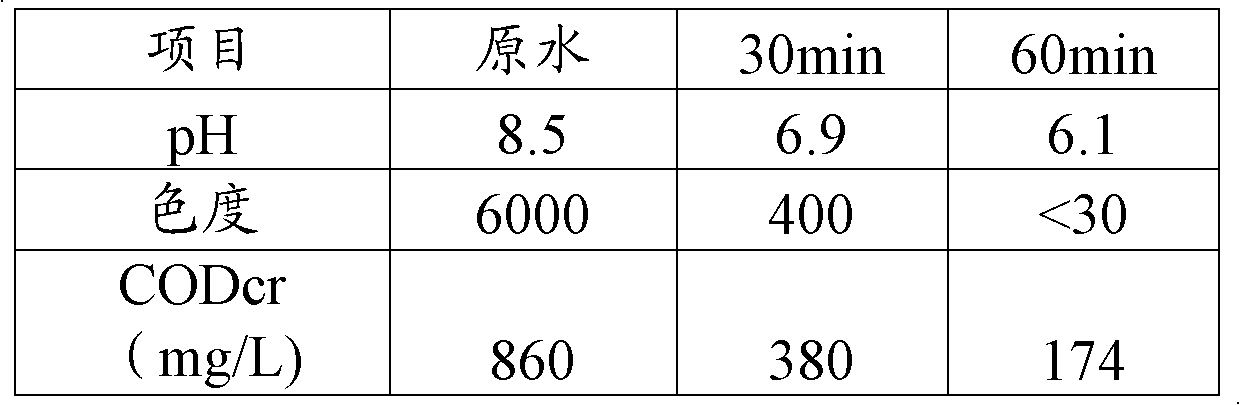

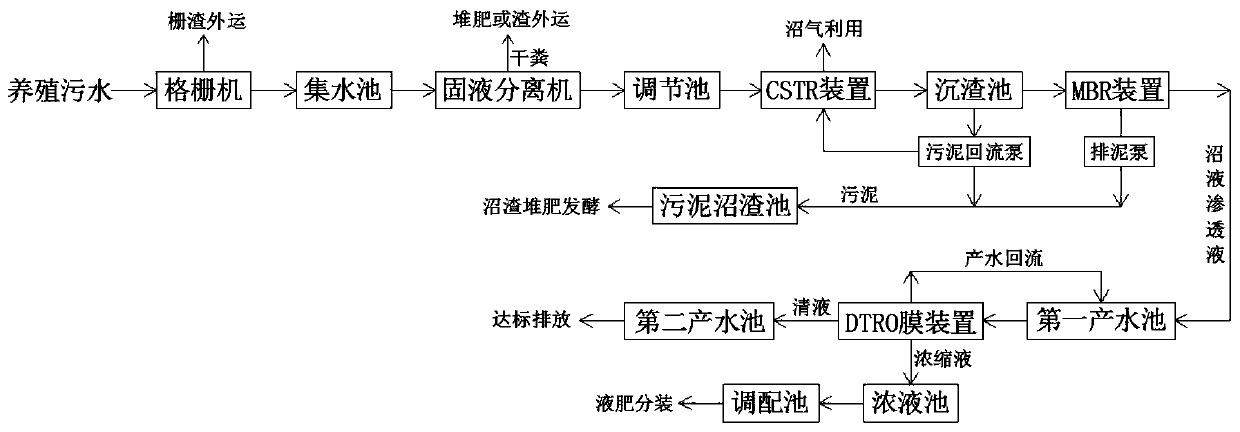

The invention discloses a method and a system for producing an anaerobic biogas slurry concentrated fertilizer. Sewage is filtered by a grillage machine, then is collected into a water collecting tank, and is pumped into a solid-liquid separator, the quality and quantity of treated sewage are balanced and adjusted in an adjusting tank, then the sewage enters a CSTR device and is subjected to anaerobic fermentation, generated biogas is recycled, generated biogas slurry is discharged into a sediment pool and precipitates, the settled biogas slurry is pumped back to the CSTR device through a sludge reflux pump for circular treatment, and sludge accumulated in the sediment pool and an MBR device is periodically discharged into a sludge biogas residue pool and is subjected to squeezing composting; a biogas slurry penetrating fluid separated by the MBR device is concentrated by a DTRO membrane device, and a clear fluid separated from the anaerobic biogas slurry by the DTRO membrane device iscollected into a second water production tank and is discharged after reaching the standard through detection; and trace elements, other nutritional ingredients and functional ingredients are added into the separated concentrated solution to prepare the liquid fertilizer, and the liquid fertilizer is sub-packaged. The problems of high biogas slurry yield, high treatment cost, difficult storage and transportation, low nutrient content and the like in the traditional anaerobic engineering are solved, and the anaerobic biogas slurry is better recycled.

Owner:GUANGDONG SHUIQING ENVIRONMENTAL PROTECTION TECH CO LTD

Auxiliary feeding device for flexible pipe of radial horizontal well

ActiveUS20190264544A1Overcome frictionContinuous and stable processLiquid/gas jet drillingDirectional drillingImpellerHorizontal wells

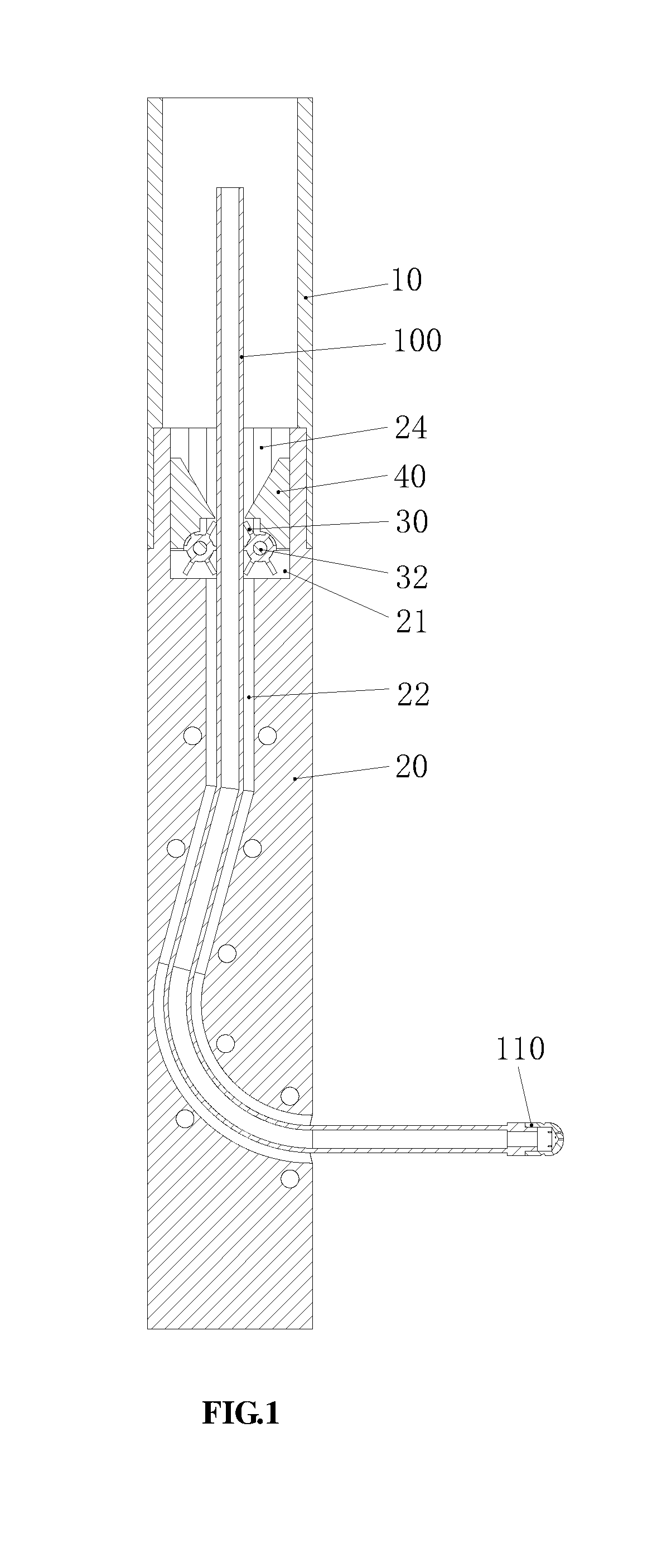

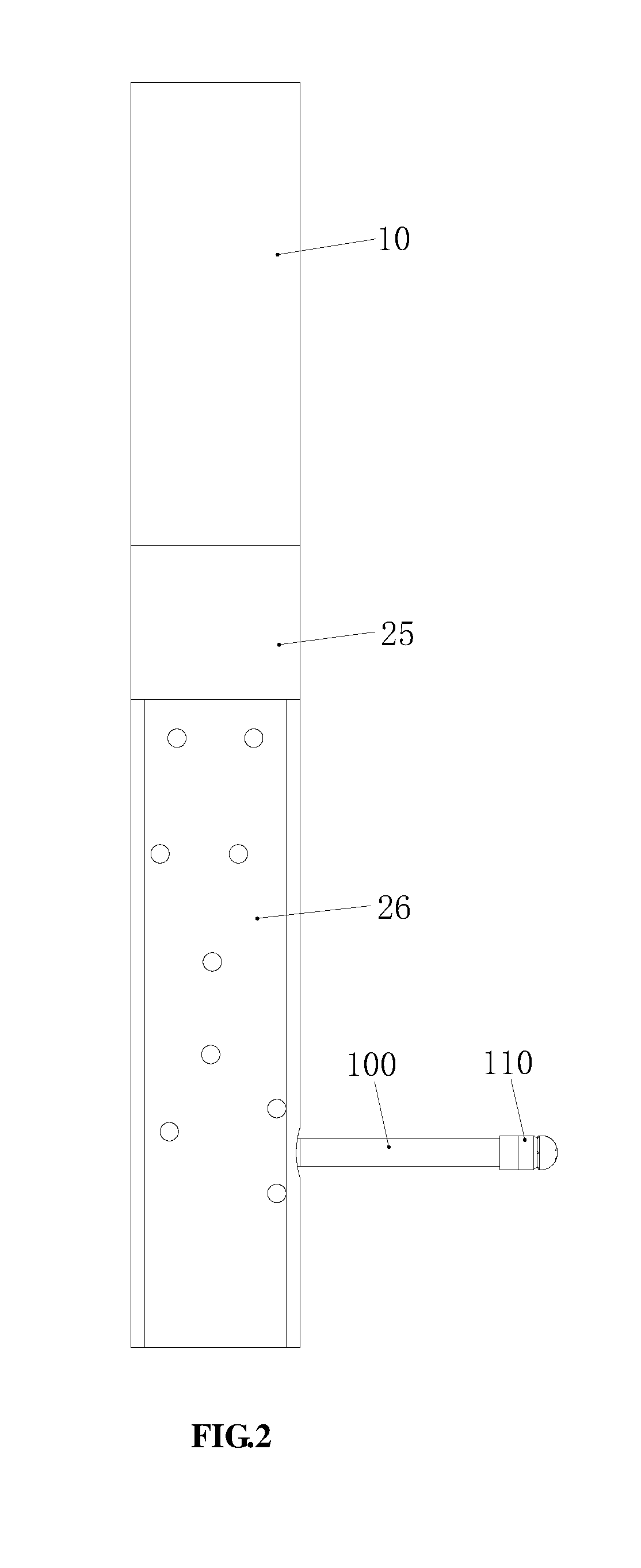

The present invention provides an auxiliary feeding device for a flexible pipe of a radial horizontal well, comprising an oil pipe, a steering gear connected to the oil pipe at a lower opening thereof, and two impellers; an upper end surface of the steering gear is provided with an accommodating groove; the steering gear is internally provided with a through steering passage in an axial direction thereof for allowing an external flexible pipe to pass through; an inlet of the steering passage is located at a bottom wall of the accommodating groove, and an outlet of the steering passage is located at a lower portion of a sidewall of the steering gear; the two impellers are symmetrically disposed on two sides of the inlet; each of the impellers comprises an impeller shaft, a barrel body rotatably surrounding the impeller shaft, and at least three blades fixed outside the barrel body and provided at a top thereof with a notch, wherein the two impeller shafts are parallel to each other; the two impellers are synchronously rotated relative to each other, and the notches on two sides of the inlet are in one-to-one correspondence relation to form a holding passage that can clamp the flexible pipe; the flexible pipe enters the steering passage through the oil pipe, the holding passage, and the inlet in sequence, and protrudes from the outlet; fluid injected through an upper opening of the oil pipe drives the impellers to rotate downward, and causes the flexible pipe to be fed downward. The present invention can enable the flexible pipe to overcome frictional resistance effectively and be fed continuously and stably.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

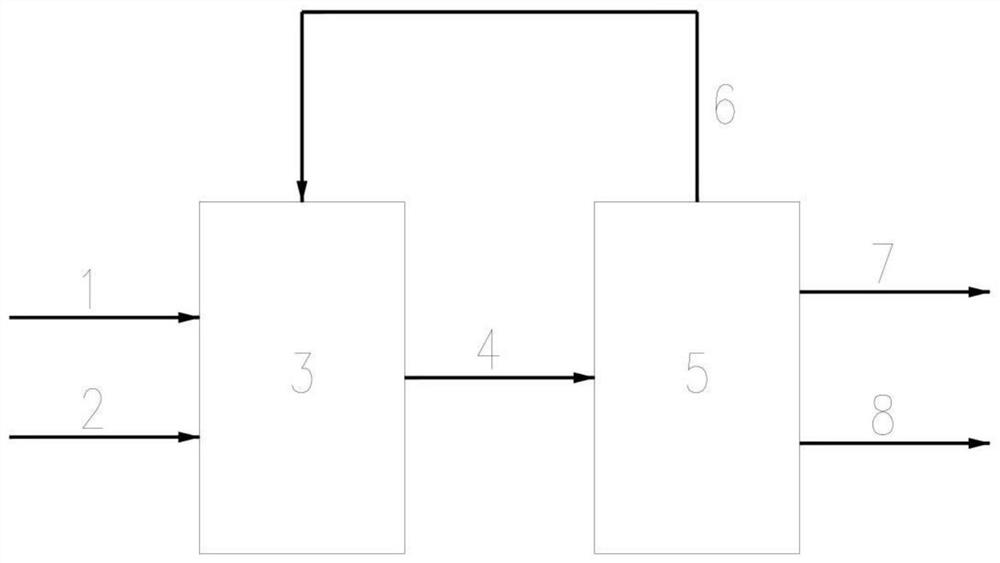

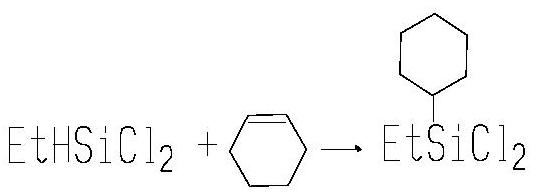

Method for removing ethyl dichlorosilane impurities in dimethyldichlorosilane

ActiveCN113444121AReduce the difficulty of separationReduce the number of traysSilicon organic compoundsChemical industryPtru catalystEthyl group

The invention relates to a method for removing ethyl dichlorosilane impurities in dimethyldichlorosilane. A reactor and a separation system are included; a dimethyldichlorosilane feed containing ethyl dichlorosilane and a hydrosilylation reactant are added into a reactor for reaction, an isopropanol solution of chloroplatinic acid hydrate or a Karstedt catalyst is adopted, and a product after the reaction enters the separation system; a rectification mode is adopted, and excessive reactant, dimethyldichlorosilane and hydrosilylation reaction products are separated through light component and heavy component removal operation; and the reacted mixture enters the separation system to be separated, and the dimethyldichlorosilane product is obtained. According to the method, ethyldichlorosilane is converted through reaction, and the characteristic that the boiling point difference between the reactant and the reaction product and dimethyldichlorosilane is large is utilized, so that the system separation difficulty is effectively reduced, the number of theoretical plates and reflux ratio requirements of subsequent rectification separation operation are reduced, the equipment investment is reduced, the energy consumption is greatly reduced, and the industrial application value is relatively high.

Owner:TIANJIN UNIV

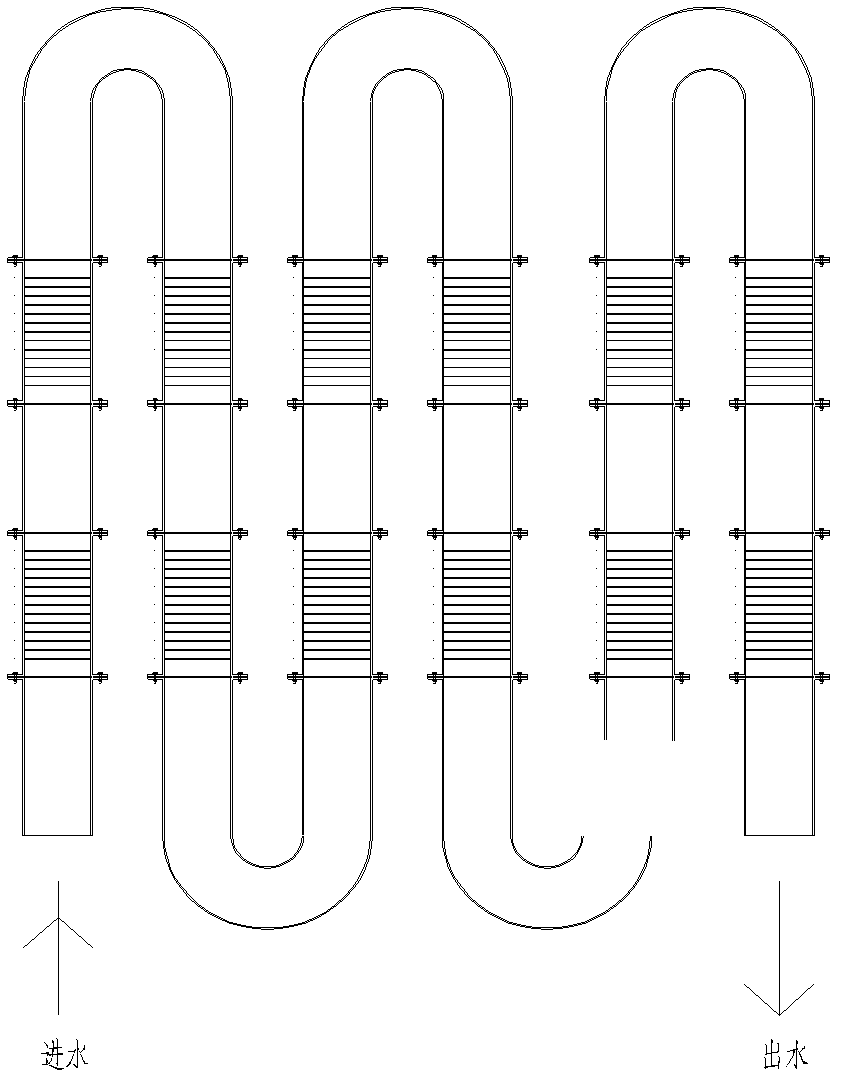

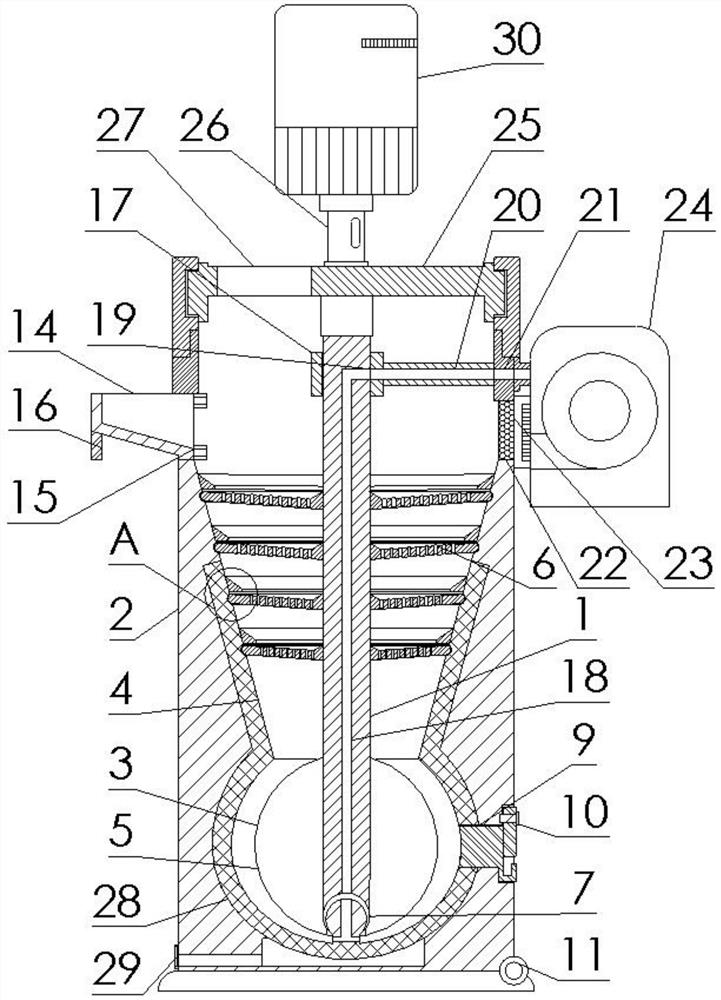

Method for synchronization of silicon hydrolysis reaction and tubular membrane separation

InactiveCN103601205ACompletely hydrolyzedSolve pollutionAlkali metal silicatesHydrogenPressure.drive

The invention relates to a silicon hydrolysis technology and particularly relates to a method for synchronization of silicon hydrolysis reaction and tubular membrane separation. According to the method, a balancing technology which is used for balancing the gravity, buoyancy and settling resistance stood by silicon powder grains in a hydrolysis solution during hydrolysis, a countercurrent-contact reaction technology and a tubular membrane separation technology are used, so that a reaction product is separated from reactants in time; meanwhile, tubular membranes are of staggered arrangement, and hydrogen gas generated during silicon hydrolysis reaction plays a role in stirring unreacted silicon powder deposited on the outside surfaces of the tubular membranes in annular gaps among the tubular membranes, so that the surface pollution of the membranes is lightened; the unreacted silicon powder intercepted on the outside surfaces of the membranes is subjected to periodical directional cleaning in a pressure-driven manner, so that the complete hydrolysis of the silicon powder is guaranteed, and the completeness and continuity of reaction are realized.

Owner:NANJING DINGSHIHE MEMBRANE TECH CO LTD

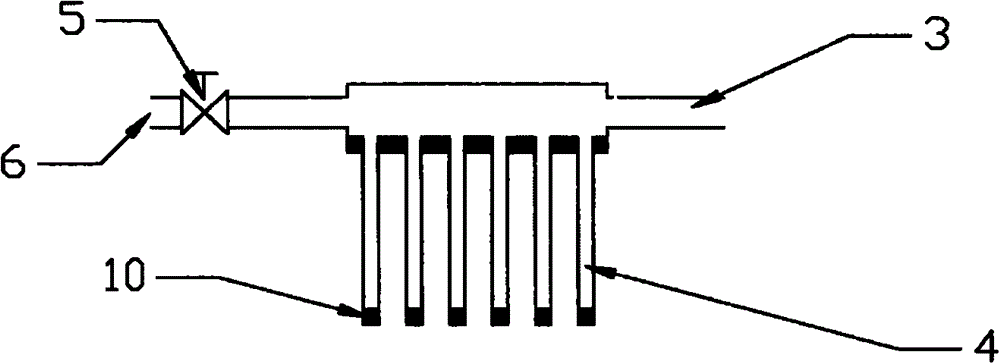

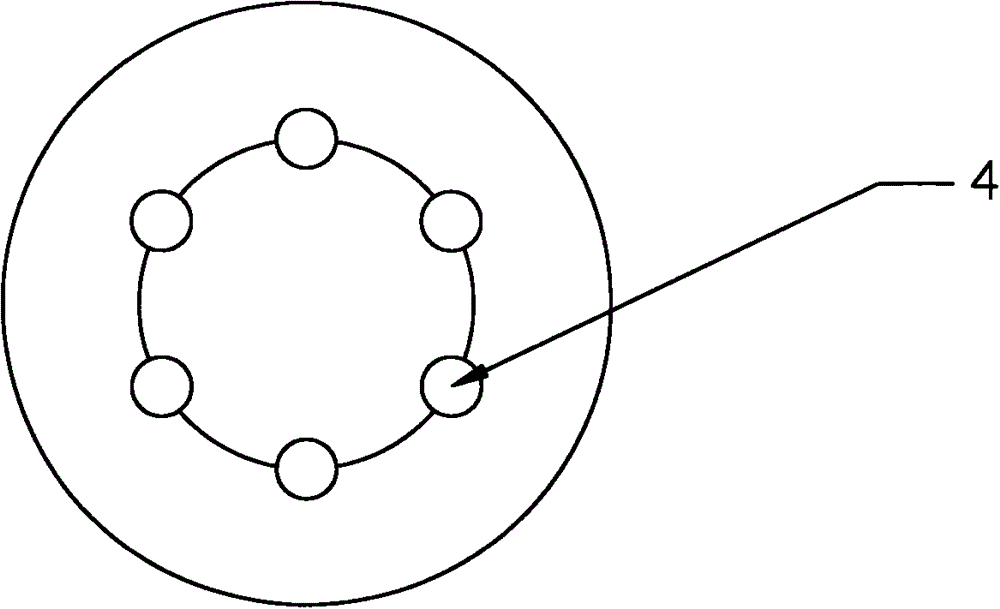

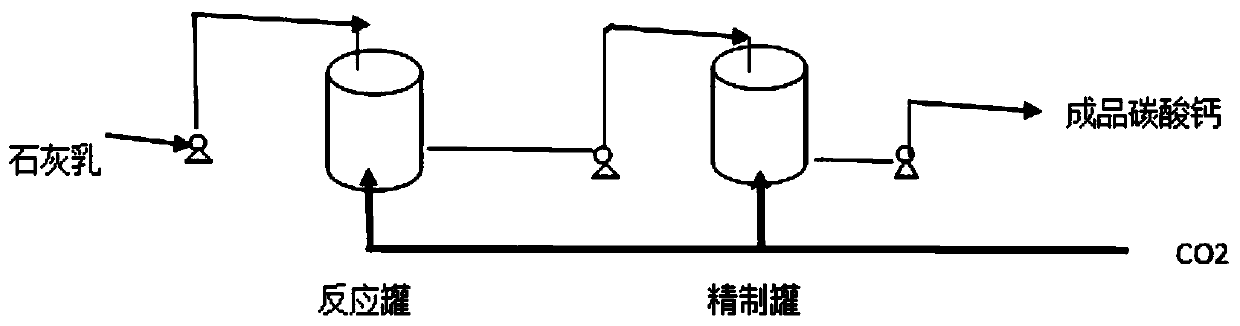

Continuous carbonation technology for producing calcium carbonate

InactiveCN110255596AHigh degree of automationContinuous and stable processCalcium/strontium/barium carbonatesCarbonationSlurry flow

The invention discloses a continuous carbonation technology for producing calcium carbonate. The continuous carbonation technology for producing the calcium carbonate comprises the steps of (1) mixing calcium carbonate crystal nuclei and a slaked lime solution to form slurry, pumping the slurry into a reaction tank continuously, and introducing CO2 from the bottom; (2) pumping out calcium carbonate slurry in the reaction tank from the bottom by means of a pump, controlling the slurry flow by measuring the conductivity of the slurry in real time, and guaranteeing that the liquid levels in the reaction tank and a refining tank are always in preset ranges; (3) injecting the calcium carbonate slurry, which is obtained through a reaction, into the refining tank, introducing CO2, and guaranteeing that a pH value in the reaction tank is 7-8.5; and (4) pumping a finished product material out of the refining tank, and cycling the process. According to the continuous carbonation technology for producing the calcium carbonate, the process is controlled by a PLC control system, the automation degree is high, the working procedures are continuous and stable, and the yield and the quality are easy to control; and equipment runs continuously, and is convenient to maintain.

Owner:常熟美特钙业有限公司

A kind of Chinese herbal medicine drying equipment

ActiveCN112044564BContinuous and stable processImprove grinding qualityDrying gas arrangementsDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention discloses a drying equipment for Chinese herbal medicine, which comprises a cylinder body, a rotating rod is arranged inside the cylinder body, and a grinding area and a drying area are respectively arranged in the cylinder body from top to bottom; The inner wall of the grinding area is provided with a ring edge above the outer edge of the grinding piece, and a ring groove is arranged below the ring edge, and the ring groove matches the grinding piece; a turning rod is provided on the drying area. A turning plate; the upper part of the cylinder One side is provided with a feeding hopper, and one side of the bottom of the cylinder is provided with a discharge port; the present invention can realize the separation and rapid drying of wet granulated and agglomerated Chinese herbal medicines, and can also be turned over while grinding and refining. Material drying, the whole operation process is efficient, convenient, stable and reliable.

Owner:湖南康易达绿茵科技有限公司

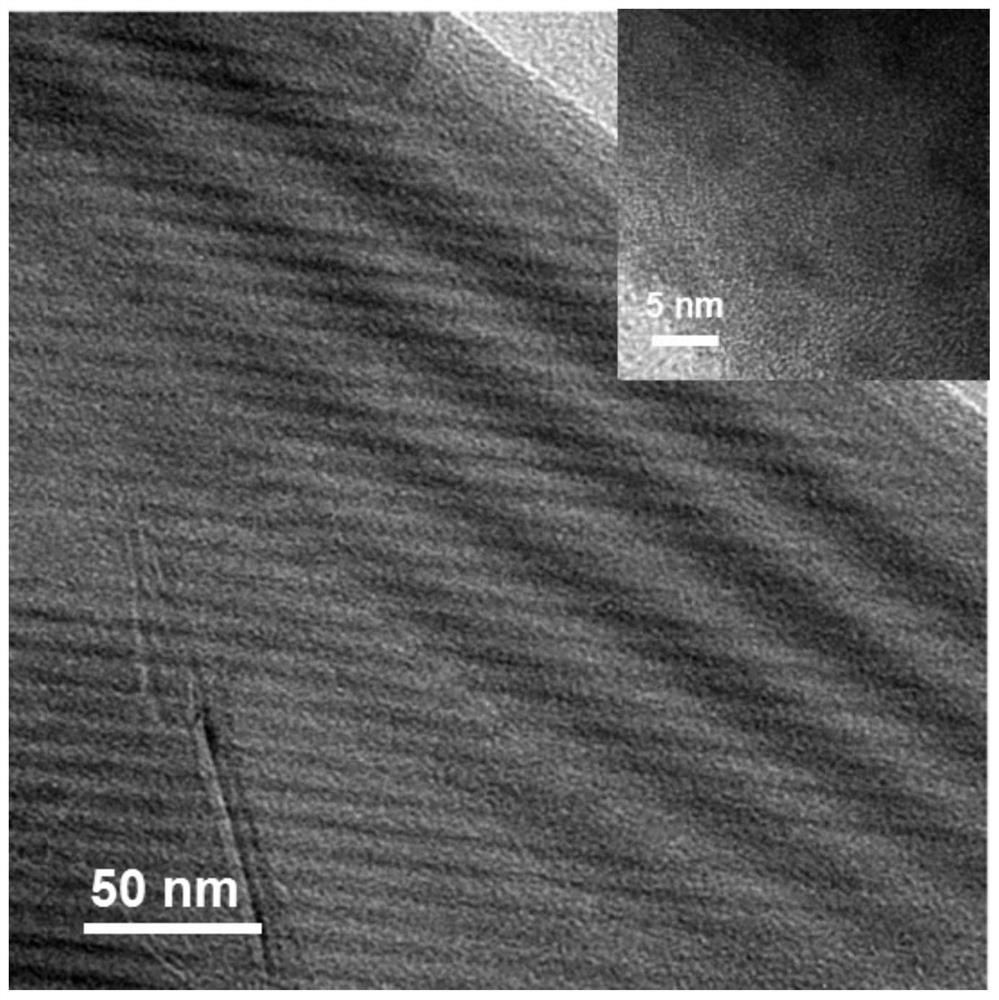

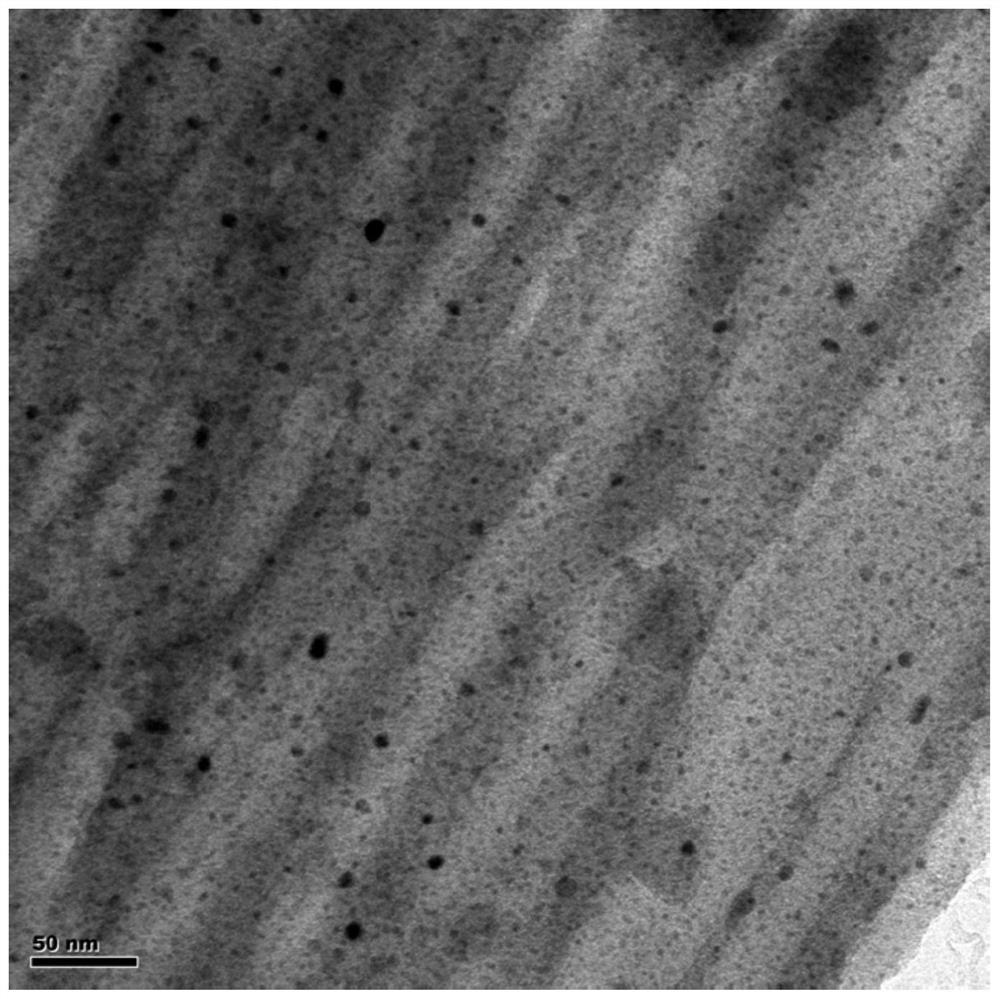

Nickel-based pure silicon type molecular sieve catalyst as well as preparation method and application thereof

InactiveCN113351239ALarge specific surface areaEvenly dispersedHydrocarbon from carbon oxidesMolecular sieve catalystsPtru catalystSilicic acid

The invention discloses a nickel-based pure silicon type molecular sieve catalyst. The specific surface area of the molecular sieve catalyst is 200-500m < 2 > / g, the size of the molecular sieve catalyst is 2-5nm, and the metal loading capacity of the molecular sieve catalyst is 5-10wt%. The preparation method of the nickel-based pure silicon type molecular sieve catalyst comprises the following steps of: mixing tetraethoxysilane, ethanol, diluted hydrochloric acid and a template agent; carrying out reflux condensation; making an obtained mixture stand still; adding a polymer spinning auxiliary solution and a metal salt solution, performing uniform stirring to obtain a spinning precursor solution; and carrying out electrostatic spinning, drying and roasting to finally obtain the pure silicon type molecular sieve catalyst. According to the nickel-based pure silicon type molecular sieve catalyst prepared by the electrostatic spinning method, the specific surface area of the catalyst is large; the active metal is uniformly dispersed on the carrier, the utilization rate of the active metal is high, the dispersity of the metal is high, the particle size is small, and the active metal is not easy to sinter in a strong exothermic reaction of synthesis gas methanation.

Owner:EAST CHINA UNIV OF SCI & TECH

Production method for flexible preparation of high-strength polyester industrial yarn with multiple composite functions

InactiveCN111411413AReduce energy consumptionImprove protectionFlame-proof filament manufactureArtificial thread manufacturing machinesPolyesterYarn

The invention relates to a production method for flexible preparation of a high-strength polyester industrial yarn with multiple composite functions. One or more functional master batches are added through a flexible online adding device; the coloring of an original solution is taken as the basic function to prepare the high-strength polyester industrial yarn with multiple composite functions, ortwo or more functional additives are compounded into composite functional master batches; and then the composite functional master batches are added by using the flexible online adding device to prepare the corresponding high-strength polyester industrial yarn with multiple composite functions. The production method provided by the invention is continuous and stable in production, can be used forproducing matching products according to the different needs of subsequent customers, effectively improves the efficiency and lowers the labor cost; and the products obtained by production have more than two (including) functional characteristics.

Owner:WUXI SUOLIDE TECH DEV CO LTD

AC plasma ejection gun, the method for supplying power to it and pulverized coal burner

ActiveUS8783196B2Small currentIncrease motivationArc welding apparatusPulverulent fuel combustion burnersEngineeringCoal

An AC plasma ejection gun, a method for supplying power to the gun, and a pulverized coal burner are provided. The ejection gun comprising a front electrode and a rear electrode. There is a gap between the electric rear electrode and said front electrode. The ejection gun can work with small current and large power, so that the life of the plasma ejection gun is prolonged.

Owner:BEIJING GUNGYAO ELECTRICITY EQUIP CO LTD

Integrated catering lampblack purification device

PendingCN109157952AEasy to handleEffective absorptionCombination devicesGas treatmentMicro nanoElectrochemical response

The invention discloses an integrated catering lampblack purification device which is structured such that a double sleeve type plasma generator is placed in an electrochemical reaction pond; the double sleeve type plasma generator is composed of inner and outer quartz sleeves; the inner sleeve is filled with conducting iron powder as a high voltage end while the outer side of the outer sleeve iscoated with an iron gauze as a low voltage end; a high frequency high voltage alternating current power supply is connected to the high voltage end and the lower voltage end; an air inlet communicating to an interlayer gap is formed in the upper part of the double sleeve type plasma generator, and an annular micro-nano air distributing system communicating to the interlayer gap is arranged at thebottom; an electrocatalytic oxidizing electrode connected to a current direct power supply is arranged in the electrochemical reaction pond, and an air outlet is formed in the top of the electrochemical reaction pond. The integrated catering lampblack purification device purifies catering lampblack efficiently by means of a method of highly coordinating a discharge plasma and electrocatalytic oxidizing technology, solves the problems of overheating of a discharge device and difficulty to clean an attached aerosol, and has the advantages of being simple in process, compact in structure, small in occupied area, simple to maintain and the like.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

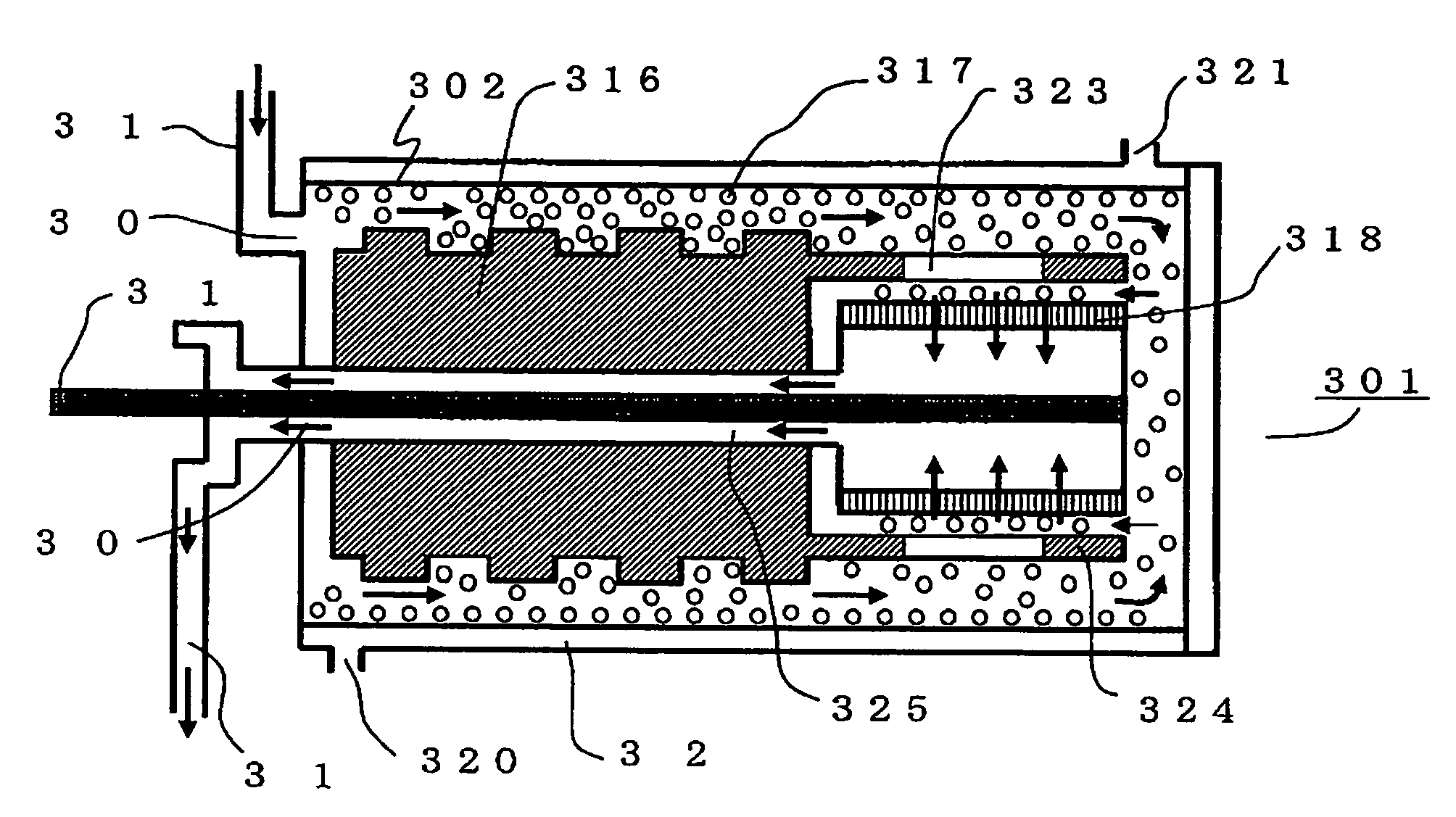

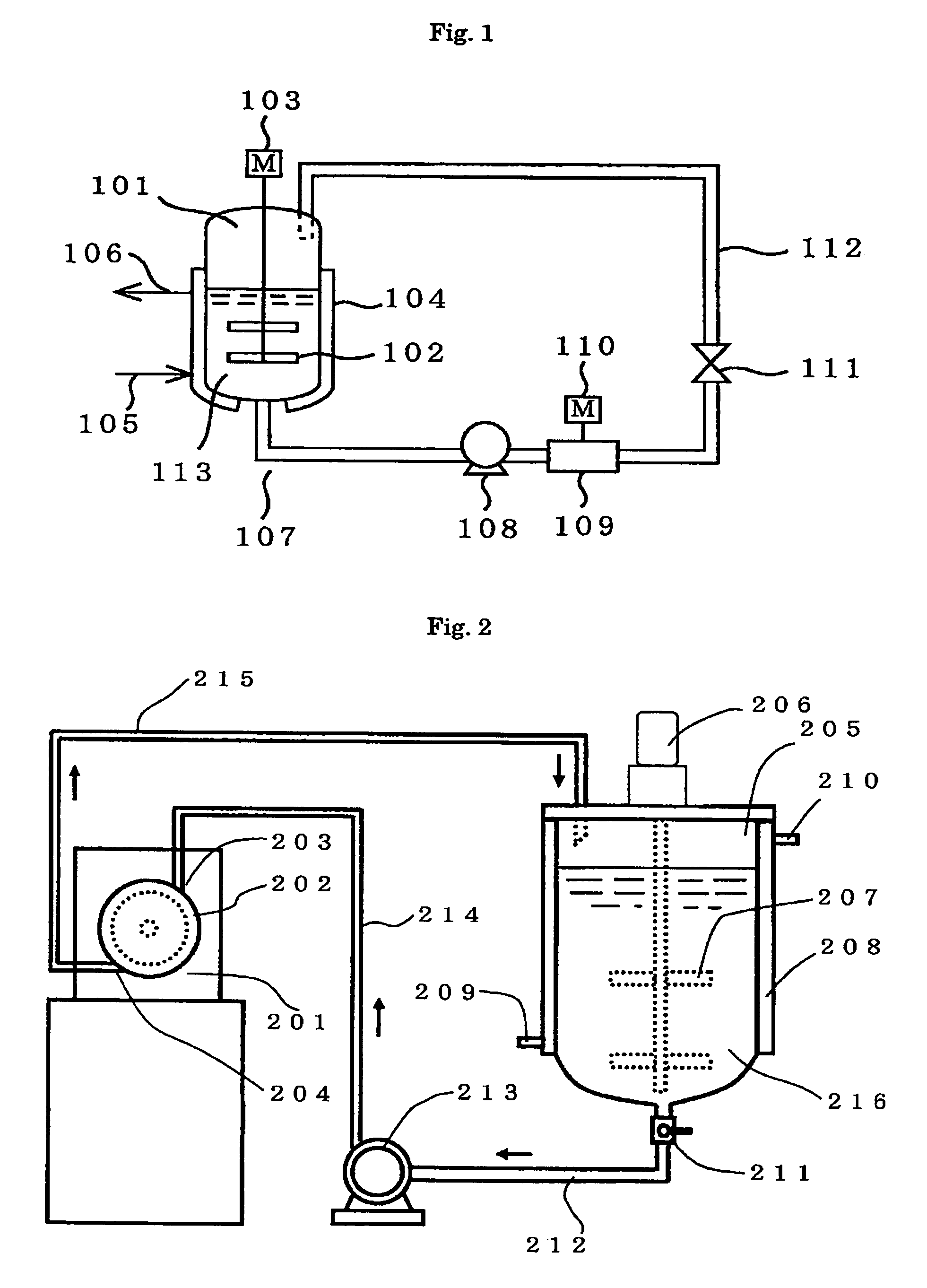

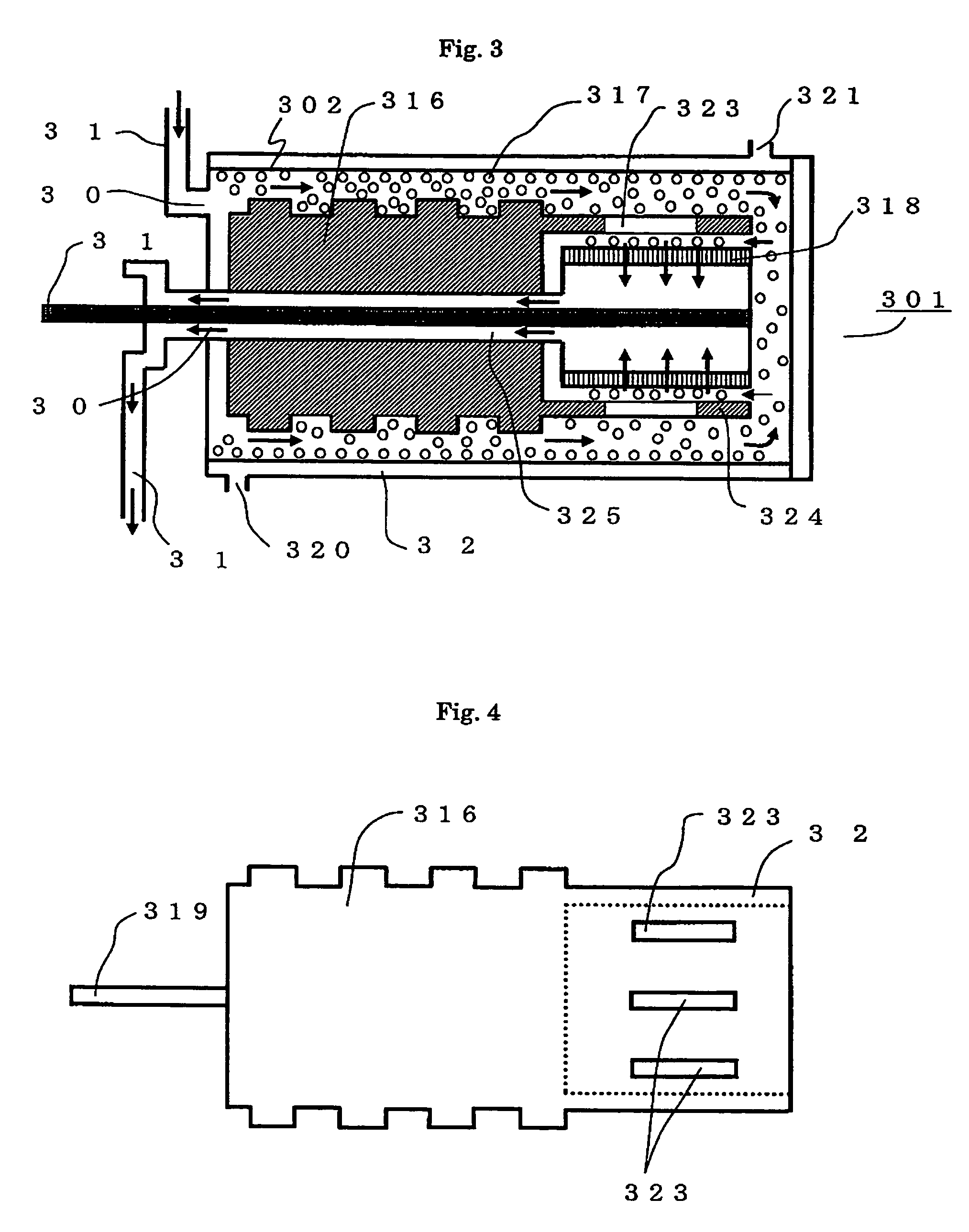

Process for producing polyolefin and vapor-phase polymerization apparatus therefor

InactiveCN1849342AContinuous and stable productionStable and continuous process for producing polyolefinsChemical/physical/physico-chemical processesPolymer sciencePolyolefin

Provided is a process for producing polyolefin by continuous vapor phase polymerization in the presence of an olefin polymerization catalyst, comprising the steps of: feeding a cooling circulating medium into the polymerization vessel from the bottom wall of the polymerization vessel and from at least one position on the sidewall thereof. There is also provided a polyolefin vapor phase polymerization device, comprising: a polymerization vessel equipped with a monomer feeding pipe, a polymer discharge pipe and an optional stirring blade, and a cooling circulating medium from the bottom wall of the polymerization vessel and at least from its side wall One position feeds the mechanical equipment of the polymerization vessel.

Owner:IDEMITSU KOSAN CO LTD

Production process of polymerized toner

A process for producing a polymerized toner, comprising the step of polymerizing a polymerizable monomer composition containing a polymerizable monomer and a colorant in the presence of a polymerization initiator in an aqueous dispersion medium to form colored polymer particles, the process comprising the steps of mixing the polymerizable monomer with the colorant to prepare a polymerizable monomer mixture having an initial viscosity of 10 to 3,000 mPa·s or 0.3 to 1 mPa·s as measured at 25° C. by a Brookfield type viscometer, and then feeding the polymerizable monomer mixture to a media type dispersing machine to finely disperse the colorant by the media type dispersing machine, thereby preparing a dispersed polymerizable monomer mixture having a viscosity after the dispersion, the ratio of increase in viscosity of which is 1.0 to 10 times or 100 to 2,000 times as high as the initial viscosity.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com