Distributed control type steam-light discharge process for desulfurizing fume by semi-wet method

A streamer discharge and distributed control technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low pulse repetition rate, low efficiency, short life, etc., and achieve continuous and stable process, high power supply, The effect of low-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

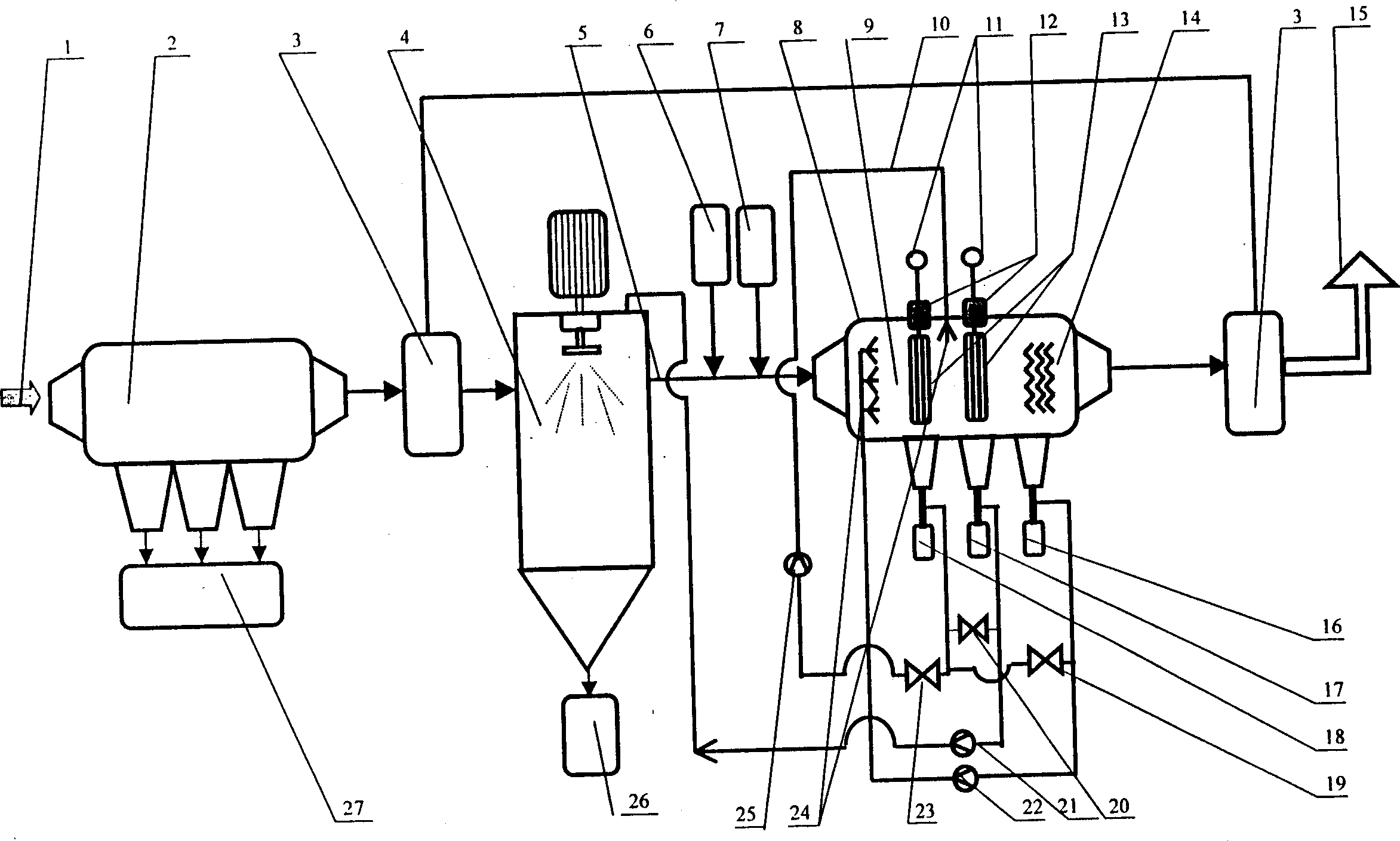

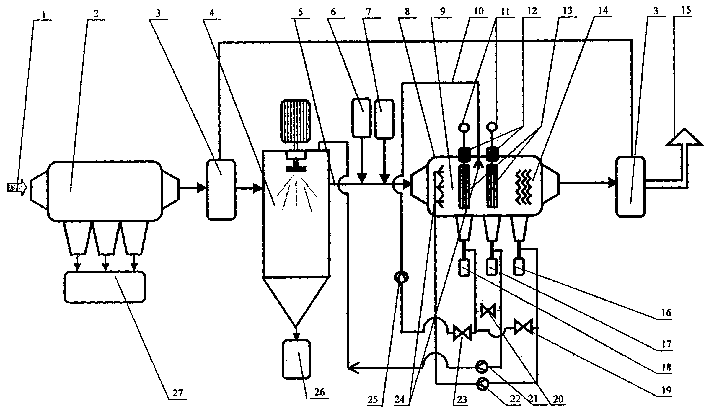

[0018] use as figure 1 The semi-wet process of flue gas desulfurization with centralized and distributed control streamer discharge as shown, treats 180,000m 3 / h The flue gas 1 from the coal-fired boiler enters 45m through the flue 2 , 4 electric field electrostatic precipitator 2, the dust concentration of the flue gas after dust removal is 80mg / m 3 , the temperature is 130°C, it enters the dryer 4 through the heat exchanger 3, and after being discharged from 4, the temperature of the flue gas drops to 75°C. The injection device 7 sprays ammonia into the flue gas, and then enters the horizontal wet discharge reactor 8. The wet reactor 8 is composed of 14 units. The unit is a rectangular box with a width of 0.5m; a height of 6.5m; a length of 2m. The ground electrode is covered with 5 mm thick cordierite lining, and the specific surface area of cordierite is 50cm 2 / g, the total volume of the wet reactor is 90m 3 , the residence time of the flue gas is 2 seconds, the le...

specific Embodiment approach 3

[0019] use as figure 1 The semi-wet process of flue gas desulfurization with centralized and distributed control streamer discharge is shown, with a treatment area of 3000m 3 / h The flue gas 1 discharged from the coal-fired boiler enters the multi-tube dust collector 2 through the flue, and the dust concentration of the flue gas after dust removal is 95mg / m 3 , the temperature is 125°C, the flue gas temperature is reduced to 65°C after passing through the dryer 4 through the heat exchanger 3, and the efficiency of the dryer 4 is 95%. 2 The NOx content is 1000ppm, and the NOx content is 100ppm. Before entering the vertical wet discharge reactor 8, water is sprayed into the flue gas by the water injection device 6 to further humidify and cool the flue gas, and the absorbent adding device 7 sprays water into the flue gas. NaOH aqueous solution, triggers thermochemical reaction. The vertical wet discharge reactor 8 is composed of 28 units connected in parallel. The unit is a c...

specific Embodiment approach 4

[0020] The technological process is the same as that of the specific embodiment 3, and 12000m is processed 3 / h The flue gas discharged from the coal-fired boiler 1, the dust concentration of the flue gas after dust removal is 90mg / m 3 , the temperature is 130°C, after the heat exchanger 3 enters the dryer 4 (its efficiency is 85%), the flue gas temperature drops to 75°C, water is sprayed into the flue gas through the water injection device 6, and then the absorbent injection device 7 Ammonia spraying enters the vertical wet discharge reactor 8, which is composed of 28 units, the unit is a circular standpipe with a diameter of 200mm, its length is 2m, and the residence time of flue gas is 2 seconds. The inner surface of the ground electrode is covered with 10mm thick cordierite lining, and the discharge electrode has 28 rice-shaped zigzag lines. The repetition rate of the power supply 11 is 70kHz, and the rest of the technical indicators are the same as those in the third emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com