Screen plunger piston flow electrolyzing device and method for treating organic wastewater

An electrolysis device, a technology for organic wastewater, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of large difference in current density distribution, difficulty in making active electrodes, and high aspect ratio. Structural limitations and other problems, to achieve continuous and stable process, small electrode spacing, and good mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The key point of the invention is a net plate plunger flow electrolysis device, which has universality for different organic waste water. EXAMPLES Experiments were carried out with two types of representative actual industrial organic wastewater.

[0022] The stencil plug flow electrolysis device is as follows:

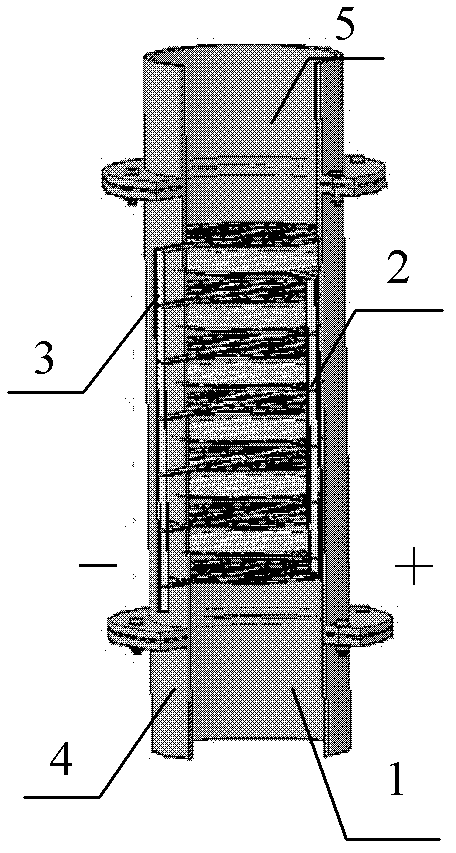

[0023] For the structure of the mesh plate plug flow electrolysis device, see figure 1 , the electrolytic cell comprises an electrolytic cell body 4, an inlet area 1, and an outlet area 5, and an anode 2 and a cathode 3 are arranged in the electrolytic cell body, and the cathode and the anode are respectively connected with the cathode and anode wires of a DC steady-current power supply, so The body of the electrolytic cell is a tubular electrolytic cell, the cathode and anode electrodes are a mesh structure, and the anode is a mesh Ti / PbO 2 The electrode, the cathode is a mesh lead plate electrode with a mesh size of 5.0×12.5mm. The anodes and cathodes are ...

Embodiment 2

[0026] The actual ink wastewater of an enterprise was treated by the screen plug flow electrolysis device of Example 1 respectively.

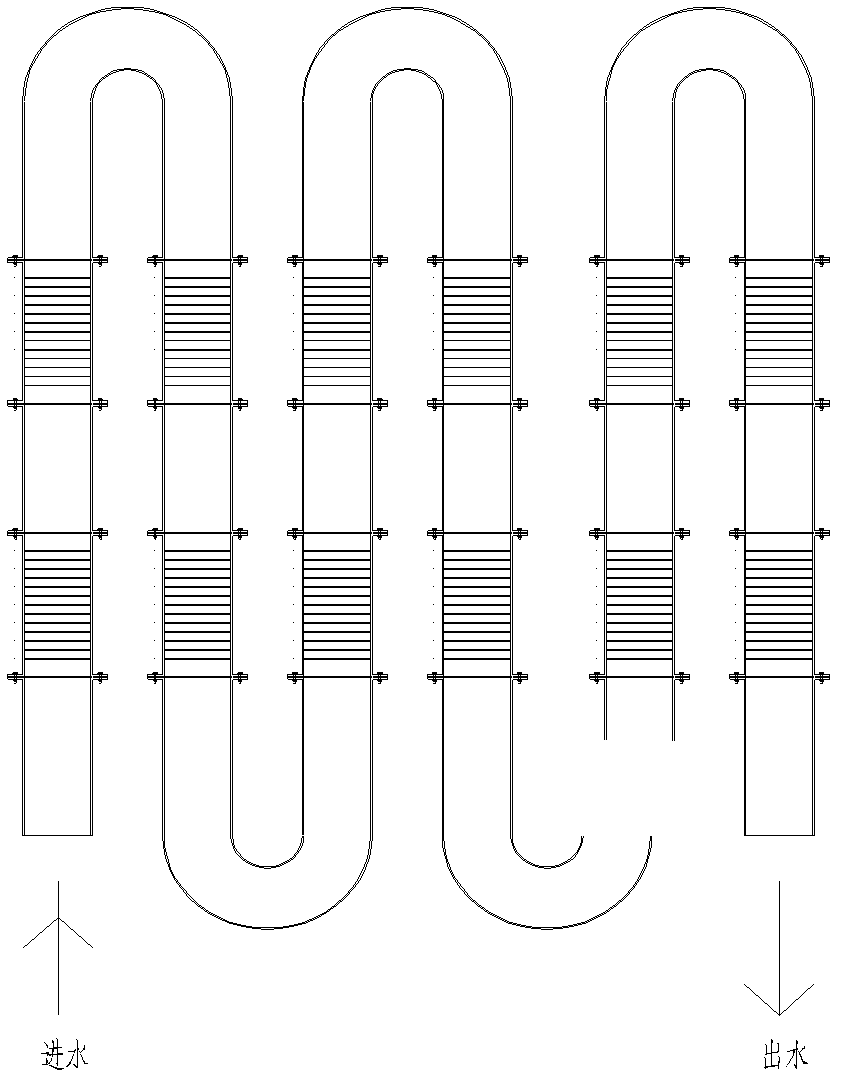

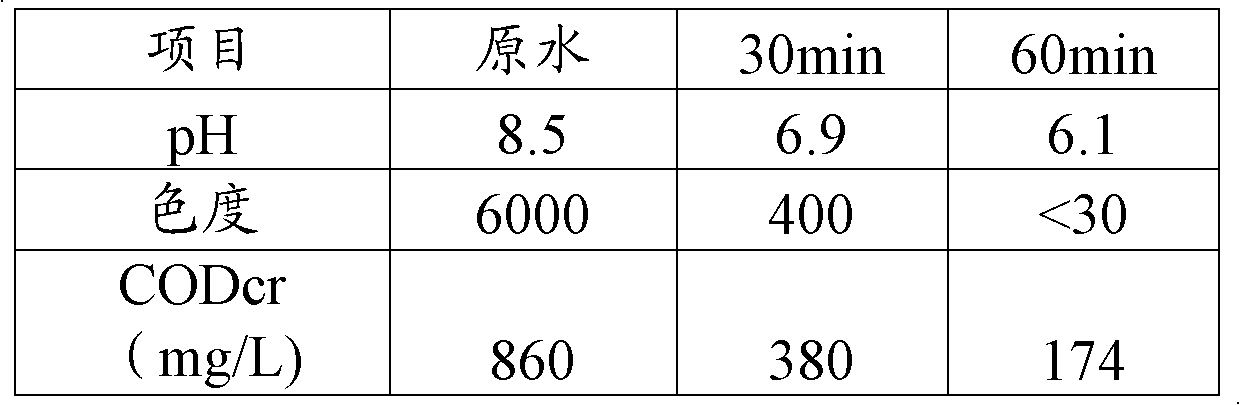

[0027] Utilize the tubular packed bed electrolysis device of the present invention to implement 1 to process the scheme and working principle of organic waste water as: when the waste water of processing is actual ink waste water, COD Cr 800~1000mg / L, chromaticity 6000 times, pH8.0~9.0. The waste water enters the electrolysis reaction area from the inlet pump through one end of the electrolytic cell through the inlet of the water flow distribution area, and the current density in the cell is 10mA / cm 2 , voltage 5V, water phase temperature and electrolysis at normal temperature, control the flow velocity in the organic wastewater pipe to 1.0, 2.0m / h, and keep the residence time of organic wastewater in the screen plunger flow electrolysis device at 30, 60min. During this period, the organic wastewater is electrolysis time. The treated waste wa...

Embodiment 3

[0036] Utilize the stencil plunger flow electrolysis device of Embodiment 1 of the present invention to deeply treat the biochemical water outlet scheme and working principle of a certain dyestuff enterprise: organic wastewater COD C 500~600mg / L, chroma 250~300 times, pH 6.0~7.0. Wastewater enters the electrolysis reaction area from the inlet pump through one end of the electrolytic cell through the inlet of the water flow distribution area, and the voltage and current density in the cell is 10mA / cm 2, 3V (the wastewater has a high conductivity), and the water phase temperature is electrolyzed under normal temperature conditions, the flow velocity in the organic wastewater pipe is controlled to be 1.0, 2.0m / h, and the retention time of the organic wastewater in the tubular packed bed electrolysis device is kept at 30, 60min, which is The period of time is the electrolysis time of organic wastewater. The treated waste water is discharged through the other end of the electrolyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com