Removal method of trace cobalt in nickel chloride solution

A technology of nickel chloride and solution, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of environmental pollution, high acidity, cumbersome chlorine, etc., achieve continuous and stable process, easy industrial production, simple and easy process line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for removing trace amounts of cobalt in nickel chloride solution, specifically comprising the following steps:

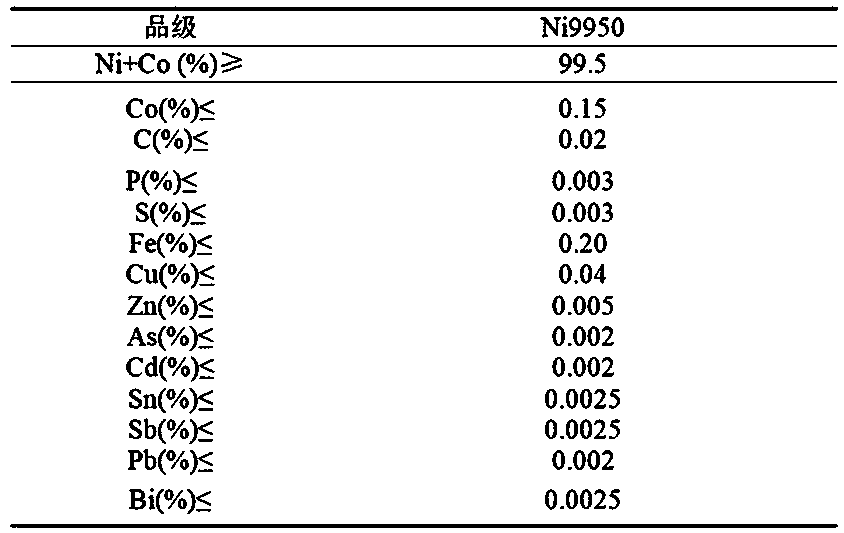

[0031] Step a. Prepare nickel chloride solution: use 99.95% nickel plate electrolysis solution to make nickel chloride solution;

[0032] Step b. adjust the pH value of the solution: adjust the pH value of the solution to be above 1 with ammonia or sodium hydroxide;

[0033] Step c. Pretreatment of extractant: prepare and extract organic phase, mix extractant Cyanex272 with sulfonated kerosene, wherein, Cyanex272 extractant is 8%, sulfonated kerosene is 92%, extractant saponification rate is 40%, soap is good The organic phase is first carried out nickel soap with pure nickel chloride, the concentration of nickel chloride for nickel soap is 5-15g / L, the ratio of nickel soap is 1:1, and the number of nickel soap series is 3;

[0034] Step d. Extraction and impurity removal: Mix the nickel chloride solution with adjusted pH value and the Cyanex272 org...

Embodiment 2

[0043] A method for removing trace amounts of cobalt in nickel chloride solution, specifically comprising the following steps:

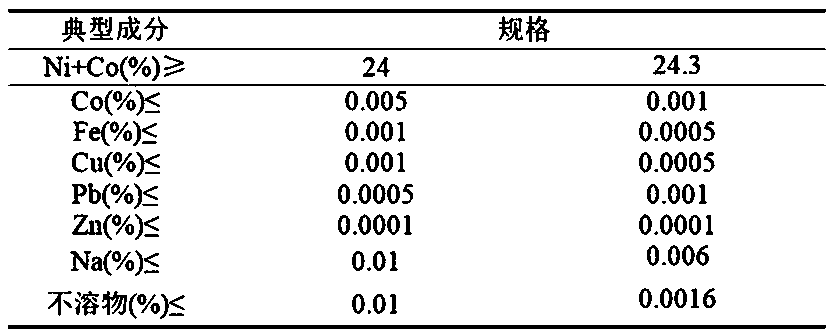

[0044] Step a. prepare nickel chloride solution: adopt nickel chloride crystal to dissolve and be made into nickel chloride solution;

[0045] Step b. adjust the pH value of the solution: adjust the pH value of the solution to be above 1 with ammonia or sodium hydroxide;

[0046] Step c. Pretreatment of extractant: prepare and extract organic phase, mix extractant Cyanex272 with sulfonated kerosene, wherein, Cyanex272 extractant is 5%, sulfonated kerosene is 95%, extractant saponification rate is 50%, soap is good The organic phase of the organic phase is first carried out nickel soap with pure nickel chloride, and the concentration of nickel chloride for nickel soap is 15g / L, and the nickel soap ratio is 1:1, and the nickel soap series is 4 grades;

[0047] Step d. Extraction and impurity removal: Mix the nickel chloride solution with adjusted pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com