Method for synchronization of silicon hydrolysis reaction and tubular membrane separation

A technology of hydrolysis reaction and tubular membrane, which is applied in the field of silicon hydrolysis and can solve problems such as imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

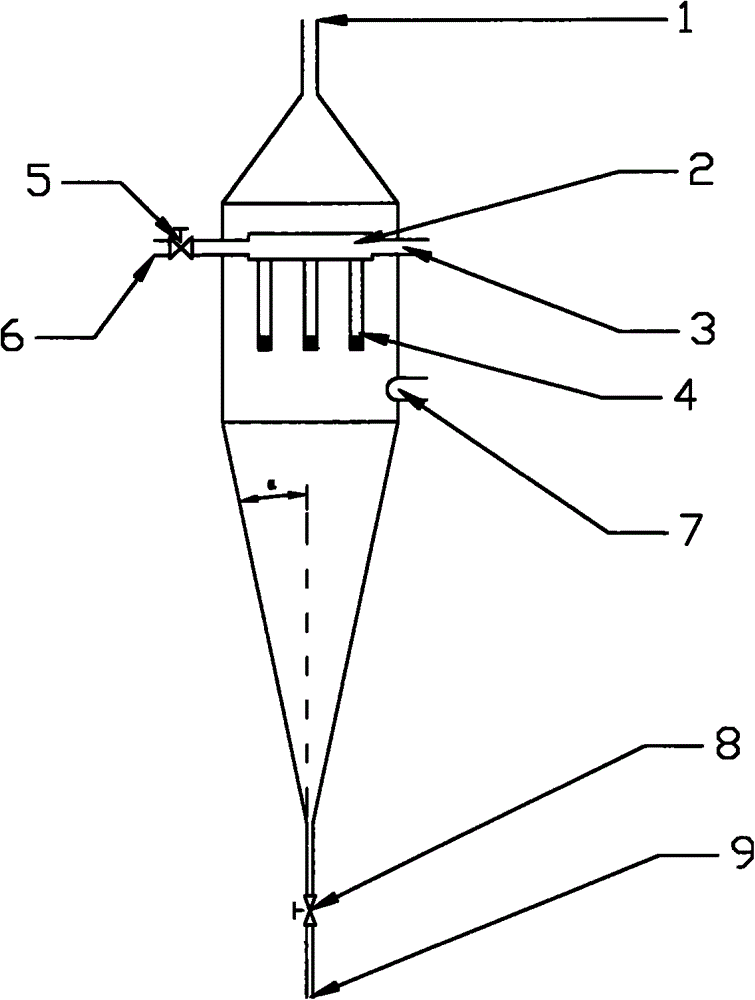

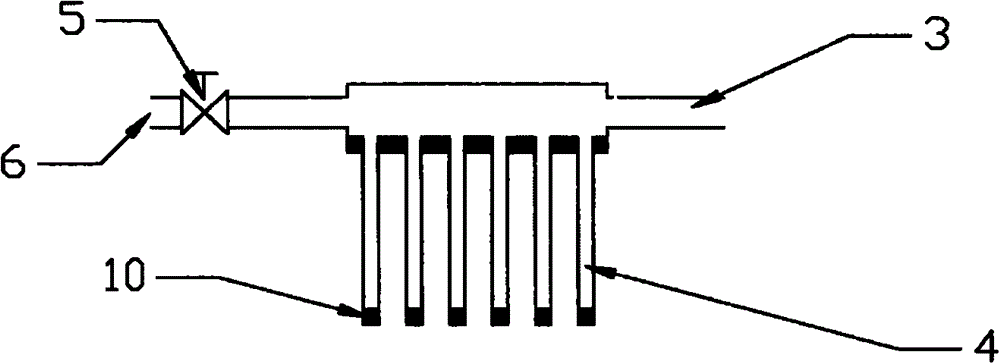

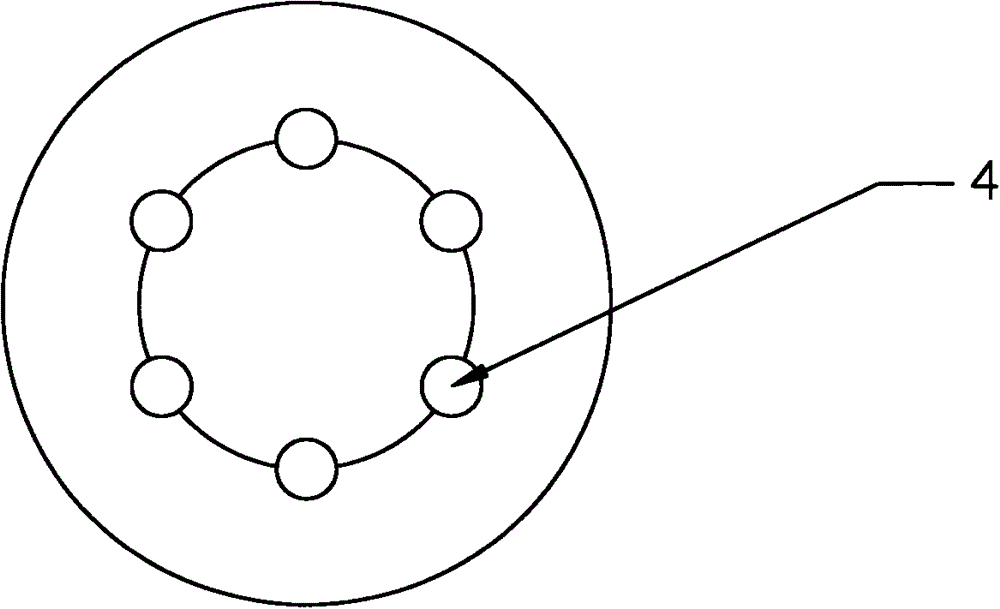

[0020] A method for synchronously carrying out silicon hydrolysis reaction and tubular membrane separation, its components are calculated in parts by weight, comprising the following process steps:

[0021] After sieving, the maximum particle size is 0.5mm, the amount of silicon powder with an average particle size of 0.2mm is 7g / min, and the feed amount of the hydrolyzate composed of 1 part of NaOH and 99 parts of water is 1000g / min. The conical reactor The taper is 15°, the height is 2m, the flow velocity of the hydrolyzate at the feed port is 0.5m / s, and the hydrolysis reaction temperature is 50°C. The separation section uses a PES tubular membrane with an inner diameter of 8 mm and a polyester non-woven fabric as the supporting tube layer. The membrane pore diameter is 0.1 μm. The membrane tubes are arranged in an equilateral triangle, the tube spacing is 16 mm, and the height of the membrane separation section is 1 m. Adjust the suction vacuum to keep the permeate volume ...

Embodiment 2

[0023] A method for synchronously carrying out silicon hydrolysis reaction and tubular membrane separation, its components are calculated in parts by weight, comprising the following process steps:

[0024] After sieving, the maximum particle size is 0.3mm, the amount of silicon powder with an average particle size of 0.15mm is 6g / min, and the feed amount of the hydrolyzate composed of 1 part of NaOH and 95 parts of water is 1000g / min. The conical reactor The taper is 15°, the height is 2m, the flow velocity of the hydrolyzate at the feed port is 0.4m / s, and the hydrolysis reaction temperature is 60°C. The separation section uses a polysulfone tubular membrane with an inner diameter of 8mm and a polyester non-woven fabric as the support tube layer. The membrane pore diameter is 0.08μm. The membrane tubes are arranged in an equilateral triangle, the tube spacing is 18mm, and the height of the membrane separation section is 1m. Adjust the suction vacuum to keep the permeate volu...

Embodiment 3

[0026] A method for synchronously carrying out silicon hydrolysis reaction and tubular membrane separation, its components are calculated in parts by weight, comprising the following process steps:

[0027] After sieving, the maximum particle size is 0.2mm, the amount of silicon powder with an average particle size of 0.12mm is 8g / min, and the feed amount of the hydrolyzate composed of 1 part of KOH and 95 parts of water is 1500g / min. The conical reactor The taper is 30°, the height is 2m, the flow velocity of the hydrolyzate at the feed port is 0.3m / s, and the hydrolysis reaction temperature is 60°C. The separation section uses a PES tubular membrane with an inner diameter of 10mm and a polyester non-woven fabric as the support tube layer. The membrane pore diameter is 0.1 μm. The membrane tubes are arranged in an equilateral triangle, the tube spacing is 14mm, and the height of the membrane separation section is 1m. Adjust the suction vacuum to keep the permeate volume at 1L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com