Nickel-based pure silicon type molecular sieve catalyst as well as preparation method and application thereof

A molecular sieve and catalyst technology, which is applied in the field of synthesis gas methanation catalyst preparation, can solve the problems of complex preparation process, difficult control of experimental conditions, and difficulty in industrial scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

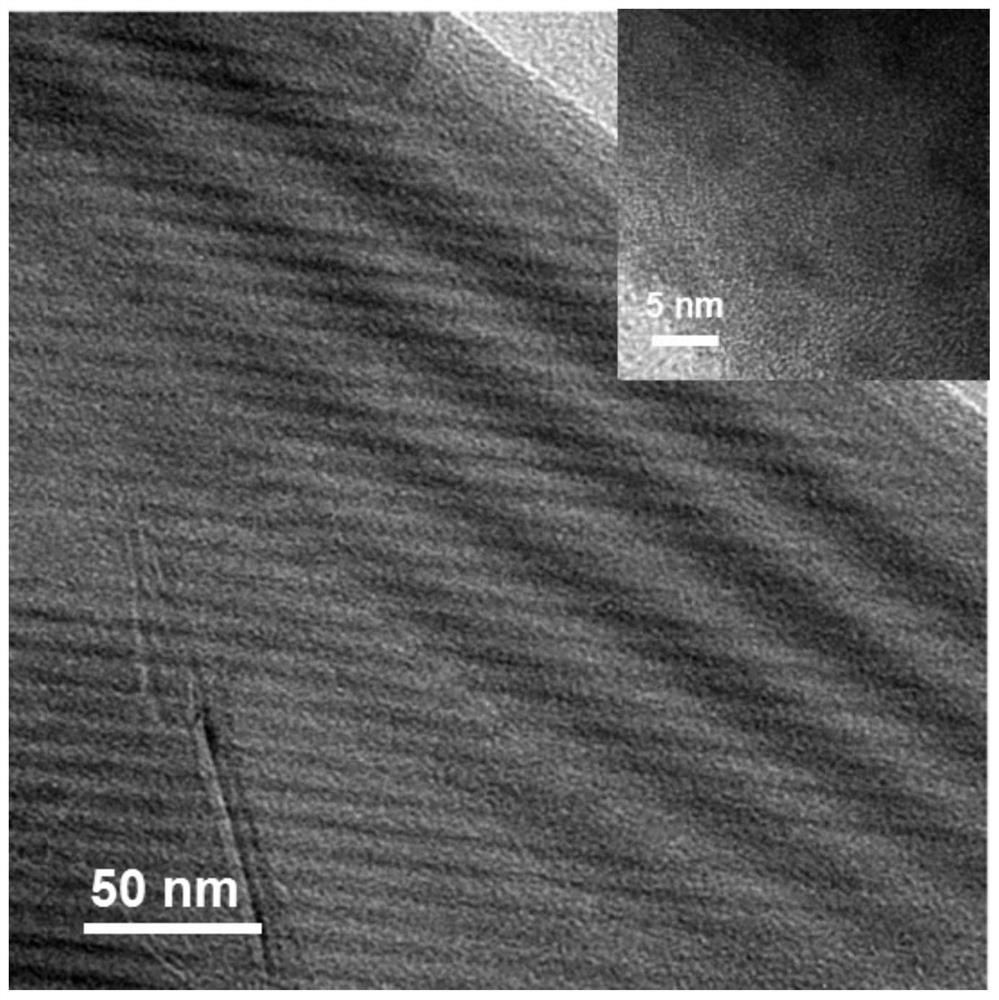

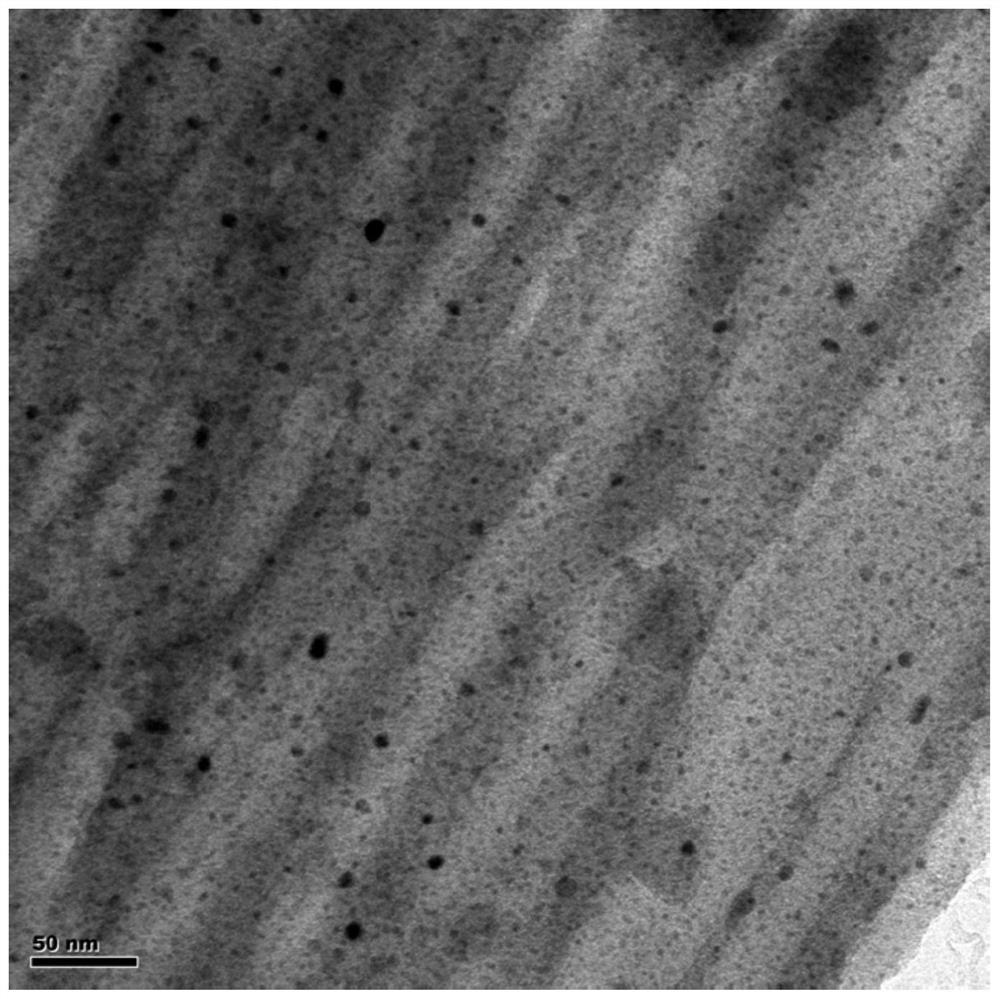

Embodiment 1

[0039] Add 3g tetraethyl orthosilicate (TEOS), 6g ethanol, 1.5g triblock copolymer P123 and 0.6g dilute hydrochloric acid (0.03mol / L) into the flask, condense and reflux for 1 hour at a temperature of 85°C, and reflux The obtained solution was placed in an oven at 40°C for 24 hours; 0.7g of PVP was weighed and added to 7gDMF, stirred for 6 hours, 0.46g of nickel nitrate hexahydrate was added to 1.5g of ethanol, stirred for 3 hours, and the above three The solution was mixed and stirred for 2 hours to prepare a spinning precursor solution. The prepared spinning precursor solution was used for electrospinning, the spinning parameters were voltage 18kV, the distance from the needle mouth to the receiving plate was 20cm, the liquid pushing speed was 0.8ml / h, the humidity was set at 20%, and the temperature was 30°C for electrospinning Silk. Dry the nanofiber membrane obtained after spinning at a temperature of 110°C for 10 hours, then place the dried nanofibers in a muffle furnac...

Embodiment 2

[0042] Add 3g tetraethyl orthosilicate (TEOS), 6g ethanol, 1.5g triblock copolymer P123 and 0.6g dilute hydrochloric acid (0.03mol / L) into the flask, condense and reflux for 1 hour at a temperature of 85°C, and reflux The obtained solution was placed in an oven at 40°C for 36 hours; 1.0g of PVP was weighed and added to 6gDMF, stirred for 6 hours, 0.46g of nickel nitrate hexahydrate was added to 1.5g of ethanol, stirred for 3 hours, and the above three The solution was mixed and stirred for 2 hours to prepare a spinning precursor solution. The prepared spinning precursor solution was used for electrospinning, the spinning parameters were voltage 18kV, the distance from the needle mouth to the receiving plate was 20cm, the liquid pushing speed was 0.8ml / h, the humidity was set at 20%, and the temperature was 30°C for electrospinning Silk. Dry the nanofiber membrane obtained after spinning at a temperature of 110°C for 10 hours, then place the dried nanofibers in a muffle furnac...

Embodiment 3

[0044] Add 6g of tetraethyl orthosilicate (TEOS), 10g of ethanol, 1.8g of triblock copolymer P123 and 1.2g of dilute hydrochloric acid (0.06mol / L) into the flask, condense and reflux for 1 hour at a temperature of 85°C, and reflux The obtained solution was placed in an oven at 40°C for 36 hours; 1.0g of PVP was weighed and added to 7gDMF, stirred for 6 hours, 0.46g of nickel nitrate hexahydrate was added to 1.5g of ethanol, stirred for 3 hours, and the above three The solution was mixed and stirred for 2 hours to prepare a spinning precursor solution. The prepared spinning precursor solution was used for electrospinning, the spinning parameters were voltage 18kV, the distance from the needle mouth to the receiving plate was 20cm, the liquid pushing speed was 0.8ml / h, the humidity was set at 20%, and the temperature was 30°C for electrospinning Silk. Dry the nanofiber membrane obtained after spinning at a temperature of 110°C for 10 hours, then place the dried nanofibers in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com