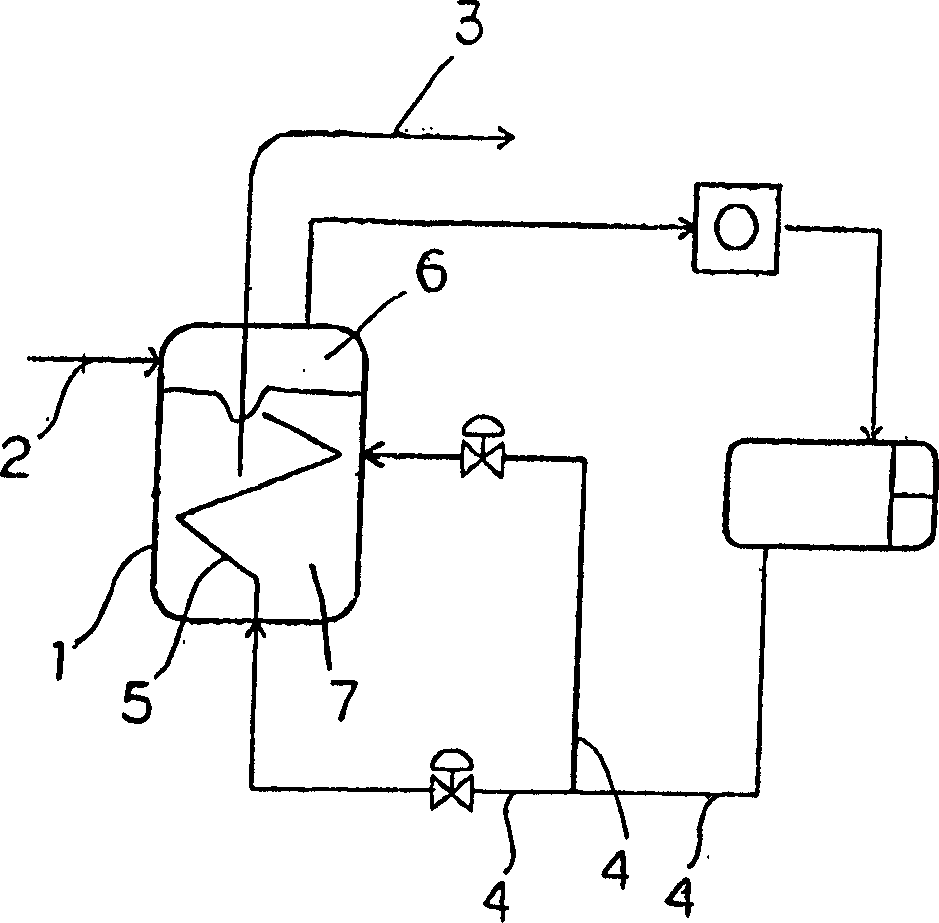

Process for producing polyolefin and vapor-phase polymerization apparatus therefor

A technology of olefin polymerization and polyolefin, applied in chemical/physical/physical-chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problems of blocking the discharge pipe of polymer particles, adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: the production of propylene-ethylene block copolymer

[0062] (1) Production of magnesium compound (a)

[0063] A glass reactor (capacity: about 12 L) equipped with a stirrer was sufficiently purged with nitrogen, and then charged with 4860 g of ethanol, 32 g of iodine and 320 g of metallic magnesium. The contents of the reactor were heated to react with each other while stirring under reflux until no hydrogen gas was generated from the reaction system to obtain a solid reaction product. The solid reaction product thus obtained was dried under reduced pressure to obtain a magnesium compound (a) [solid product].

[0064] (2) Preparation of solid catalyst component (A)

[0065] Into a three-neck glass Erlenmeyer flask (volume: 5 L) which was sufficiently purged with nitrogen gas, 160 g of the above-mentioned unpulverized magnesium compound (a), 80 ml of purified heptane, 24 ml of silicon tetrachloride and 23 ml of diethyl phthalate were charged. ester. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com