Overhead conveyor

a technology of overhead conveyor and conveyor belt, which is applied in the direction of elevated railways with suspended vehicles, monorails, vehicles, etc., can solve the problems of high labor intensity, high labor intensity, and high labor intensity of workers, and achieves stable assembly process, simple configuration, and continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

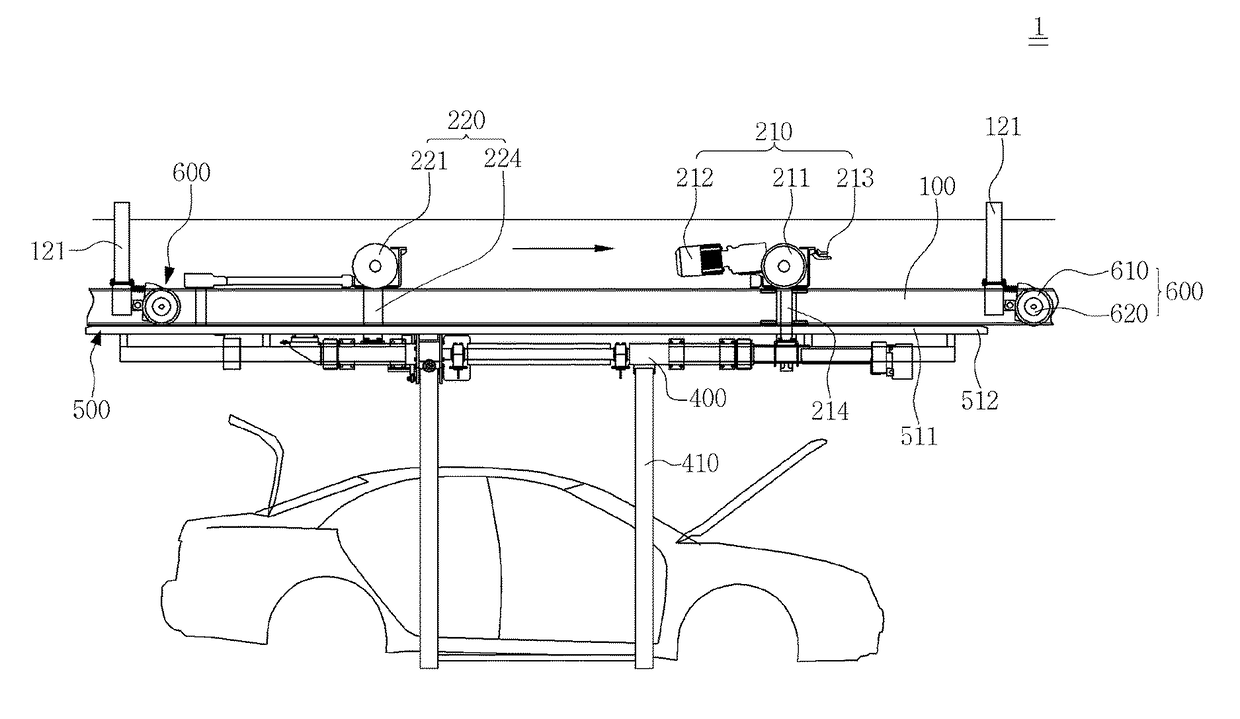

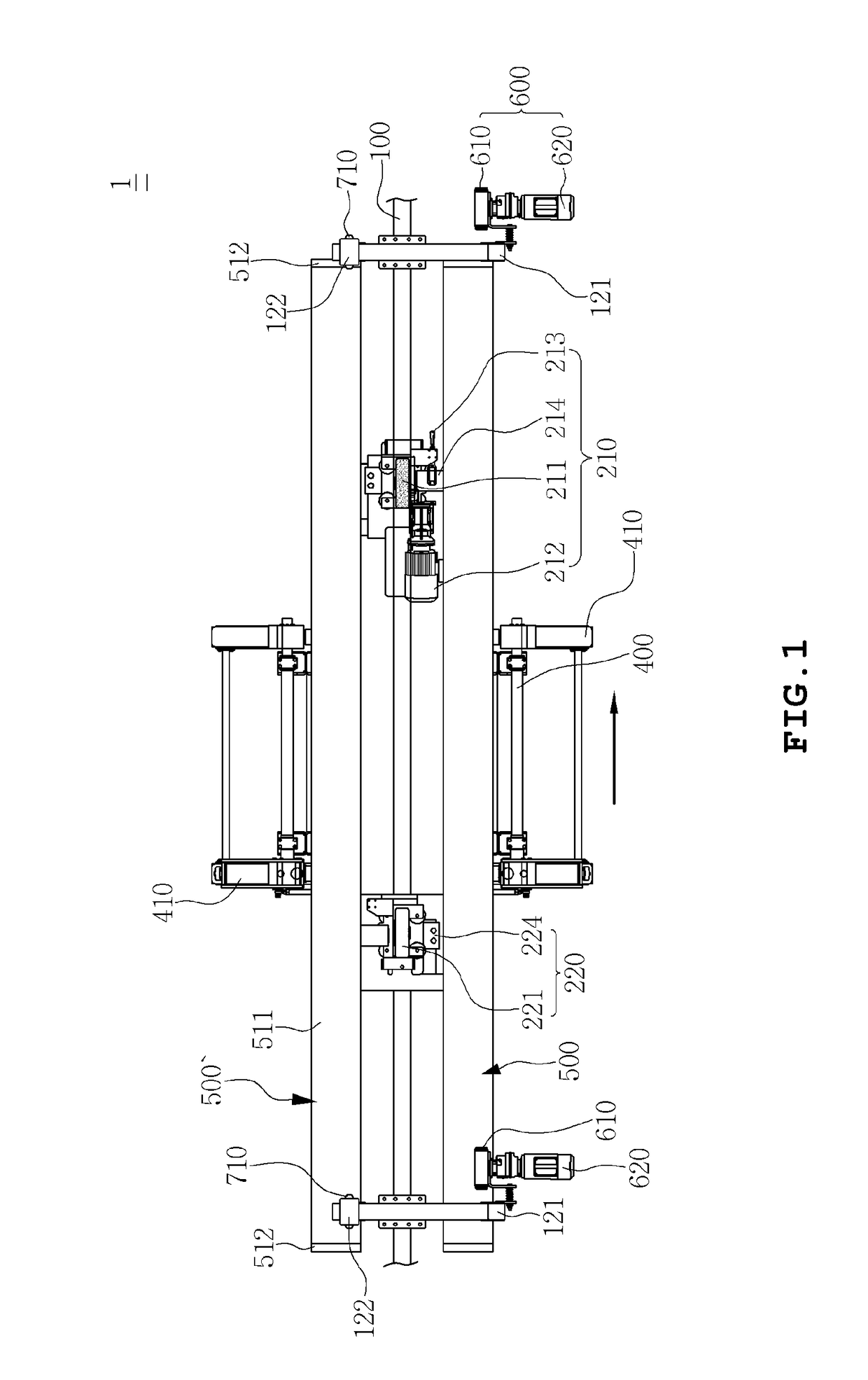

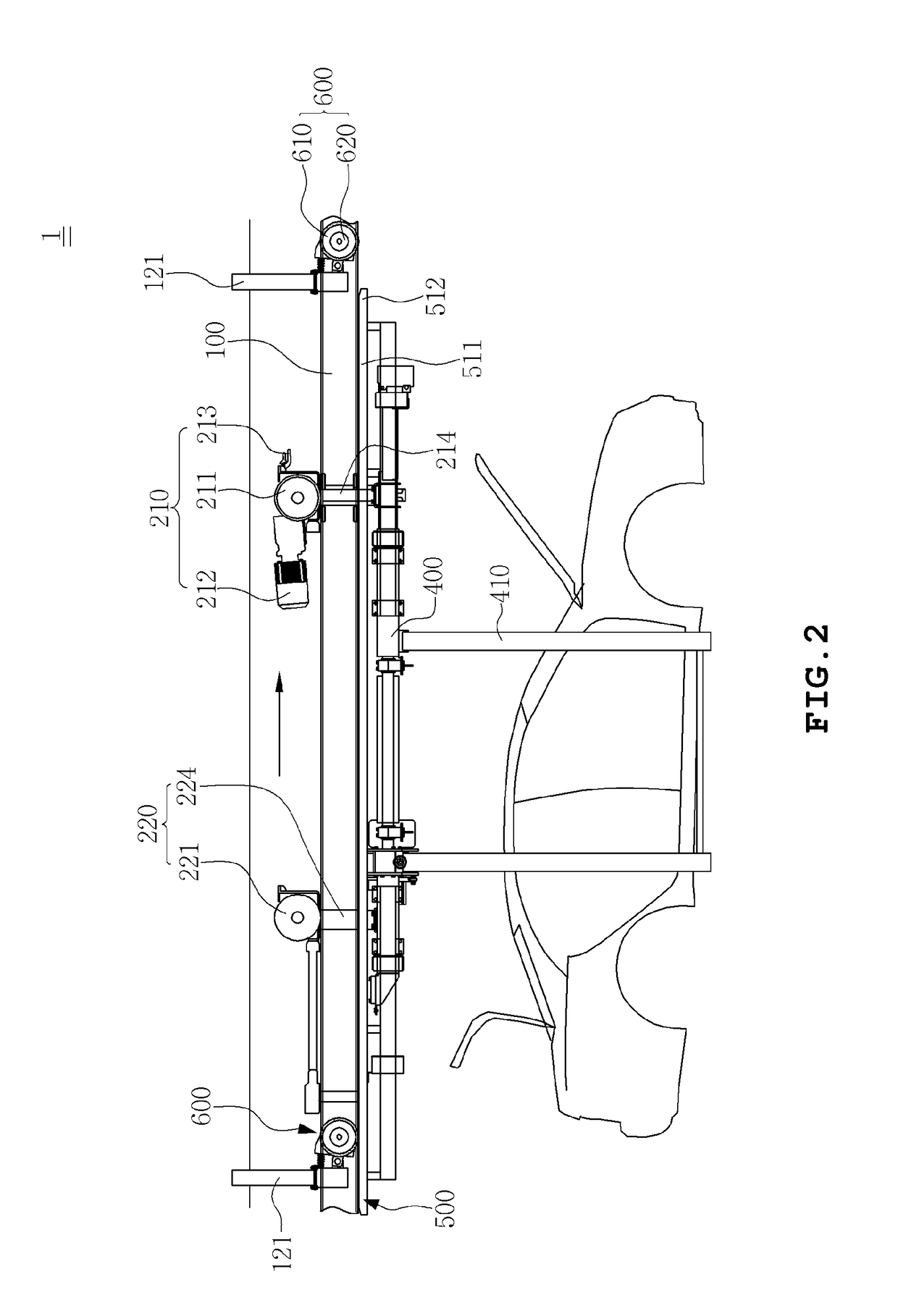

[0026]Hereinbelow, an overhead conveyor according to embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0027]Advantages and features of the present invention and a method of accomplishing them will be apparent from the following embodiments in conjunction with the accompanying drawings. Wherever possible, the same reference numerals will be used throughout the drawings and the description to refer to the same or like parts. In the following description, it is to be noted that when the functions of conventional elements and the detailed description of elements related with the present invention may make the gist of the present invention unclear, a detailed description of those elements will be omitted.

[0028]The present invention relates to a suspended-type overhead conveyor 1 that can run a hanger 400 carrying an object thereon along a monorail 100 hanging from the ceiling on an upper side of a working space in two running mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com