Continuous carbonation technology for producing calcium carbonate

A technology of calcium carbonate and carbonation, applied in the fields of calcium carbonate/strontium/barium, calcium/strontium/barium compounds, inorganic chemistry, etc., can solve problems such as equipment impact and adverse effects on performance, and achieve easy control of output and quality, and process Continuous, stable and easy-to-maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

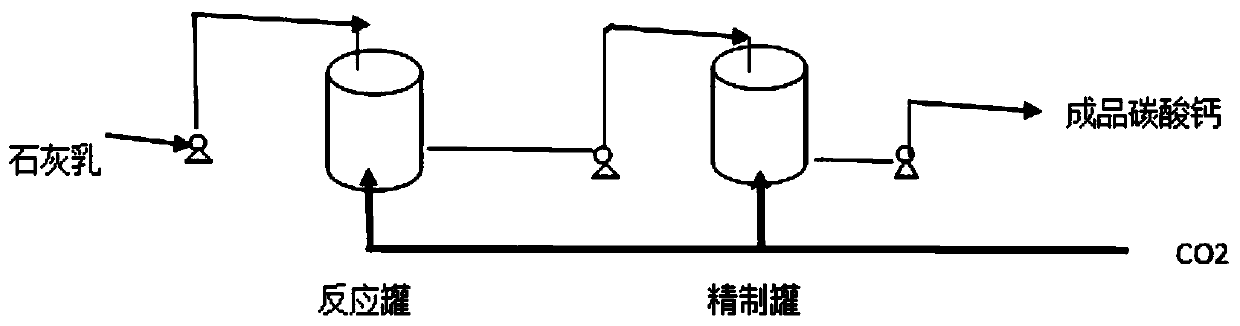

[0014] Such as figure 1 In the process, the reaction tank and the refining tank are connected in series, and a feed pump and a discharge pump are arranged at the feed pipe and the discharge pipe of the reaction tank, and a discharge pump is arranged at the discharge pipe of the refining tank (the discharge of the reaction tank The pump is also the feed pump for the refining tank)

[0015] Step 1. Mix calcium carbonate crystal nuclei with a particle size of 1.5-2 μm and slaked lime solution to form a slurry. The calcium carbonate crystal nuclei account for 5-10% of the slurry; continuously pump the above slurry (milk of lime) into the reaction At the same time, CO2 is introduced from the bottom of the reaction tank; the reaction occurs in the reaction tank, and the generated calcium carbonate continues to grow on the surface of the calcium carbonate crystal nucleus;

[0016] Step 2: Use a pump to pump the reacted calcium carbonate slurry out from the bottom, enter the refining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com