Method and system for producing anaerobic biogas slurry concentrated fertilizer

A production method and production system technology, applied in anaerobic digestion treatment, chemical instruments and methods, organic fertilizers, etc., can solve the problems of low nutrient content, storage and transportation difficulties, large biogas slurry output, etc., and achieve a high degree of automation, The effect of improving crop yield and promoting crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and embodiments, as well as the method and system of the present invention.

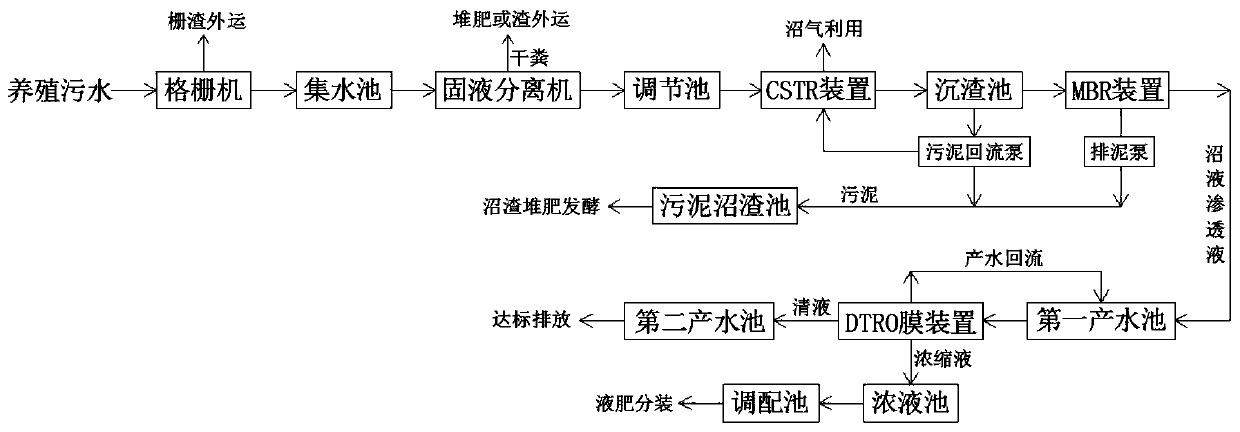

[0025] like figure 1 A kind of anaerobic biogas slurry concentrated fertilizer production method and system shown,

[0026] Firstly, the aquaculture sewage discharged from the barn is separated from the large solid particles by the grid machine, and then the grid residue is collected and transported, and the sewage is collected into the sump, and then the sewage is pumped into the solid-liquid separator for solid-liquid separation, and the separated Most of the small particles of feces and slag suspended matter are composted or slag is transported out for comprehensive recovery treatment, and the wastewater is processed in the next step;

[0027] Then discharge the slag-removed wastewater into the regulating tank to balance the water quality and quantity. After 10 hours of hydraulic rete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com