Integral solution refrigerating and concentrating device and refrigerating and concentrating method thereof

A freeze-concentration, all-in-one technology, used in solution crystallization, chemical instruments and methods, heat exchange cooling crystallization, etc., can solve the damage of porous water permeability, the inability to achieve the effect of separating ice crystals from mother liquor, and the inability of mother liquor to be thrown out by centrifugal force, etc. problem, to achieve the effect of improving the concentration effect, compact structure and good concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

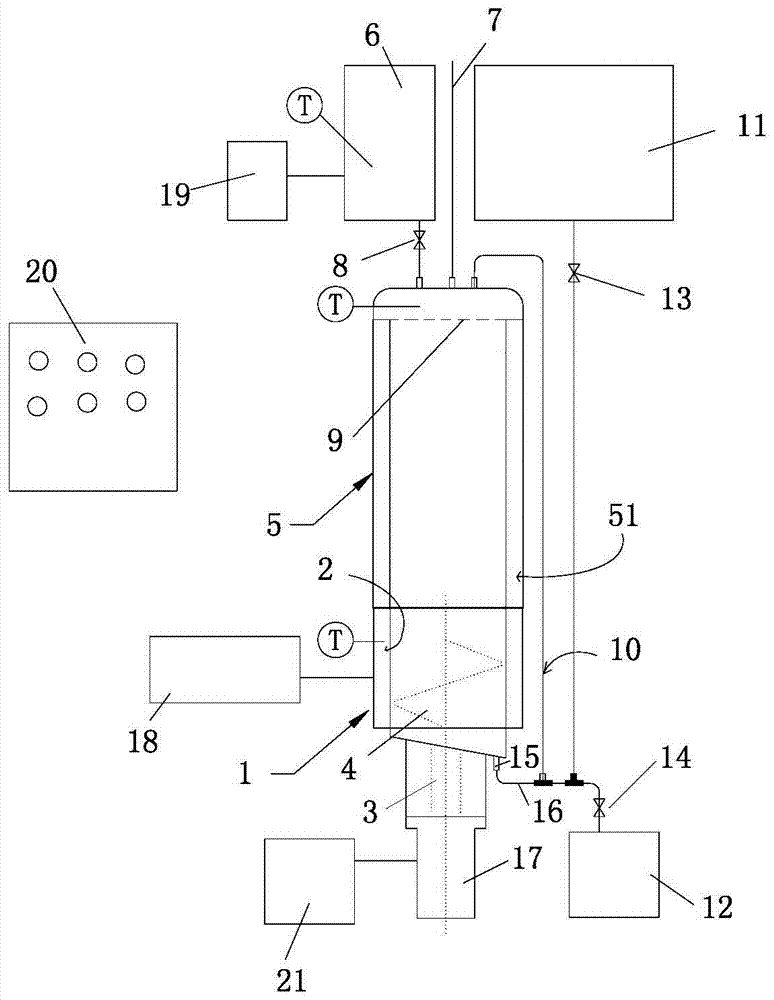

[0040] This embodiment is the application method of the integrated solution freeze concentration equipment in embodiment 1, including the following steps:

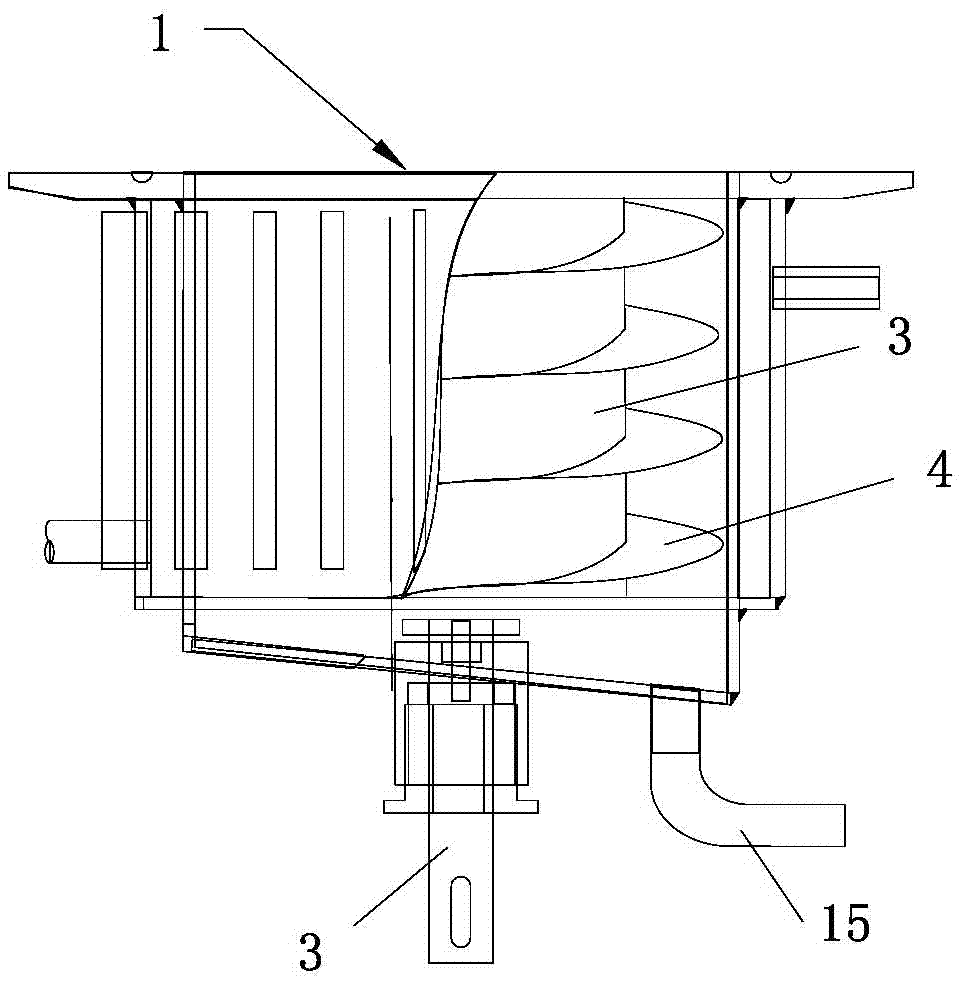

[0041] Step 1, open the feed valve 13, close the discharge valve 14 and the water inlet valve 8, inject the solution to be concentrated in the raw material box 11 into the scraped surface heat exchanger 1 and fill the crystallization-washing chamber 5;

[0042] Step 2, close the feed valve 13, the discharge valve 14 and the water inlet valve 8, start the second refrigeration unit 19 to pre-cool the washing water, start the spiral scraper 4 and start the first refrigeration unit 18 of the scraped surface heat exchanger 1, The solution to be concentrated crystallizes on the frozen wall 2 of the scraped surface heat exchanger, and the spiral scraper 4 scrapes off the crystals on the frozen wall 2, and the crystal is pushed by the spiral scraper 4 to the crystallization-washing chamber 5; then, the crystallization-washing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com