Method for removing impurities in phosphoric acid

A phosphoric acid and impurity technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of products not meeting high standard requirements, reduced nutrients, gray color of finished ammonium phosphate, etc., and improve the qualification rate of total nutrients , fineness, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

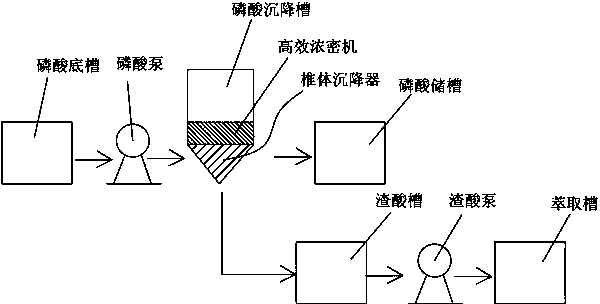

[0011] like figure 1 Shown, a kind of impurity removal method in phosphoric acid comprises the following steps:

[0012] First, a phosphoric acid settling tank is installed, and a high-efficiency thickener is installed in the tank, and then a cone settler is provided at the bottom of the phosphoric acid settling tank, and the precipitated impurities are discharged once every 0.5-1.5h, and discharged into the slag acid tank. Then it is pumped into the extraction tank through the slag acid pump to achieve liquid-solid separation, the purity of the finished phosphoric acid is improved, and the solid impurities are recycled, thereby realizing the process improvement of removing impurities in phosphoric acid.

[0013] The phosphoric acid solution in the phosphoric acid settling tank is driven into the phosphoric acid settling tank from the phosphoric acid bottom tank by a phosphoric acid pump.

[0014] The finished phosphoric acid solution in the phosphoric acid settling tank is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com