Solvent desorption device and method

A desorption and solvent technology, applied in the field of desorption devices, can solve the problems of non-reusable, low desorption efficiency, long-term two-phase equilibrium, etc., and achieve the effects of ensuring quality control, high desorption efficiency, and improving concentration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A solvent desorption device, comprising an adsorption tube, an adsorption tube connector, a pump and a desorption flow path;

[0058] The sample to be tested is adsorbed in the adsorption tube; the adsorption tube can be a traditional adsorption tube, or an adsorption medium such as a filter membrane that collects the sample to be tested is packed into a container to form;

[0059] The adsorption tube communicates with the desorption flow path through an adsorption tube joint.

[0060] The pump is in the desorption flow path. When the adsorption tube is connected to the desorption flow path and the desorption liquid is also added to the desorption flow path, the pump drives the desorption liquid so that the desorption liquid passes through the adsorption tube and circulates in the desorption flow path. to desorb the sample in the adsorption tube to an equilibrium state.

[0061] Further, the solvent desorption device also includes a flow control module to control the p...

Embodiment 2

[0093] This embodiment is an application example of embodiment 1 when desorbing the adsorption tube that collects the air in the workplace.

[0094] The sampling process of the adsorption tube with the sample to be tested provided in this application example is as follows: According to the occupational health standard of the Ministry of Health - "Determination of Toxic Substances in the Workplace Air Aromatic Hydrocarbon Compounds" (GBZ / T160.42-2007) It is stipulated that in the production workshop of the pesticide atrazine, the air in the workplace is collected for 8 hours through a 10 mg, approximately 2 cm long activated carbon adsorption tube at a sampling flow rate of 50 mL / min. The suction tube is installed on the upper part of the laborer's chest to collect the air in his breathing zone.

[0095] The desorption liquid used in this application example is carbon disulfide.

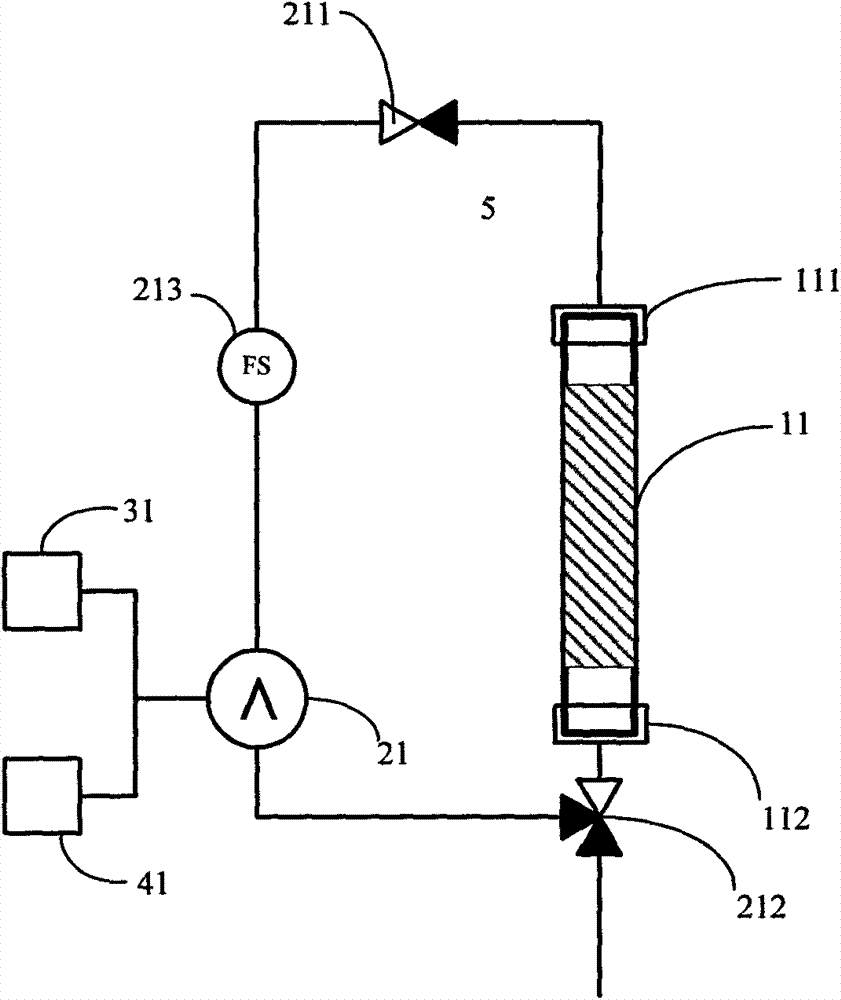

[0096] see figure 1 , the solvent desorption device provided in this application example include...

Embodiment 3

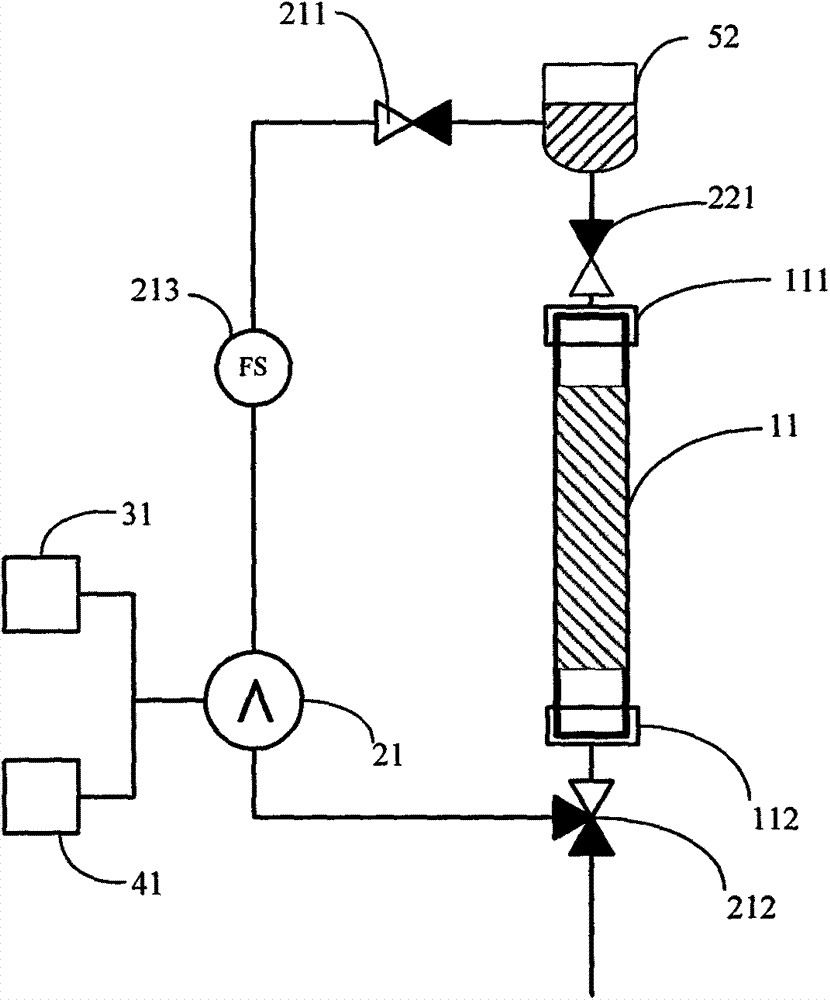

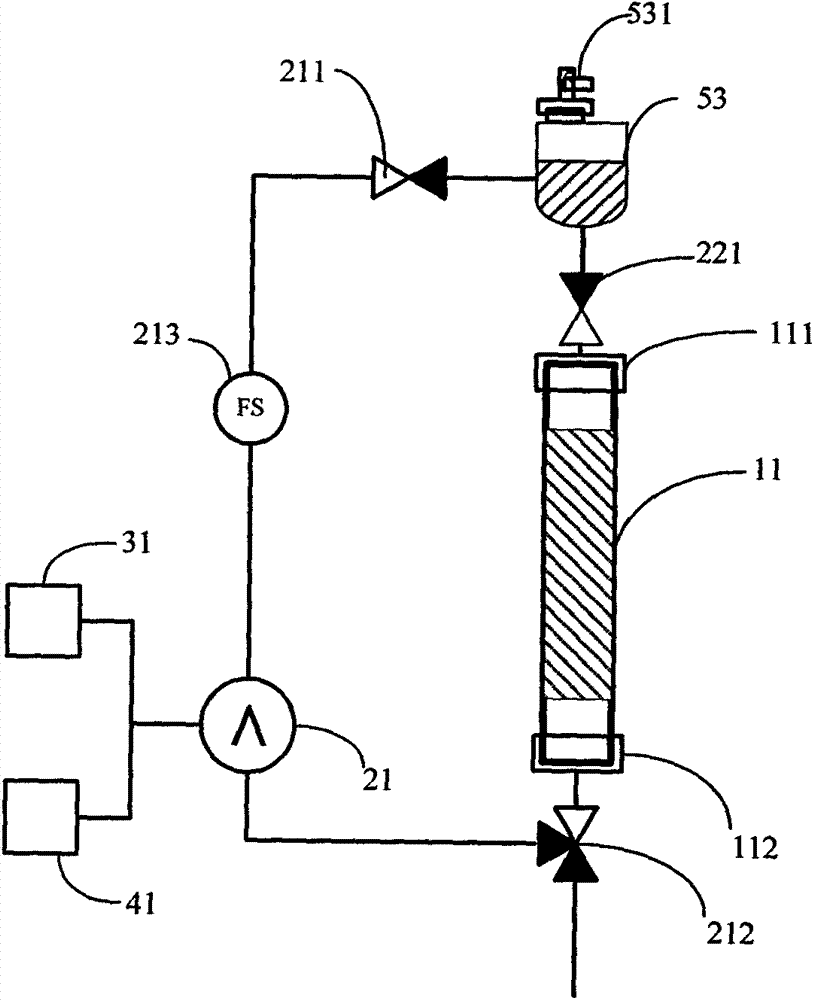

[0108] see figure 2 , the solvent desorption device provided in this embodiment is different from the solvent desorption device described in Example 2 in that:

[0109] The solvent desorption device also includes a liquid storage bottle 52 in the desorption flow path, and the liquid storage bottle 52 is located between the solenoid valve 211 and the solenoid valve 221;

[0110] The pump 21 pumps the sample in the desorption flow path into the liquid storage bottle 52 for storage, and then takes a sample from the liquid storage bottle.

[0111] Preferably, a scale is engraved on the outer wall of the liquid storage bottle, so as to facilitate reading the liquid volume in the liquid storage bottle.

[0112] This embodiment also provides a solvent desorption method, which is different from the solvent desorption method described in Example 2:

[0113] In step B, the solenoid valve 211, solenoid valve 212, and solenoid valve 221 are opened, and the pump 21 pumps 1 mL of carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com