Automatic liquid supply device for magnesium alloy cast rolling

An automatic liquid supply and magnesium alloy technology, applied in the field of metal smelting or casting equipment, can solve the problems of increasing daily maintenance workload, maintenance work safety risks, low output, and multi-equipment investment in daily cleaning work, etc., to avoid liquid supply. The effect of instability, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

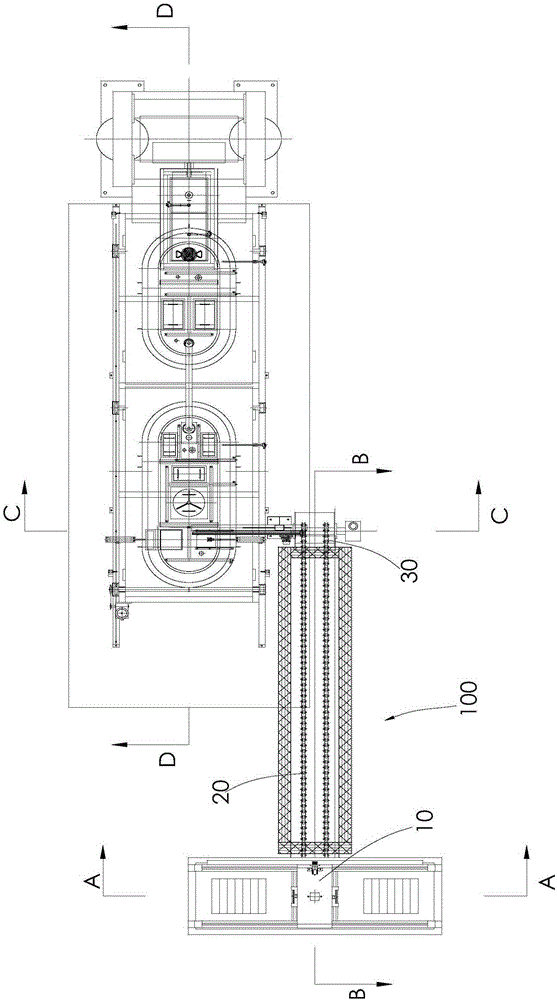

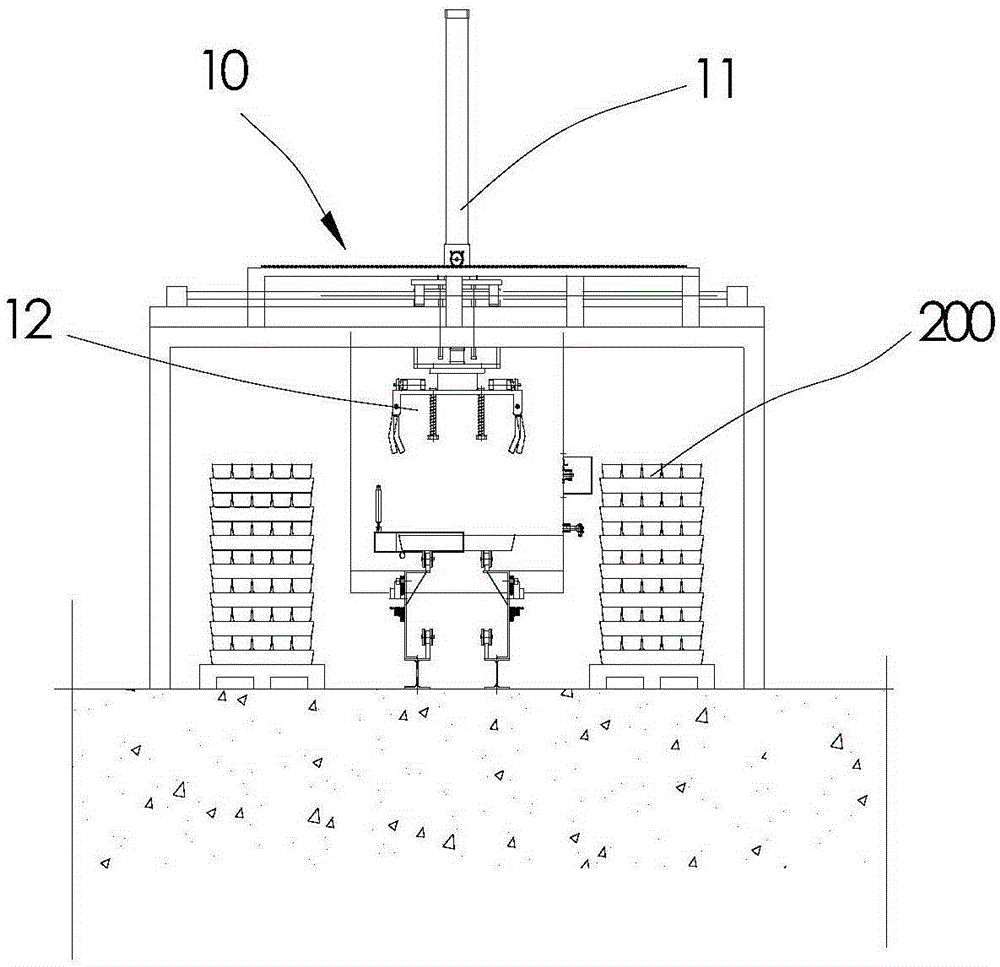

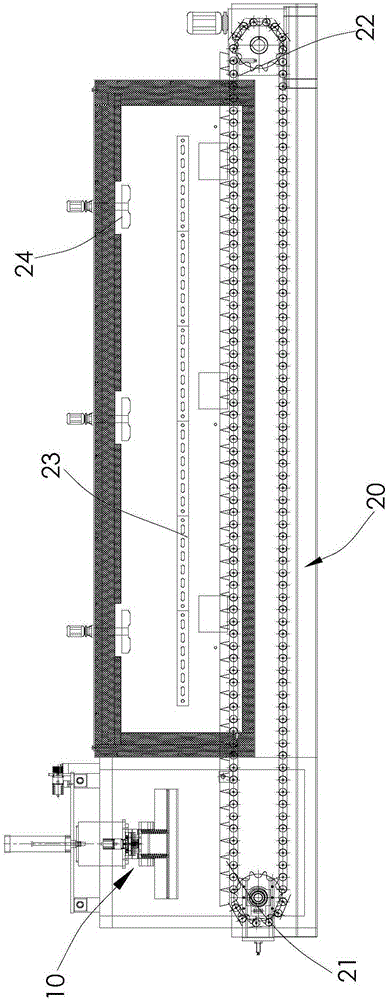

[0029] Such as Figure 1-5 The automatic liquid supply device for casting and rolling of magnesium alloys includes a casting machine 90, a front liquid tank 80, a heat preservation and standing furnace 60, a melting furnace 40 and a magnesium ingot conveying device 100, the outlet of the front liquid tank 80 and the casting of the casting machine 90 The nozzle 91 is connected, and is used to provide magnesium liquid to the casting and rolling machine 90, so that the magnesium alloy is formed; at the same time, the outlet of the heat preservation static furnace 60 is connected with the inlet of the front liquid tank 80, and is used to provide magnesium liquid in the front liquid tank 80; the heat preservation static furnace 60 communicates with the melting furnace 40 through the siphon tube 50. When starting the operation, the magnesium ingot 200 is deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com