Purification method for nickel electric accumulated liquid for manufacturing high-purity nickel plate

A technology of electrowinning and nickel plates, applied in the field of purification of nickel electrowinning solution for preparing high-purity nickel plates, can solve the problems that cobalt cannot form anions, environmental pollution, high acidity, etc., achieve good impurity removal effect, continuous and stable process, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

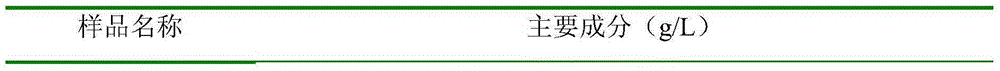

[0024] The solution after nickel plate electrolysis is used for extraction and impurity removal, the extraction agent Cyanex272, the organic phase concentration is 2-10%, solvent oil, the saponification rate is 30-50%, the extraction ratio is 1:1, and the raffinate is degreased after electrolysis It can be reused after loaded with organic stripping, pickling and saponification. The results of the three parallel experiments are shown in Table 1.

[0025] Table 1 Comparison of solution indicators before and after nickel chloride solution removal

[0026]

[0027]

[0028] Electrowinning the extracted solution, the experimental conditions are: temperature 50-70°C, current density 30-100A / m 2 , the nickel concentration is 50-220g / L, and the nickel content in the obtained nickel plate is 99.9997%. The experimental results are shown in Table 3.

Embodiment 2

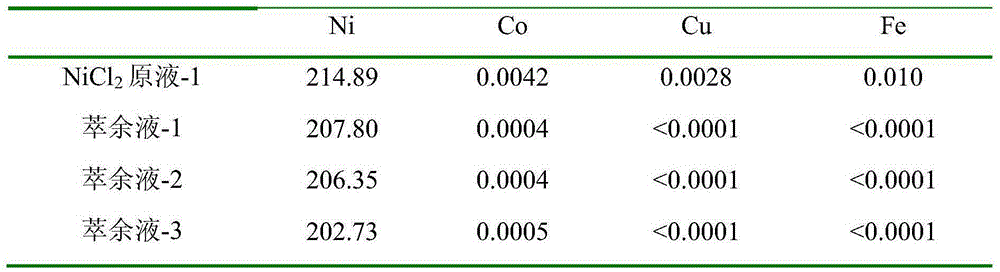

[0030] The solution after dissolving nickel chloride crystals was taken for extraction experiments. The extraction agent was Cyanex272, the concentration of the organic phase was 2-10%, the solvent oil was 90-98%, the saponification rate was 30-50%, and the extraction ratio was 1:1. The results are shown in Table 2.

[0031] Table 2 Comparison of solution indicators before and after nickel chloride solution removal

[0032]

[0033] The above-mentioned purified nickel chloride solution was subjected to electrowinning under the same experimental conditions as above, and the nickel content in the obtained nickel plate was 99.999724%. The experimental results are shown in Table 4.

[0034] It can be seen from the above that, through the method of the present invention, the solution with a purity of 99.95% nickel plate electrolysis or nickel chloride crystal dissolution can effectively remove impurities cobalt, copper, and iron after being extracted by Cyanex272, and realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com