Preparation method of voglibose impurity vinyl voglibose

A technology for voglibose and preparation process, which is applied in the preparation of organic compounds, preparation of aminohydroxy compounds, chemical instruments and methods, etc., can solve the problems of no hydrogen spectrum and mass spectrometry, defective preparation process, unreliable data, etc. , to achieve the effect of convenient operation, simple post-processing and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

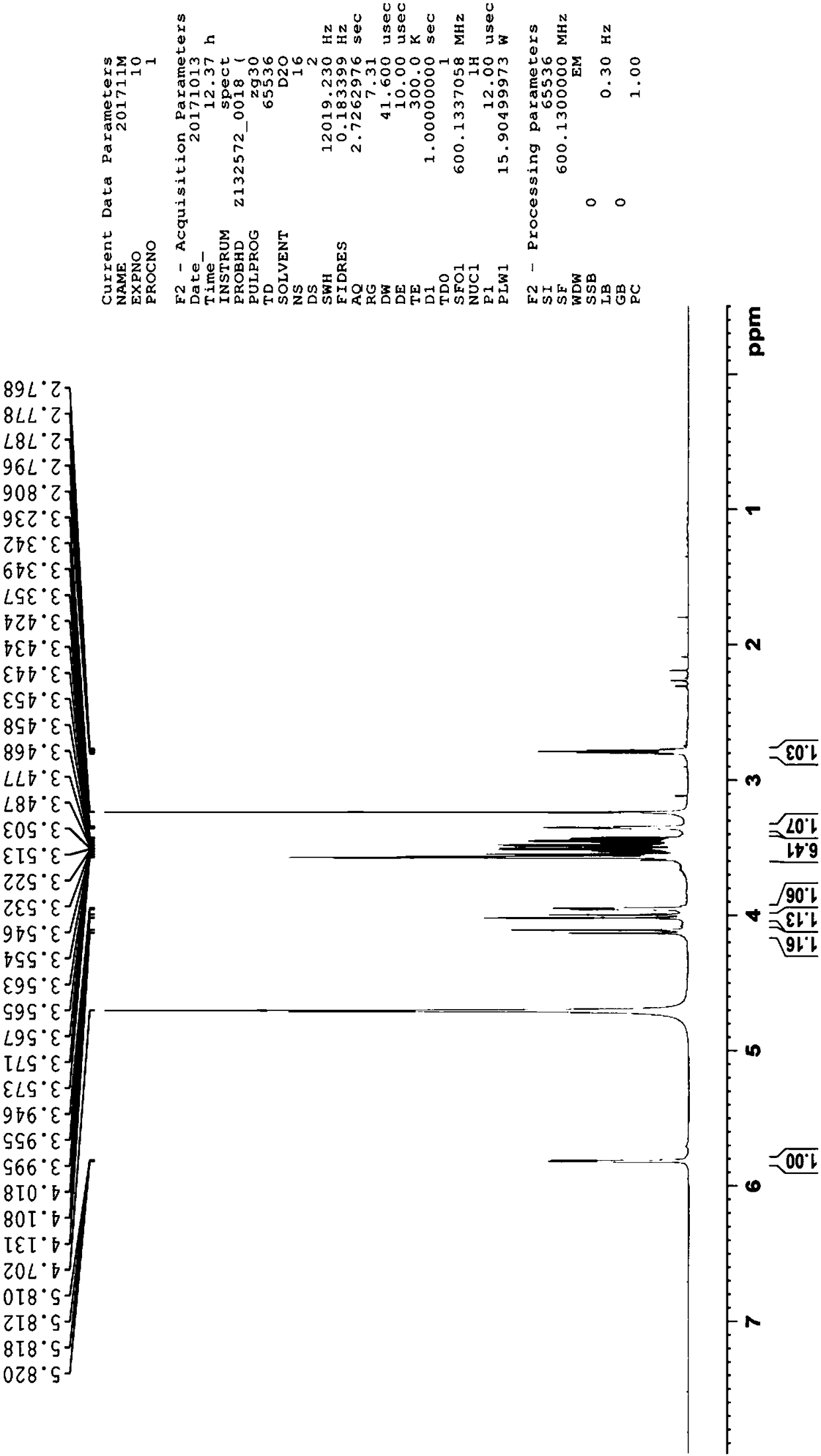

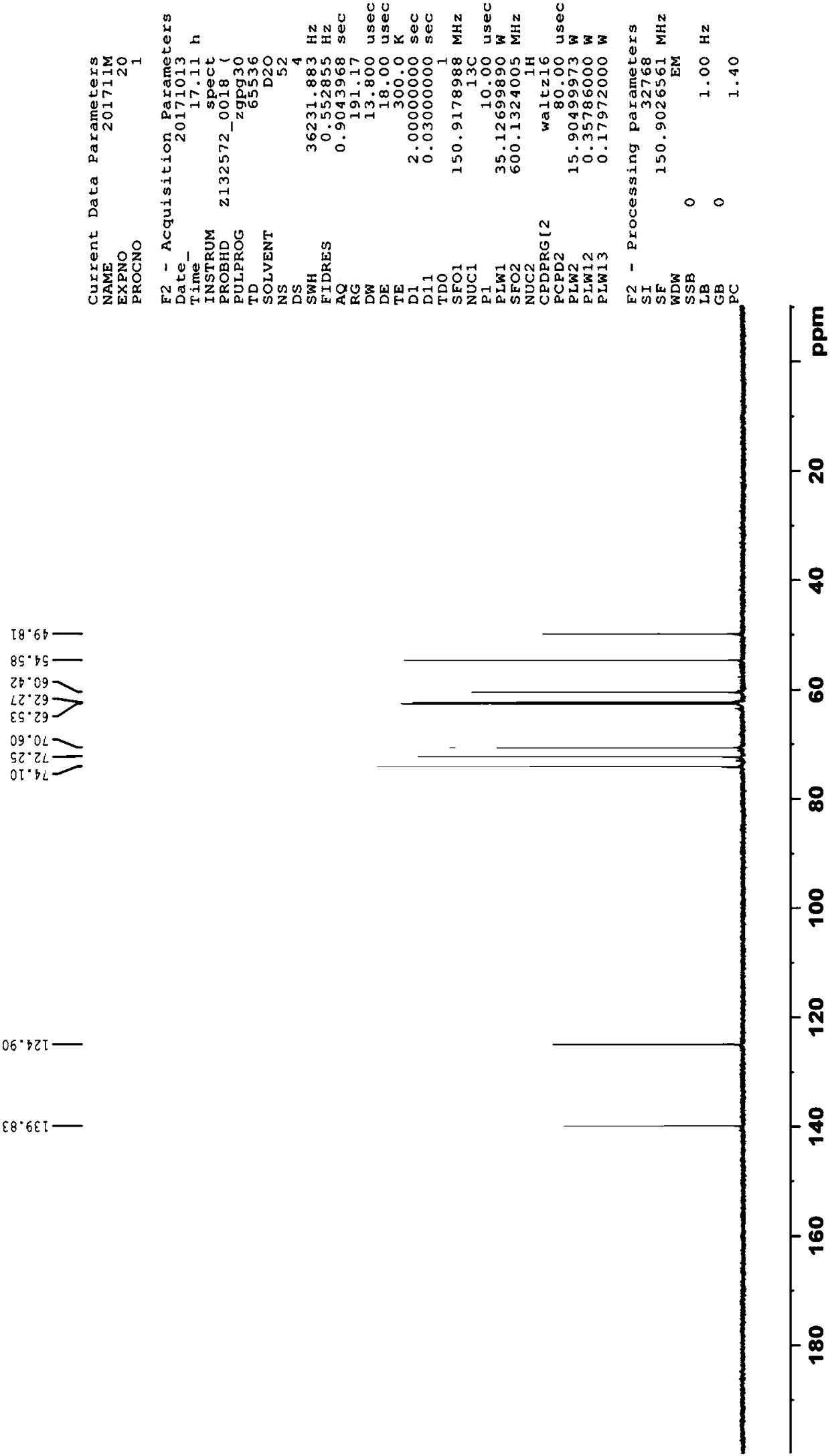

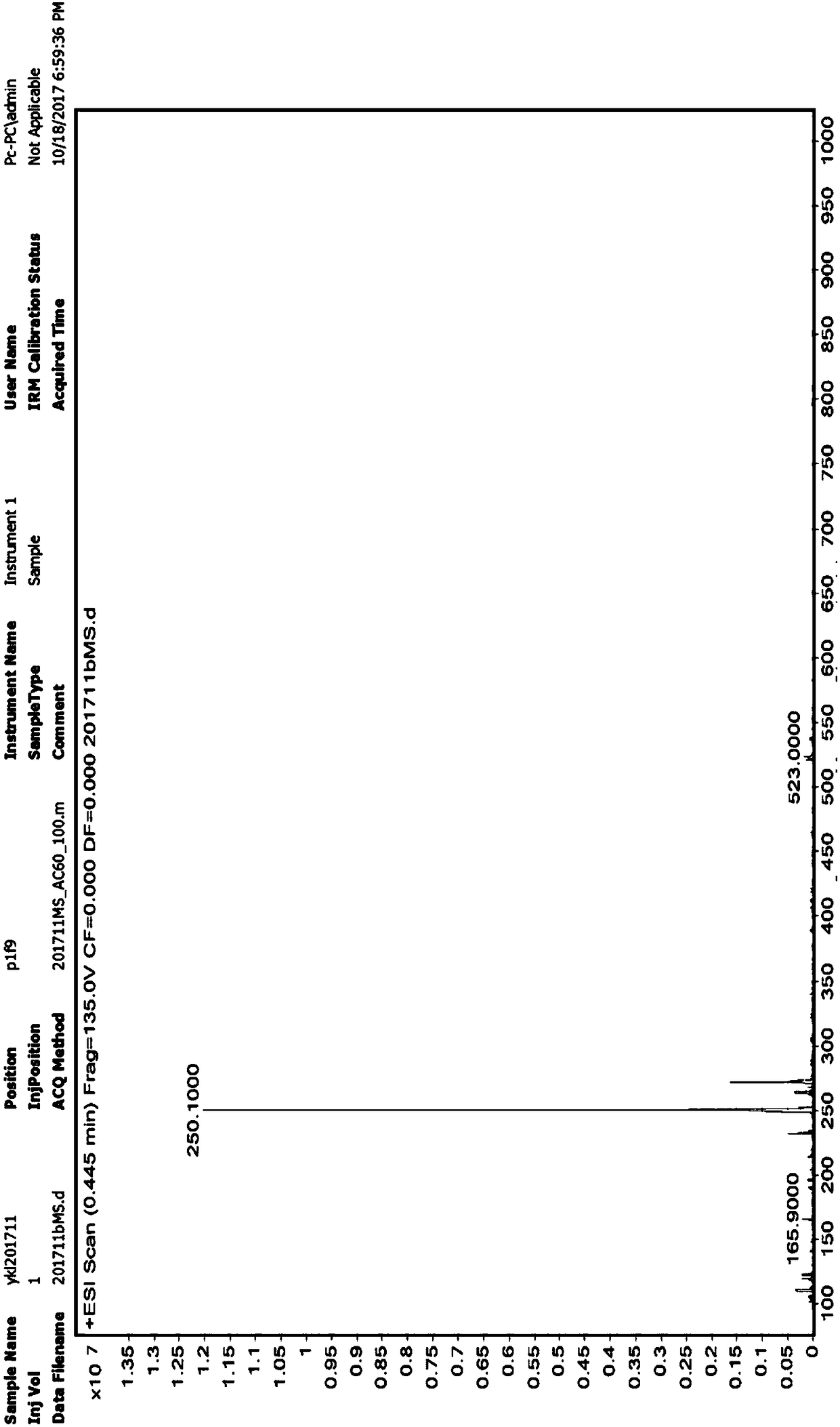

Image

Examples

Embodiment 1

[0029] Add 2.63g (0.015mol) of enamine to a 100ml single-necked flask, then add 1.62g (0.018mol) of 1,3-dihydroxyacetone, then add 40ml of acetone, stir well and then add 0.79g (0.021mol) Sodium borohydride, the reaction was stirred overnight at room temperature. Use concentrated hydrochloric acid to adjust PH=7, after concentrating acetone, add 50ml of water to dissolve the residue, add the mother liquor to 200ml of 732 resin, stir and absorb for half an hour, then put it on the chromatographic column to let off the water, then rinse the resin with 100ml of water, and then Add 100ml of 25-28% concentrated ammonia water to the resin, absorb for 1 hour, and release concentrated ammonia water. The concentrated ammonia water was concentrated to obtain 3.53 g of crude vinyl voglibose with a content of 79.56% and a yield of 75.11%.

Embodiment 2

[0031] Add 1.75g (0.01mol) of enamine to a 100ml single-necked flask, then add 1.35g (0.015mol) of 1,3-dihydroxyacetone, then add 40ml of tetrahydrofuran, stir well and then add 15ml of 1M (0.015mol) Borane tetrahydrofuran complex, stirred overnight at room temperature. Use concentrated hydrochloric acid to adjust PH=7, concentrate THF, then add 50ml of water to dissolve the residue, add the mother liquor to 150ml of 732 resin for half an hour, then put it on the column to let off the water, then rinse the resin with 100ml of water, and then add 80ml Add 25-28% concentrated ammonia water to the resin, absorb it for 1 hour, and release concentrated ammonia water. The concentrated ammonia water was concentrated to obtain 2.56 g of the crude product of vinyl voglibose with a content of 89.88% and a yield of 92.31%.

[0032] Add the obtained crude product into 20ml of absolute ethanol, raise the temperature to reflux, heat filter after complete dissolution, cool the filtrate in...

Embodiment 3

[0034] Add 1.40g (0.008mol) of enamine to a 100ml single-necked flask, then add 1.30g (0.014mol) of 1,3-dihydroxyacetone, then add 40ml of acetonitrile, stir well and then add 1.95g (0.016mol) Sodium triethylborohydride, stirred overnight at room temperature. Use concentrated hydrochloric acid to adjust PH=7, concentrate acetonitrile, then add 50ml of water to dissolve the residue, add the mother liquor to 120ml of 732 resin for half an hour, then put it on the column to let off the water, then rinse the resin with 80ml of water, and then add 70ml of 25 Add ~28% concentrated ammonia water to the resin, absorb it for 1 hour, and release concentrated ammonia water. The concentrated ammonia water was concentrated to obtain 1.96 g of crude vinyl voglibose with a content of 82.75% and a yield of 81.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com