Modified gamma-Al2O3 and processing method thereof

A processing method and modification technology, applied in the field of modified γ-Al2O3 and its processing, can solve the problems of poor high temperature resistance, great influence of ammonia water, high cost of raw materials, etc., and achieve low cost, environmental friendliness, and good high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

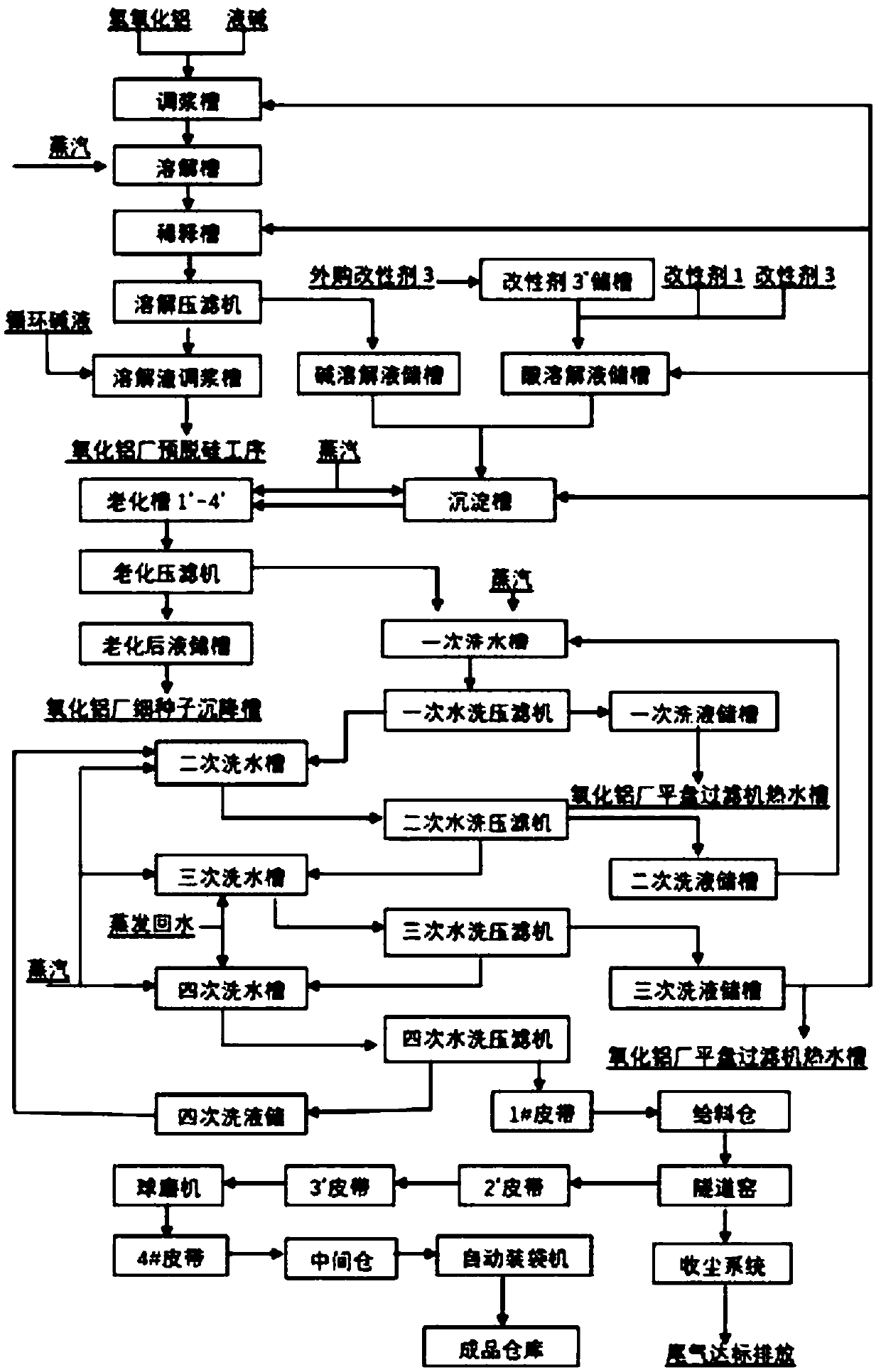

Image

Examples

Embodiment 1

[0038] The filtrate obtained from three washings is used as the bottom liquid, and industrial aluminum hydroxide and lye are added to the slurry mixing tank according to the mass ratio of 1:1 while stirring, and the solid ratio of the alkali immersion liquid is adjusted to 2. After pulping, the material is transferred to the dissolving tank by the pulping pump, and steam is passed into the dissolving tank to indirectly heat to 100°C, and stirred and mixed to form a sodium aluminate solution. The dissolved sodium aluminate solution flows into the dilution tank through the pipeline and mixes, and the alkali concentration is diluted to 60g / L by the pseudo-boehmite washing solution, and the mixture is evenly stirred. The diluted sodium aluminate solution is pumped into the dissolving filter press for filtration through the dilution pump. After filtering, the dissolved filter press residue is discharged into the dissolving slag mixing tank and mixed with the circulating lye from the...

Embodiment 2

[0077] The filtrate obtained from three washings is used as the bottom liquid, and industrial aluminum hydroxide and lye are added to the slurry mixing tank according to the mass ratio of 2:1 while stirring, and the solid ratio of the alkali immersion liquid is adjusted to 3. After pulping, the material is transferred to the dissolving tank by the pulping pump, and steam is passed into the dissolving tank to indirectly heat to 140°C, and stirred and mixed to form sodium aluminate solution. The dissolved sodium aluminate solution flows into the dilution tank through the pipeline and mixes, and the alkali concentration is diluted to 85g / L by the pseudo-boehmite washing solution, and the mixture is evenly stirred. The diluted sodium aluminate solution is pumped into the dissolving filter press for filtration through the dilution pump. After filtering, the dissolved filter press residue is discharged into the dissolving slag mixing tank and mixed with the circulating lye from the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com