Preparation method and application of amorphous carbon film with piezoresistive properties and toughness on flexible substrate surface

A flexible substrate and amorphous carbon film technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of less application of flexible sensors, high cost, and difficulty in mass production, and achieve good toughness , easy preparation, and the effect of improving the piezoresistive coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this implementation example, the flexible base material is PI, and an amorphous carbon film is prepared on the surface of the flexible base, as follows:

[0039] (1) The flexible substrate is ultrasonically cleaned with acetone and dried, then placed in a vacuum coating chamber and evacuated to 2.7×10 - 3 Pa, then etched the substrate surface with argon plasma for 30min;

[0040] (2) Adopt high-power pulse magnetron sputtering technology, select high-purity graphite target, sputter carbon atoms from the high-purity graphite target through ionized argon gas, and deposit on the surface of the flexible substrate after step (1) Amorphous carbon film, the pressure of argon gas in the vacuum coating chamber is controlled to 0.1Pa, the high-power pulse power supply voltage is 800V, the pulse duty ratio is 1%, and the flexible substrate DC pulse negative voltage is -10V to obtain an amorphous carbon film.

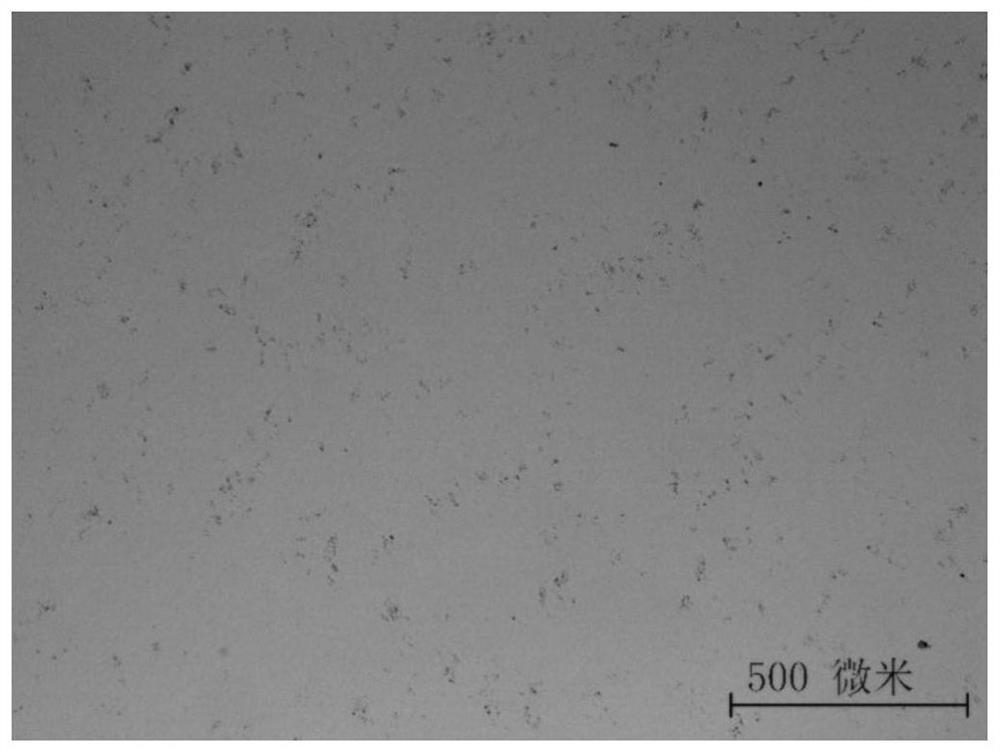

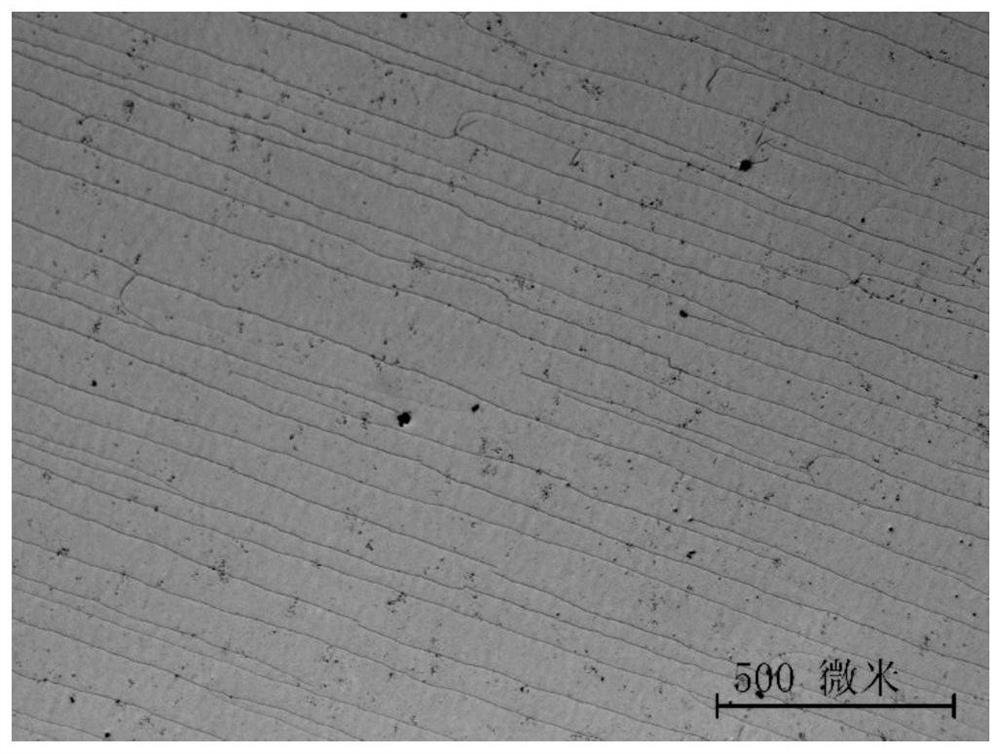

[0041] The above-mentioned flexible substrate deposited on the sur...

Embodiment 2

[0063] In this implementation example, the flexible substrate is the same as in Example 1, and an amorphous carbon film is prepared on the surface of the flexible substrate, as follows:

[0064] (1) is identical with the step (1) in embodiment 1;

[0065] (2) is basically the same as step (2) in embodiment 1, and difference is that the high-power pulse power supply voltage is 1000V;

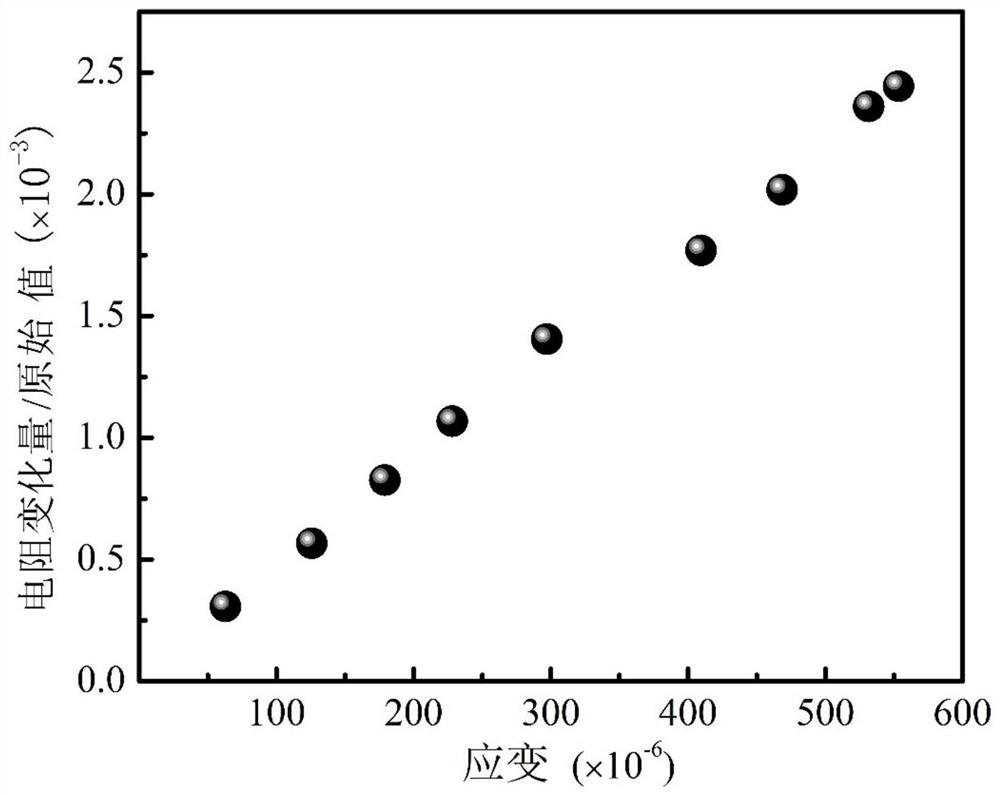

[0066] Similar to Example 1, the above-mentioned flexible substrate deposited on the surface of the amorphous carbon film was stretched and deformed to test the piezoresistive properties of the amorphous carbon film, and the results were as follows Figure 5 It is shown that the amorphous carbon film has good piezoresistive properties. Similar to Example 1, after the piezoresistive test, the amorphous carbon film did not crack due to the deformation test, and had good toughness.

Embodiment 3

[0068] In this implementation example, the flexible substrate is the same as in Example 1, and an amorphous carbon film is prepared on the surface of the flexible substrate, as follows:

[0069] (1) is identical with the step (1) in embodiment 1;

[0070] (2) is basically the same as step (2) in embodiment 1, and difference is that the pulse duty cycle is 5%;

[0071] Similar to Example 1, the above-mentioned flexible substrate deposited on the surface of the amorphous carbon film was stretched and deformed to test the piezoresistive properties of the amorphous carbon film, and the results were as follows Image 6 It is shown that the amorphous carbon film has good piezoresistive properties. Similar to Example 1, after the piezoresistive test, the amorphous carbon film did not crack due to the deformation test, and had good toughness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com