A beneficiation method that can improve the flotation concentrate rate and recovery rate of fine-grained refractory iron ore

A beneficiation method and fine particle technology, which are applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high iron grade in tailings, low iron recovery rate in concentrates, and high cost, and achieve high iron recovery rate. , The effect of low renovation cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

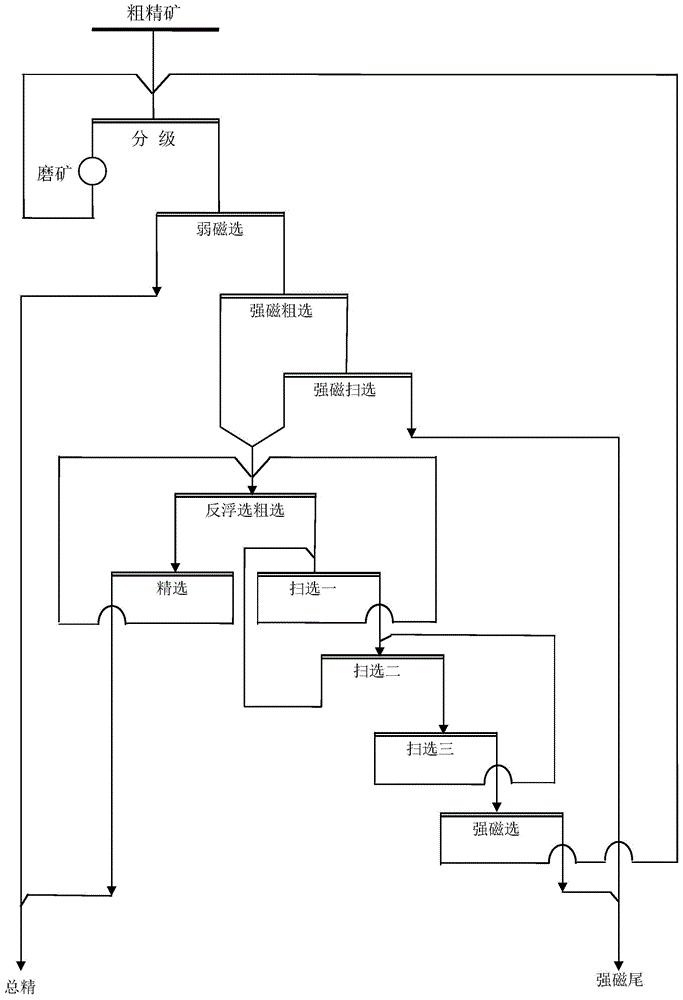

[0029] The main component of iron minerals in the ore processed by a concentrator is specularite, followed by magnetite and hematite, and a small amount of siderite and limonite; the gangue minerals are mainly quartz, followed by amphibole and mica , and a small amount of garnet, kyanite, chlorite and trace apatite. The specularite is widely distributed, often in the form of euhedral, semi-euhedral plates, flakes or granular, and a few are needle-shaped; the crystal grain size varies greatly, the coarse ones can reach 0.6mm, and the fine ones are less than 0.01mm, generally between 0.03~0.4 mm. use as figure 1 Shown mineral processing method of the present invention handles aforementioned iron ore, specifically comprises the following steps:

[0030](1) Grinding in the early stage: the raw iron ore is first crushed to below 12mm, and then enters a closed-circuit grinding and grading system for a stage of grinding and grading, and the fineness of the grading overflow is contr...

Embodiment 2

[0038] The iron minerals in the ore processed by a concentrator are mainly hematite and magnetite, followed by semi-false to false hematite, and sporadic limonite is occasionally seen; the gangue minerals are mainly quartz. The particle size of magnetite mostly ranges from 0.05mm to 0.20mm, which belongs to the category of fine-grained intercalation; while most of the particle sizes of hematite are distributed between 0.01mm and 0.08mm, which belongs to the category of fine-grained intercalation. use as figure 1 Shown mineral processing method of the present invention handles aforementioned iron ore, specifically comprises the following steps:

[0039] (1) Grinding in the early stage: the raw iron ore is first crushed to below 12mm, and then enters a closed-circuit grinding and grading system for a stage of grinding and grading, and the fineness of the grading overflow is controlled to be -200 mesh, accounting for 50%~ 55%, the classified grit returns to the closed-circuit gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com