Refractory castable containing viscoplasticity phase and preparation method thereof

A technology of refractory castables and plastic phases, applied in the field of unshaped refractory materials, can solve the problems of resistance to mechanical stress impact, short service life, poor thermal shock resistance, etc., and achieve the goal of improving toughness, strength and thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

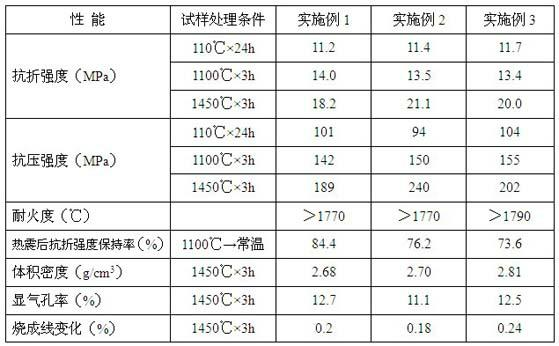

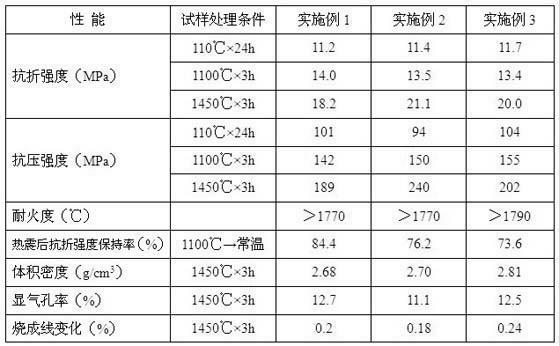

Examples

Embodiment 1

[0030] A preparation method of a plastic phase-containing refractory castable, comprising the following steps:

[0031] 1) Selection of materials

[0032] Select raw materials with appropriate particle size, including special-grade bauxite clinker particles, mullite particles, white corundum fine powder, super-grade bauxite fine powder, mullite fine powder, kyanite powder, metallic aluminum powder, elemental silicon powder, Alumina micropowder, silica micropowder and calcium aluminate cement, etc. The particle size of each selected material is: 1-8mm for special-grade bauxite clinker particles and mullite particles, 0.044-1mm for special-grade bauxite fine powder, mullite fine powder and white corundum fine powder, kyanite powder, metal The particle size of aluminum powder and elemental silicon powder is 0.044-0.15mm, alumina micropowder and silica micropowder are less than 5 microns, and calcium aluminate cement is less than 0.088mm.

[0033] 2) Preparation of refractory fi...

Embodiment 2

[0044] A preparation method of a plastic phase-containing refractory castable, comprising the following steps:

[0045] 1) Selection of materials

[0046] Select raw materials with appropriate particle size, including special-grade bauxite clinker particles, mullite particles, white corundum fine powder, super-grade bauxite fine powder, mullite fine powder, kyanite powder, metallic aluminum powder, elemental silicon powder, Alumina micropowder, silica micropowder and calcium aluminate cement, the particle size of each selected material is: super-grade bauxite clinker particles and mullite particles are 1-8mm, super-grade bauxite fine powder, mullite fine powder and white Corundum fine powder is 0.044-1mm, the particle size of kyanite powder, metallic aluminum powder and elemental silicon powder is 0.044-0.15mm, alumina fine powder and silica fine powder are less than 5 microns, and calcium aluminate cement is less than 0.088mm. ready after completion;

[0047] 2) Preparation...

Embodiment 3

[0058] A preparation method of a plastic phase-containing refractory castable, comprising the following steps:

[0059] 1) Selection of materials

[0060] Select raw materials with appropriate particle size, including special-grade bauxite clinker particles, white corundum particles, white corundum fine powder, special-grade bauxite fine powder, kyanite powder, metal aluminum powder, elemental silicon powder, alumina fine powder, silicon oxide fine powder And calcium aluminate cement, the particle size of each material selected is: super-grade bauxite clinker particles and mullite particles are 1-8mm, super-grade bauxite clinker particles, mullite particles and white corundum fine powder are 0.044-1mm , the particle size of kyanite powder, metal aluminum powder and elemental silicon powder is 0.044-0.15mm, the alumina micropowder and silica micropowder are less than 5 microns, and the calcium aluminate cement is less than 0.088mm.

[0061] 2) Preparation of refractory fine po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com